48U Advanced Rack Extension Kit (RDHX 付き) の取り付け

48U Advanced Rack Extension Kit と RDHX の取り付け方法については、このトピックを参照してください。

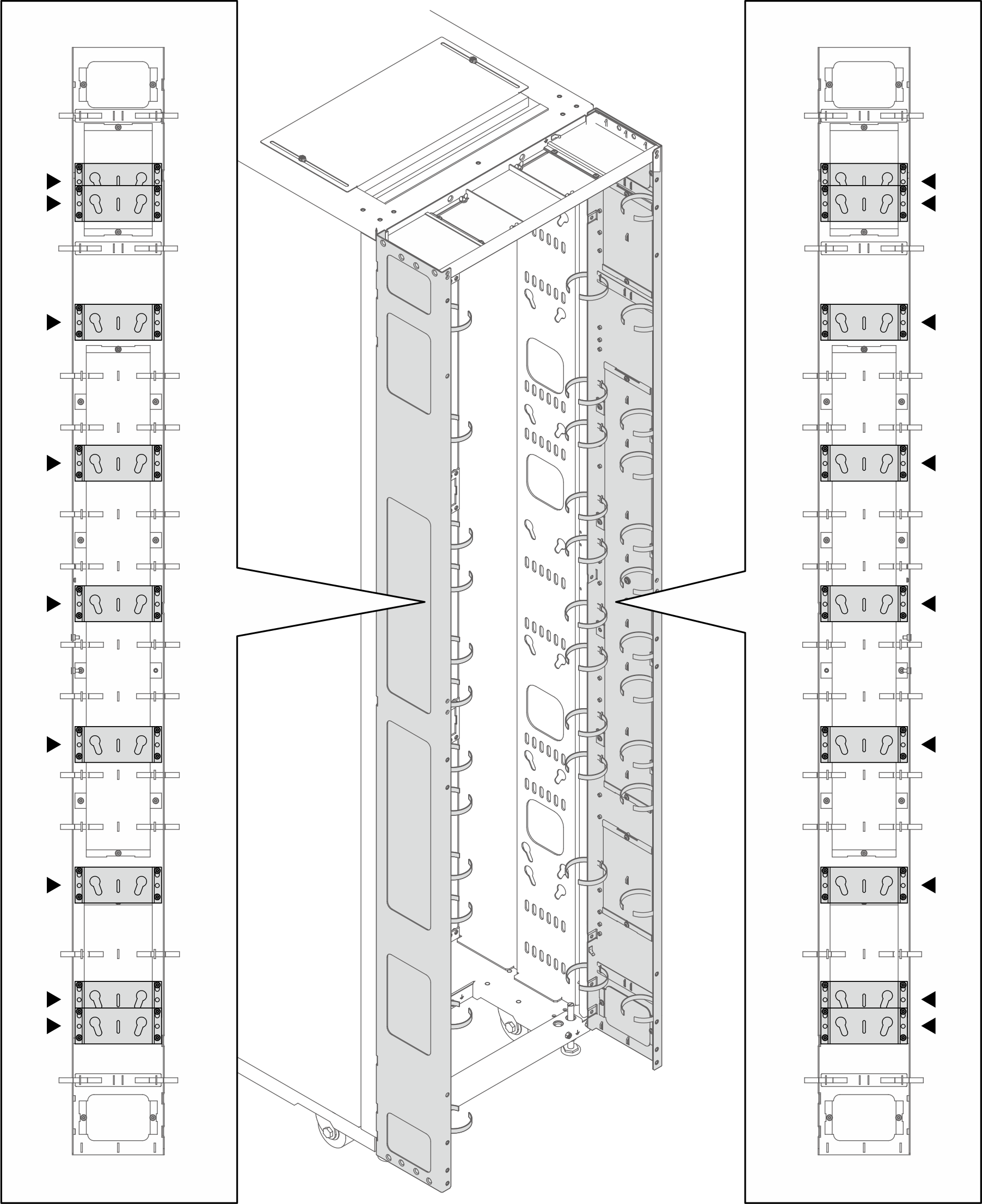

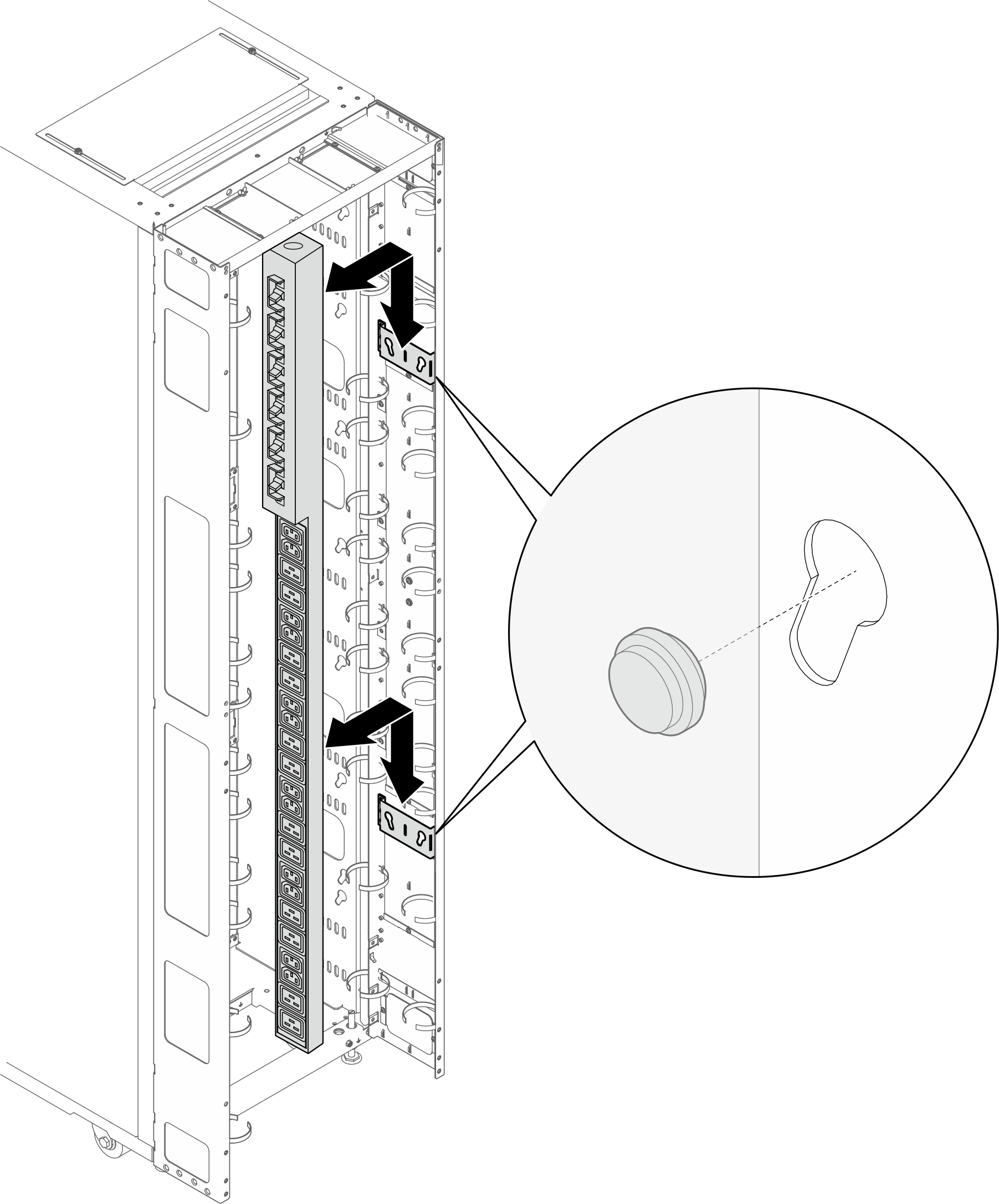

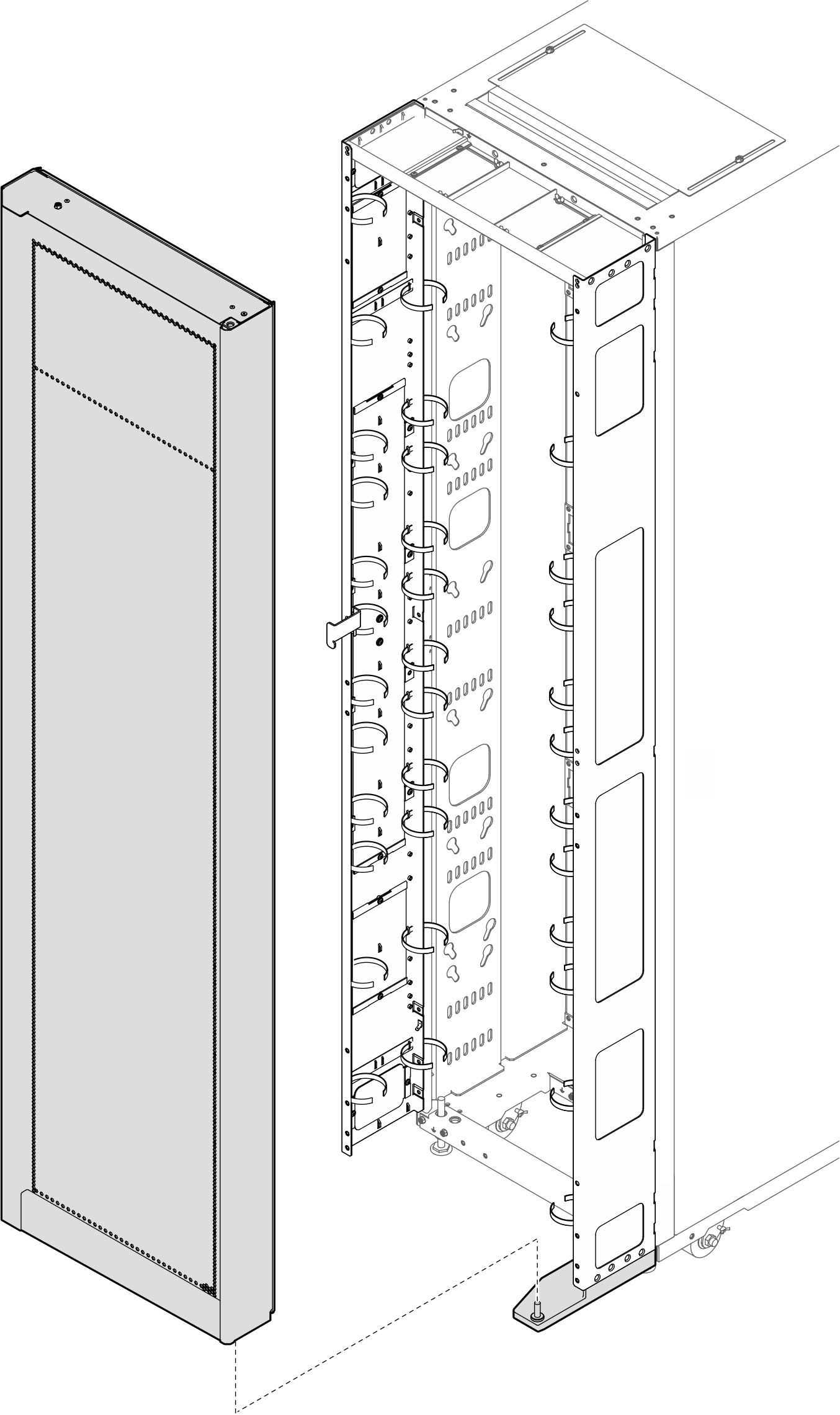

ラック拡張キットの各ユニットには、ラックの両側に最大 2 個の 0U PDU、または 1 個の 0U PDU と 1 個の多岐管を収納できる追加容量が付属しています。

