Remover uma GPU B200 traseira

Siga as instruções nesta seção para remover uma GPU B200 traseira. O procedimento deve ser executado por um técnico treinado.

Sobre esta tarefa

Atenção

- Leia Diretrizes de instalação e Lista de verificação de inspeção de segurança para garantir que esteja trabalhando de forma segura.

- Desligue o servidor e os dispositivos periféricos e desconecte os cabos de alimentação e todos os cabos externos. Consulte Desligar o servidor.

- Se o servidor estiver instalado em um rack, deslize o servidor para fora dos trilhos deslizantes do rack para acessar a tampa superior ou remover o chassi do rack. Consulte Remover o servidor do rack.

- Duas pessoas e um dispositivo de elevação no local que podem suportar até 400 lb (181 kg) são necessários para executar esse procedimento. Se você ainda não tiver um dispositivo de içamento disponível, a Lenovo oferece o Genie Lift GL-8 material lift que pode ser adquirido em Data Center Solution Configurator. Inclua o freio e a plataforma de carga ao pedir o Genie Lift GL-8 material lift.

- Uma chave de fenda de torque estará disponível para solicitação se você não tiver uma em mãos.

Nota

Certifique-se de ter as ferramentas necessárias listadas abaixo disponíveis para substituir adequadamente o componente:

