Installation du module de plaque froide GPU B200 arrière

Suivez les instructions de la présente section pour installer le module de plaque froide GPU B200 arrière. La procédure doit être exécutée par un technicien qualifié.

À propos de cette tâche

Avertissement

- Lisez Conseils d’installation et Liste de contrôle d’inspection de sécurité pour vous assurer que vous travaillez en toute sécurité.

- Mettez l’emballage antistatique contenant le composant contre une zone métallique non peinte du serveur, puis déballez et posez le composant sur une surface de protection antistatique.

- Un tournevis dynamométrique est disponible sur demande si vous n’en avez pas à portée de main.

Remarque

Assurez-vous de disposer des outils requis répertoriés ci-dessous afin de pouvoir remplacer correctement le composant:

- Tournevis à tête T15 Torx

- Rallonge Torx T15 200mm

- Tournevis cruciforme n°1

- Tournevis cruciforme n°2

- Tampon de nettoyage à l’alcool

- PCM B200

- B200 SXM6 PAD-1

- B200 SXM6 PAD-2

- Kit de support d’expédition F&R GPU B200

Important

Directives de remplacement des tampons de mastic/matériau à changement de phase (PCM)

- Avant de remplacer le tampon de mastic ou le matériau à changement de phase, nettoyez délicatement la surface du matériel à l’aide d’un chiffon doux imbibé d’alcool.

- Maintenez le tampon de mastic/le PCM avec précautions afin de ne pas le déformer. Assurez-vous qu’aucun trou de vis ou orifice n’est obstrué par le tampon de mastic/PCM.

- N’utilisez pas de tampon de mastic/PCM périmé. Vérifiez la date de péremption sur l’emballage du tampon de mastic ou du PCM. Si les tampons de mastic/le PCM ont dépassé la date limite d’utilisation, achetez-en de nouveaux afin de les remplacer correctement.