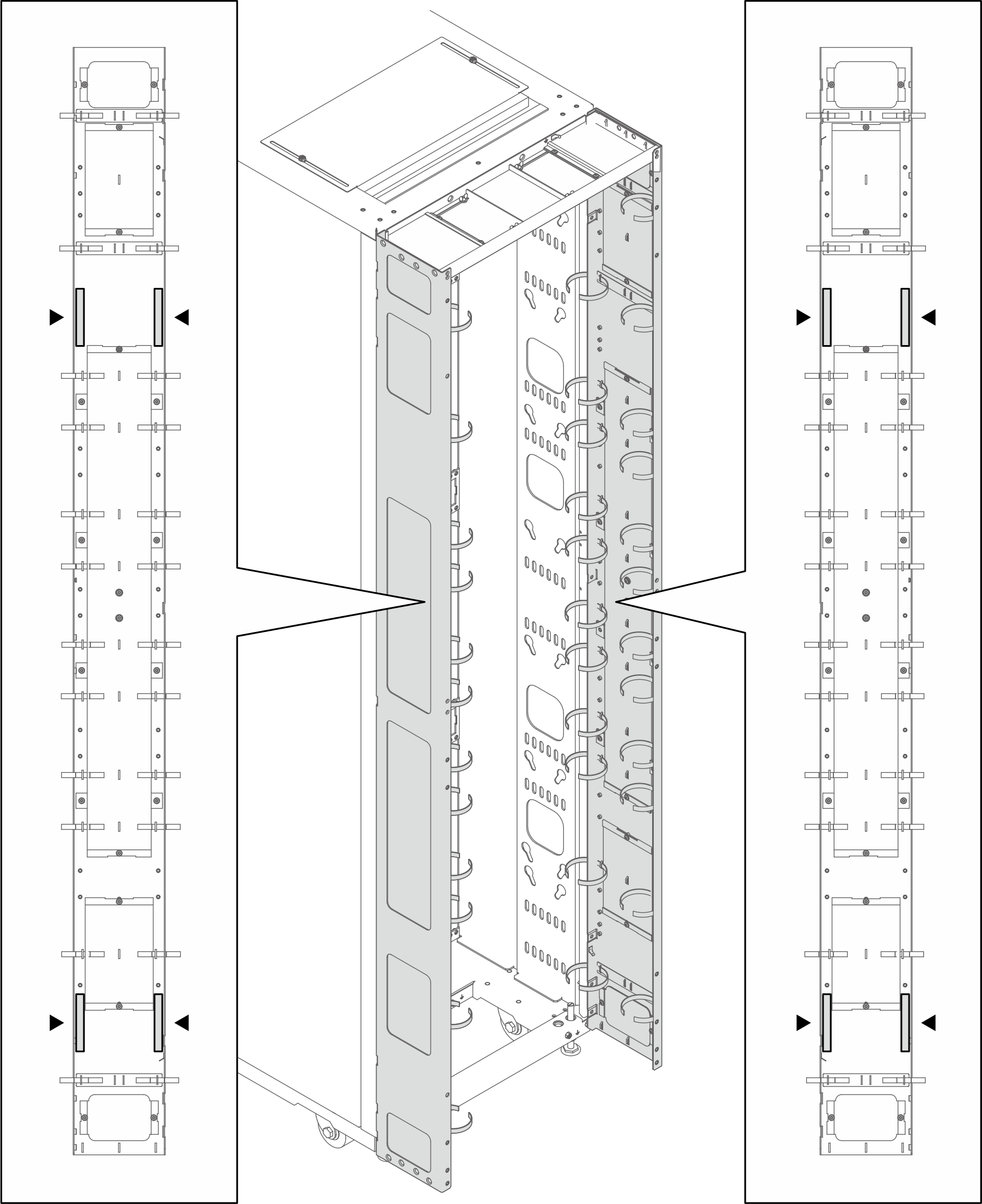

各ラック・キャビネットは、最大 2 つのラック拡張キット (前面に 1 つ、背面に 1 つ) をサポートします。

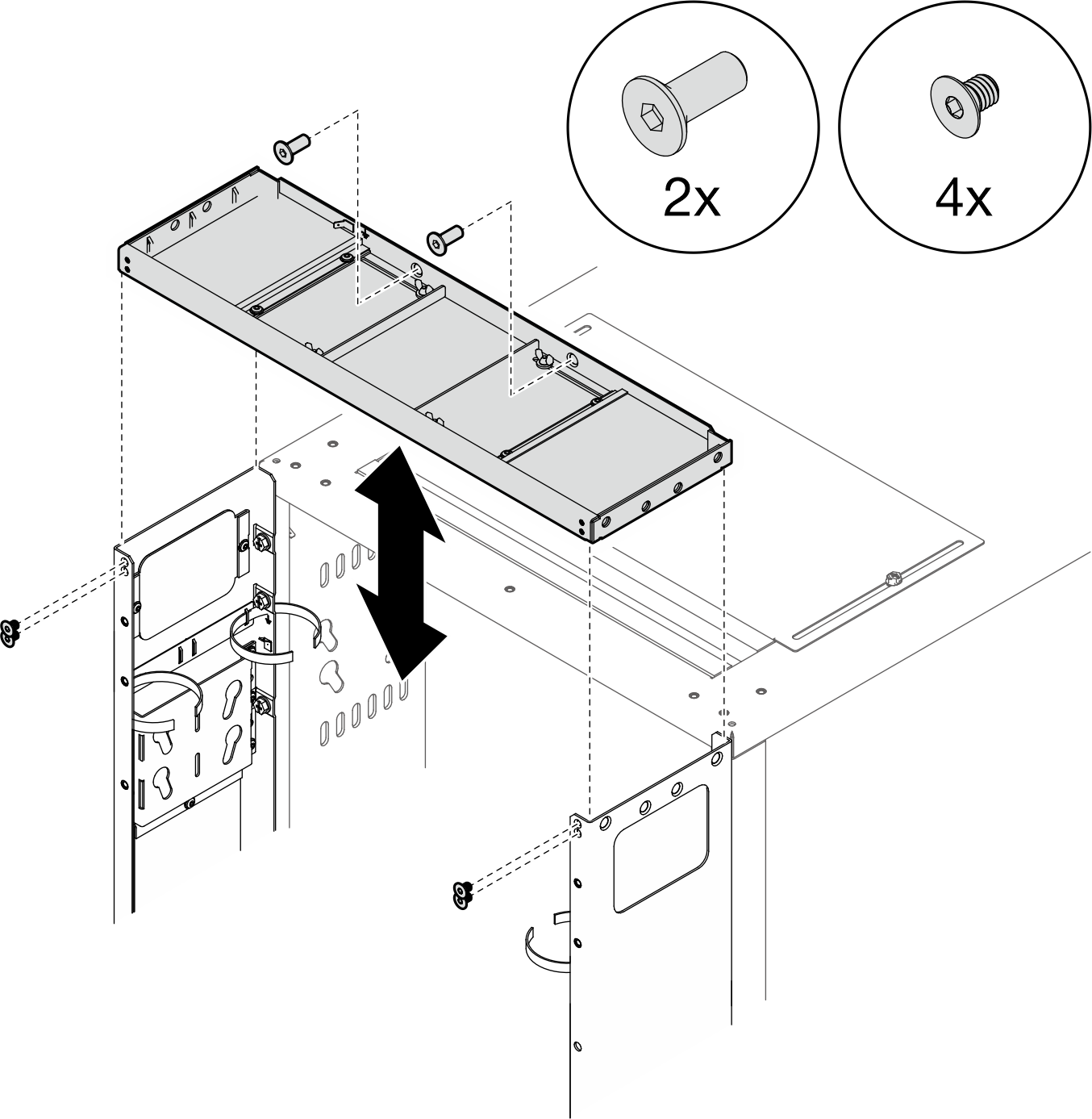

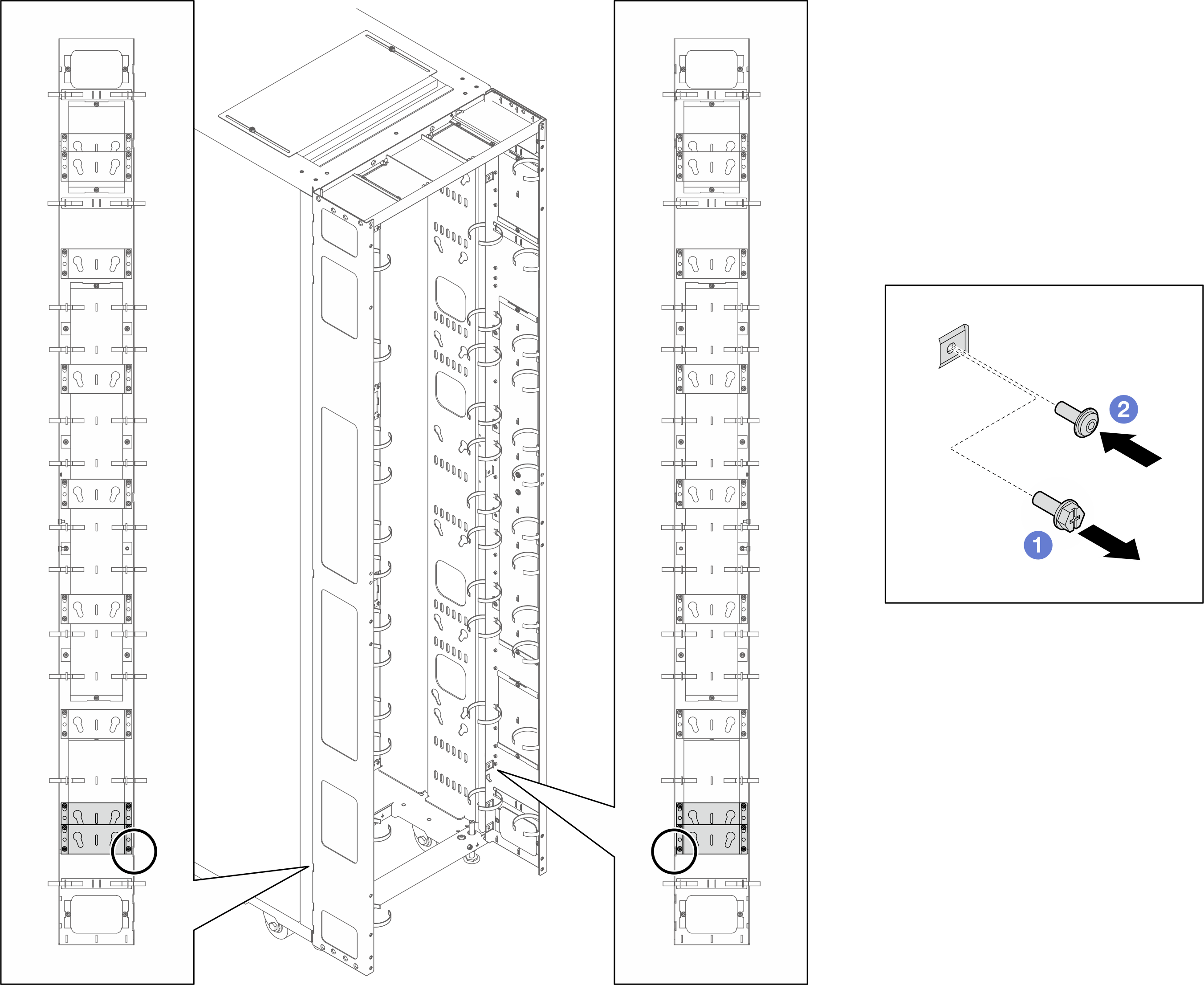