- Chave de fenda de cabeça Torx T15

- 2 x bit de extensão Torx T15 de 200 mm

- Chave de fenda de cabeça Phillips nº 1

- Chave de fenda de cabeça Phillips nº 2

- Pano de limpeza com álcool

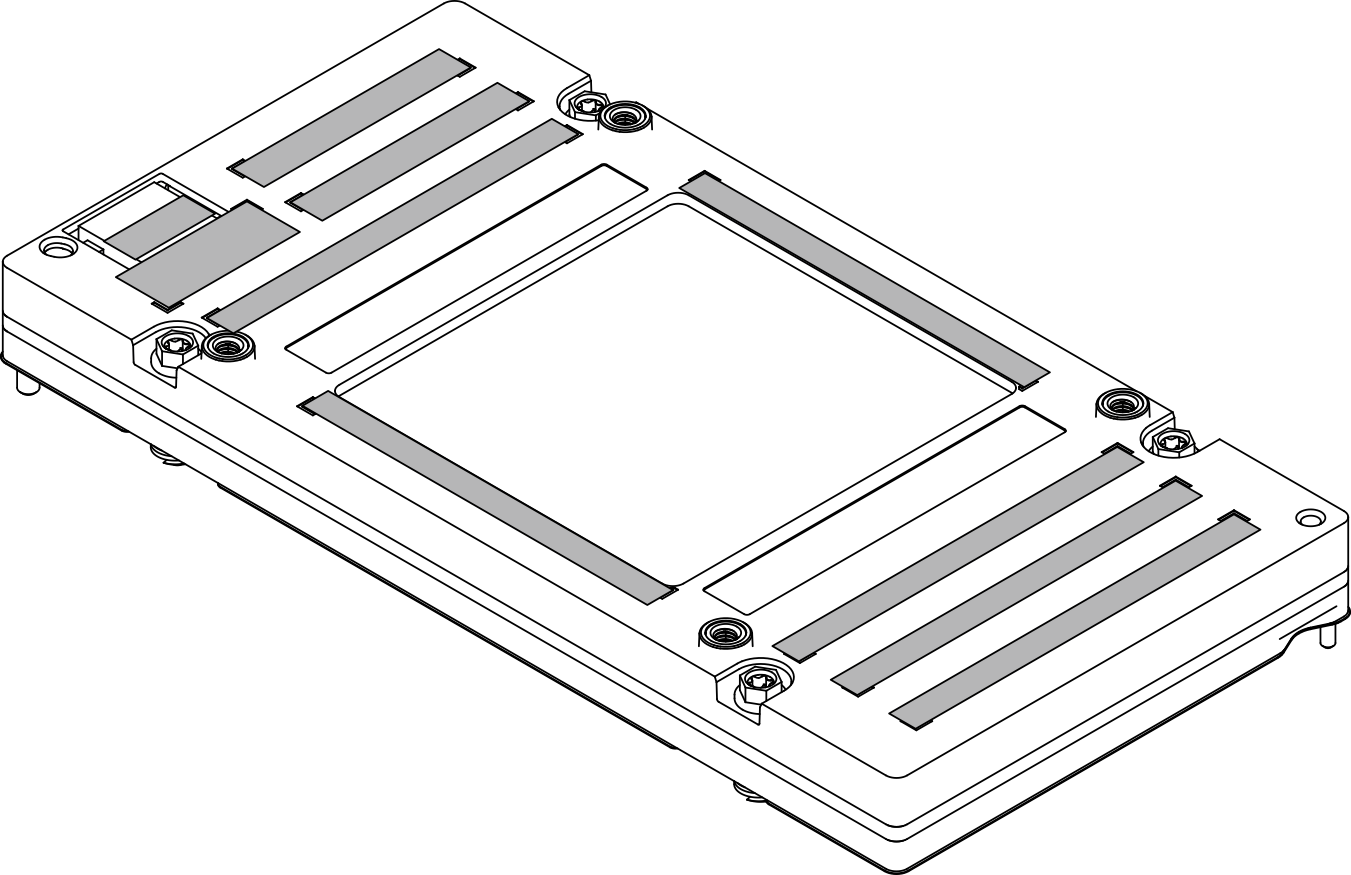

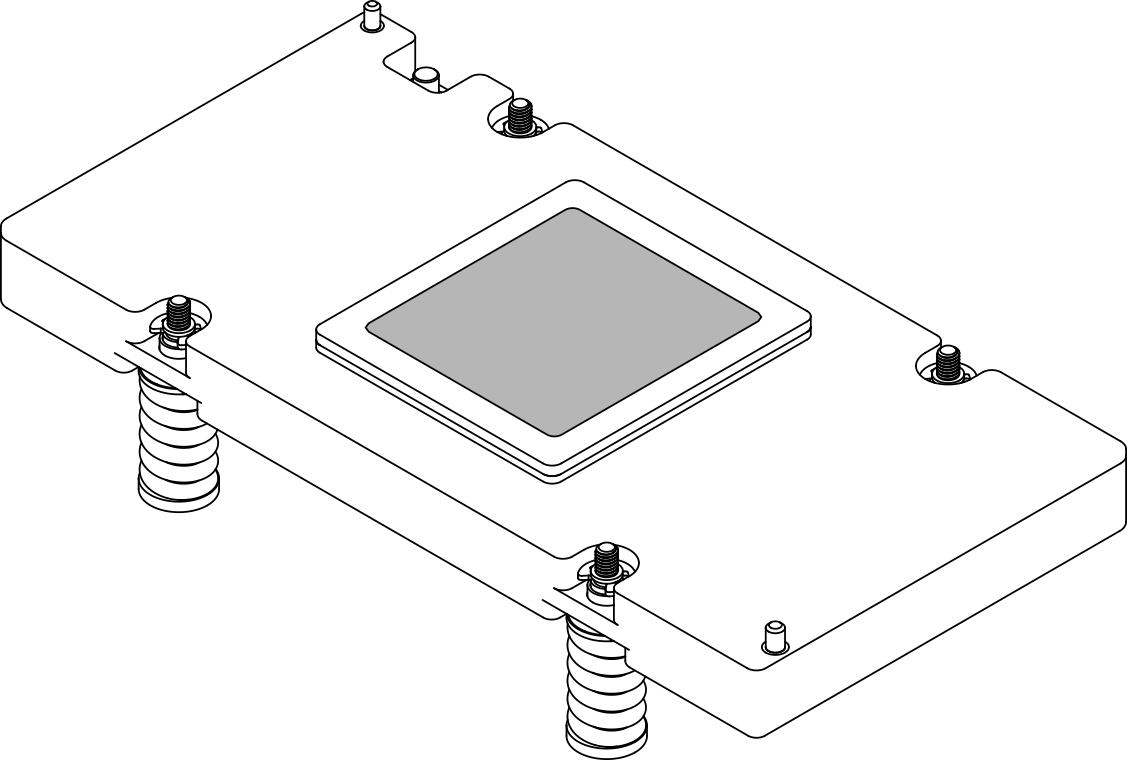

- PCM B200

- B200 SXM6 PAD-1

- B200 SXM6 PAD-2

- Kit de serviço de GPU B200

Importante

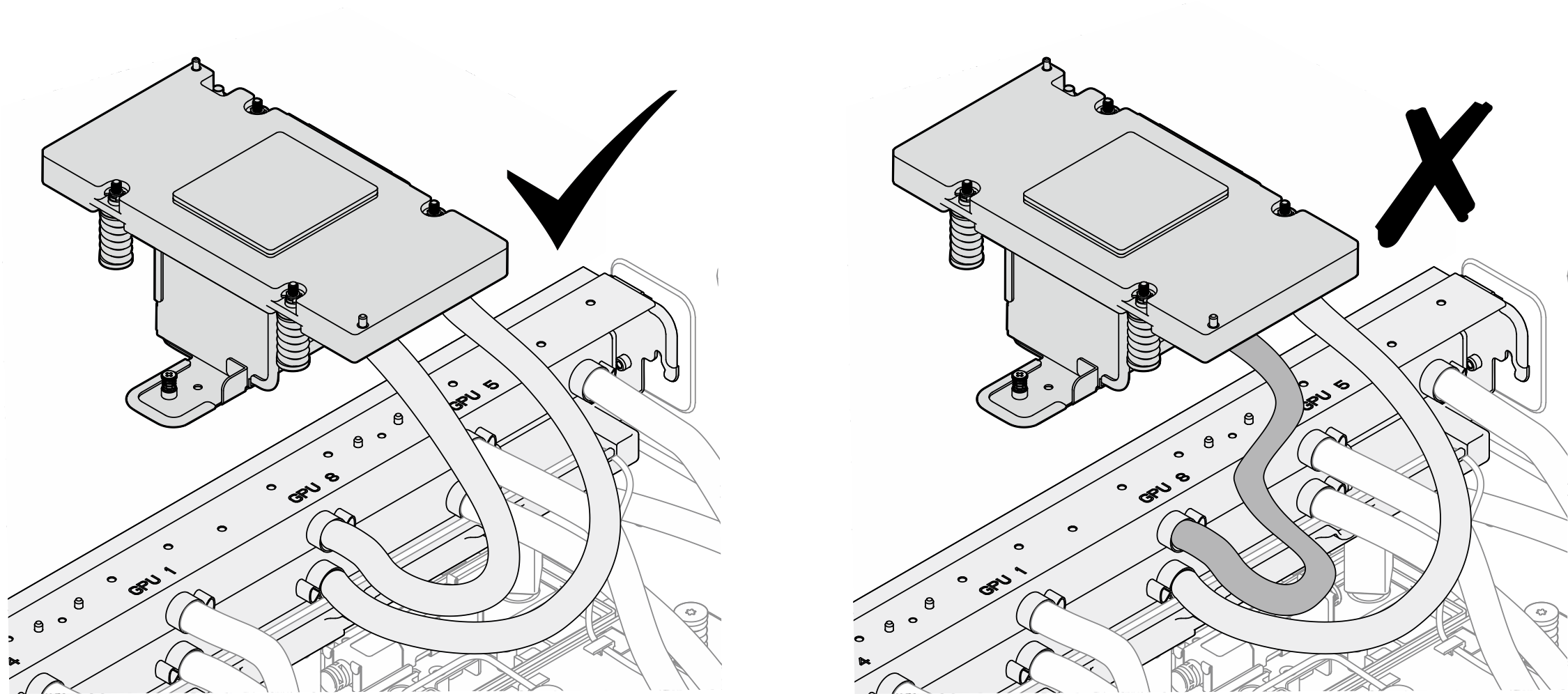

Diretrizes de substituição do protetor putty/material de mudança de fase (PCM)

- Antes de substituir o protetor putty/PCM, limpe suavemente a superfície do hardware com um pano de limpeza com álcool.

- Segure o protetor putty/PCM com cuidado para evitar deformação. Certifique-se de que nenhum orifício ou abertura do parafuso esteja bloqueado pelo protetor putty/PCM.

- Não use protetor putty/PCM vencido. Verifique a data de validade na embalagem do protetor putty/PCM. Se os protetores putty/PCM tiverem vencido, adquira novos para substituí-los adequadamente.