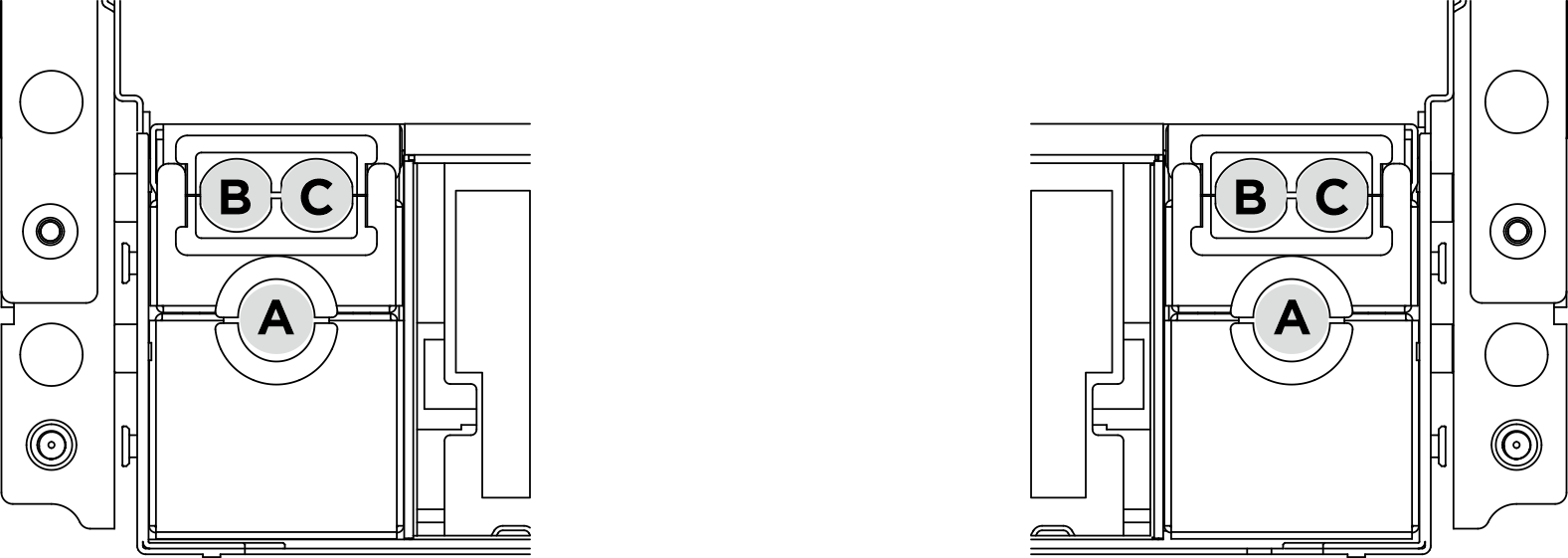

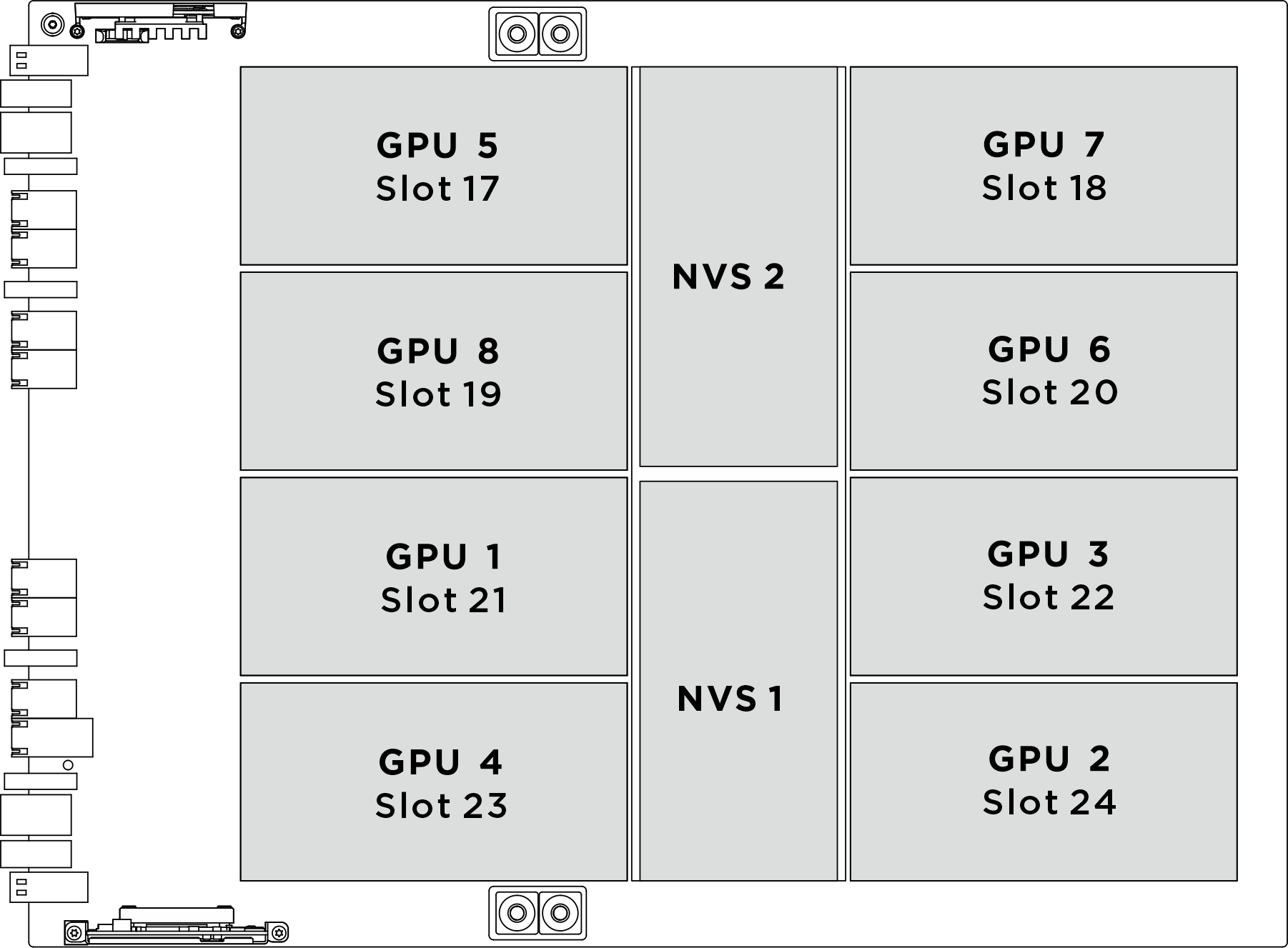

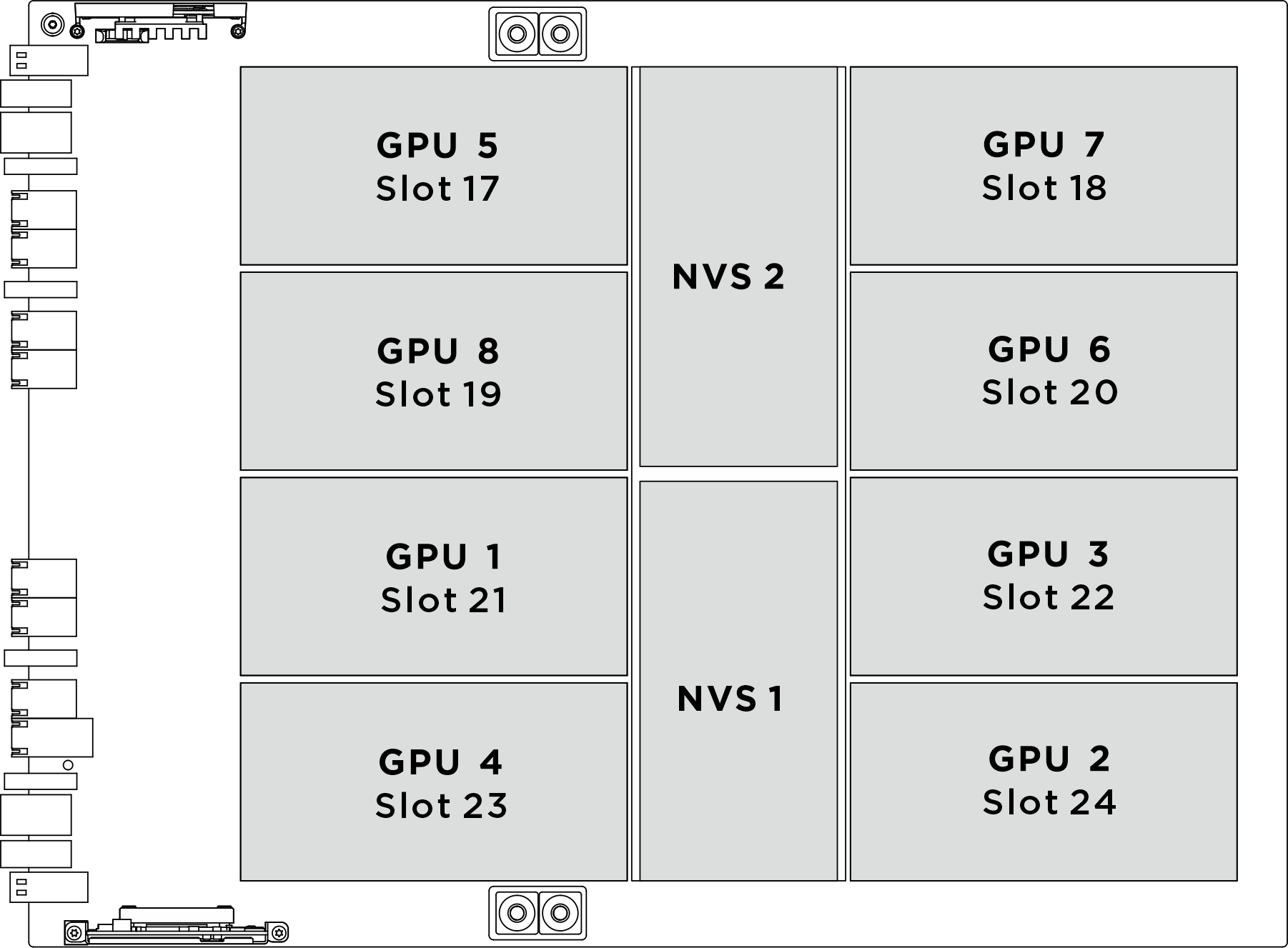

L’illustration suivante présente la numérotation GPU B200 et la numérotation des emplacements associés dans XCC.

Figure 1. Numérotation GPU B200

| Socket GPU physique | Numérotation des emplacements dans XCC | Numéro logique dans nvidia-smi |