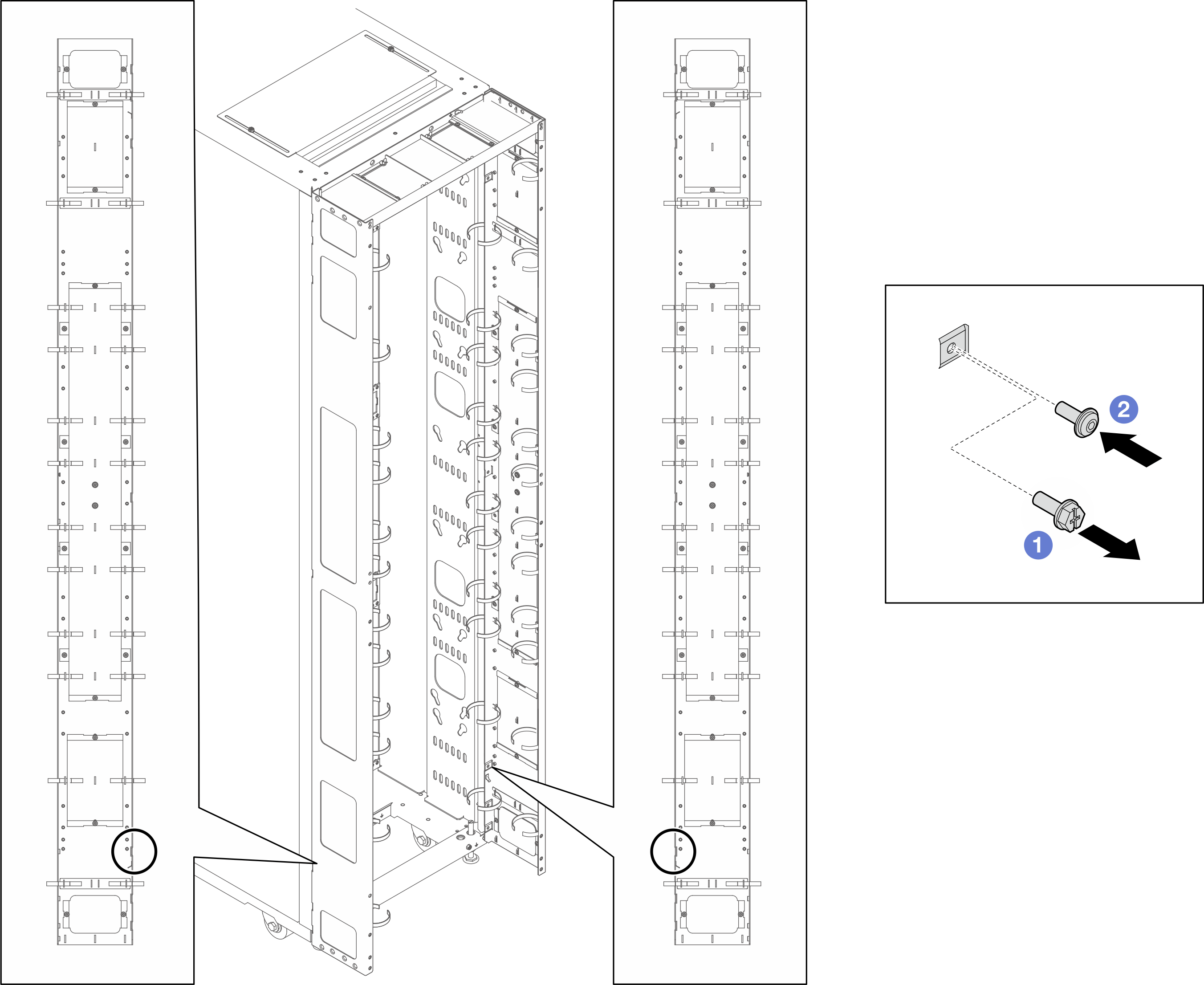

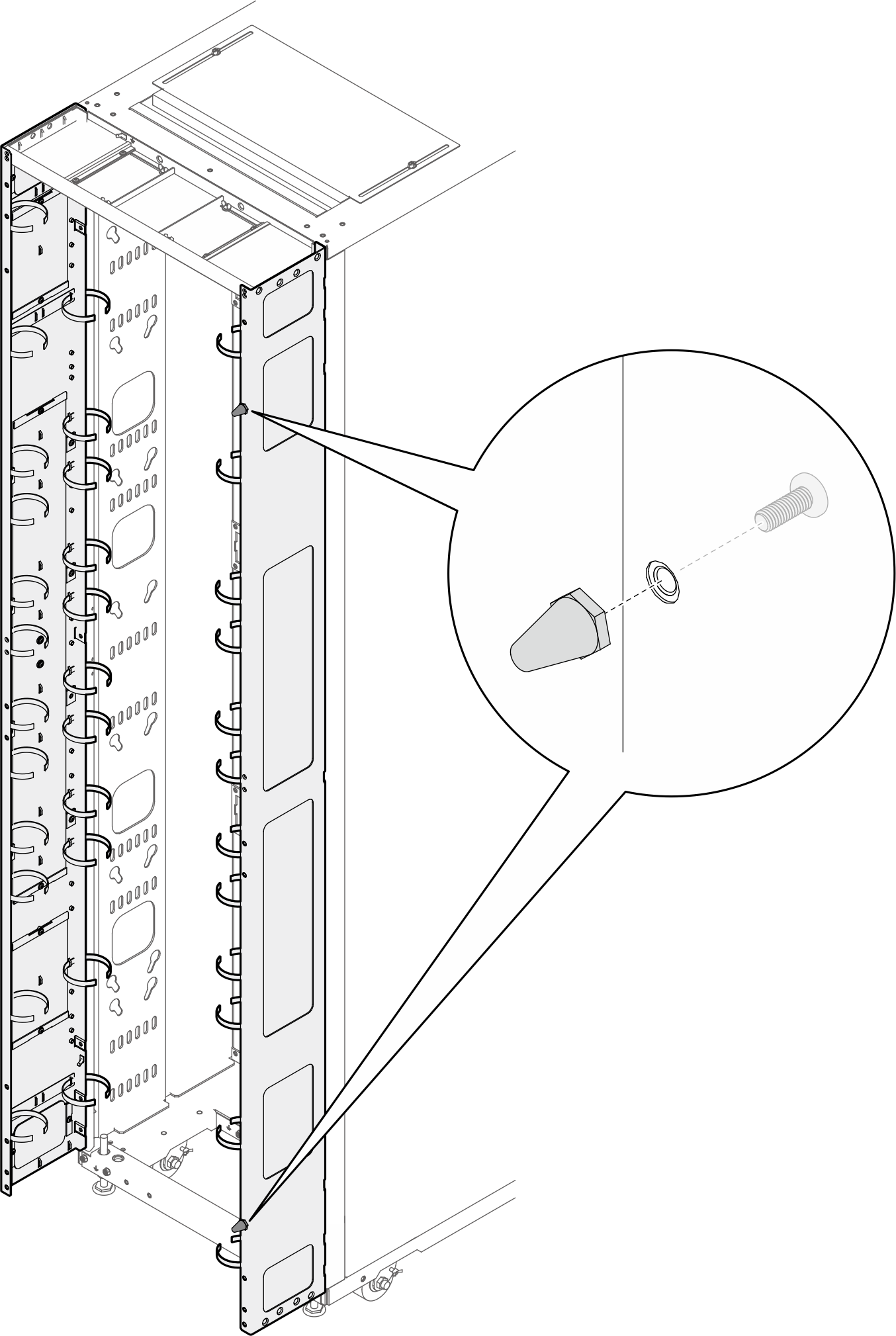

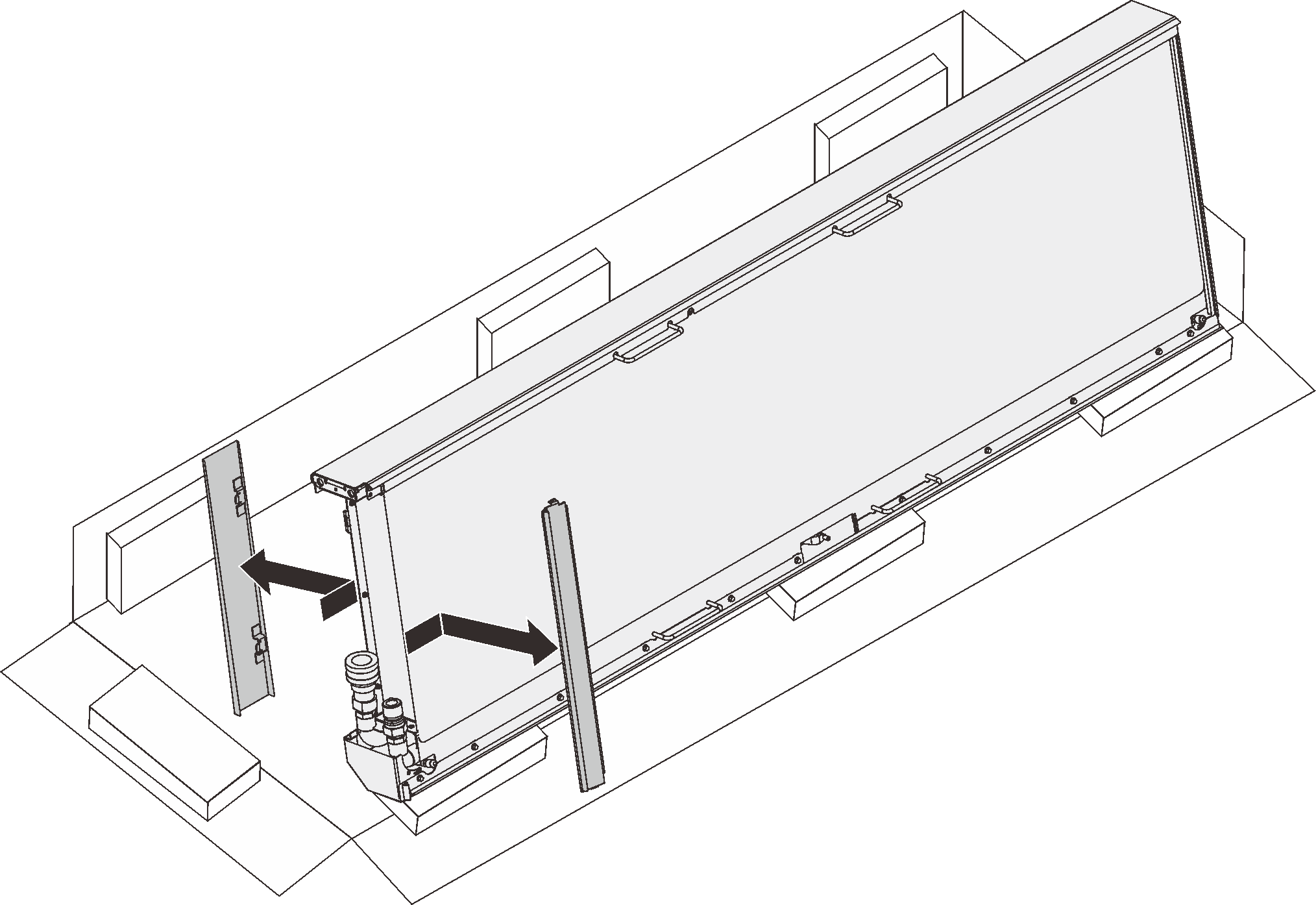

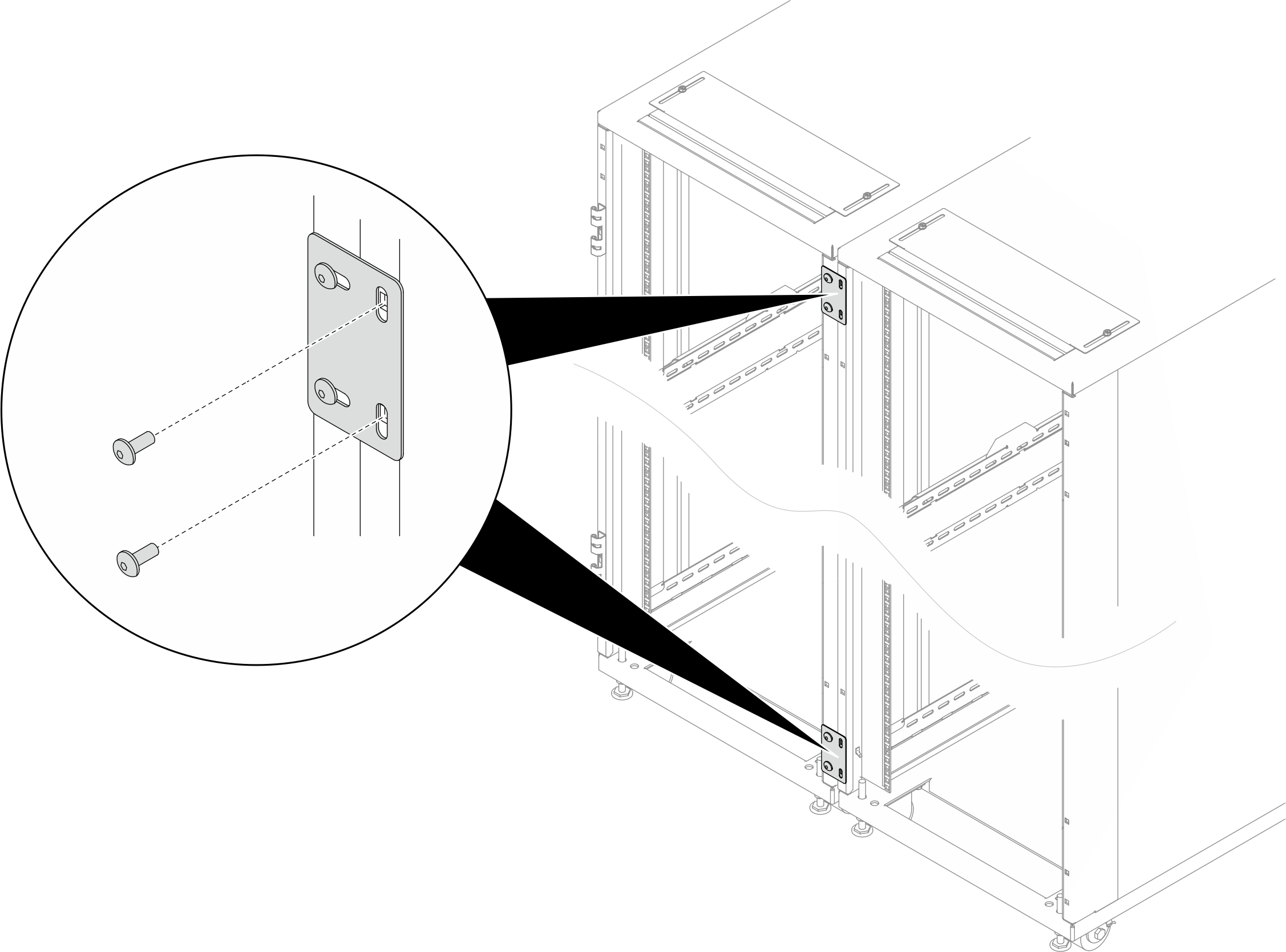

隣接するキャビネットの 1 つだけをエクステンション付きで取り付けるときにベイイング・キットを取り付ける計画がある場合は、必ずベイイング・キットを最初に取り付けてください (ベイイング・キットの取り付けを参照)。次に、この手順の準備として、ラック拡張キットを取り付けるキャビネットの上部と下部から 2 本のねじを取り外し、2に進みます。

