Install the power distribution board

Use this information to install the power distribution board.

About this task

To avoid a shock hazard:

- Connect all power cords to a properly wired and grounded electrical outlet/source.

- Connect any equipment that will be attached to this product to properly wired outlets/sources.

- When possible, use one hand only to connect or disconnect signal cables.

- Never turn on any equipment when there is evidence of fire, water, or structural damage.

- The device might have more than one power cord, to remove all electrical current from the device, ensure that all power cords are disconnected from the power source.

Read Installation Guidelines and Safety inspection checklist to ensure that you work safely.

Ensure you have SD650-I V3 Neptune DWC Waterloop Service Kit

in hand to install components.

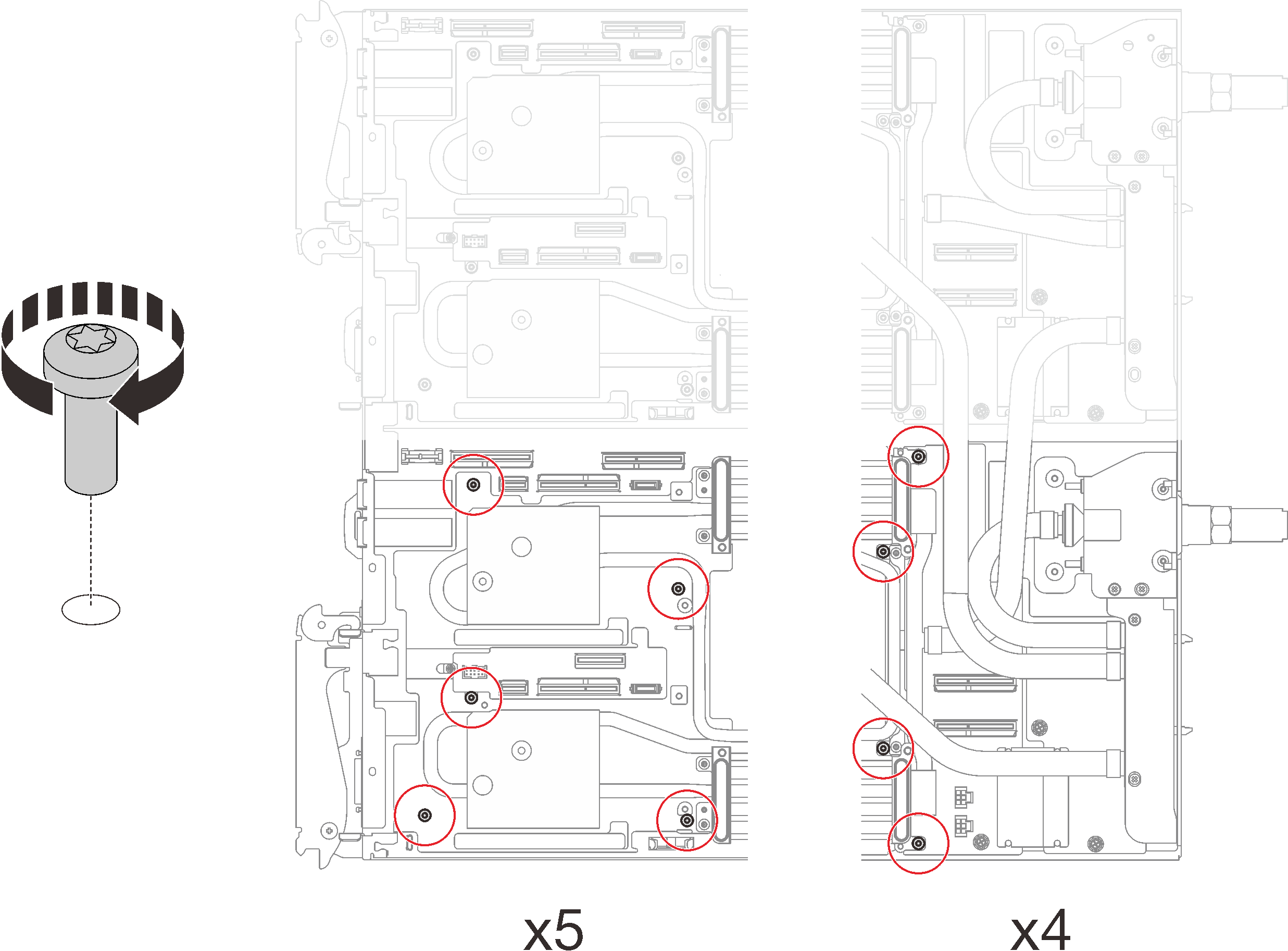

| Screwdriver Type | Screw Type |

|---|---|

| Torx T10 head screwdriver | Torx T10 screw |

| Torx T30 head screwdriver | Torx T30 screw |

| Phillips #1 head screwdriver | Phillips #1 screw |

| Phillips #2 head screwdriver | Phillips #2 screw |

Go to Drivers and Software download website for ThinkSystem SD650 V3 to see the latest firmware and driver updates for your server.

Go to Update the firmware for more information on firmware updating tools.

- A video of this procedure is available at YouTube.

