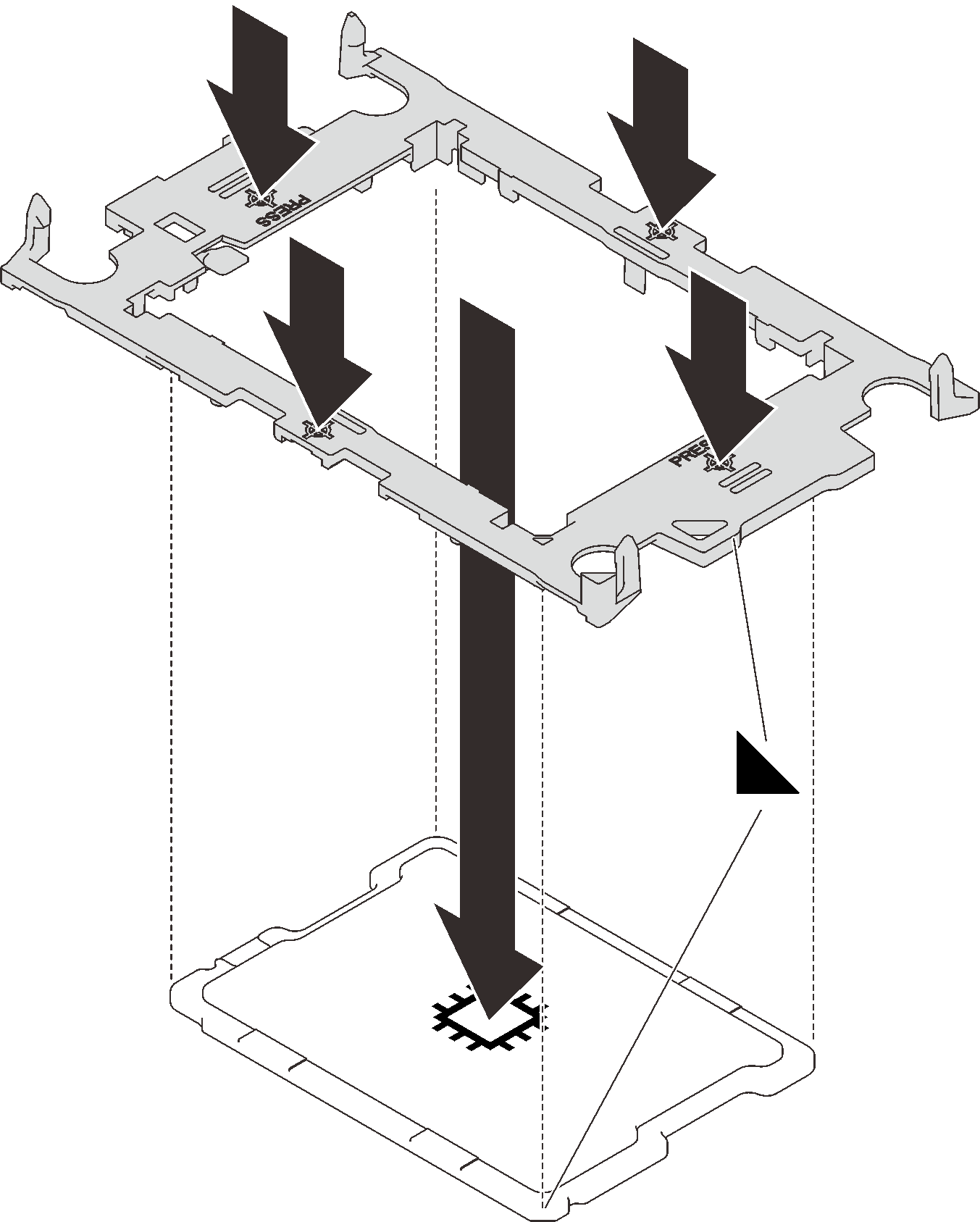

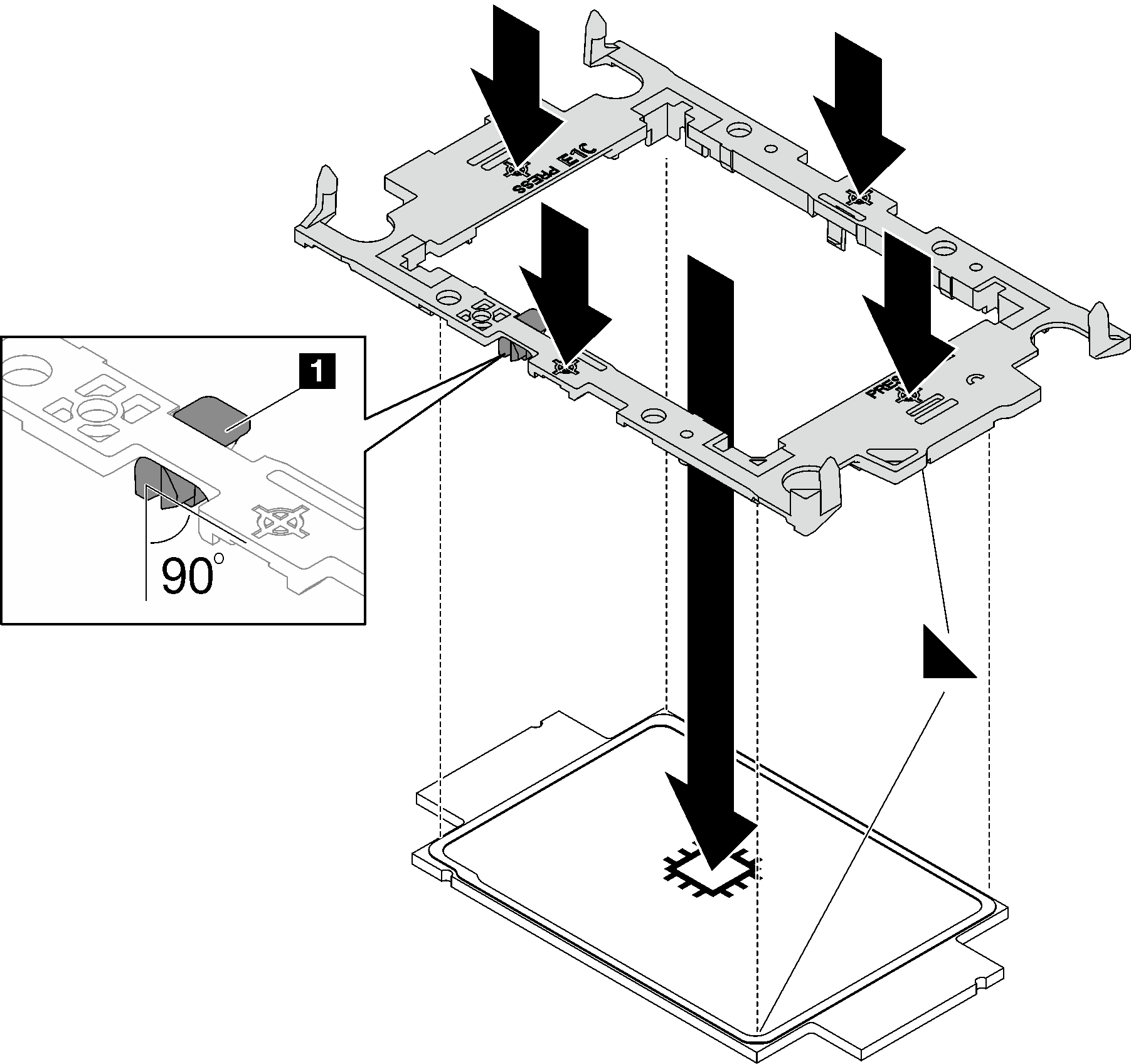

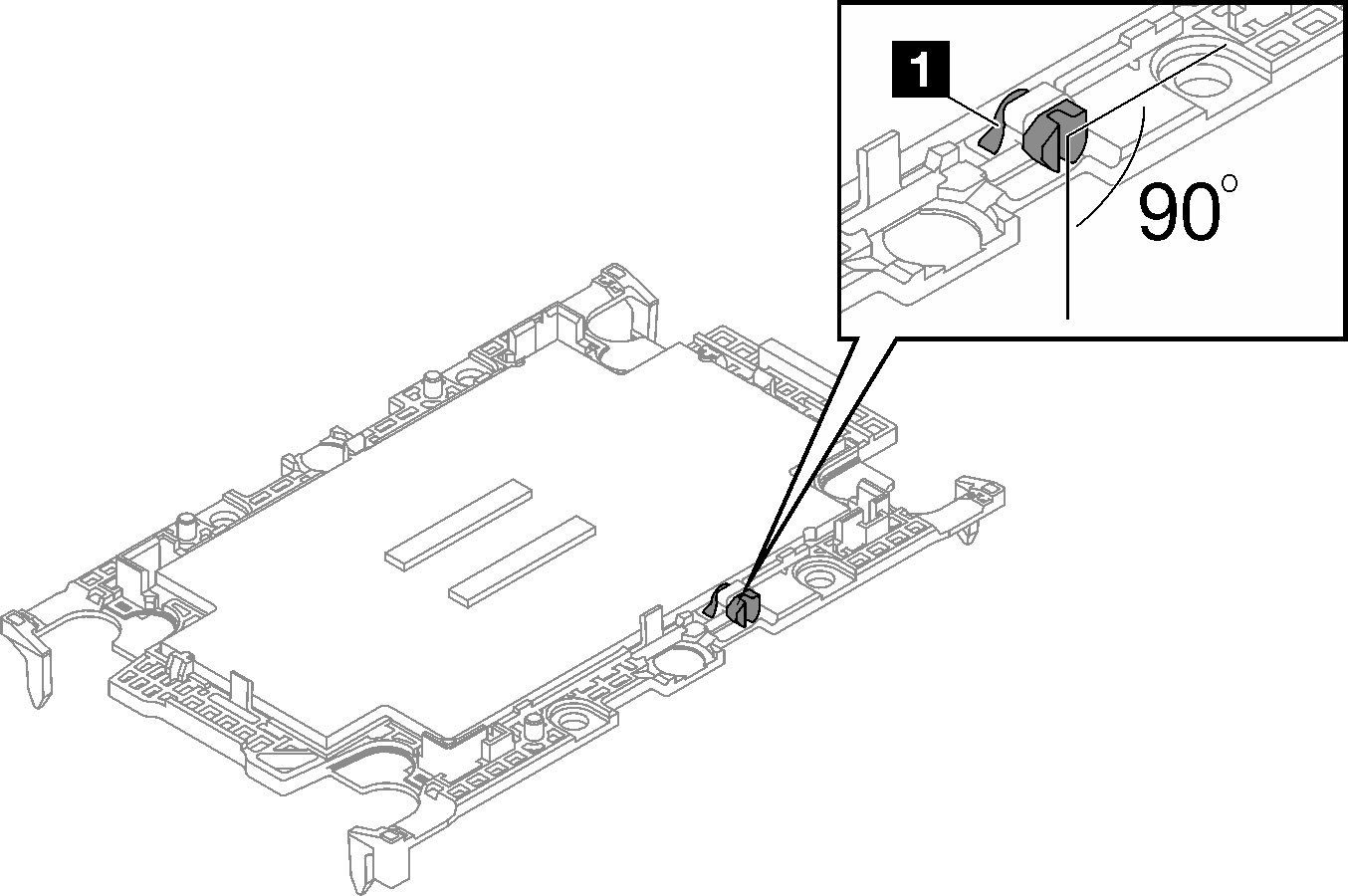

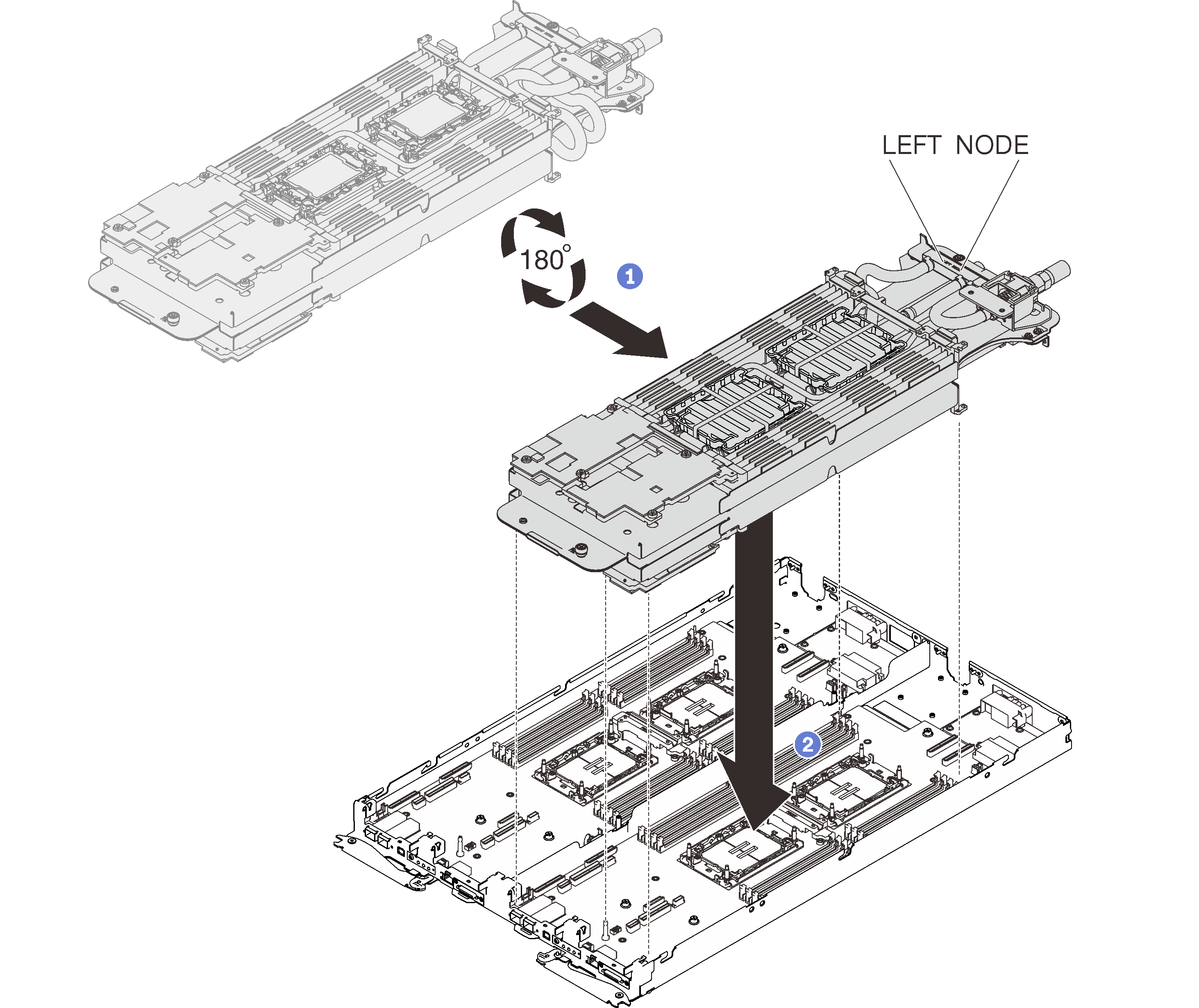