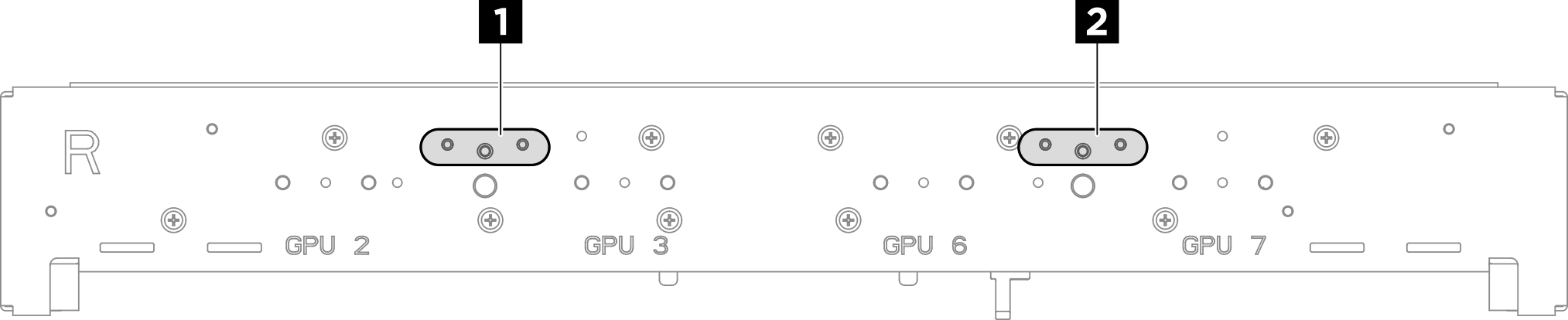

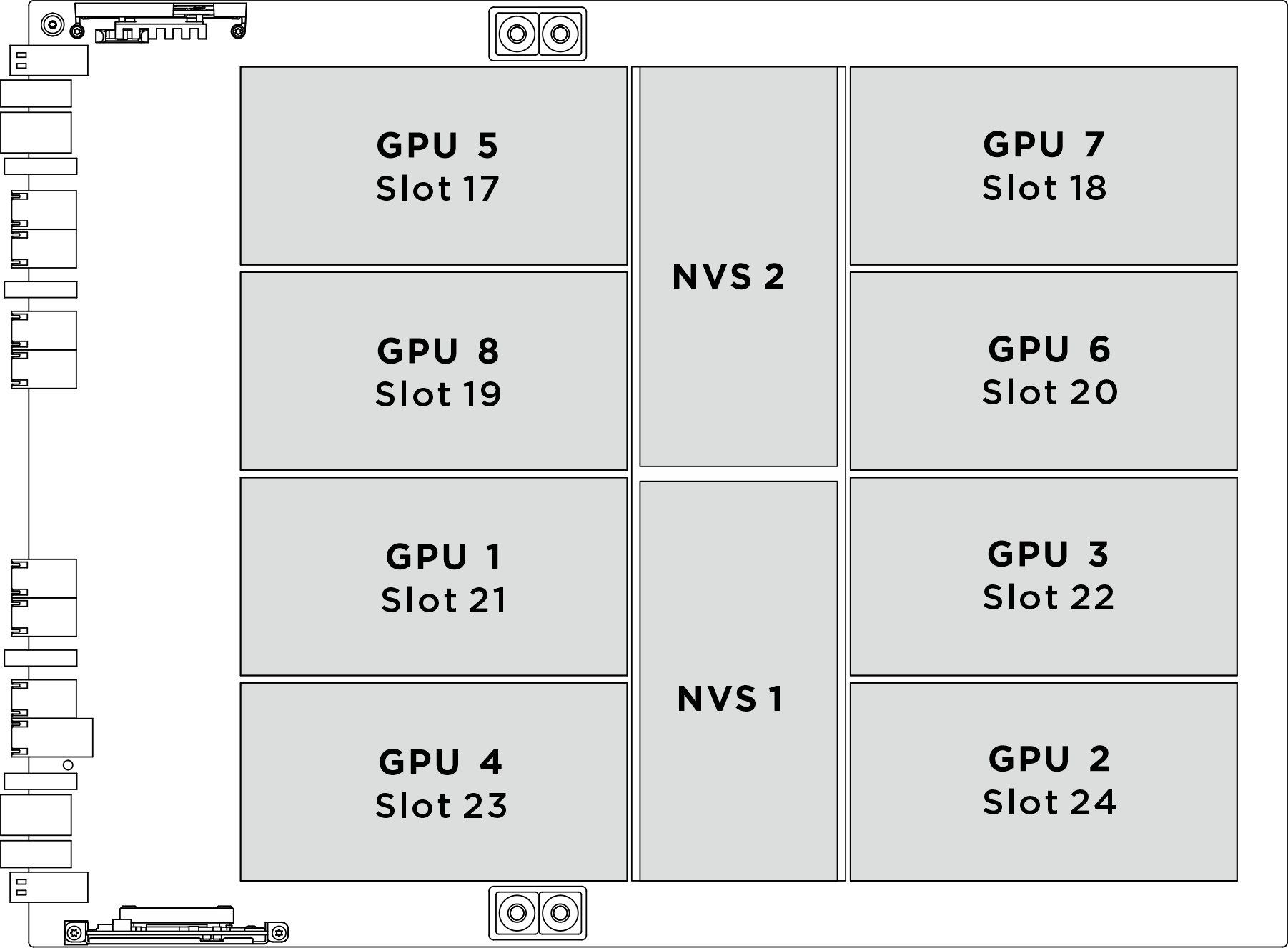

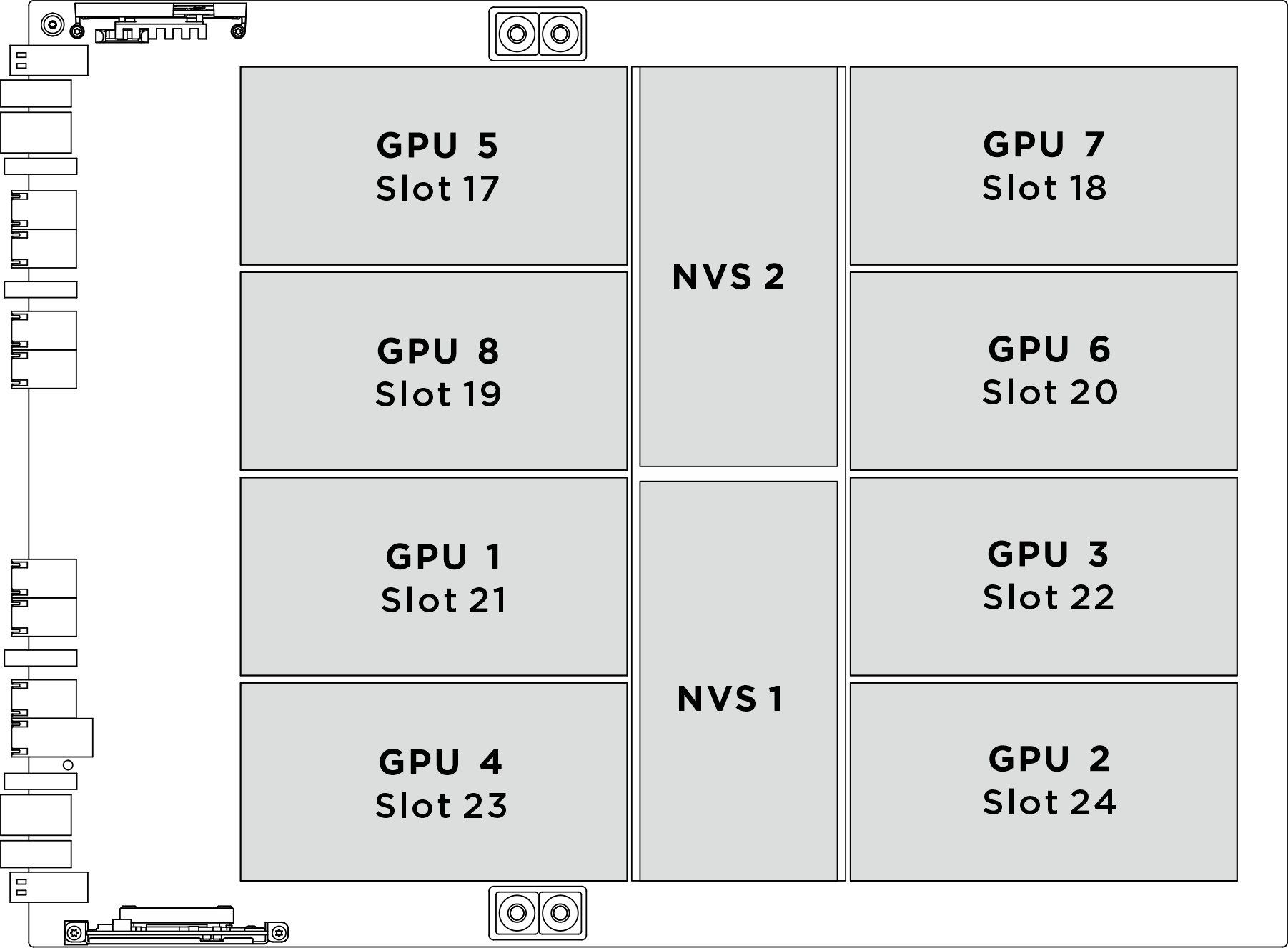

A ilustração a seguir mostra a numeração da GPU B200 e a numeração de slots correspondente no XCC.

Figura 1. Numeração da GPU B200

| Soquete de GPU físico | Numeração de slot no XCC | Número lógico em nvidia-smi |

|---|---|---|

GPU 1 | Slot 21 | 4 |

GPU 2 | Slot 24 | 7 |

GPU 3 | Slot 22 | 5 |

GPU 4 | Slot 23 | 6 |

GPU 5 | Slot 17 | 0 |

GPU 6 | Slot 20 | 3 |

GPU 7 | Slot 18 | 1 |

GPU 8 | Slot 19 | 2 |

Procedimento

Depois de concluir

- Instale uma unidade de substituição. Consulte Instalar uma GPU B200 traseira.

- Se você receber instruções para retornar o componente ou o dispositivo opcional, siga todas as instruções do pacote e use os materiais do pacote para remessa que foram fornecidos.