Procedure

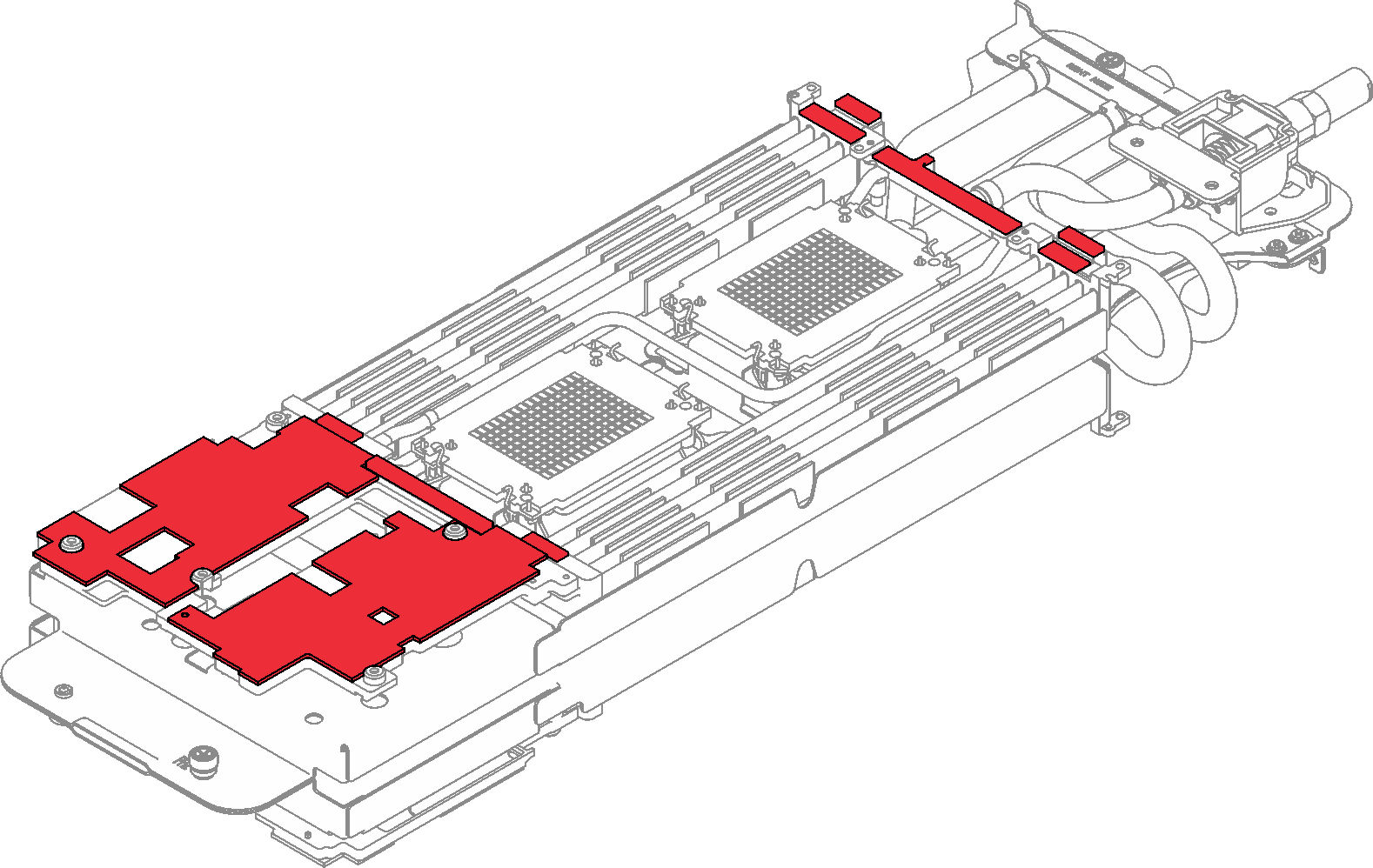

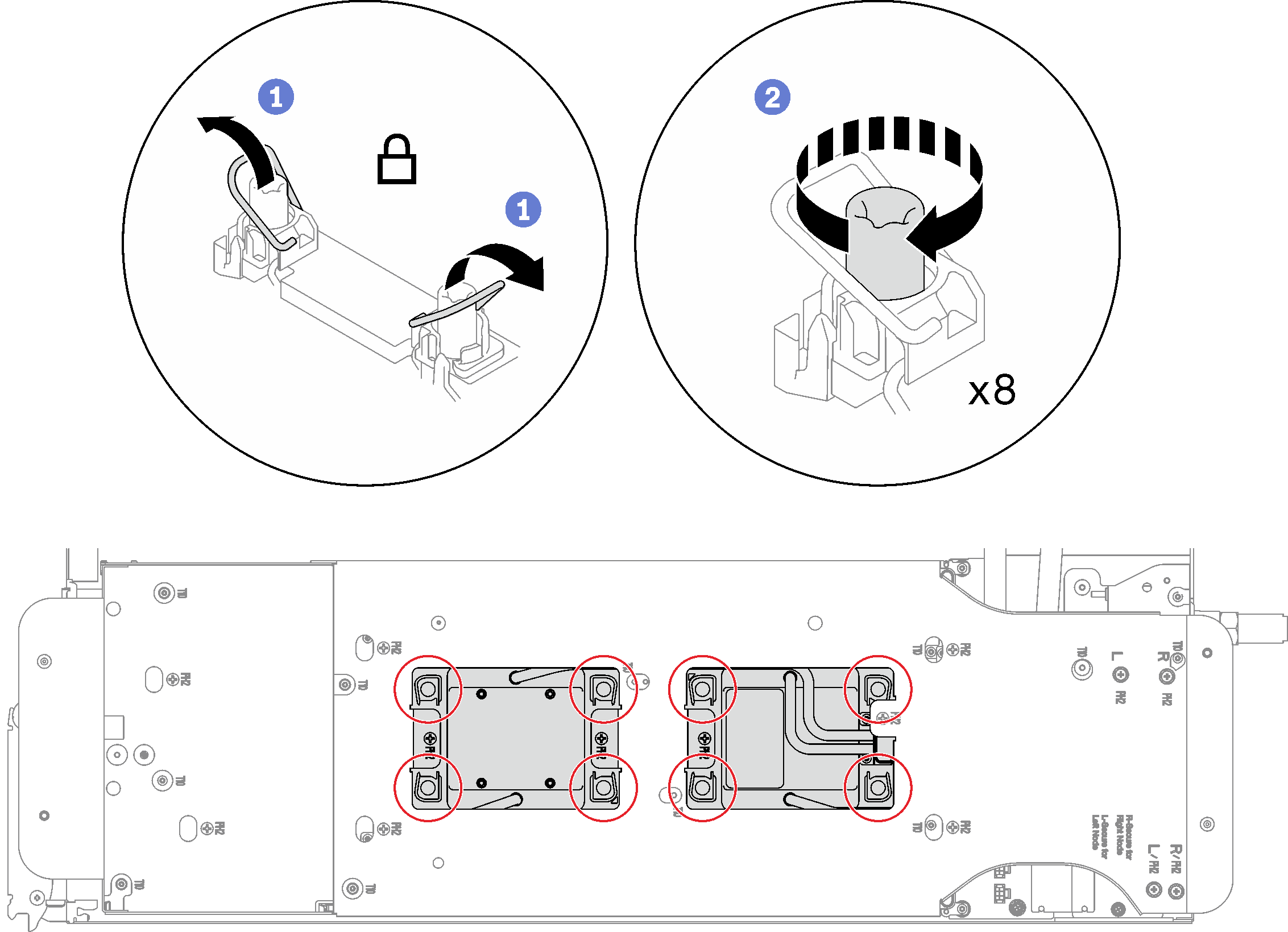

Make sure to follow Gap pad/putty pad replacement guidelines.