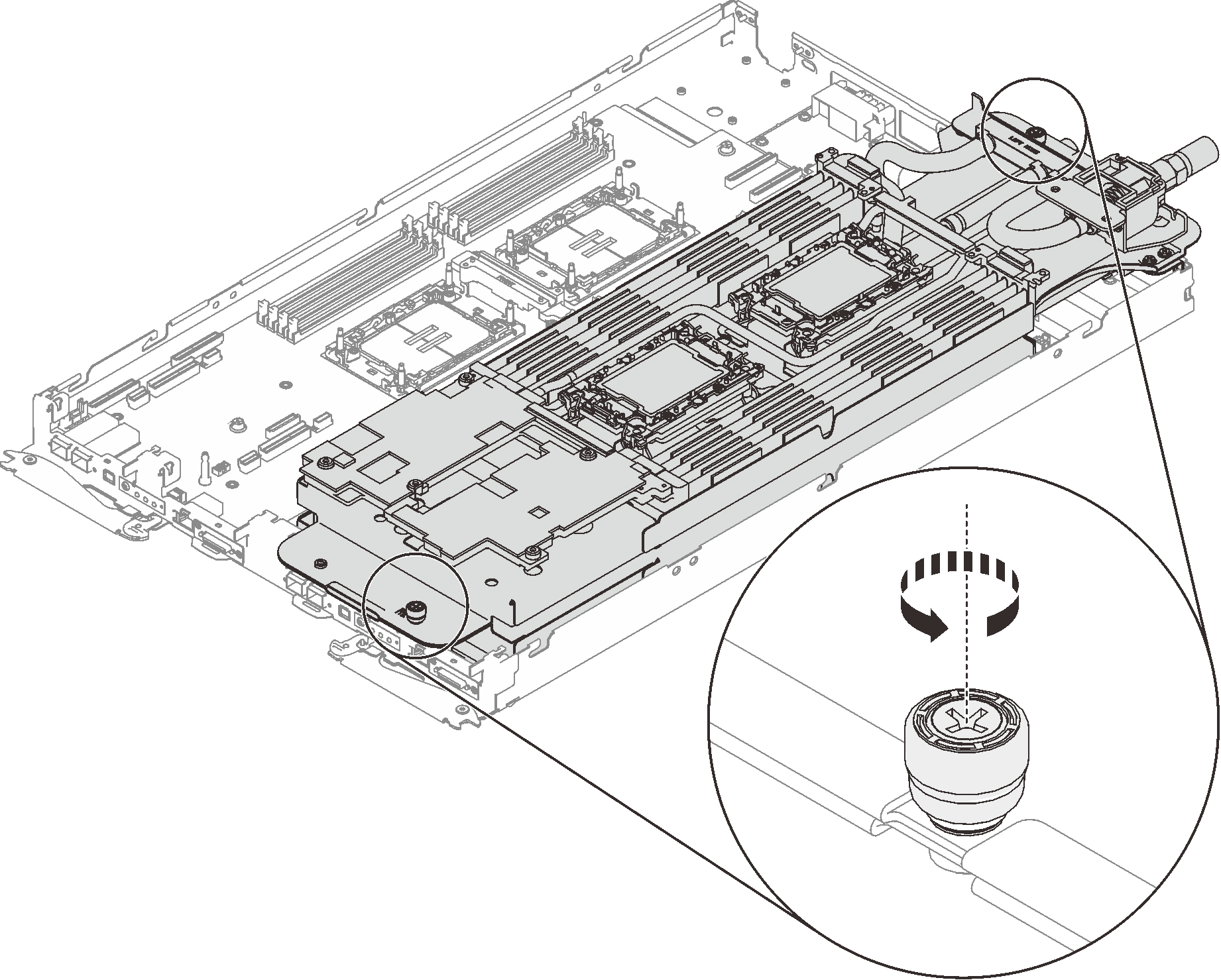

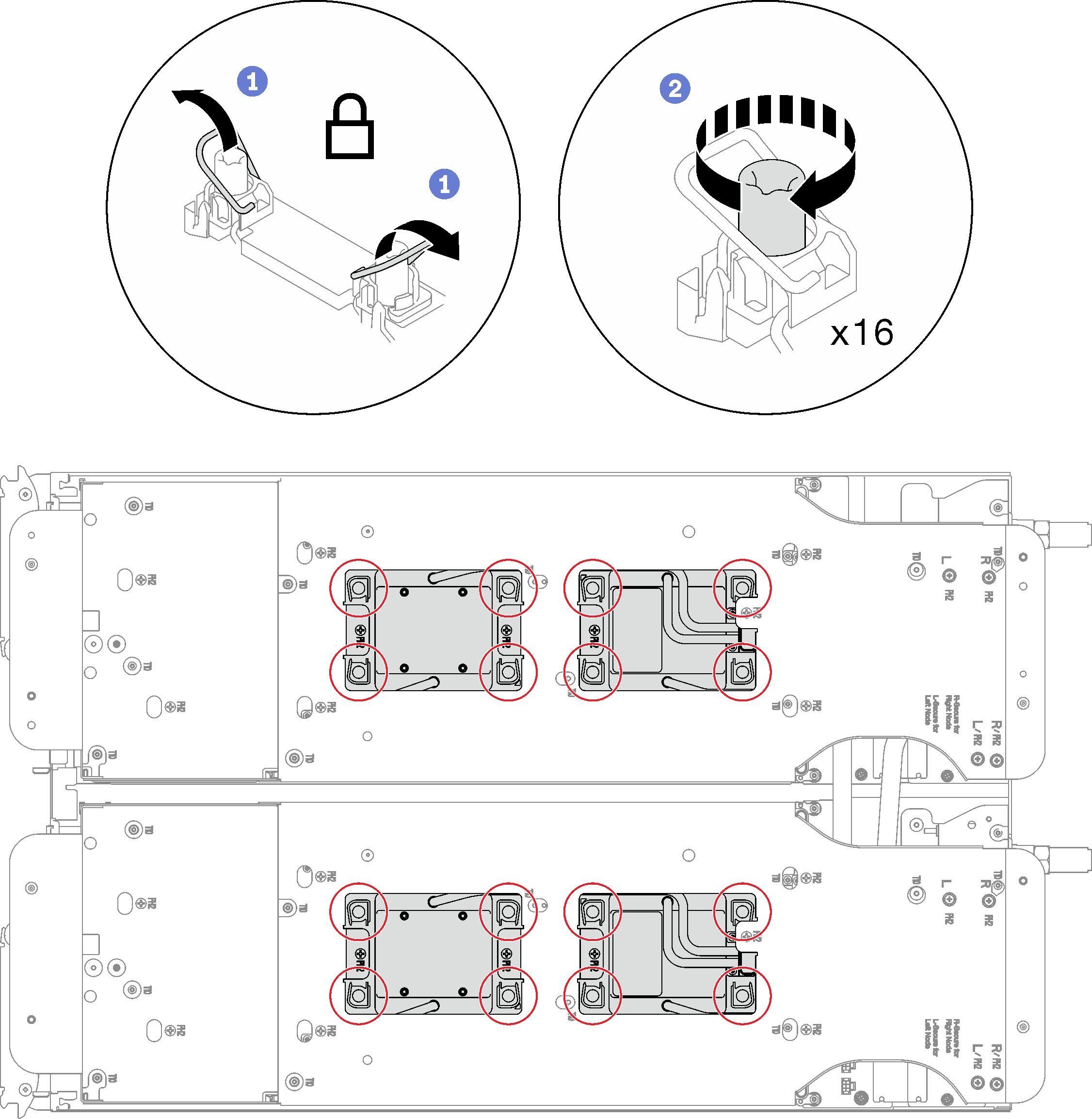

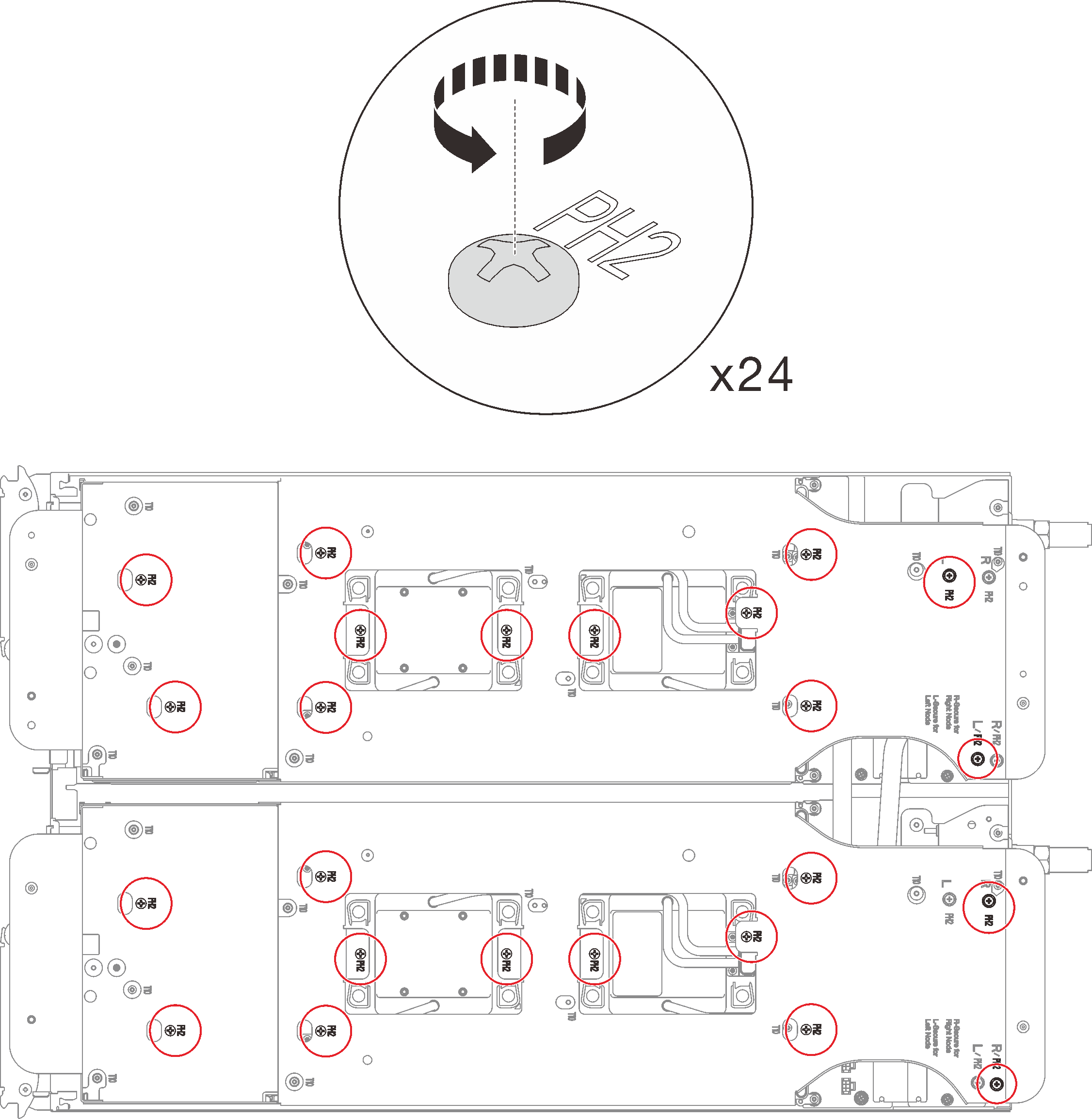

Install the water loop (SD650 V3)

Use this information to install the water loop in the SD650 V3 tray.

About this task

Read Installation Guidelines and Safety inspection checklist to ensure that you work safely.

Turn off the corresponding DWC tray that you are going to perform the task on.

Disconnect all external cables from the enclosure.

Use extra force to disconnect QSFP cables if they are connected to the solution.