Enviar feedback

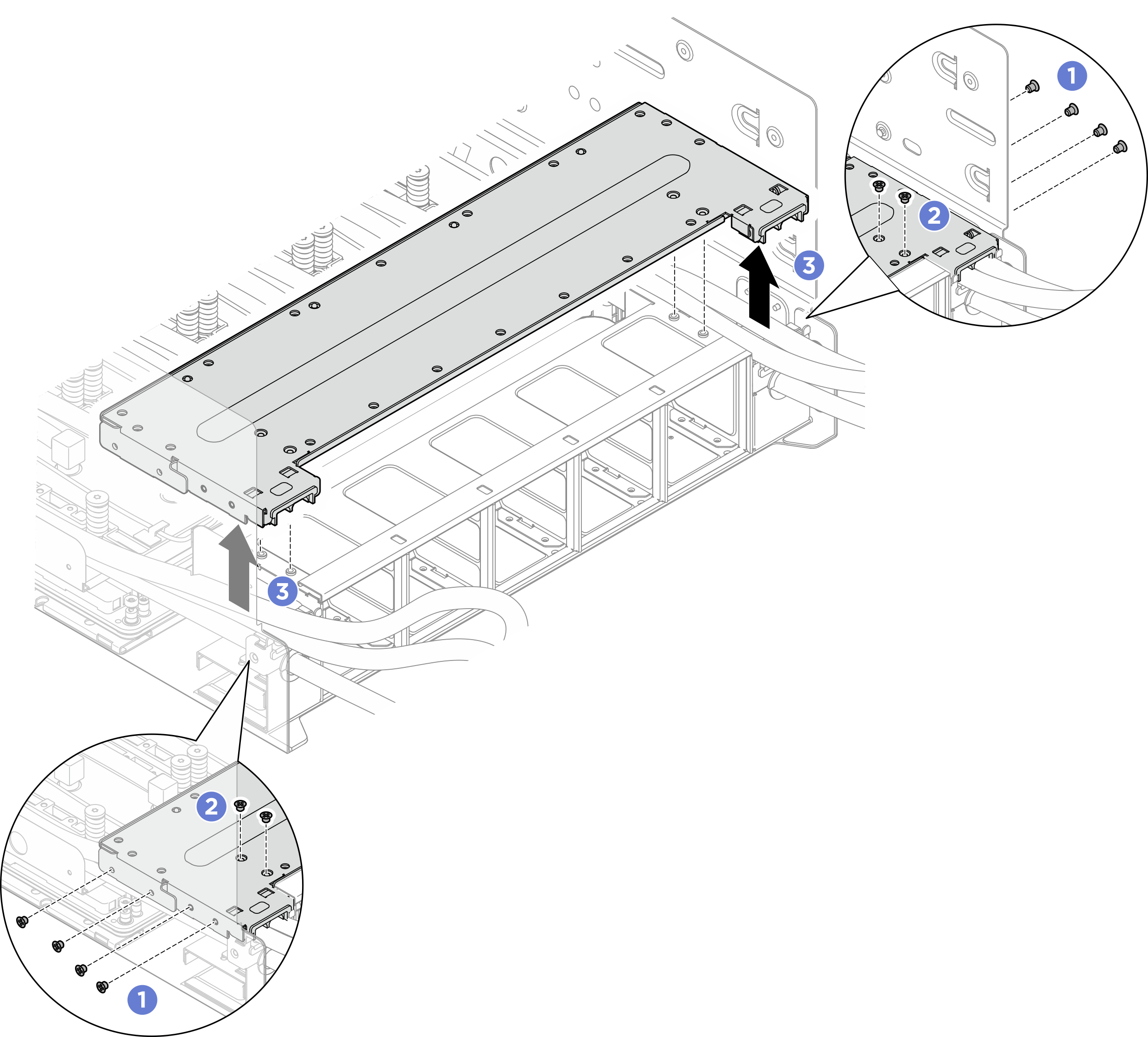

Solte os oito parafusos M3 que prendem o suporte de apoio da gaiola do ventilador traseiro no chassi.

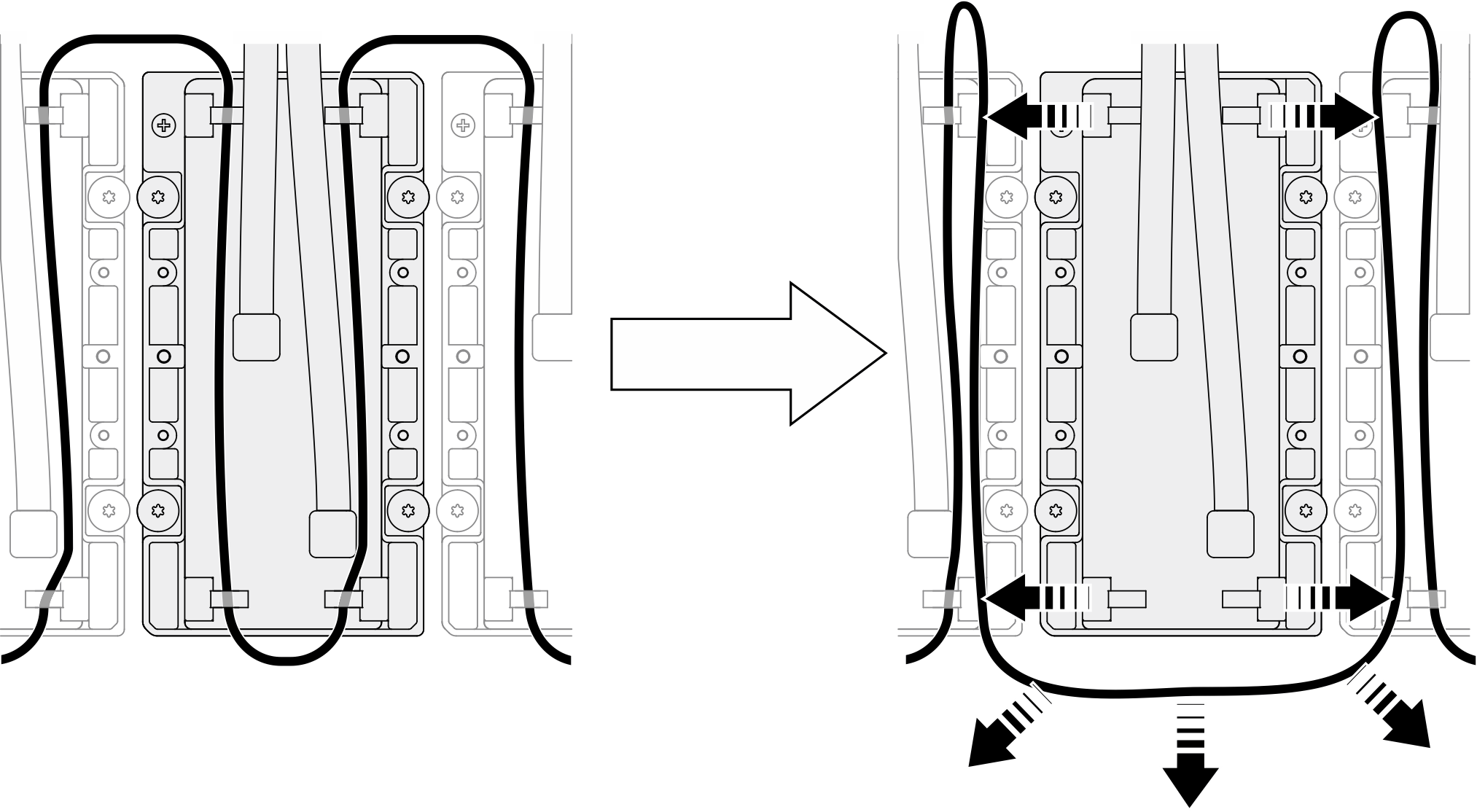

Solte os oito parafusos M3 que prendem o suporte de apoio da gaiola do ventilador traseiro no chassi. Solte os quatro parafusos M3 que prendem o suporte de apoio da gaiola do ventilador traseiro na gaiola do ventilador.

Solte os quatro parafusos M3 que prendem o suporte de apoio da gaiola do ventilador traseiro na gaiola do ventilador. Segure o suporte de apoio da gaiola do ventilador traseiro para erguê-lo da gaiola do ventilador.

Segure o suporte de apoio da gaiola do ventilador traseiro para erguê-lo da gaiola do ventilador.