|---|---|---|

GPU 1 | Emplacement 21 | 4 |

GPU 2 | Emplacement 24 | 7 |

GPU 3 | Emplacement 22 | 5 |

GPU 4 | Emplacement 23 | 6 |

GPU 5 | Emplacement 17 | 0 |

GPU 6 | Emplacement 20 | 3 |

GPU 7 | Emplacement 18 | 1 |

GPU 8 | Emplacement 19 | 2 |

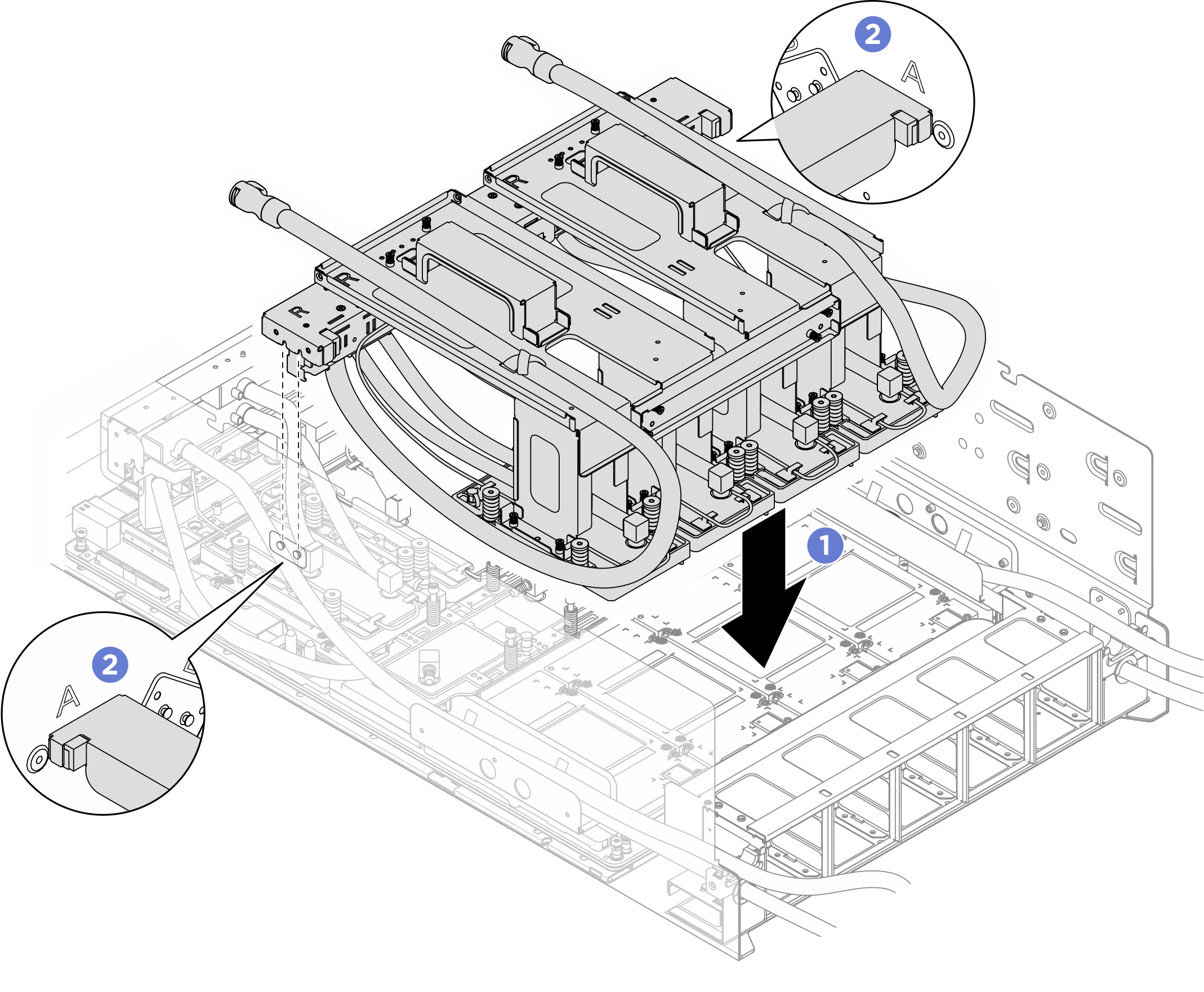

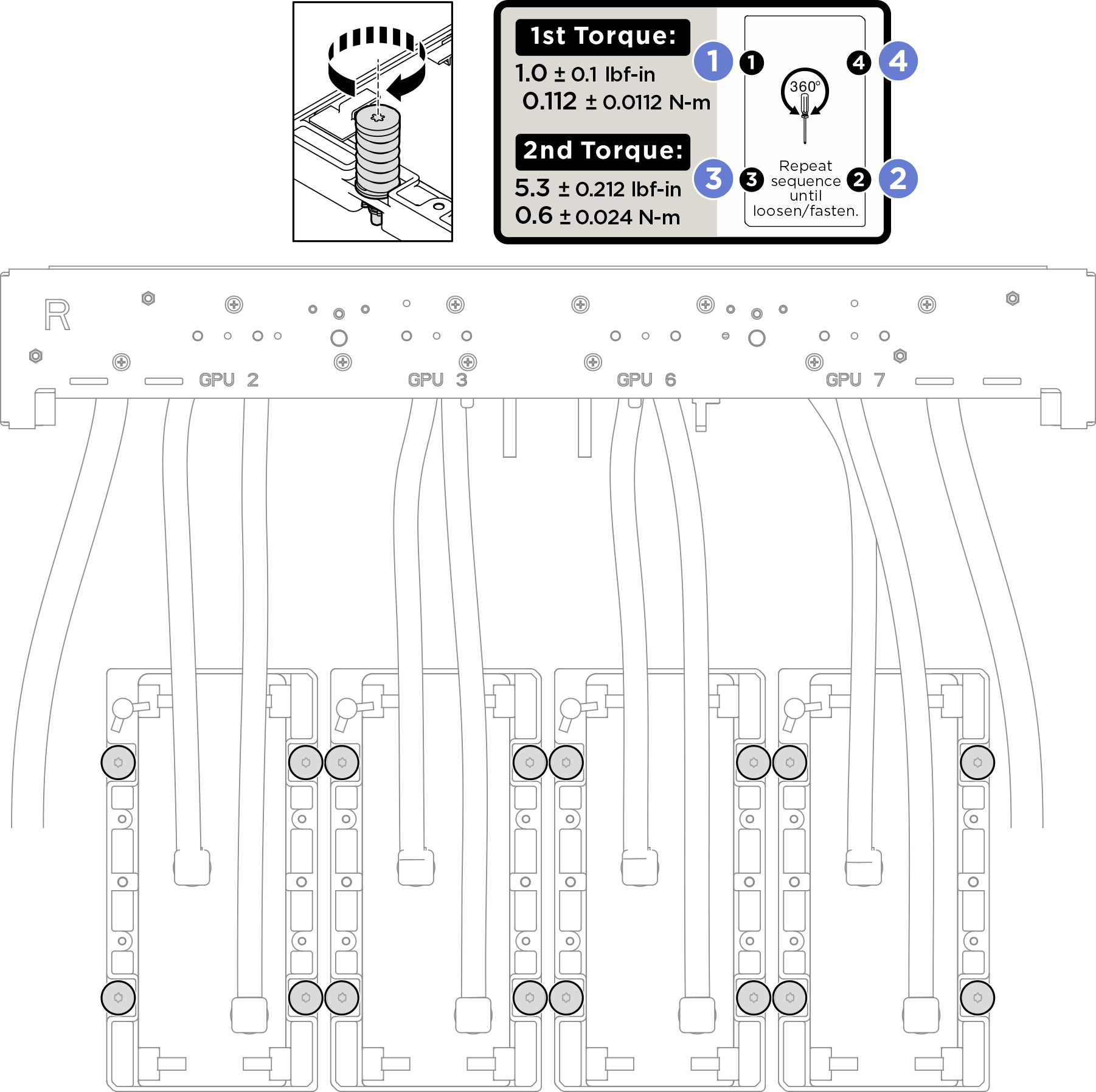

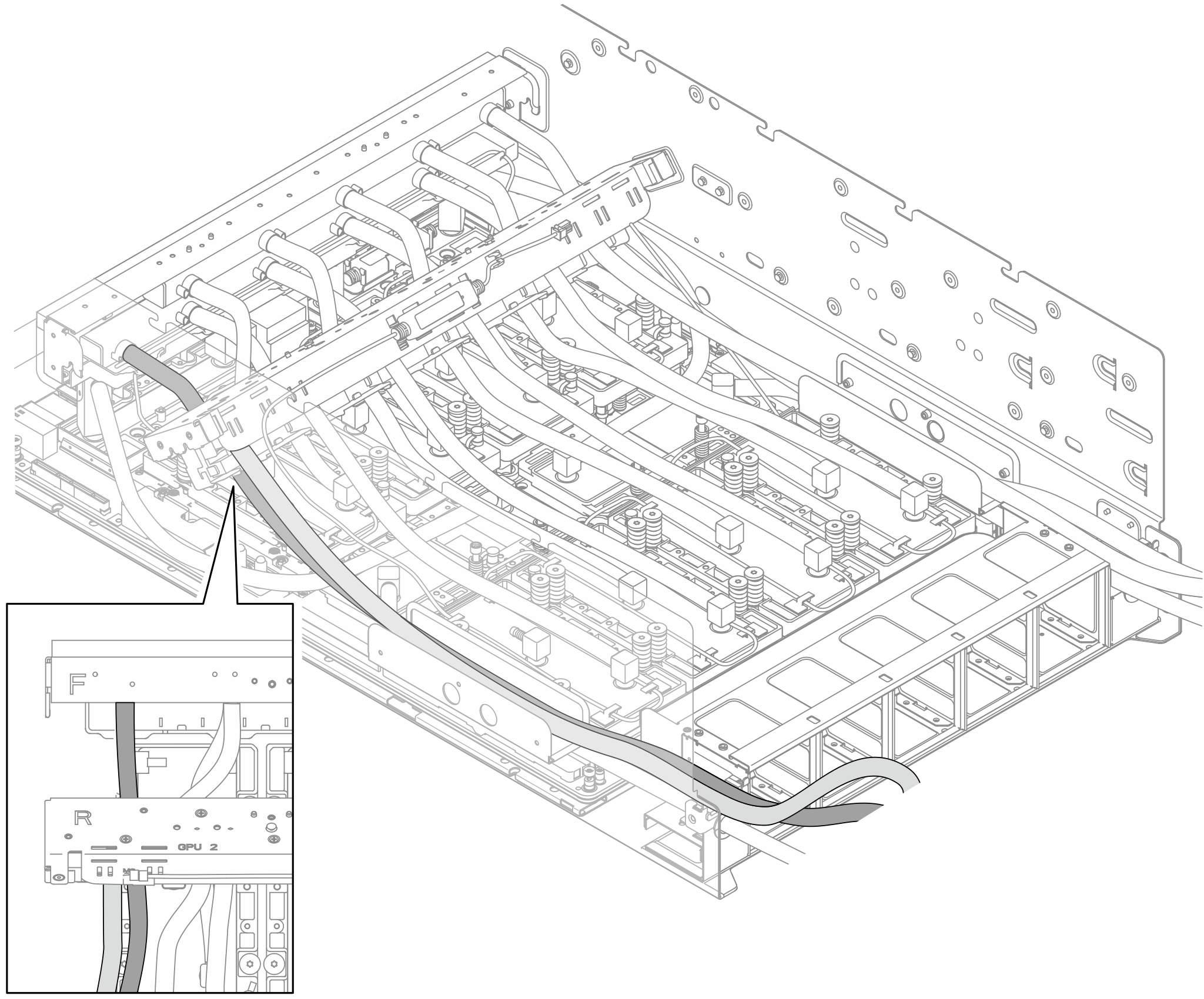

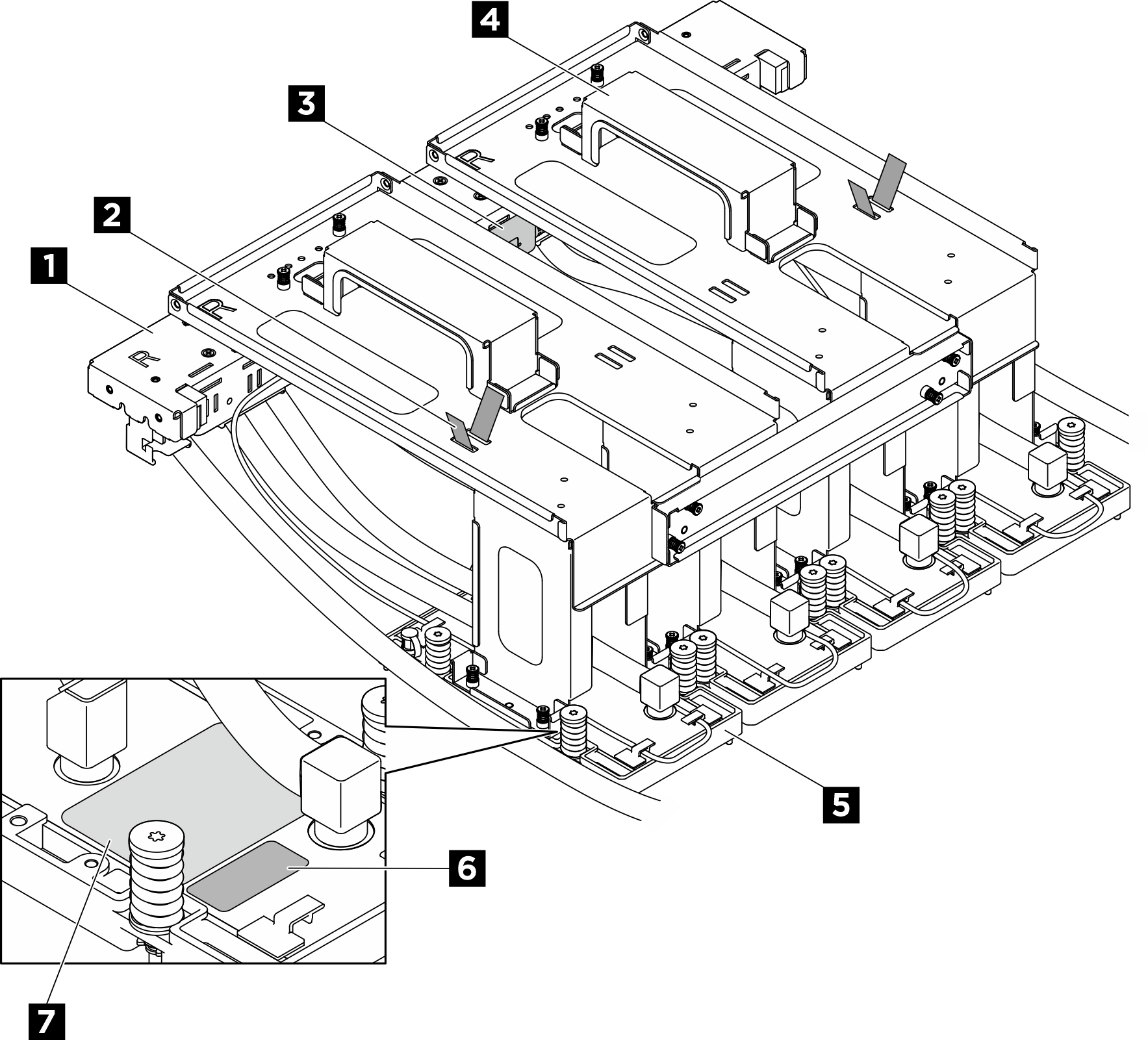

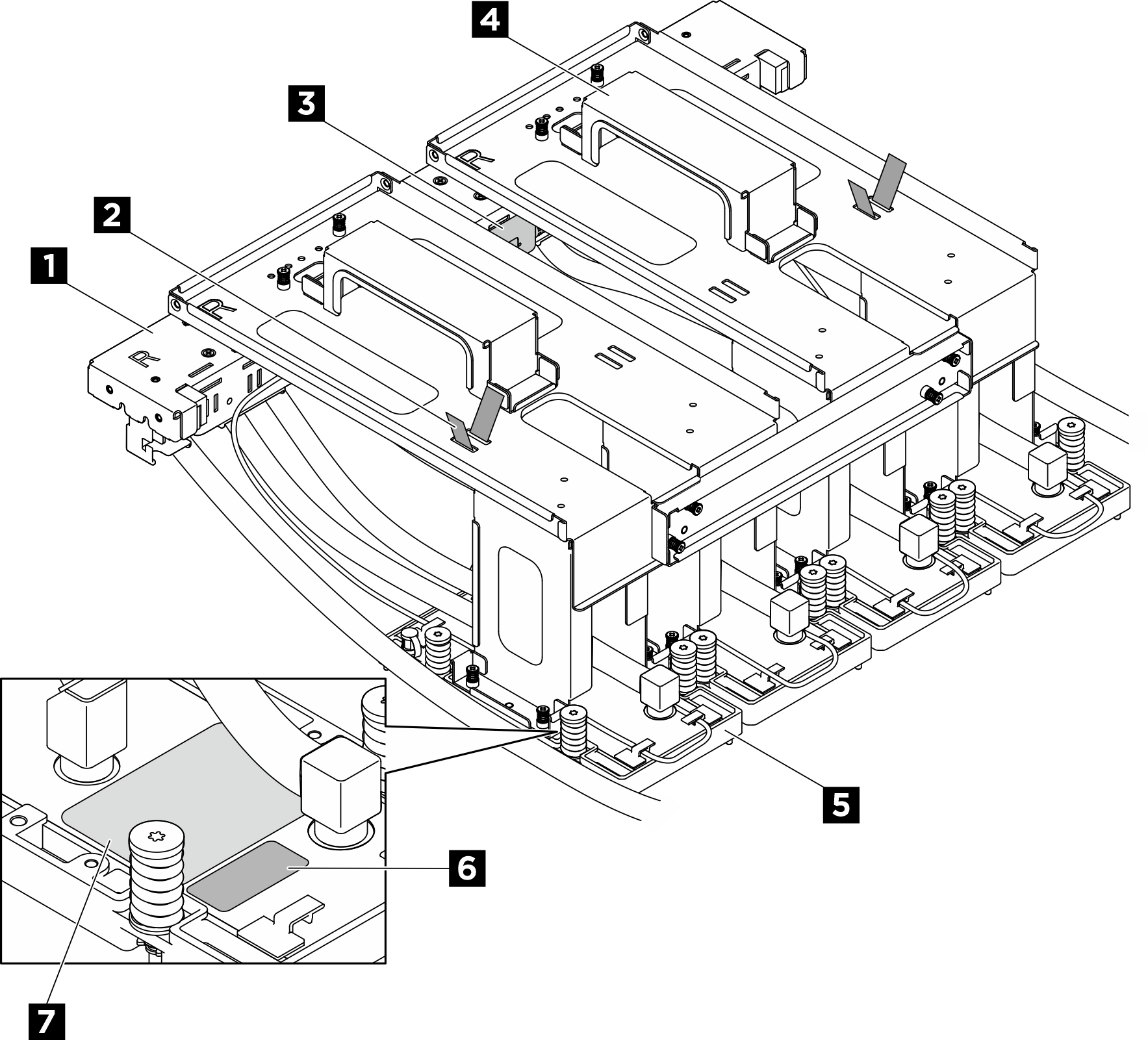

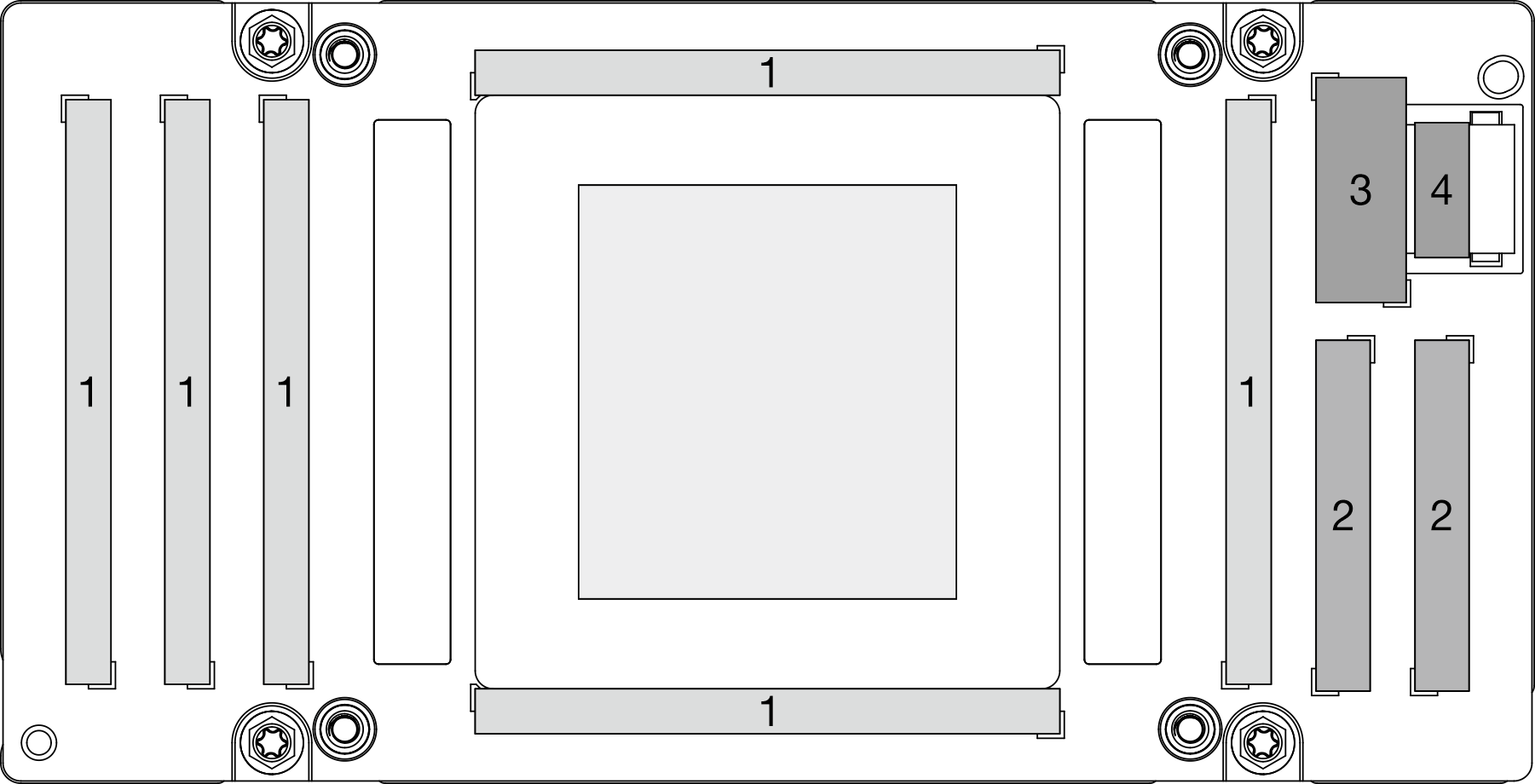