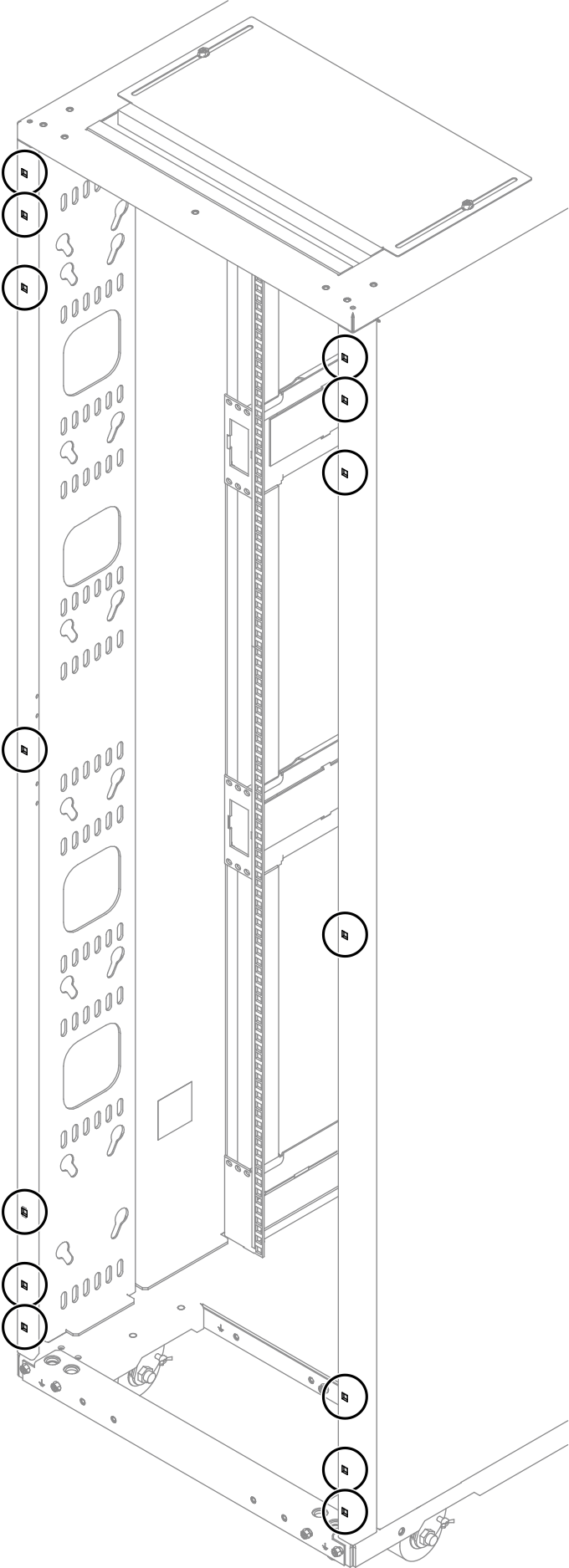

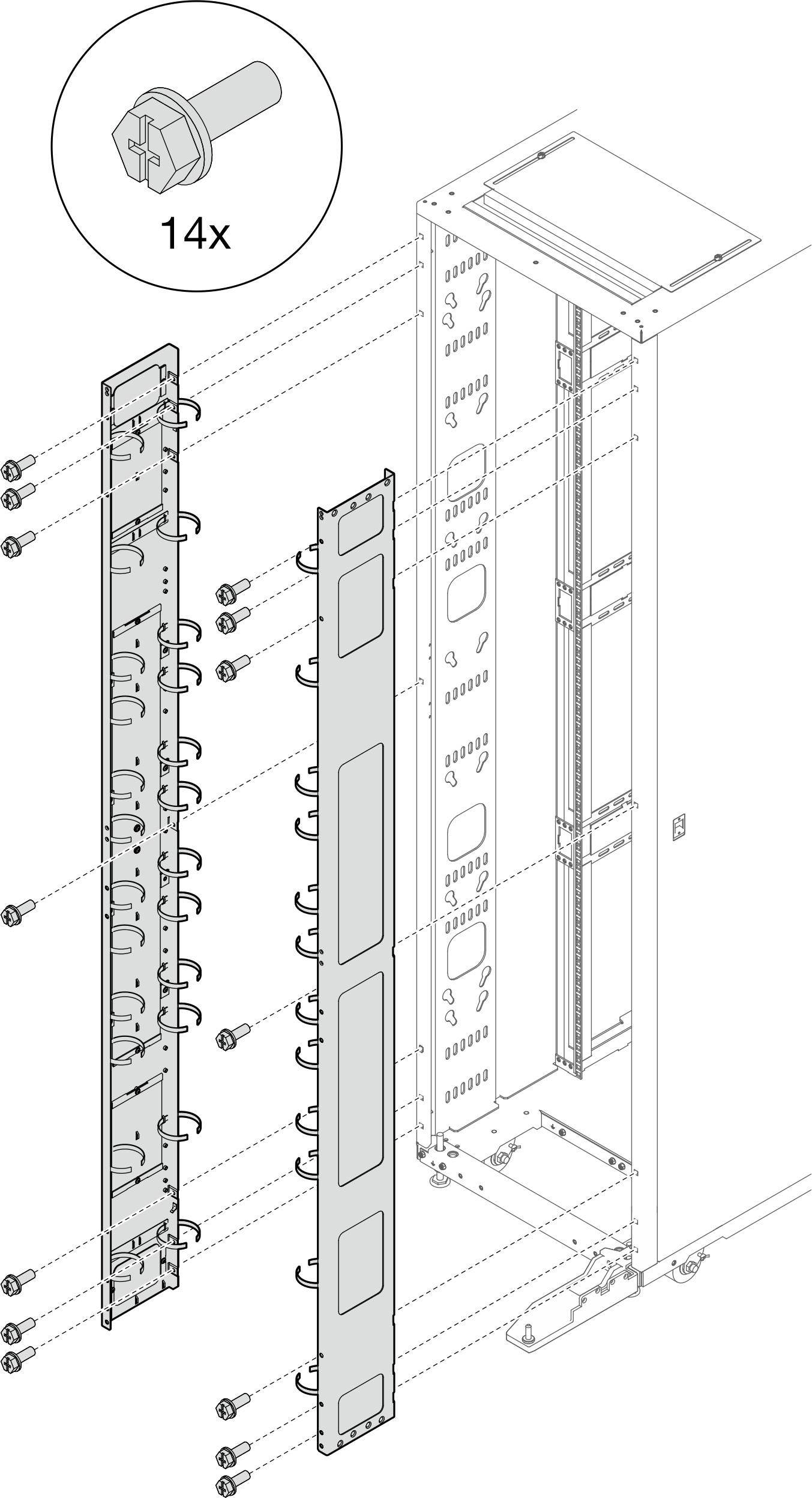

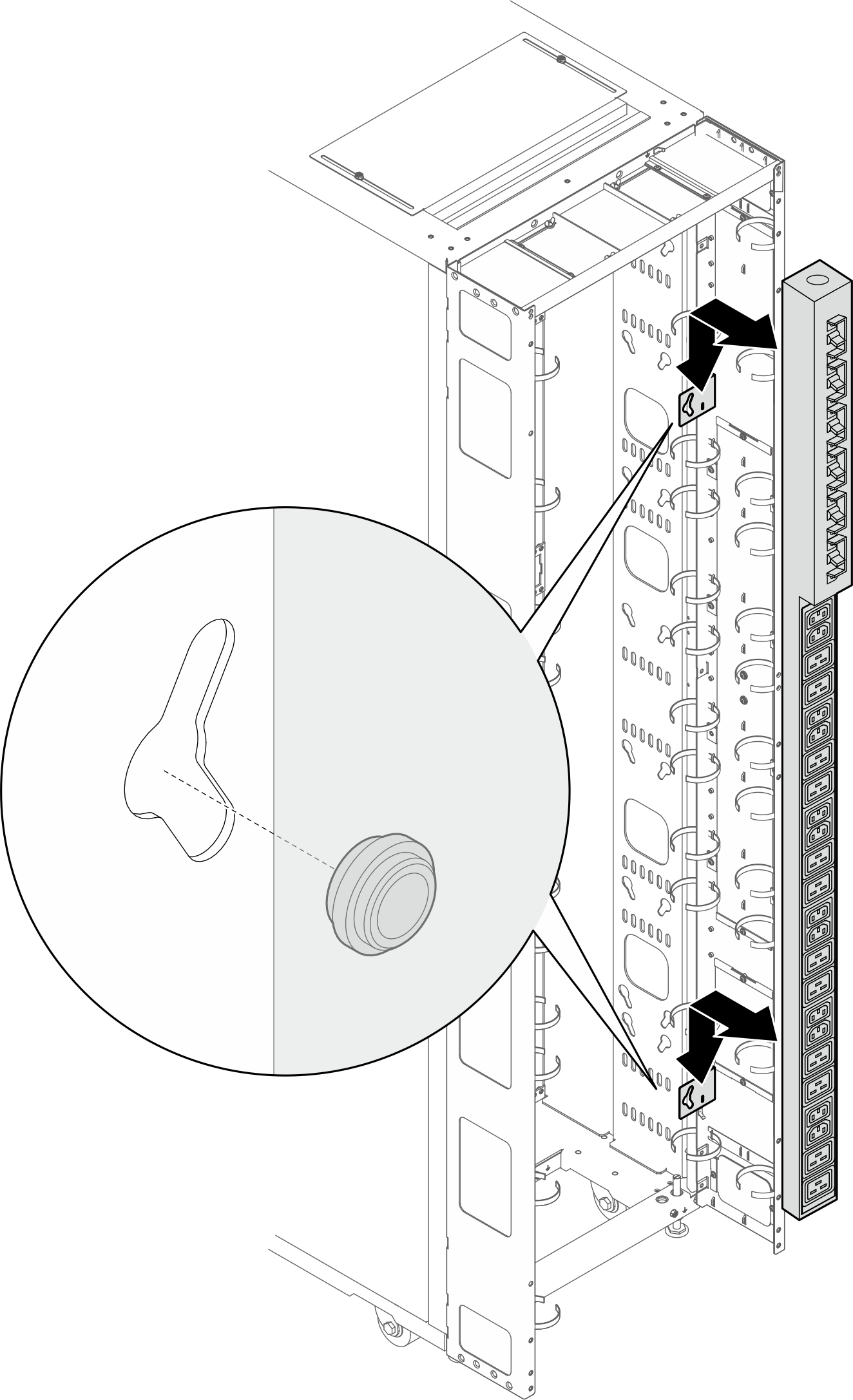

図 1. 拡張取り付け準備のためのねじの取り外し

- 必要なツール

- パッケージを開梱するためのプラスチック製の刃/はさみが付いた工具 x 1

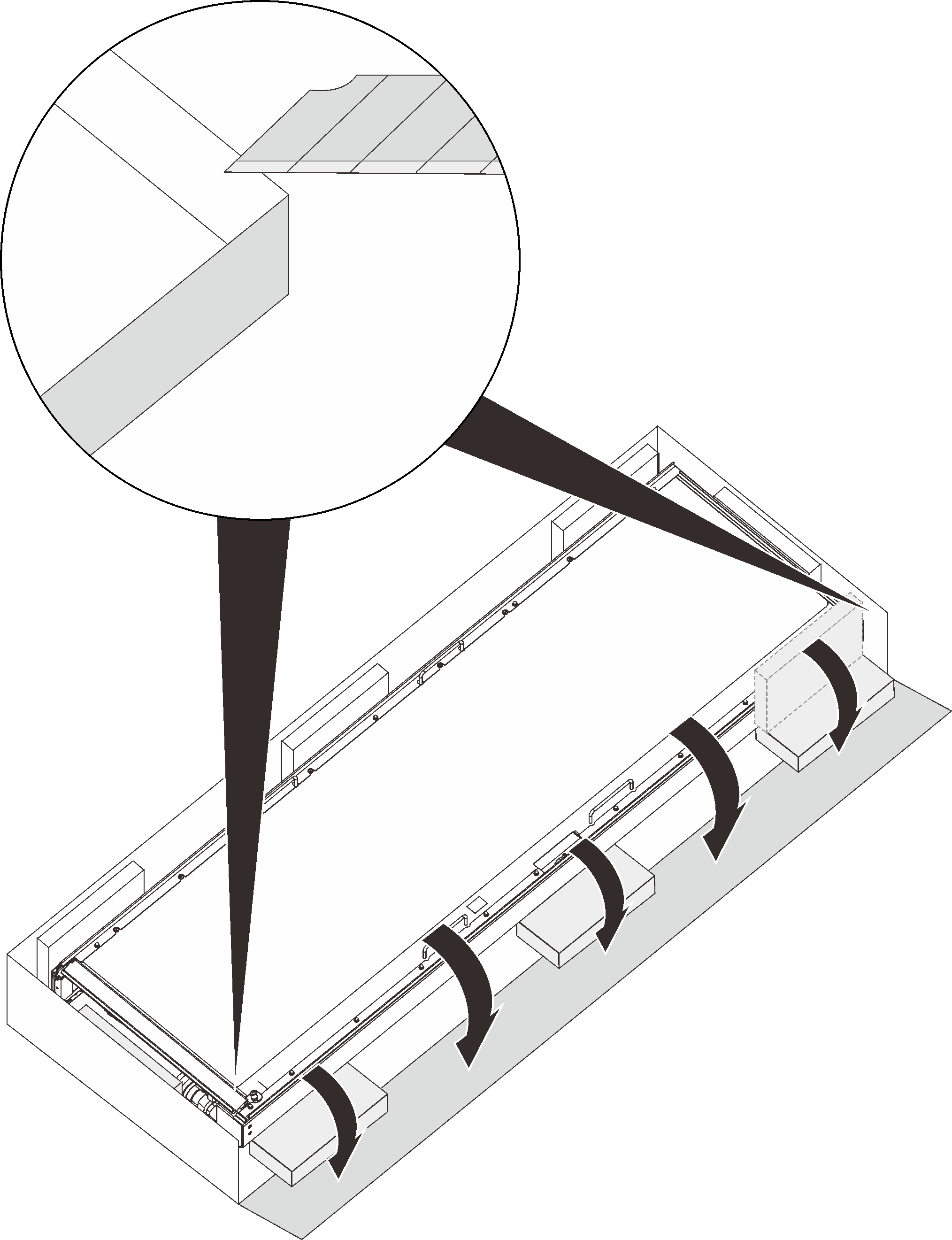

- 延長パネルをラックの側面に合わせるためのゴム製ハンマー x 1

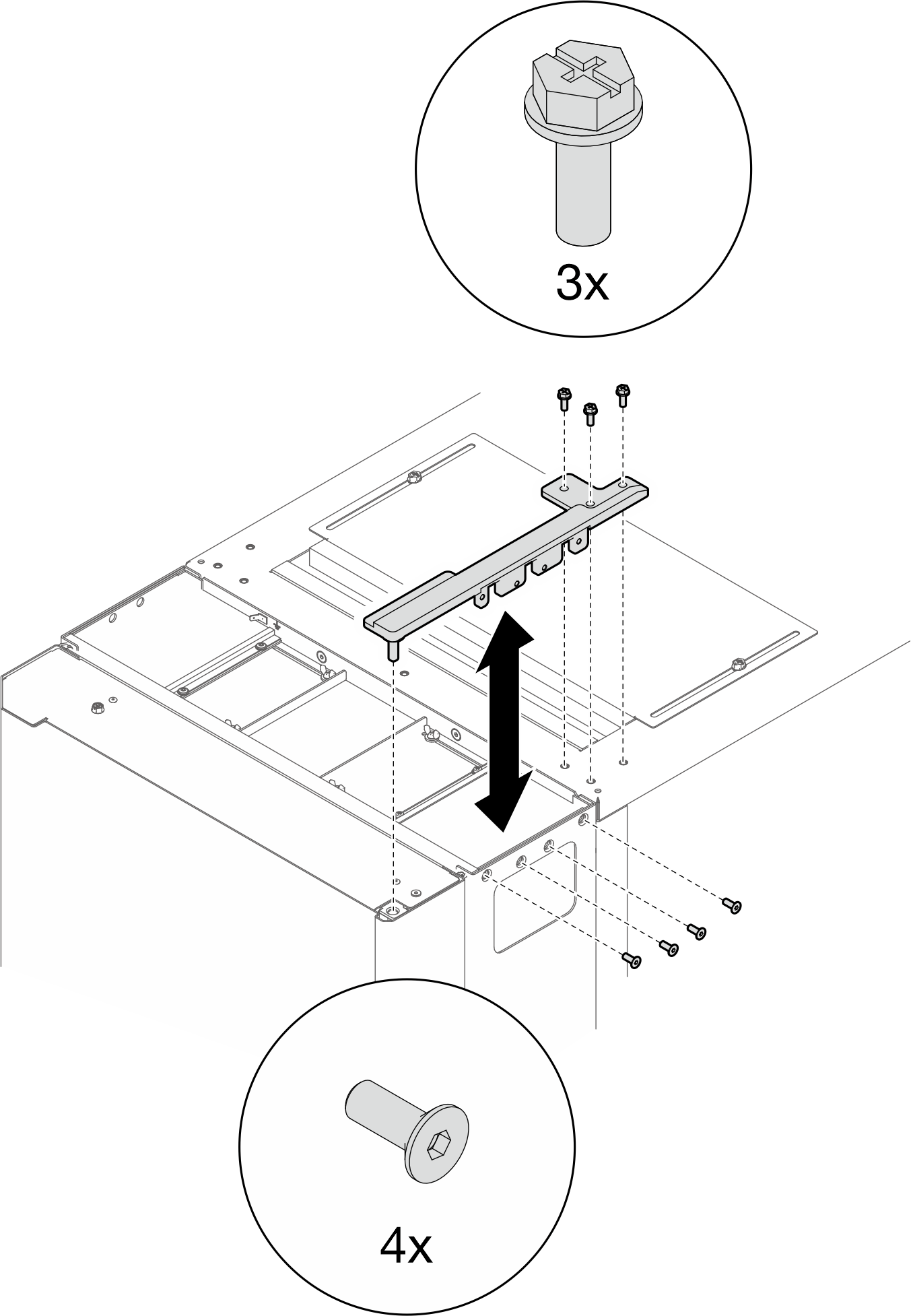