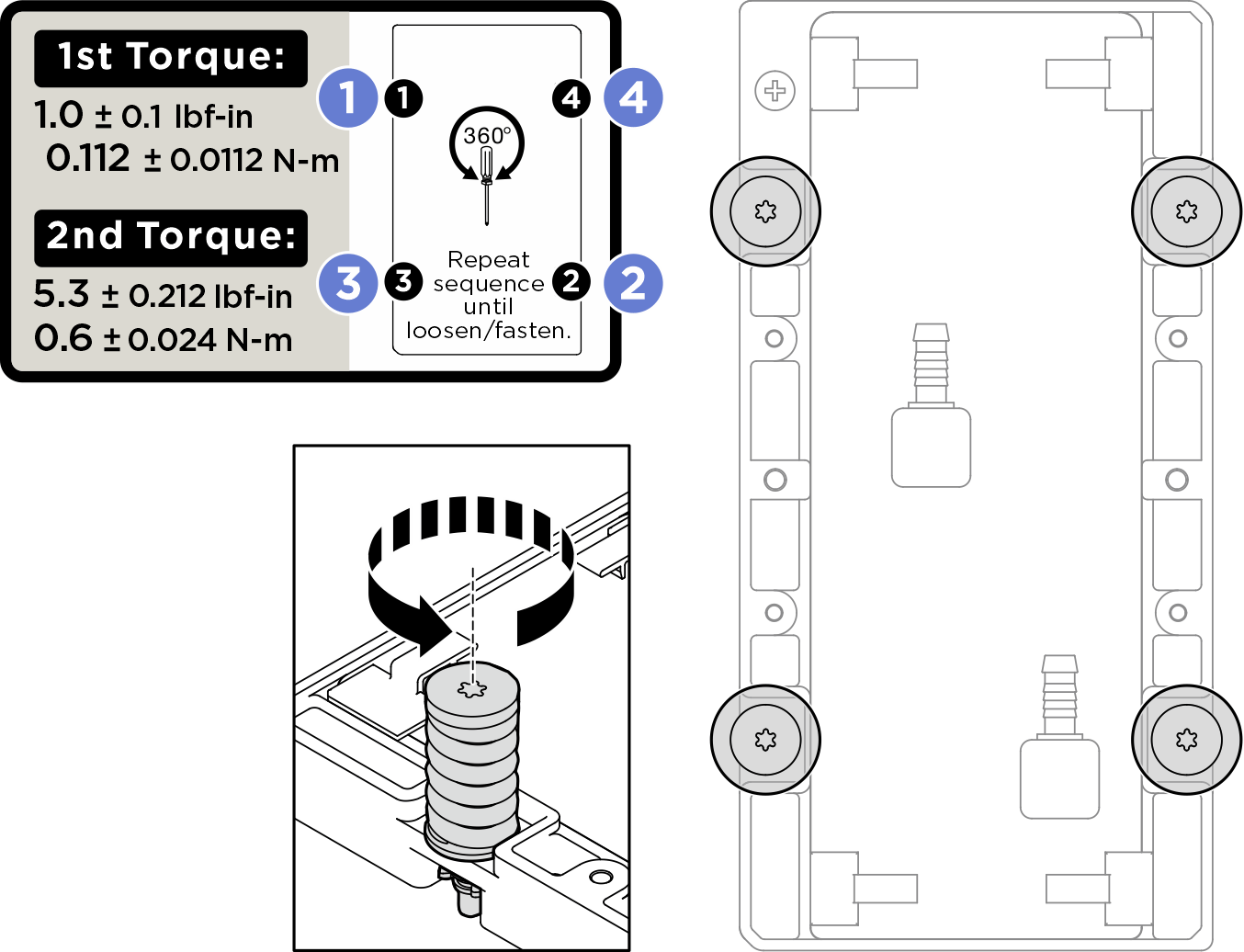

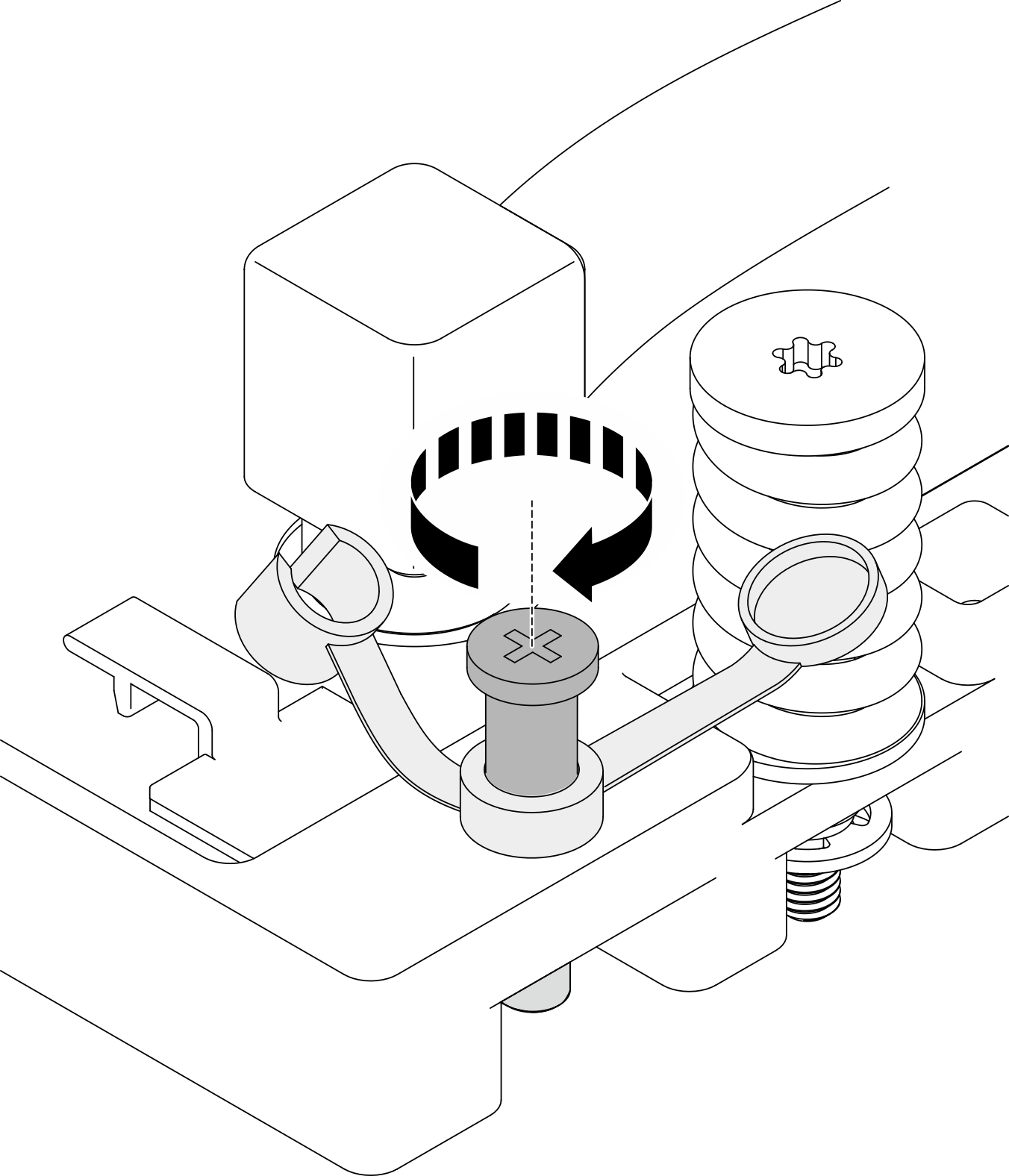

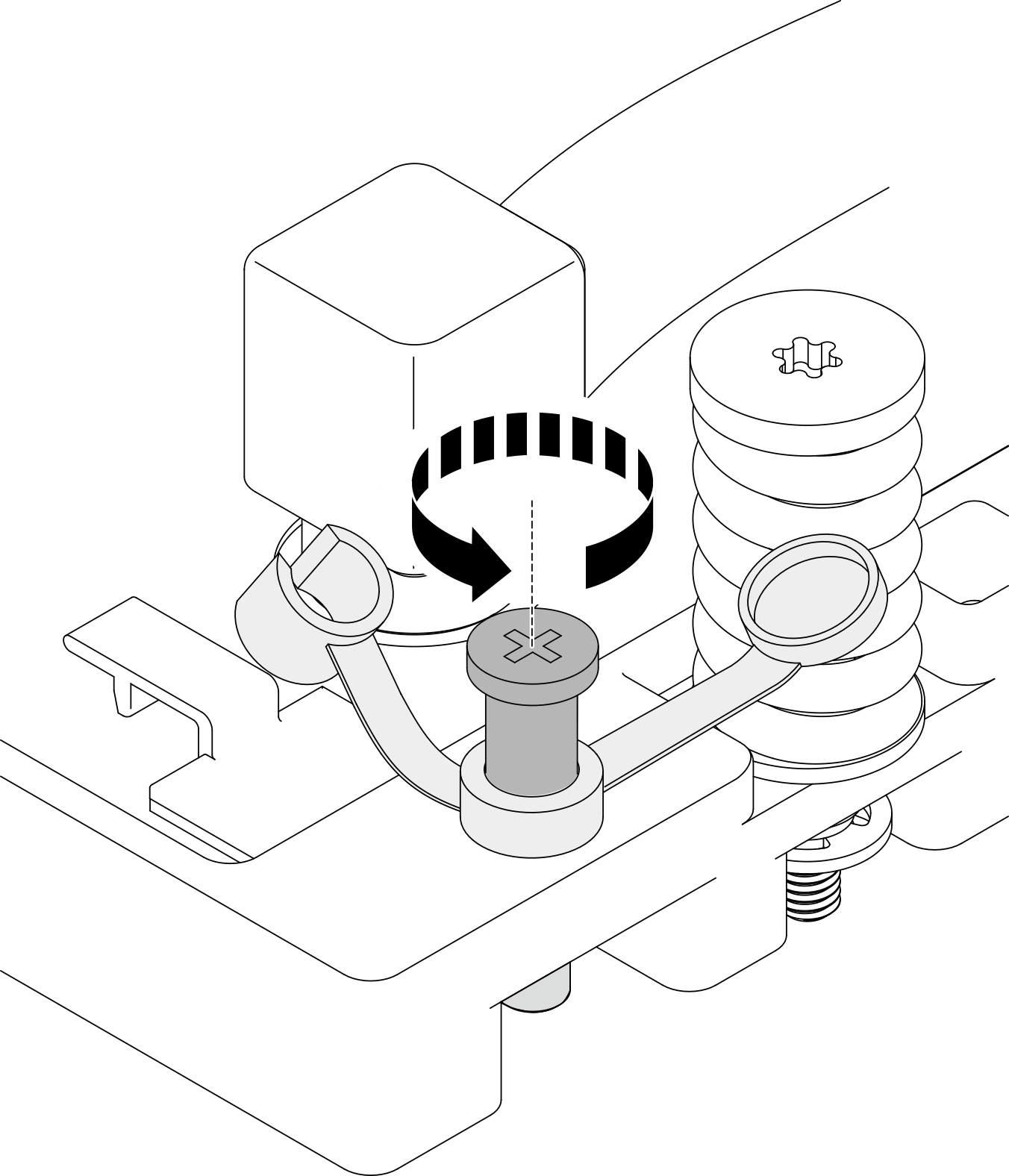

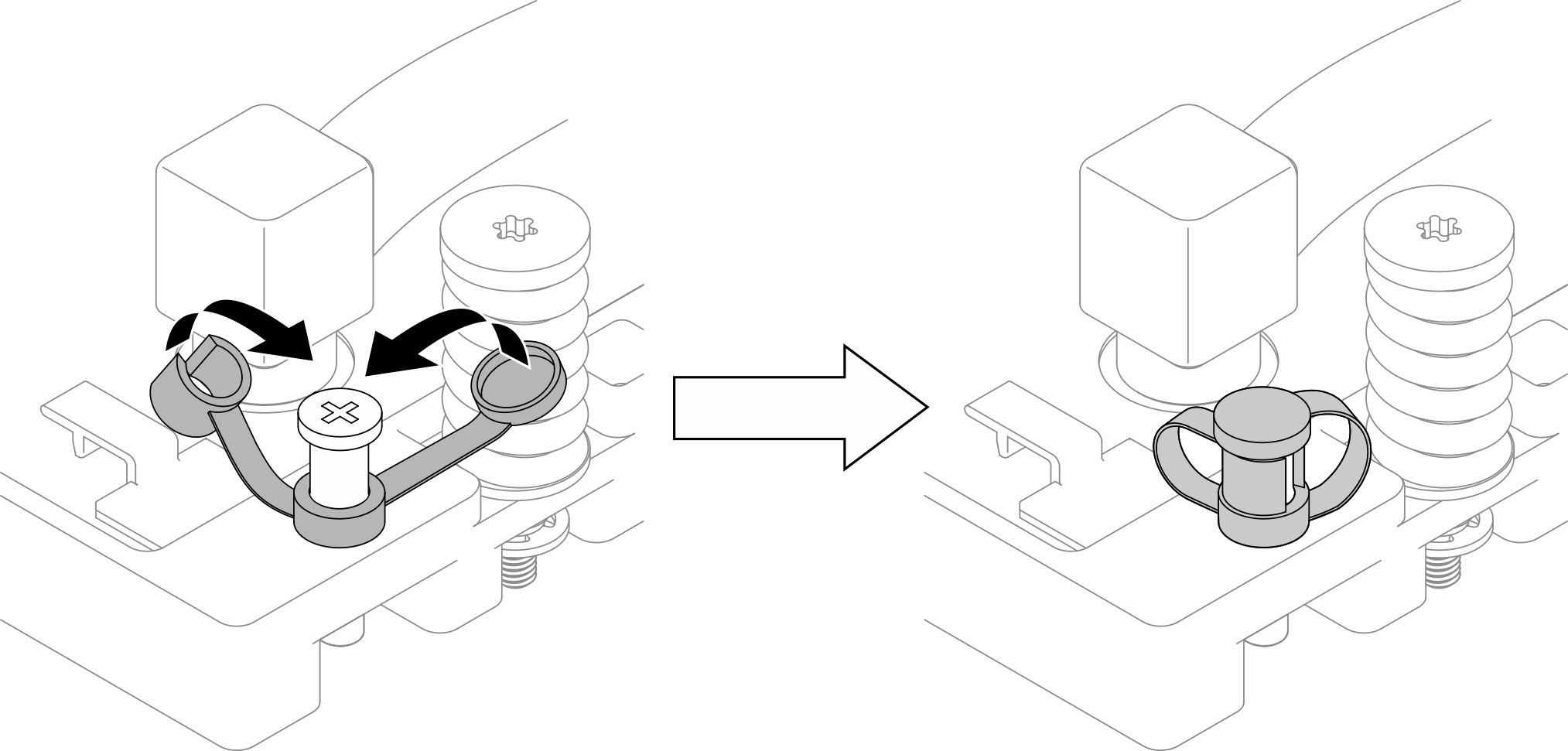