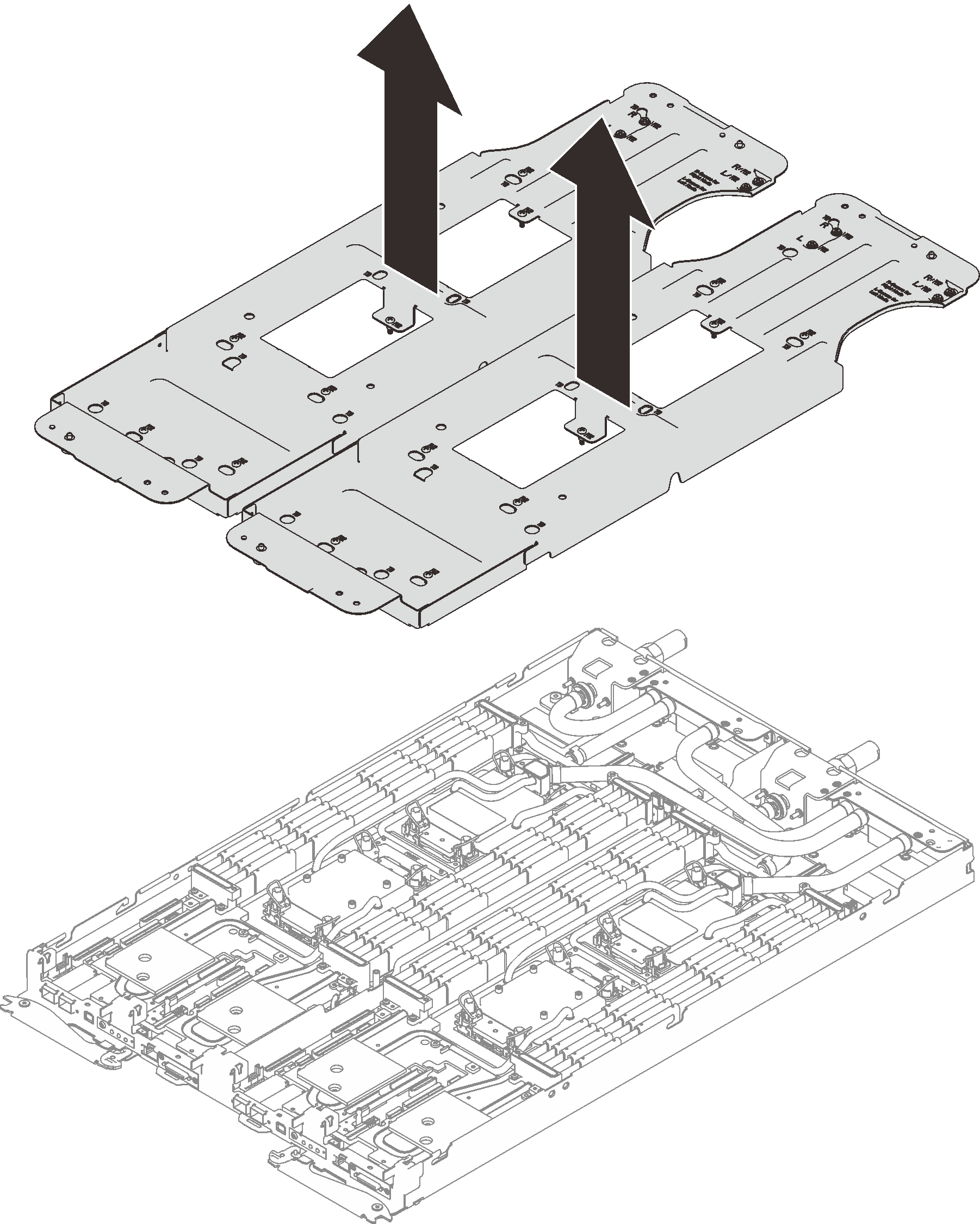

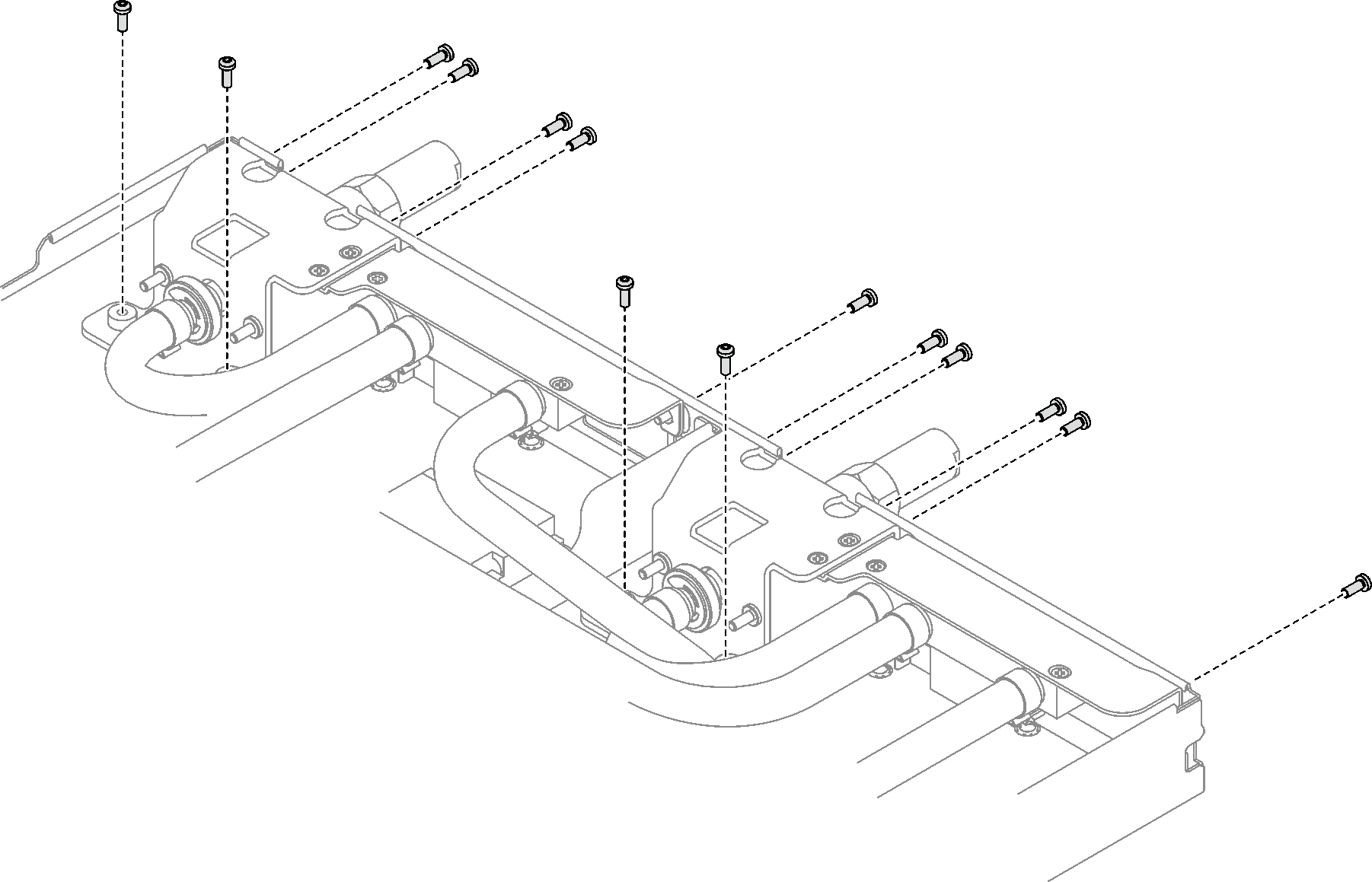

To avoid damaging the water loop, always use the water loop carrier when removing, installing or folding the water loop.

After updating XCC firmware, perform virtual reseat via SMM2 to optimize system, see SMM2 User Guide.