- M6 ねじを締めるための No. 3 プラス・ビット付きドライバー x 1 (次の箇条書きの 9)

- M6 ねじを締めるための 10 mm 保持六角ビット付きナット・ドライバー x 1 (次の箇条書きの 9)

- M4 ねじを締めるための 2.5 mm 六角ビット・ソケット x 1 (次の箇条書きの 13)

- M5 ねじを締めるための 3 mm 六角ビット・ソケット x 1 (PDU/多岐管ブラケット、拡張パネルの開口部カバー)

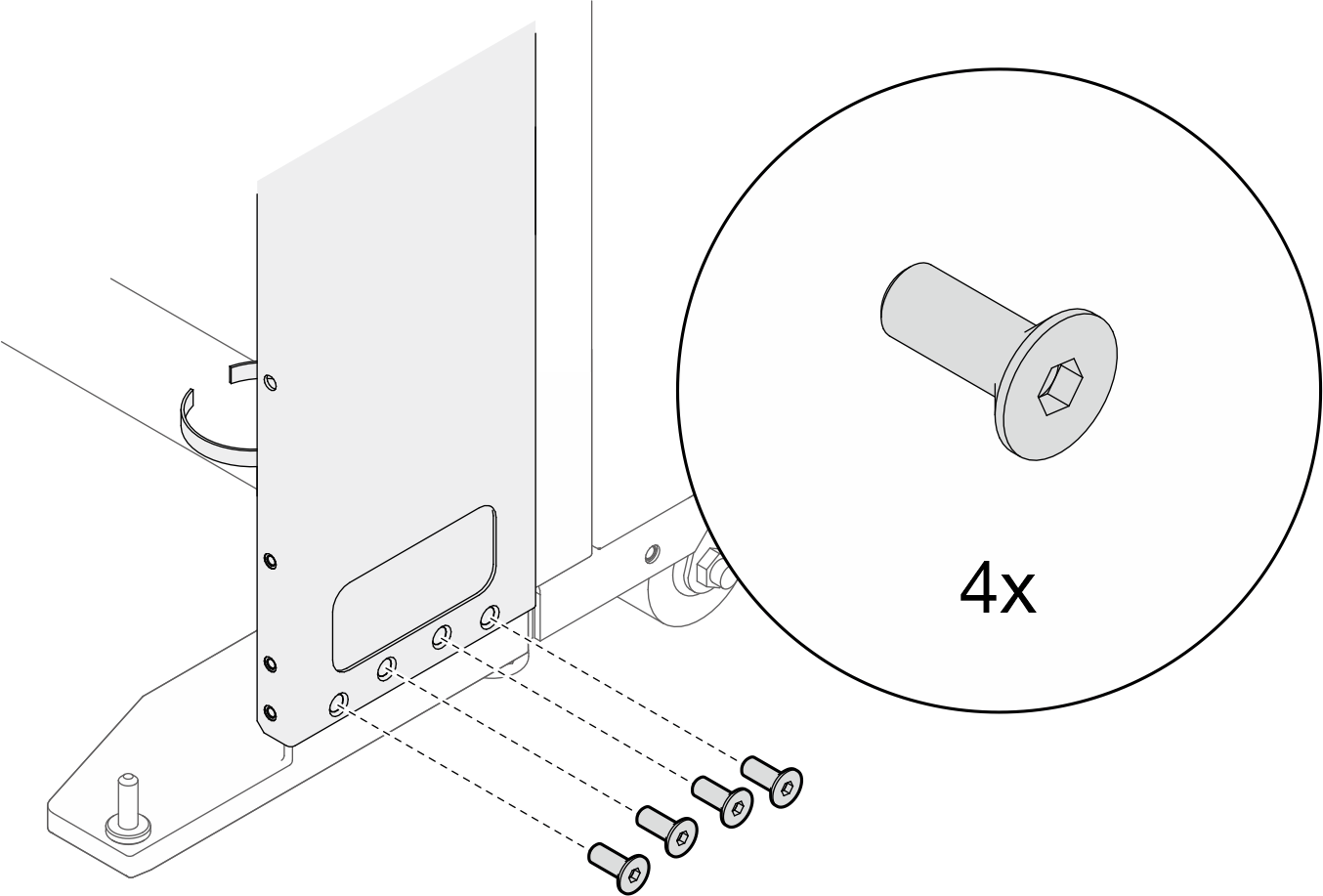

- M6 ねじを締めるための 4 mm 六角ビット・ソケット x 1 (次の箇条書きの 4 および 14)