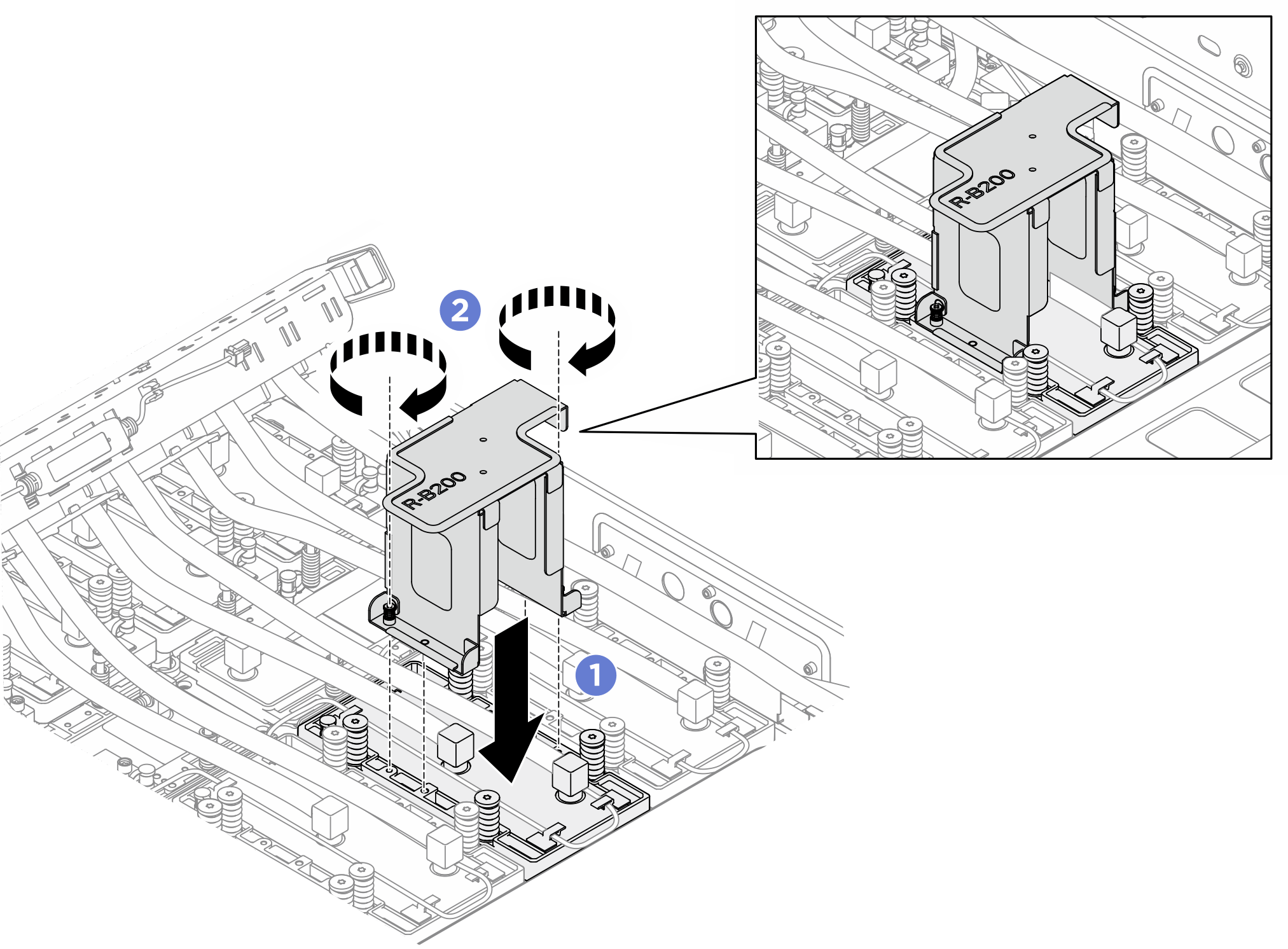

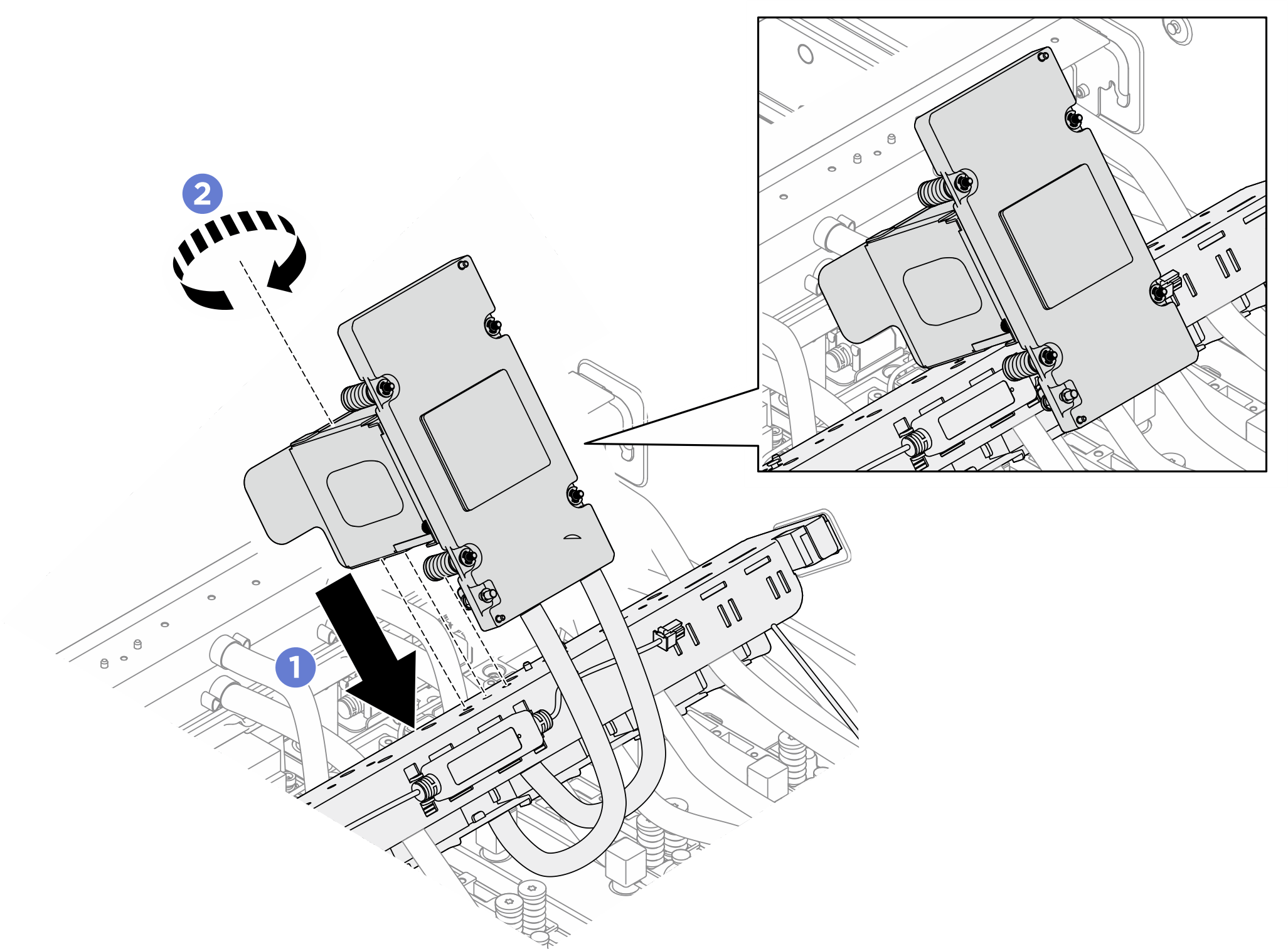

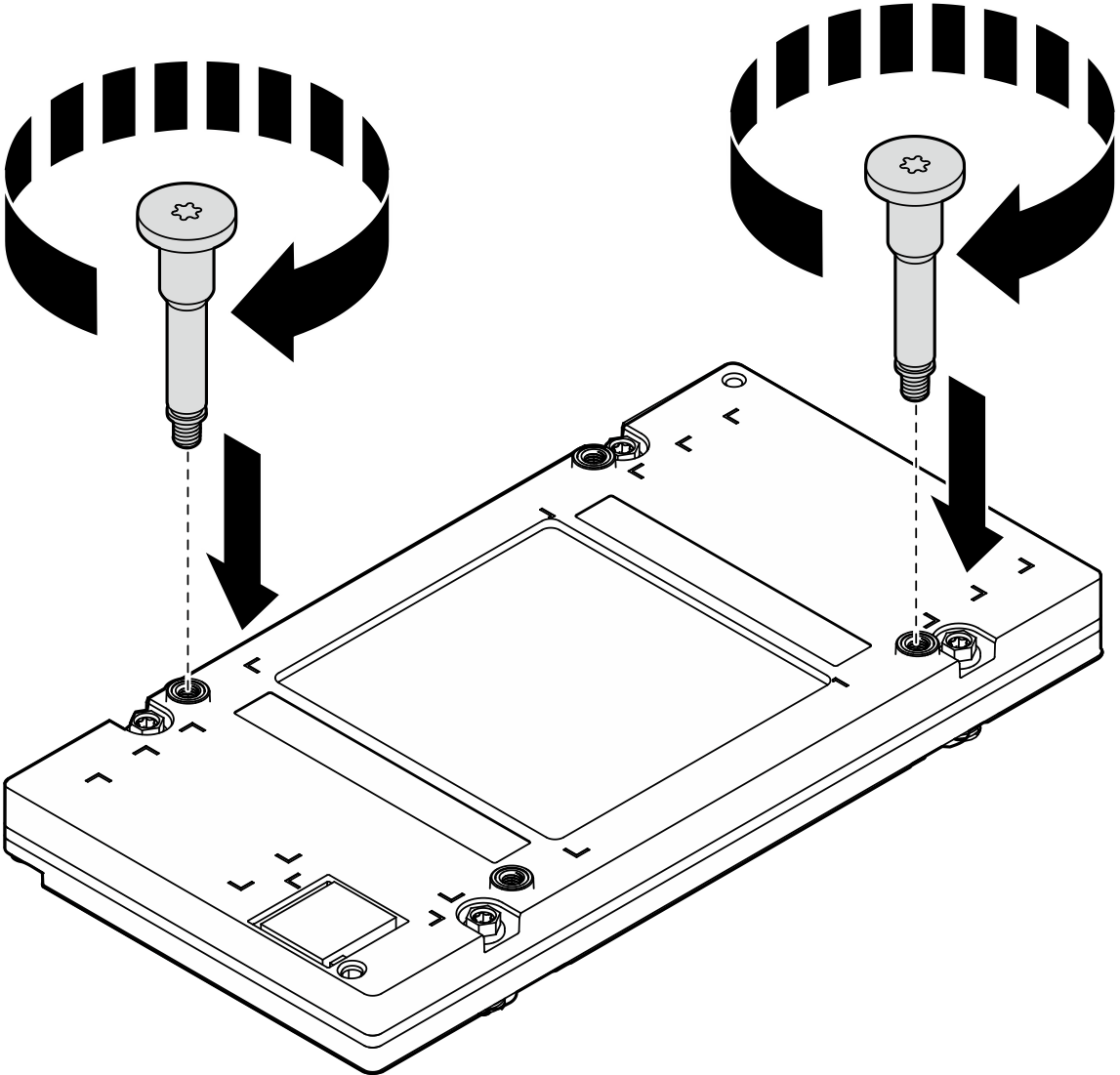

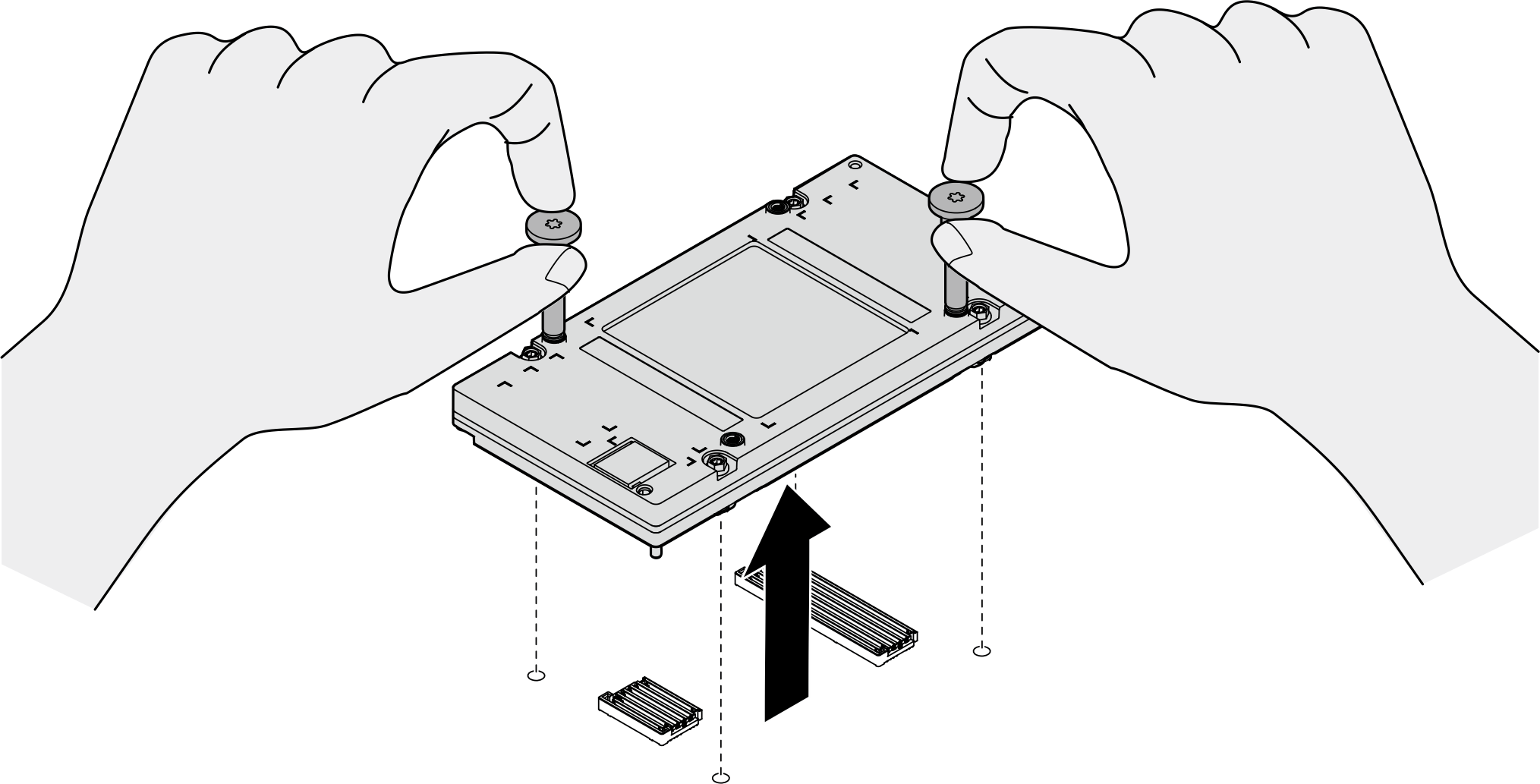