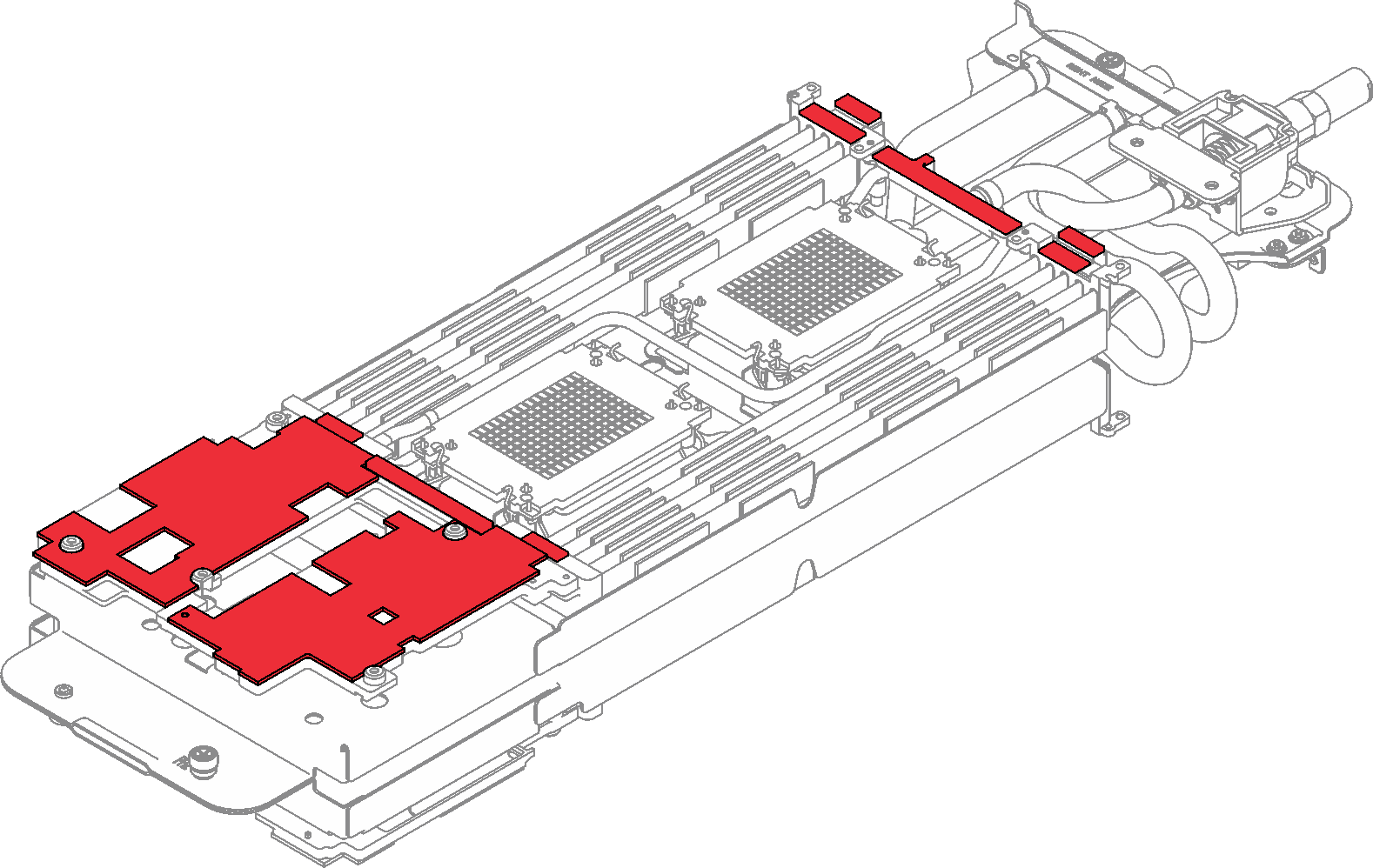

Ensure you have SD650 V3 Neptune DWC Waterloop Service Kit

in hand to install components.

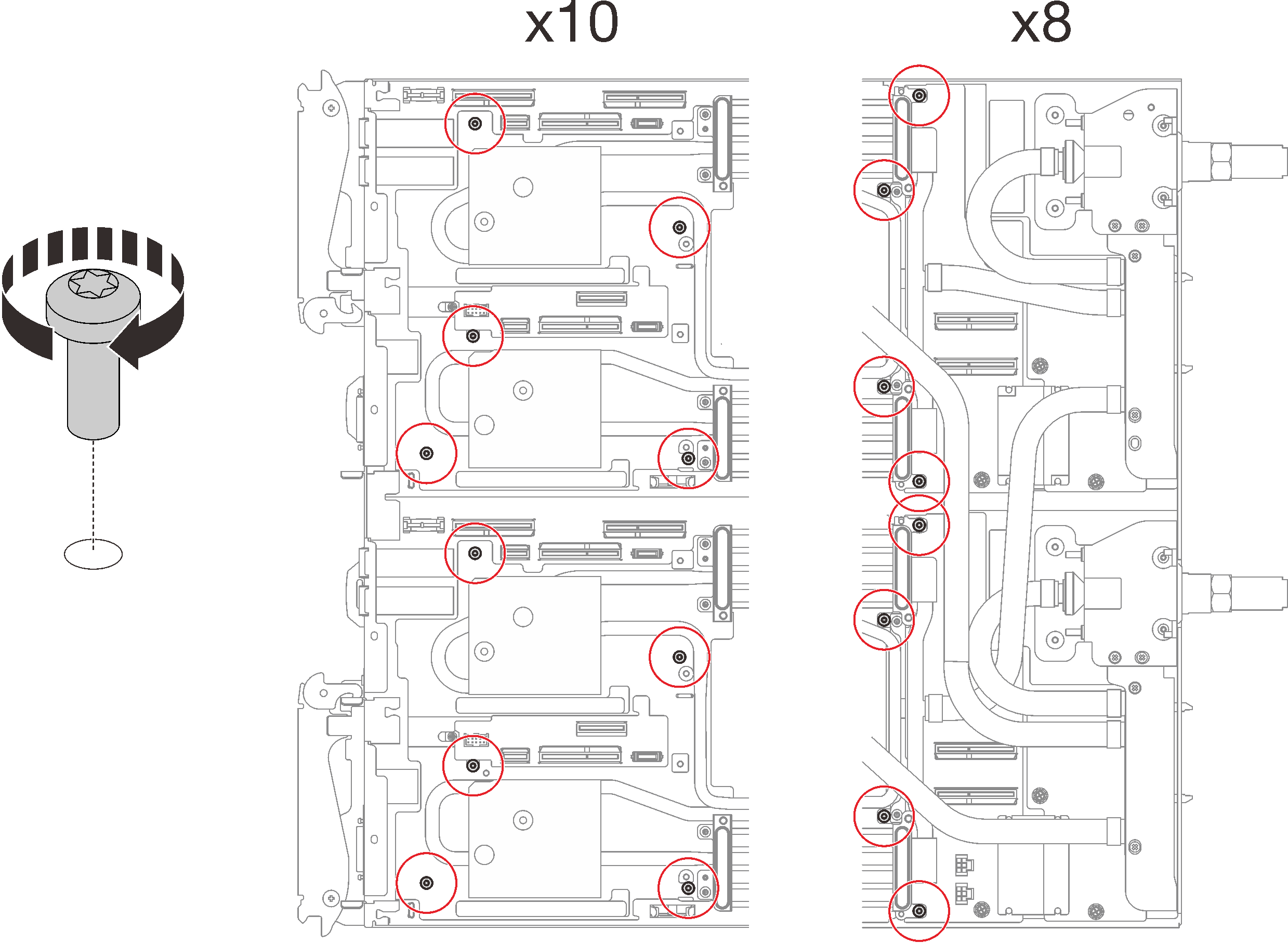

| Screwdriver Type | Screw Type |

|---|---|

| Torx T10 head screwdriver | Torx T10 screw |

| Torx T30 head screwdriver | Torx T30 screw |

| Phillips #1 head screwdriver | Phillips #1 screw |

| Phillips #2 head screwdriver | Phillips #2 screw |

- A video of this procedure is available at YouTube.

Procedure

Install the PCIe riser assembly. See Install a PCIe riser assembly (ConnectX-6) , PCIe riser assembly replacement (ConnectX-7 NDR 200), or Install a PCIe riser assembly (ConnectX-7 NDR 400).

Install the drive cage. See Install a drive cage assembly.

Install the M.2 backplane assembly. See Install the M.2 backplane assembly.