L’illustration suivante présente les composants du module de plaque froide GPU B200 arrière.

Figure 2. Identification des composants du module de plaque froide GPU B200 arrière

| 1 Collecteur | 2 Collier de serrage |

| 3 Module de détecteur de fuite | 4 Support de transport |

| 5 Plaque froide GPU | 6 Étiquette de numéro d’emplacement GPU |

| 7 Étiquette sur le couple des vis de la plaque froide GPU |

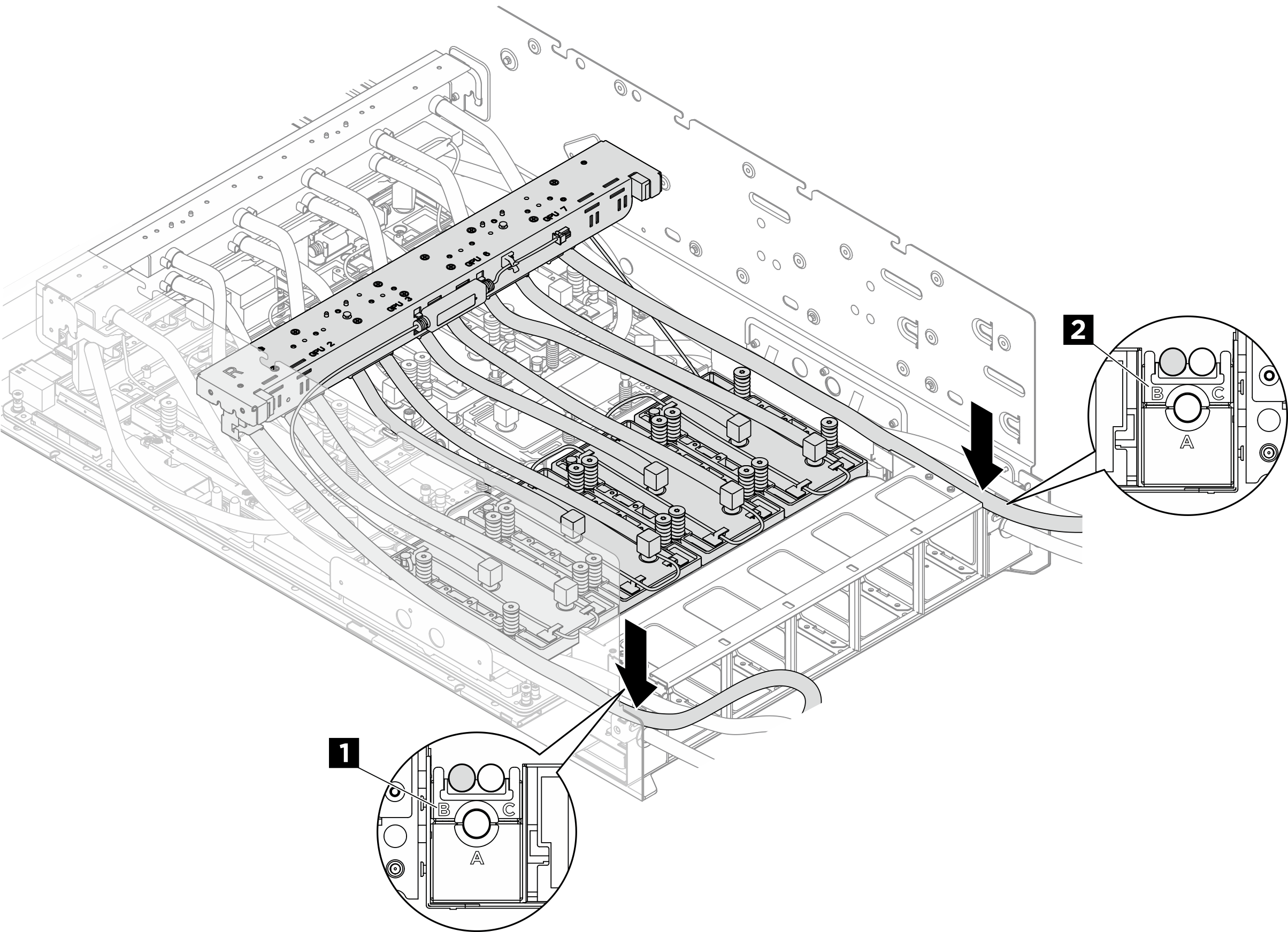

Procédure

Après avoir terminé

- Reconnectez tous les câbles débranchés précédemment. Voir Cheminement interne des câbles.

- Réinstallez le complexe d’alimentation. Voir Installation du complexe d’alimentation.

- Réinstallez le complexe UC. Voir Installation du complexe UC.

- Réinstallez le boîtier de ventilation. Voir Installation du boîtier de ventilation (technicien qualifié uniquement).

- Réinstallez le carter supérieur arrière. Voir Installation du carter supérieur arrière.

- Réinstallez le carter supérieur avant. Voir Installation du carter supérieur avant.

- Terminez de remplacer les composants. Voir Fin du remplacement des composants.