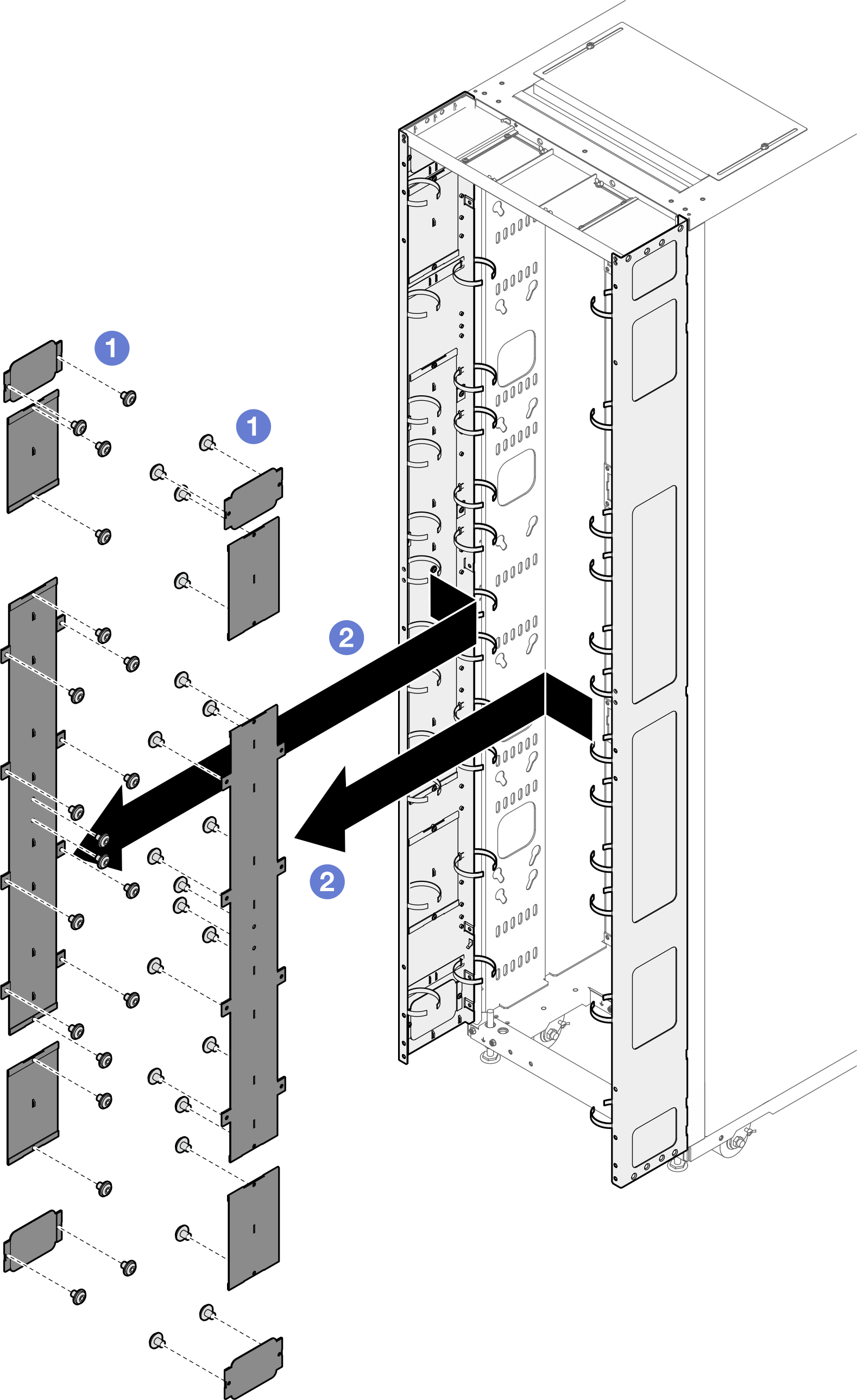

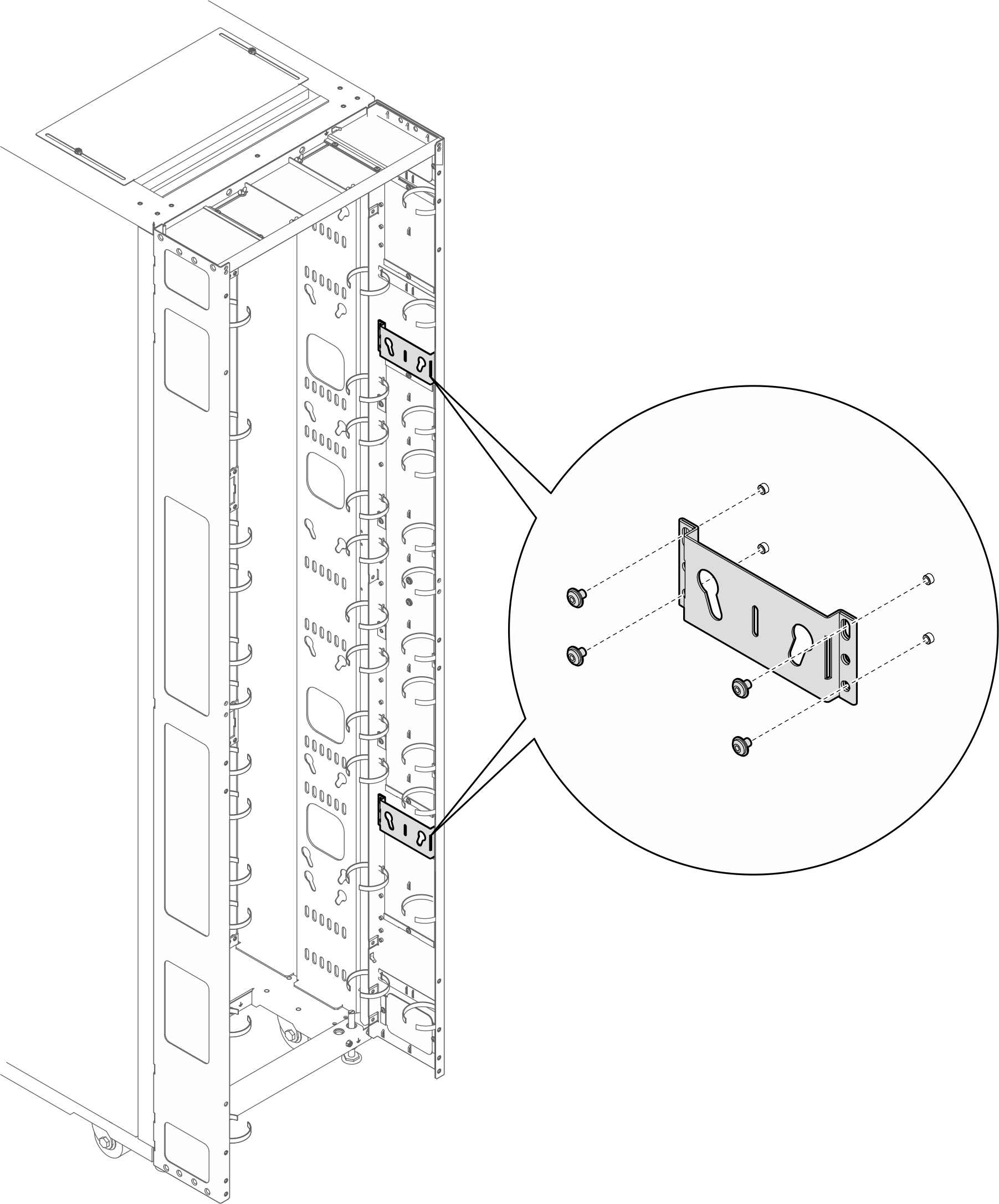

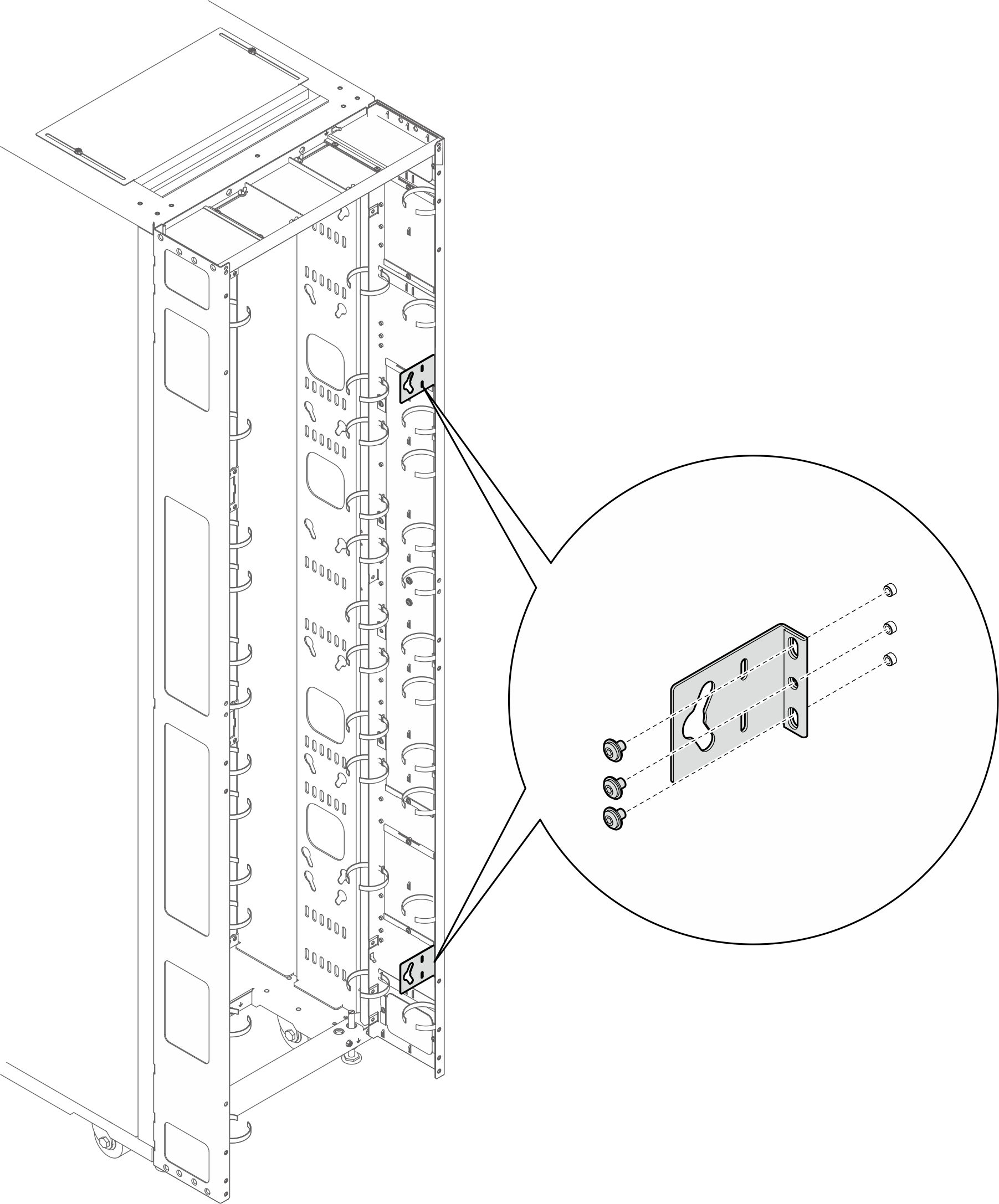