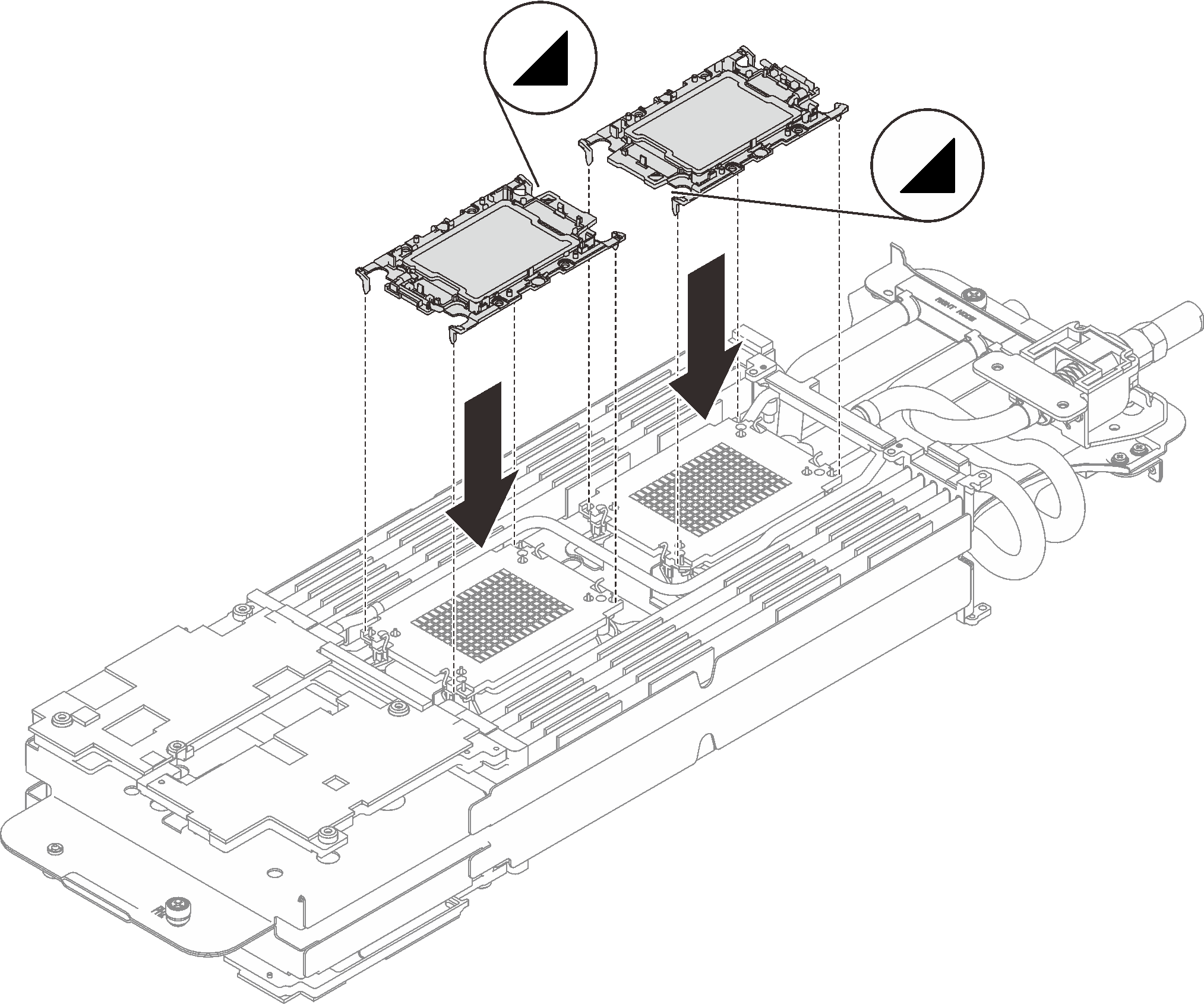

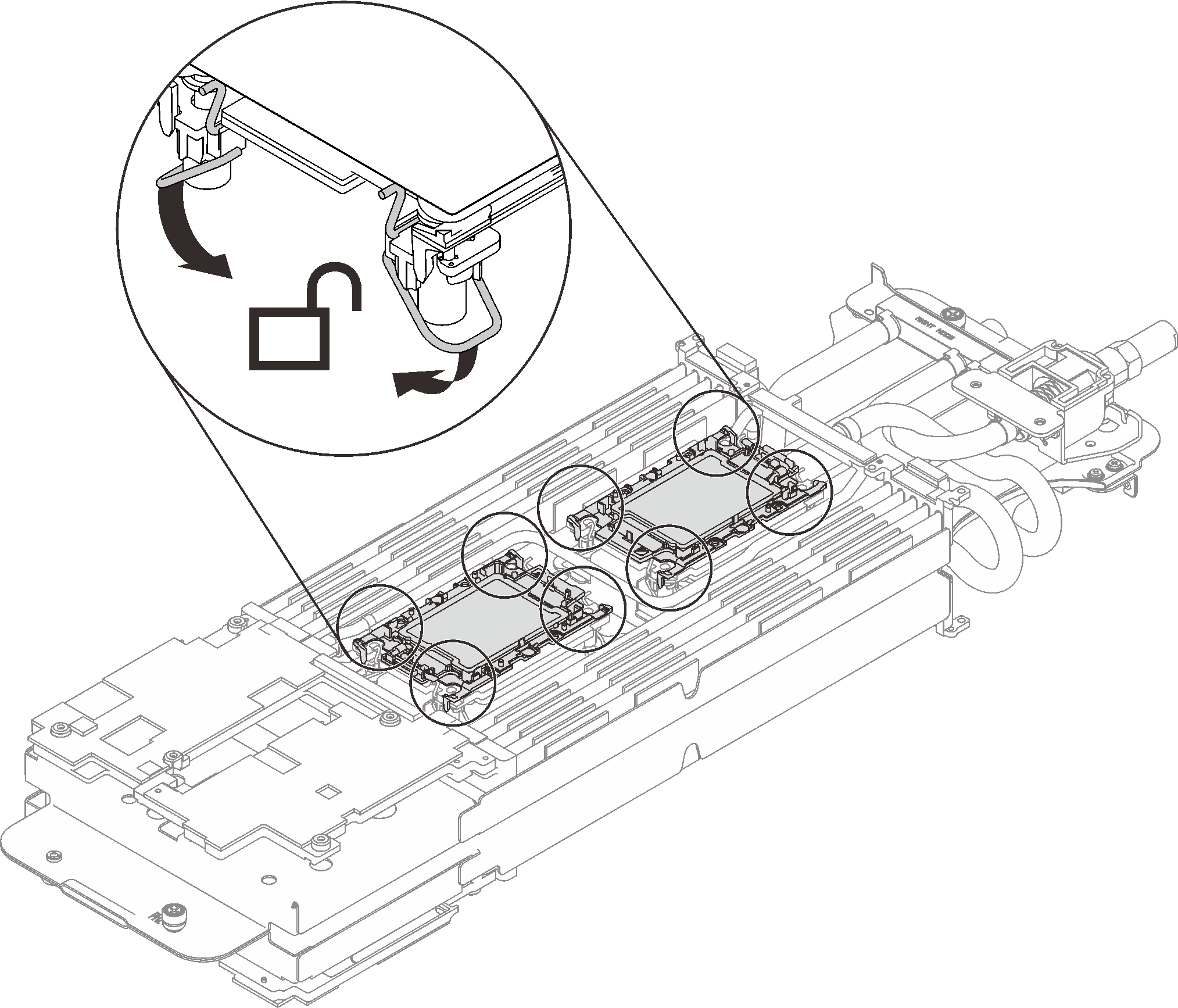

Install the memory modules. See Install a memory module.