Envoyer des commentaires

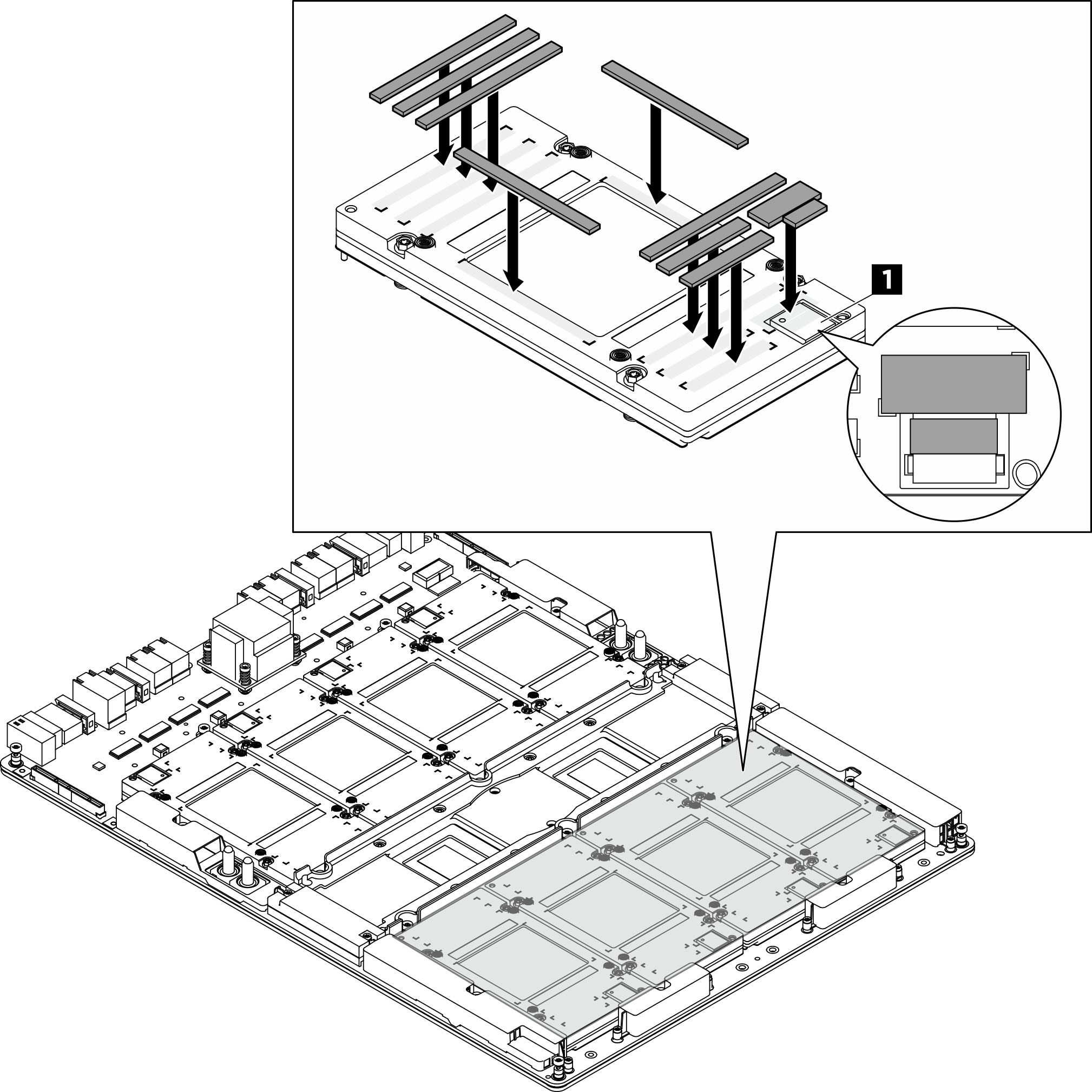

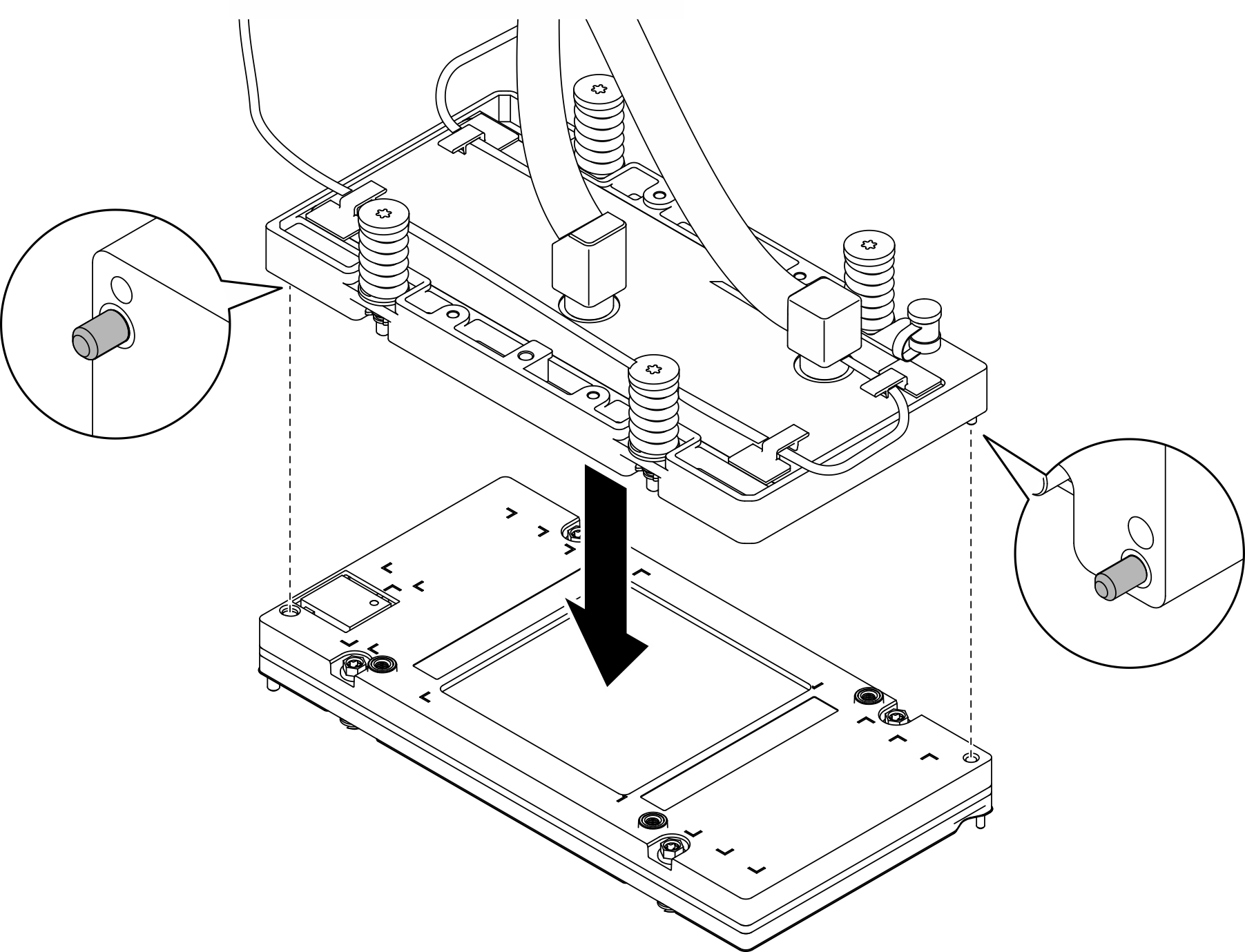

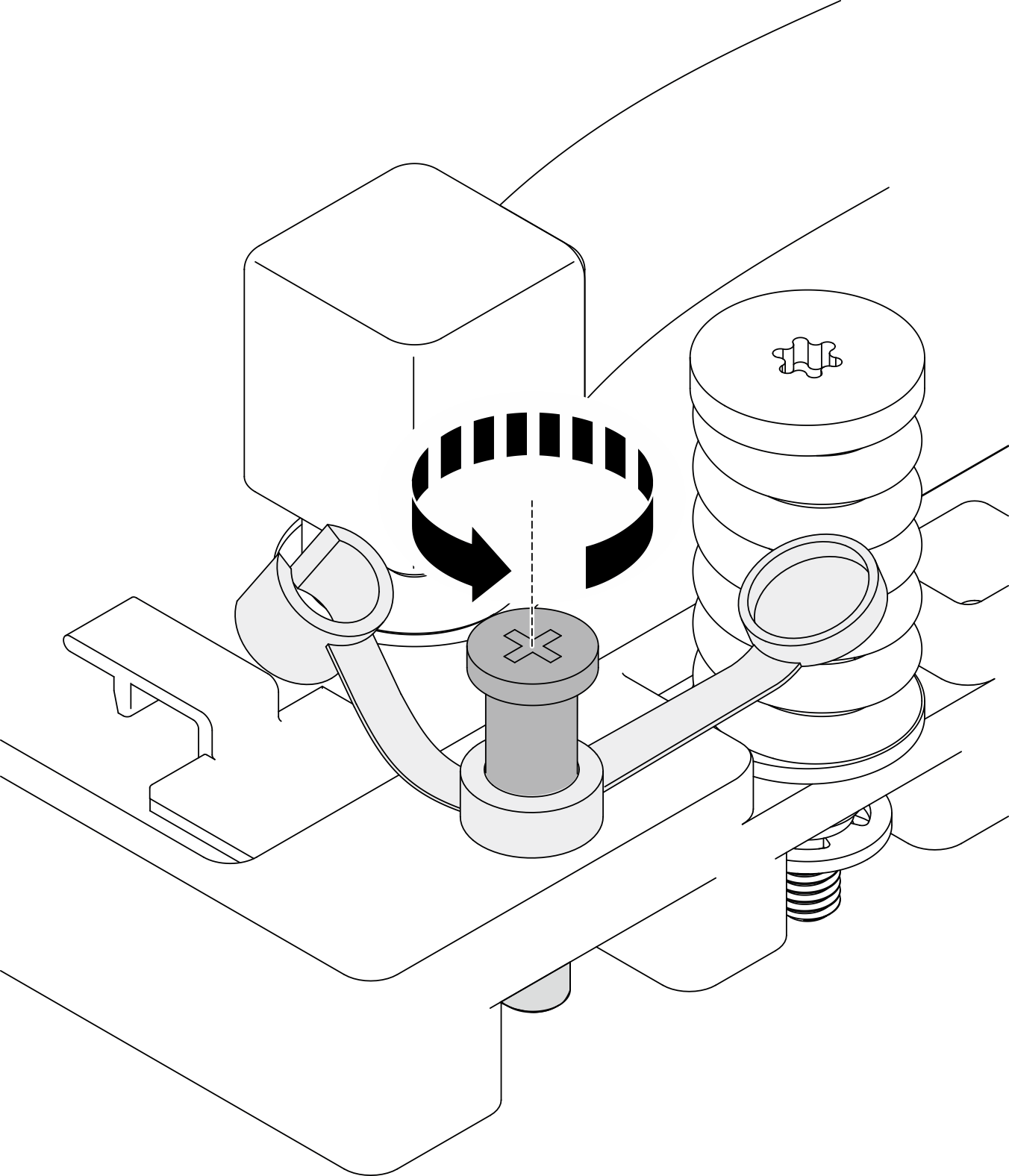

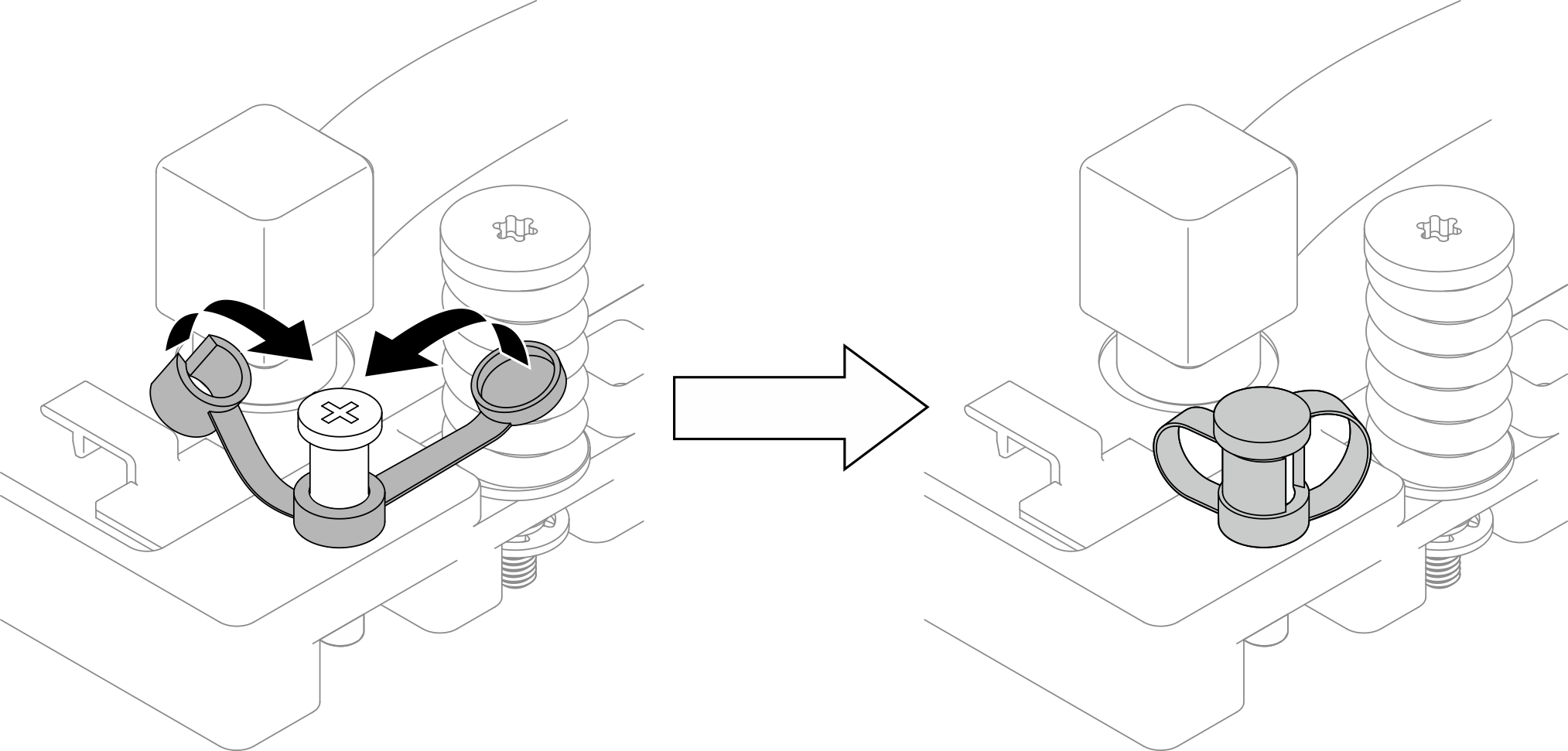

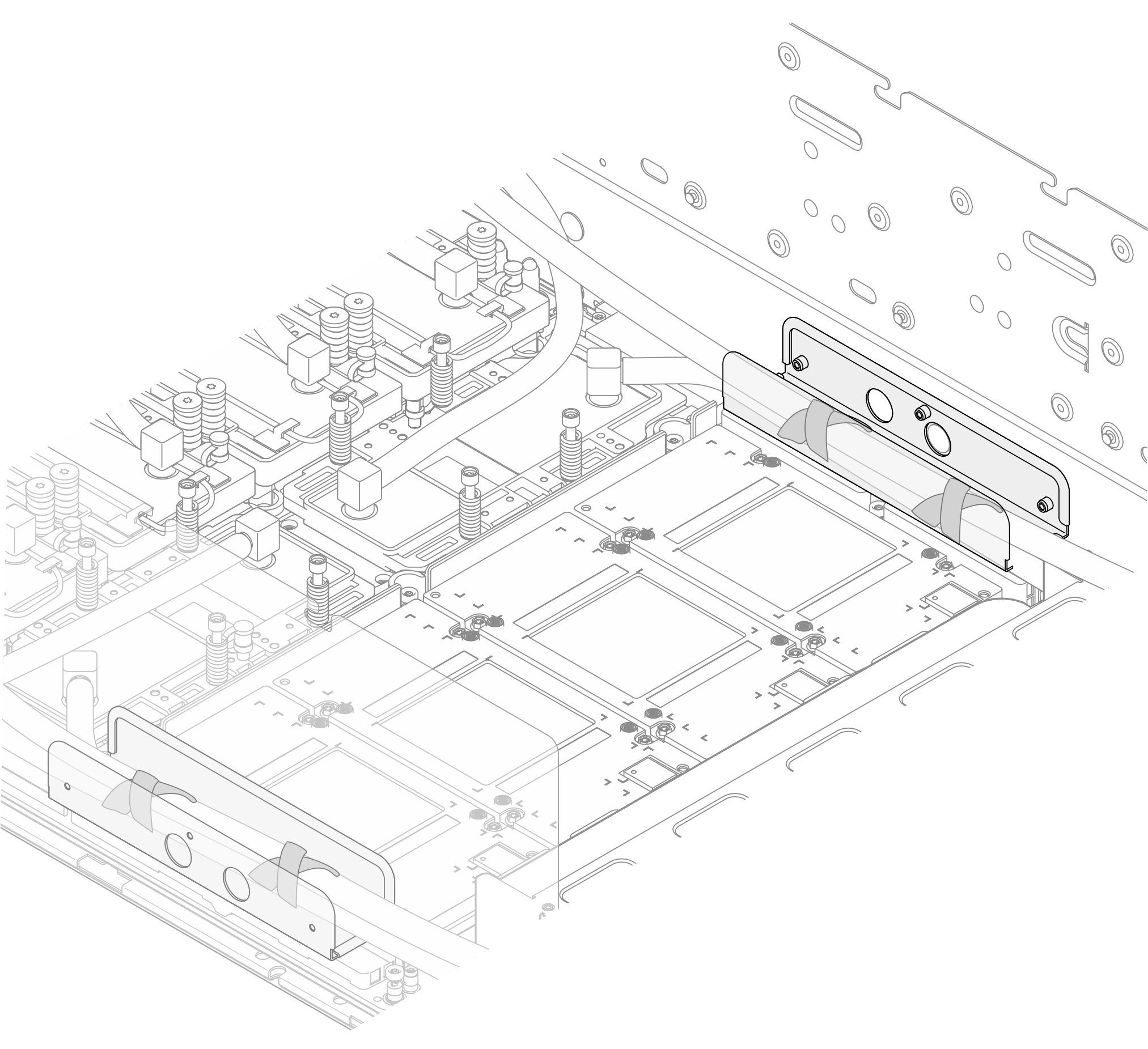

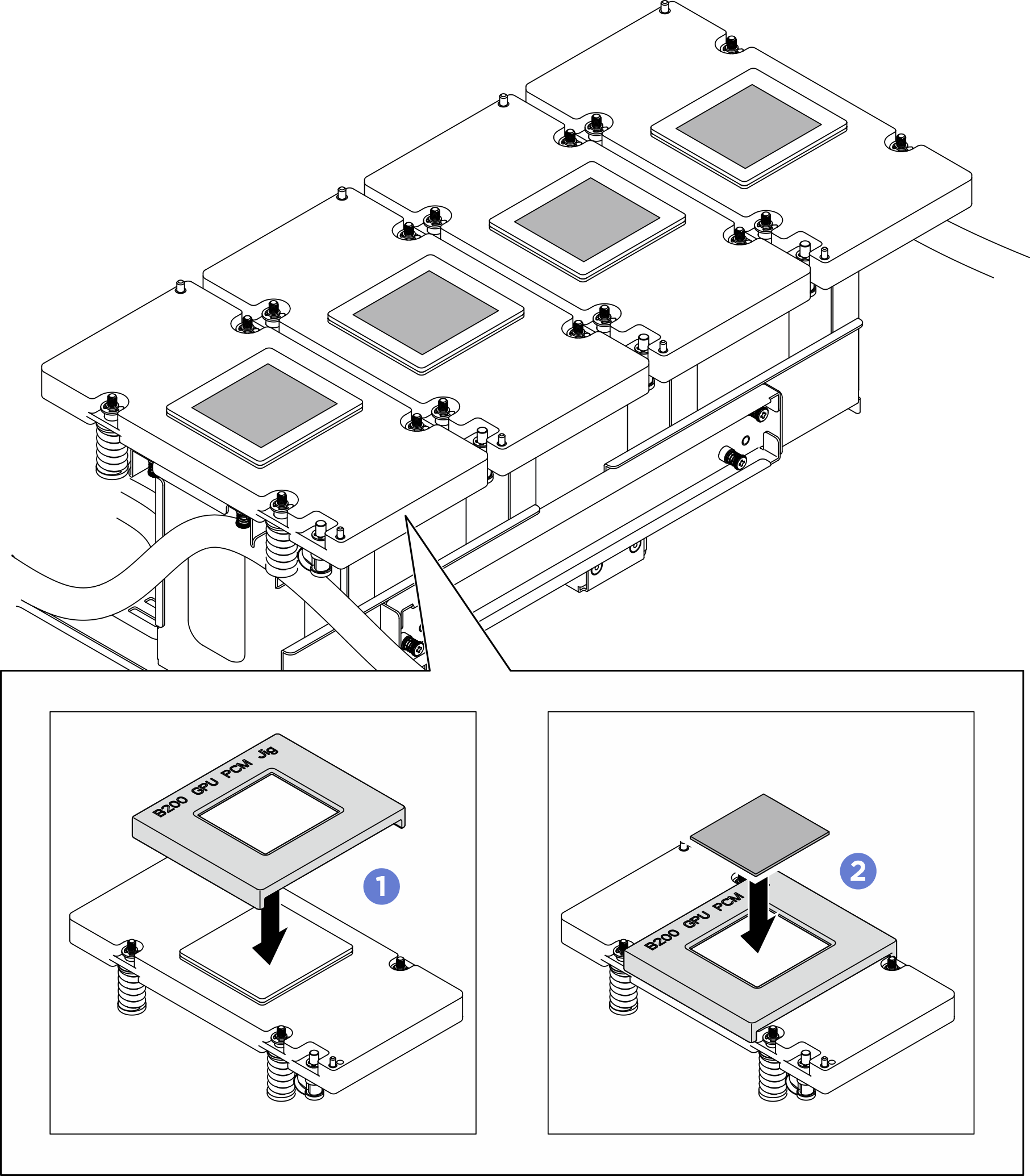

Assurez-vous que le support de transport est fixé au module de plaque froide GPU. Retournez le module et placez-le sur une surface avec la plaque froide orientée vers le haut.

Assurez-vous que le support de transport est fixé au module de plaque froide GPU. Retournez le module et placez-le sur une surface avec la plaque froide orientée vers le haut. Appliquez le gabarit PCM sur la plaque froide GPU.