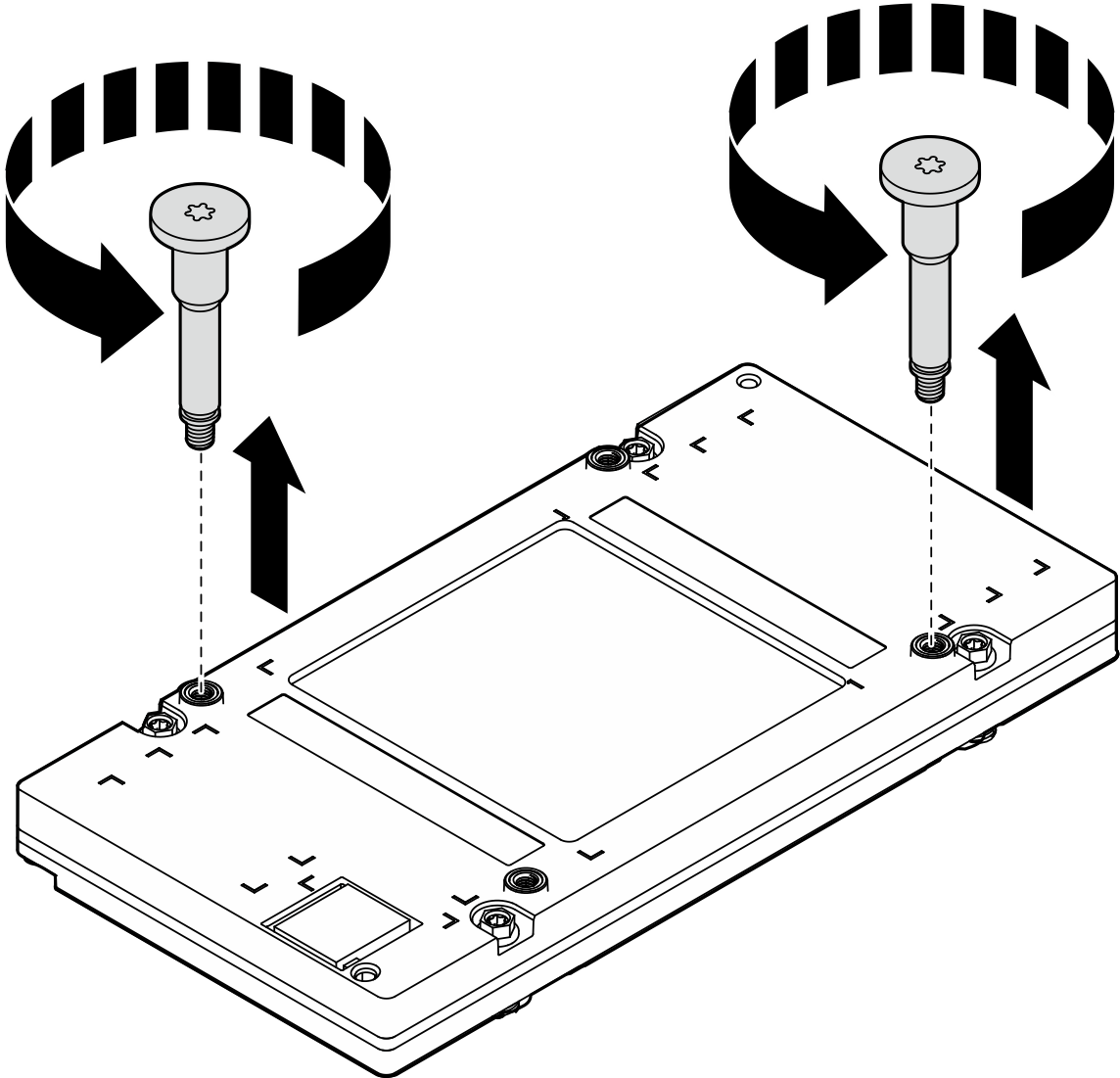

especificada na etiqueta da placa fria e solte totalmente os quatro parafusos Torx T15 com uma chave de fenda de torque ajustada para o torque adequado.

especificada na etiqueta da placa fria e solte totalmente os quatro parafusos Torx T15 com uma chave de fenda de torque ajustada para o torque adequado.