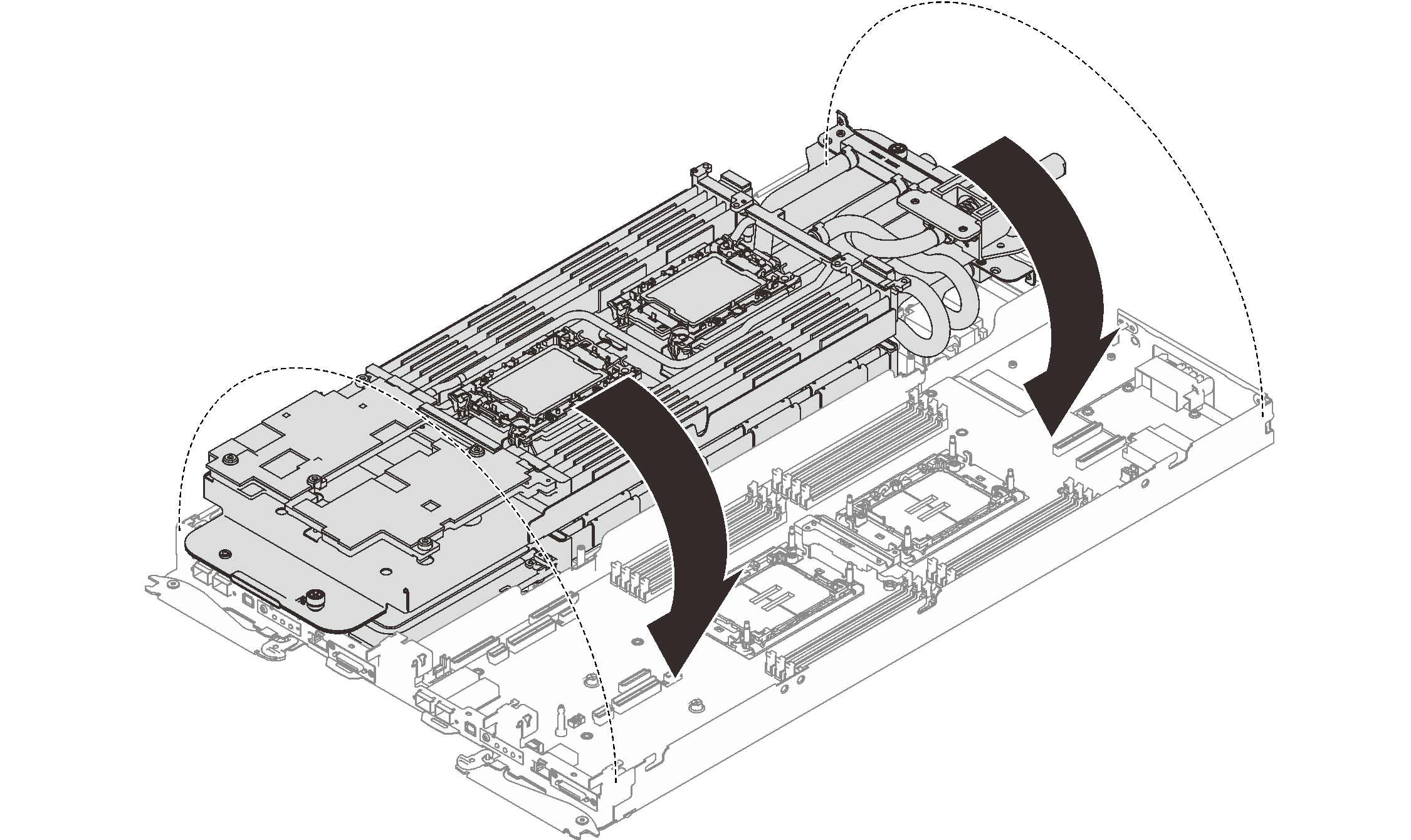

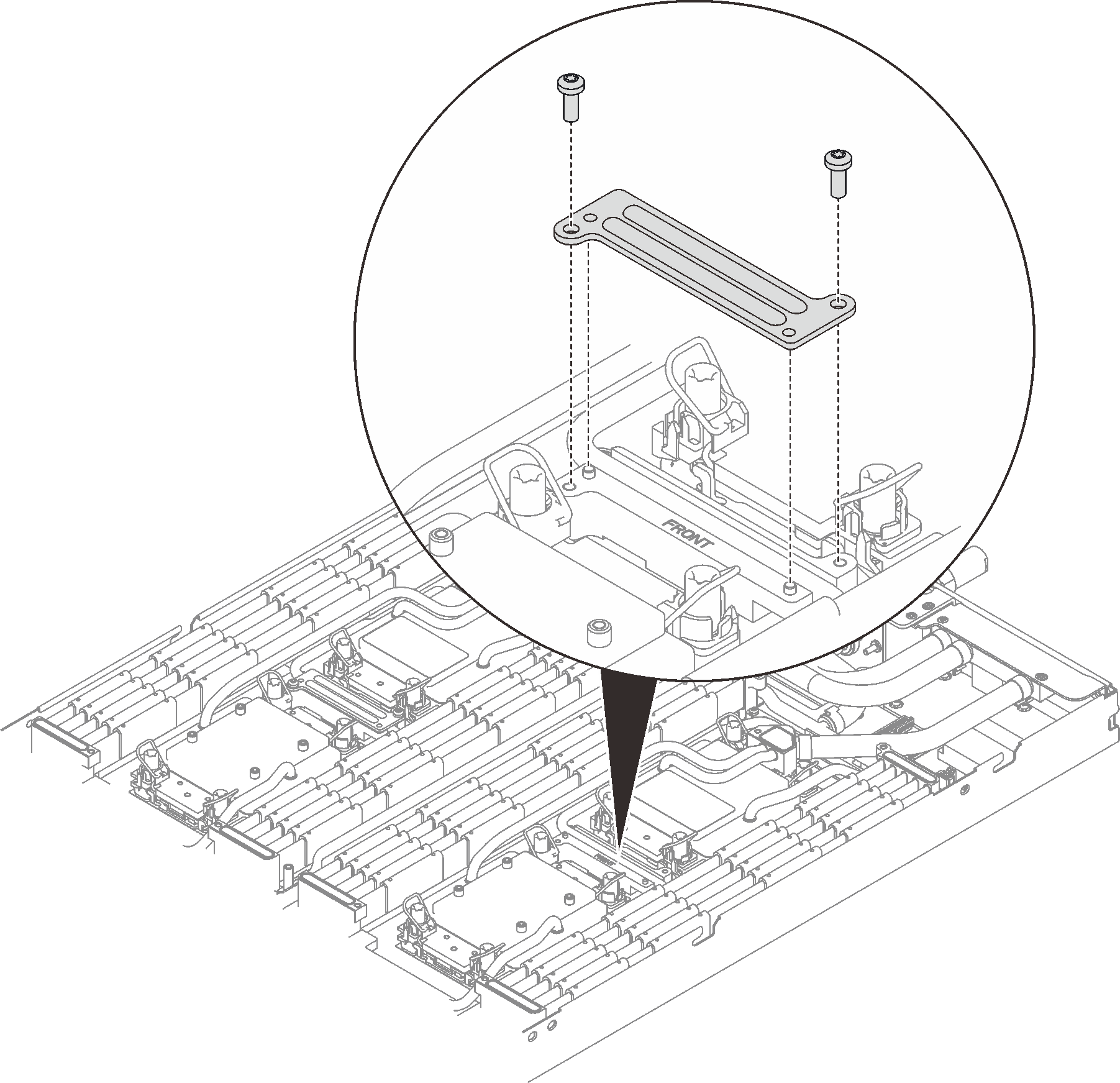

Install the cross braces. See Install the cross braces (SD650-I V3).

Install the tray cover. See Install the tray cover.

Install the tray into the enclosure. See Install a DWC tray in the enclosure.

- Connect all required external cables to the solution.NoteUse extra force to connect QSFP cables to the solution.

Check the power LED on each node to make sure it changes from fast blink to slow blink to indicate all nodes are ready to be powered on.