Appliquez le gabarit PCM sur la plaque froide GPU. Retirez le revêtement d’un côté du tampon. Alignez le PCM sur le gabarit et placez-le sur la plaque froide. Retirez le gabarit ; appliquez ensuite une pression du doigt sur toute la surface du PCM pour éliminer l’air emprisonné et laissez agir 1 à 2 minutes jusqu’à ce qu’il soit solidement fixé. Retirez avec précaution le revêtement supérieur restant.

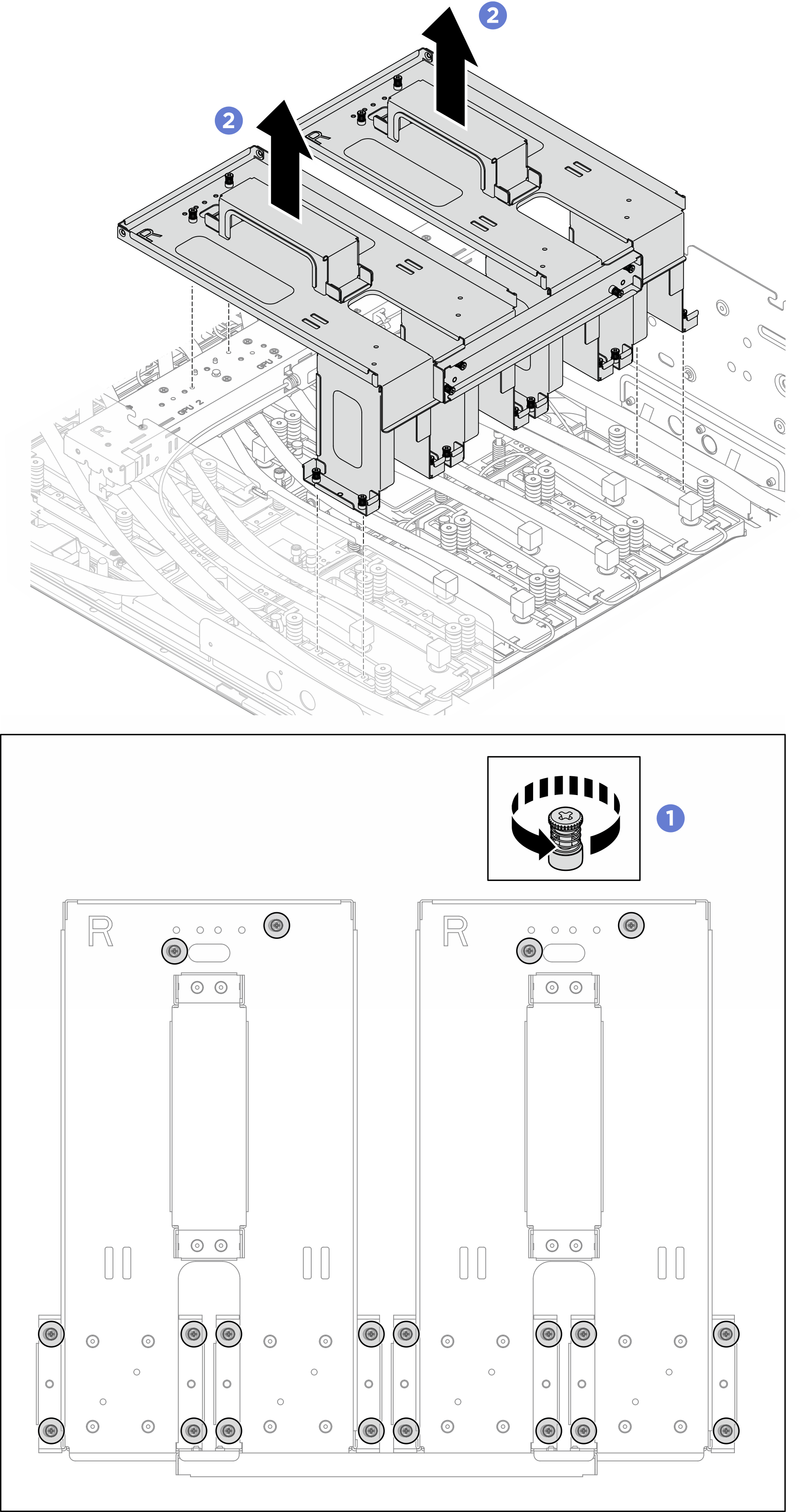

Retirez le revêtement d’un côté du tampon. Alignez le PCM sur le gabarit et placez-le sur la plaque froide. Retirez le gabarit ; appliquez ensuite une pression du doigt sur toute la surface du PCM pour éliminer l’air emprisonné et laissez agir 1 à 2 minutes jusqu’à ce qu’il soit solidement fixé. Retirez avec précaution le revêtement supérieur restant. Répétez l’opération pour remplacer le PCM sur les quatre plaques froides.

Répétez l’opération pour remplacer le PCM sur les quatre plaques froides.

Répétez la procédure pour remplacer tous les tampons de mastic des quatre GPU.

Répétez la procédure pour remplacer tous les tampons de mastic des quatre GPU.