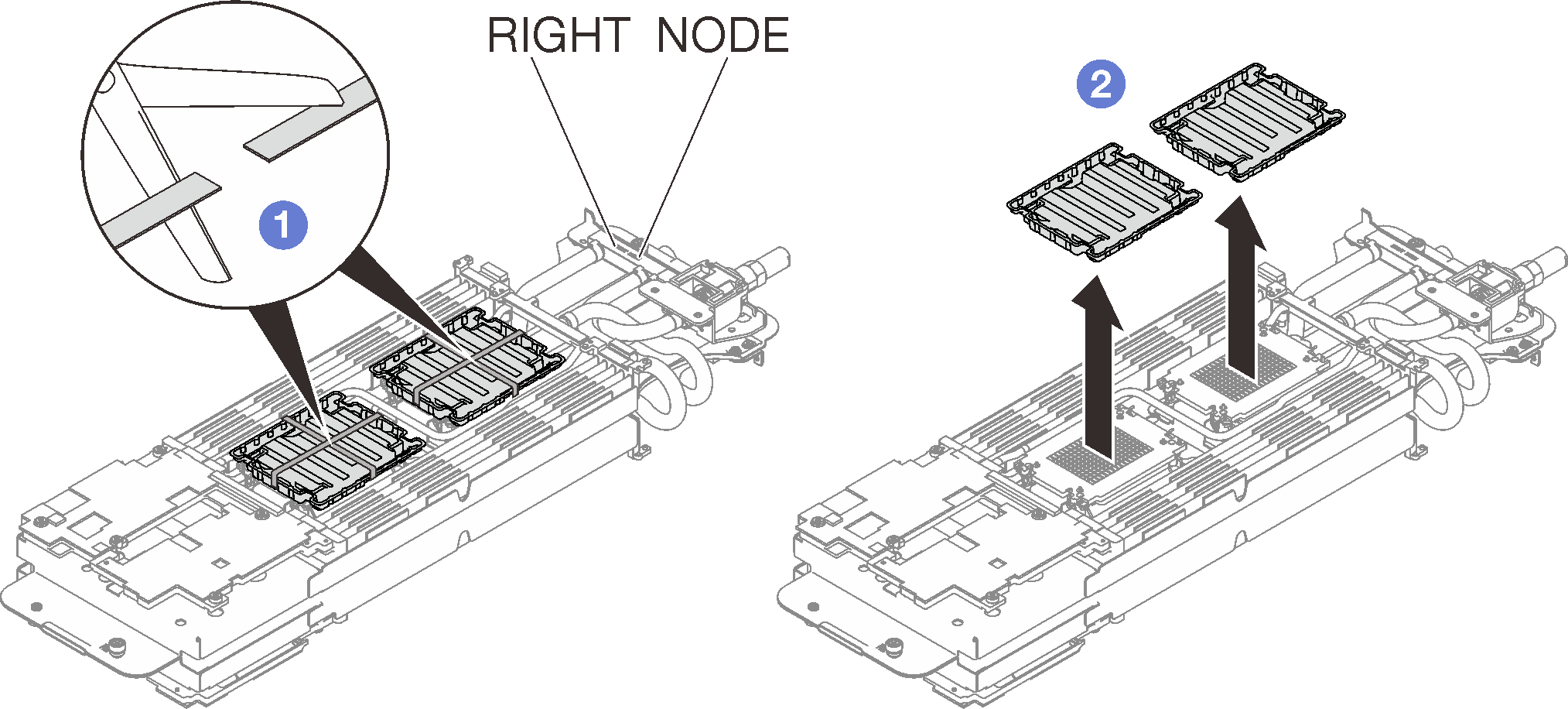

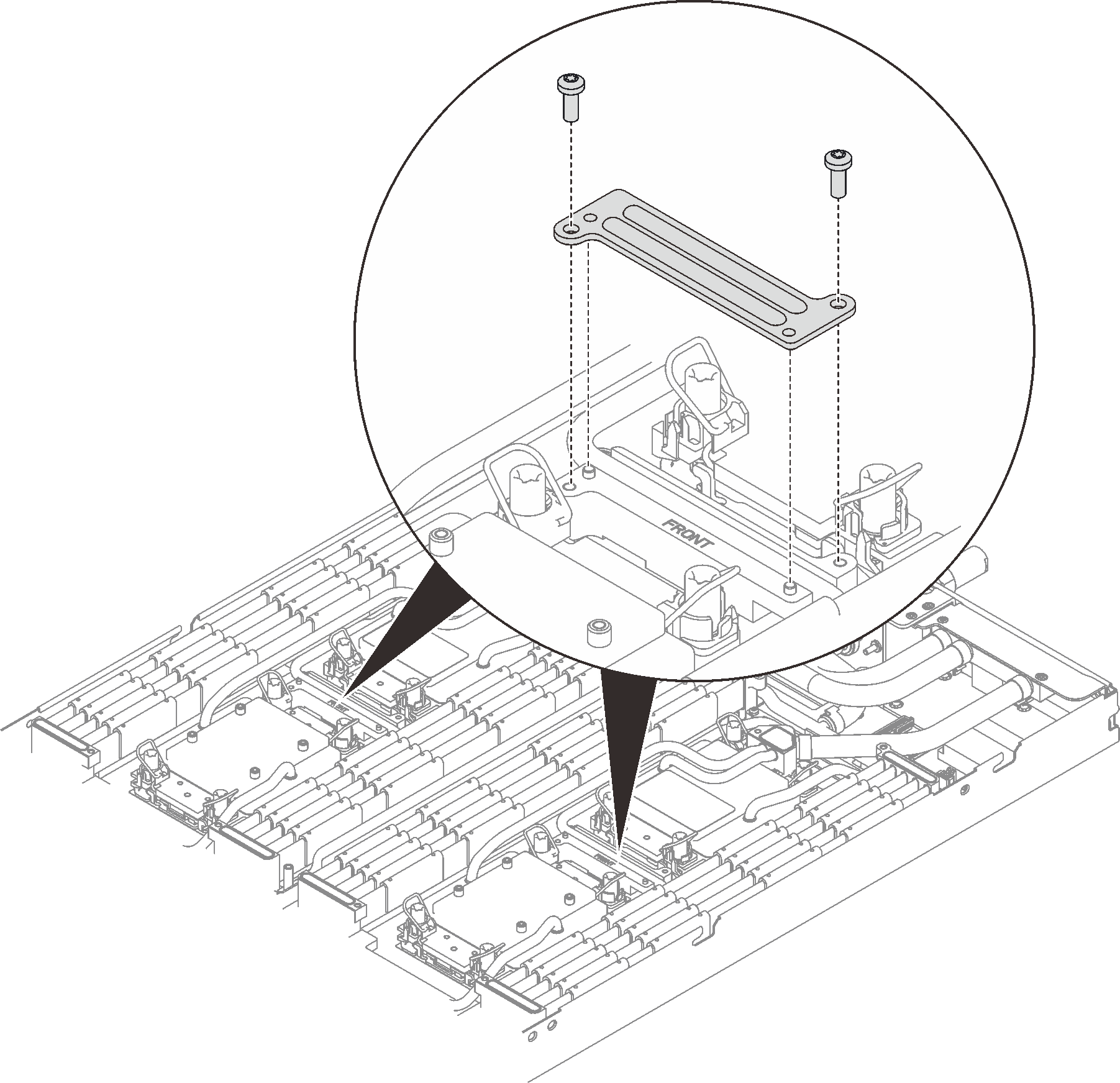

Install the DIMM comb. See Install a DIMM comb.

Install the cross braces. See Install the cross braces (SD650 V3).

Install the tray cover. See Install the tray cover.

Install the tray into the enclosure. See Install a DWC tray in the enclosure.

- Connect all required external cables to the solution.NoteUse extra force to connect QSFP cables to the solution.

Check the power LED on each node to make sure it changes from fast blink to slow blink to indicate all nodes are ready to be powered on.