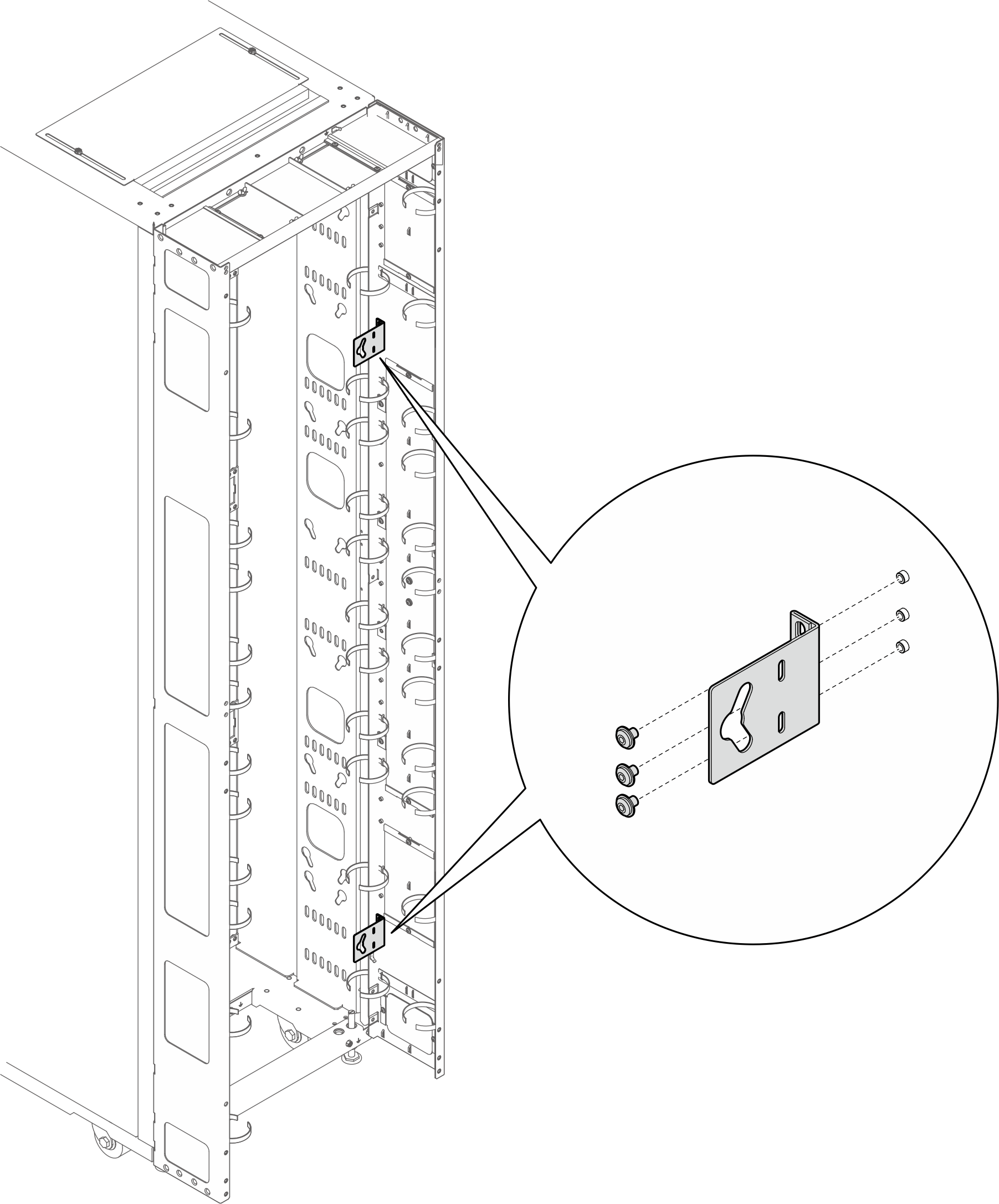

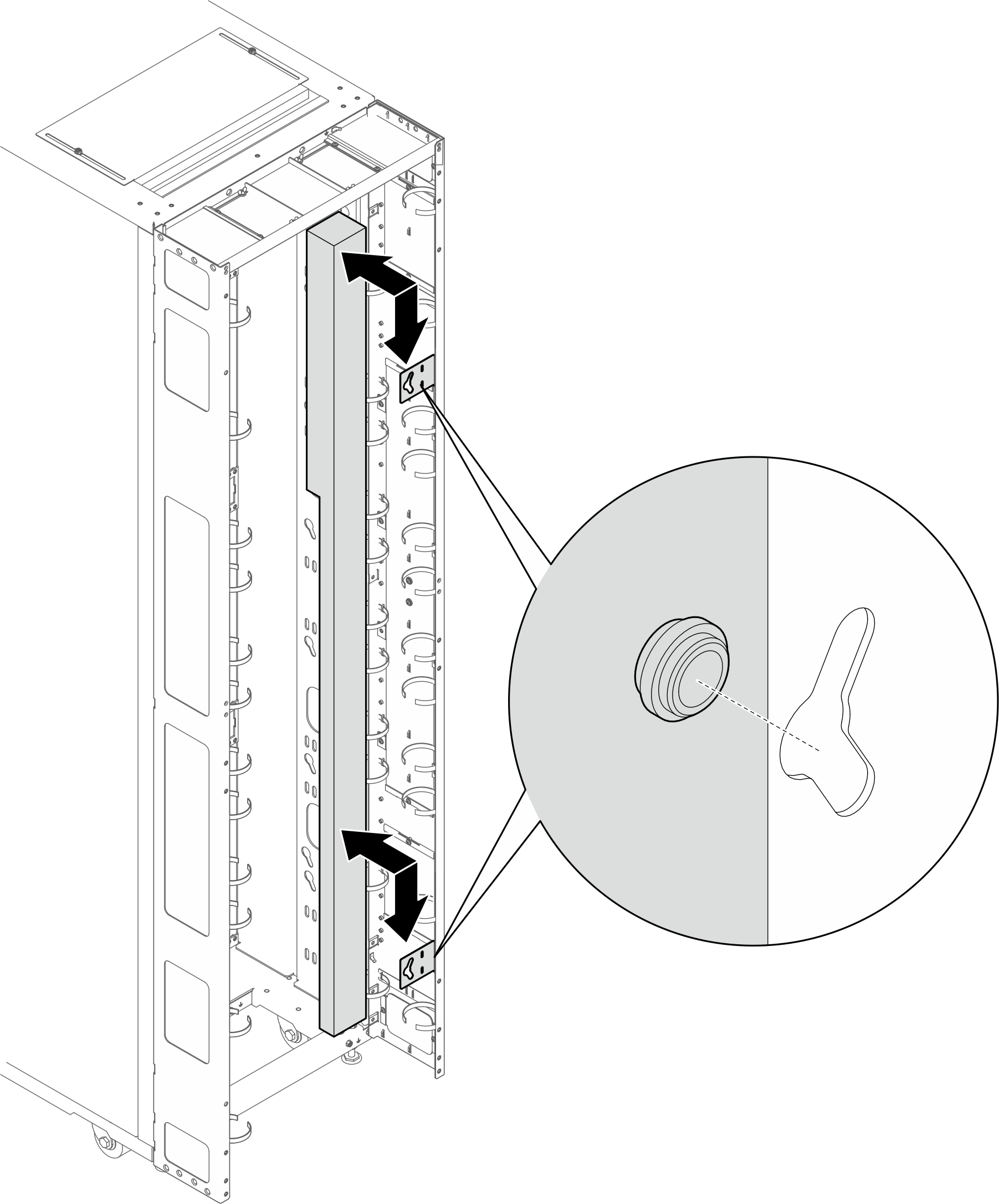

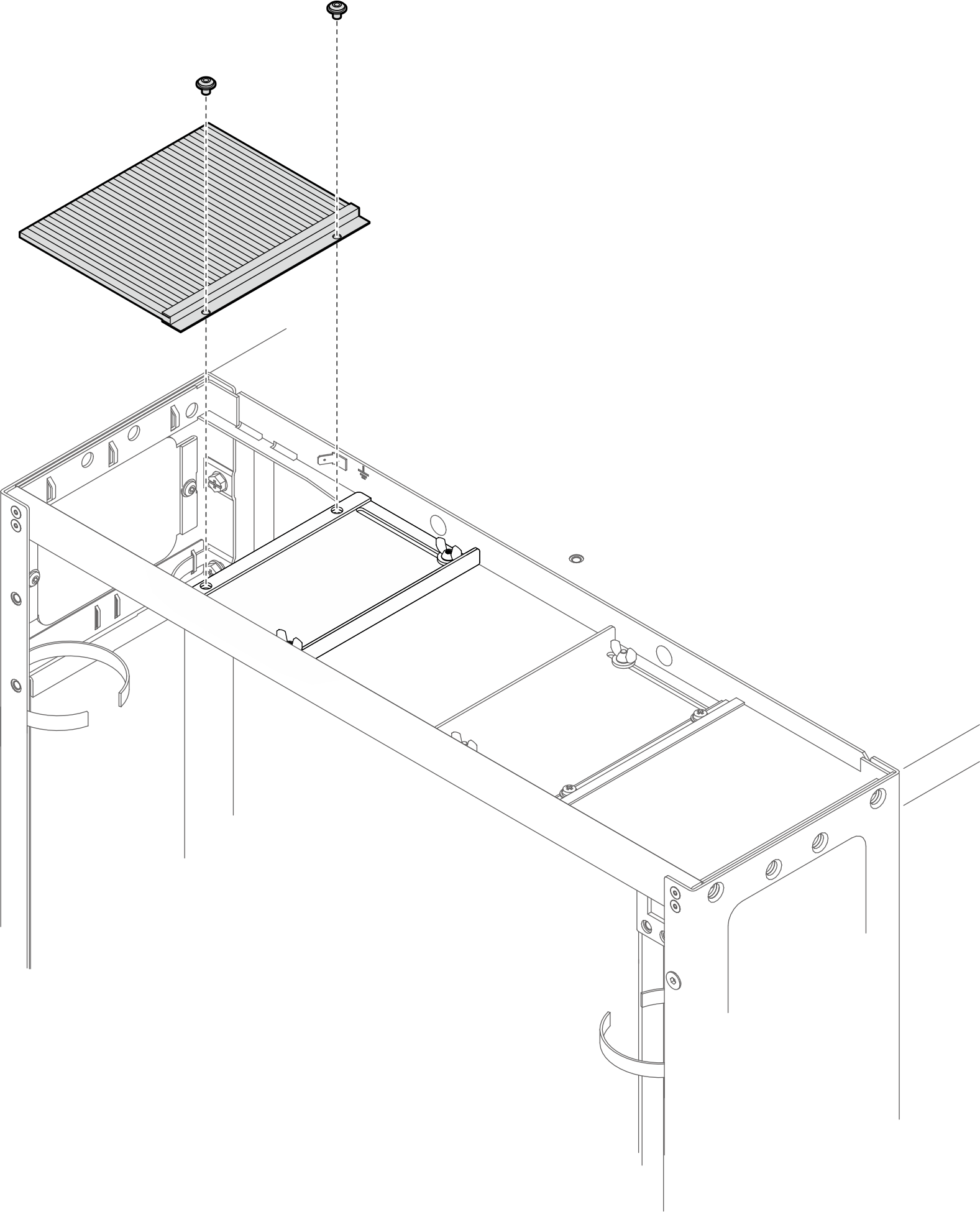

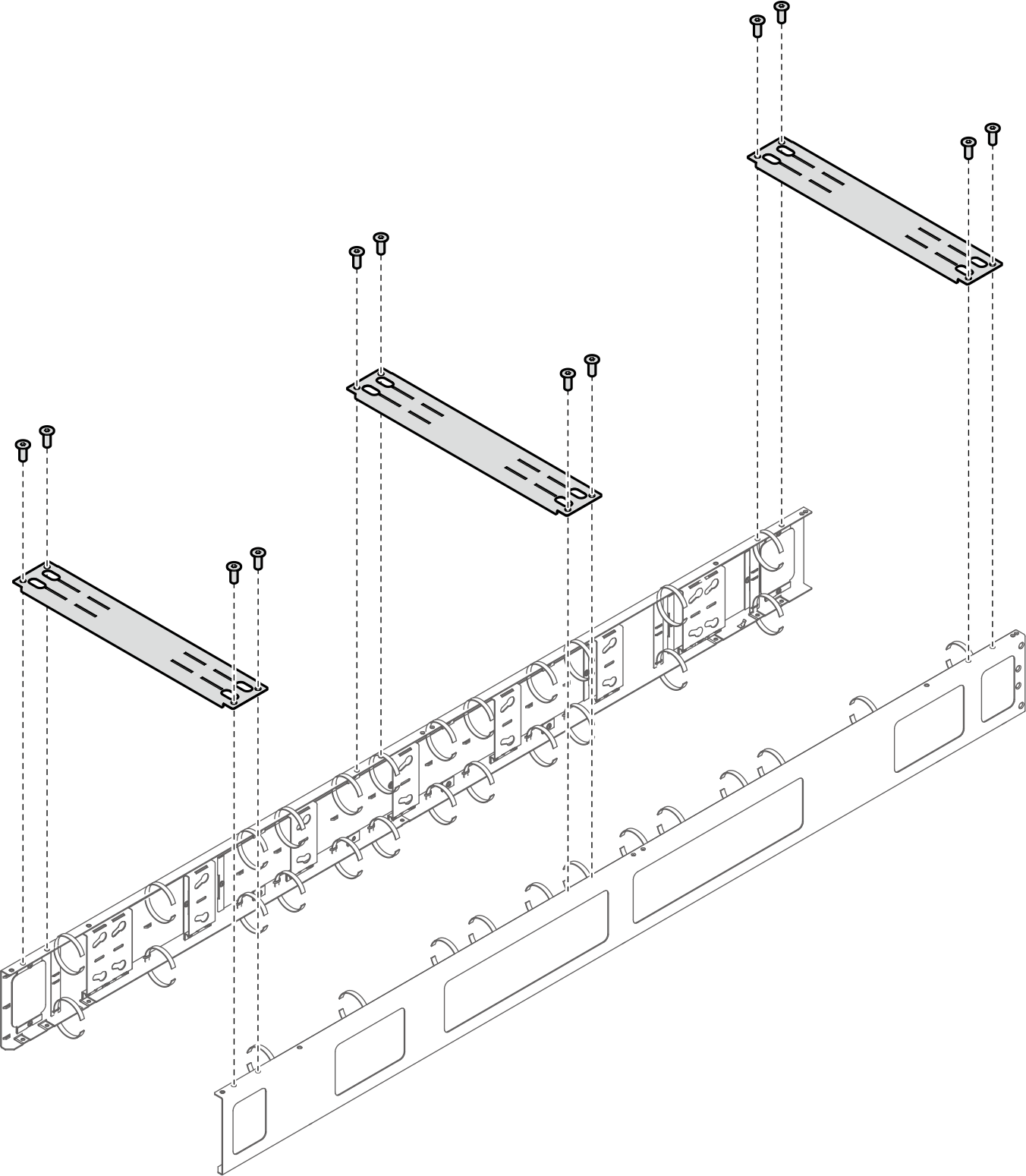

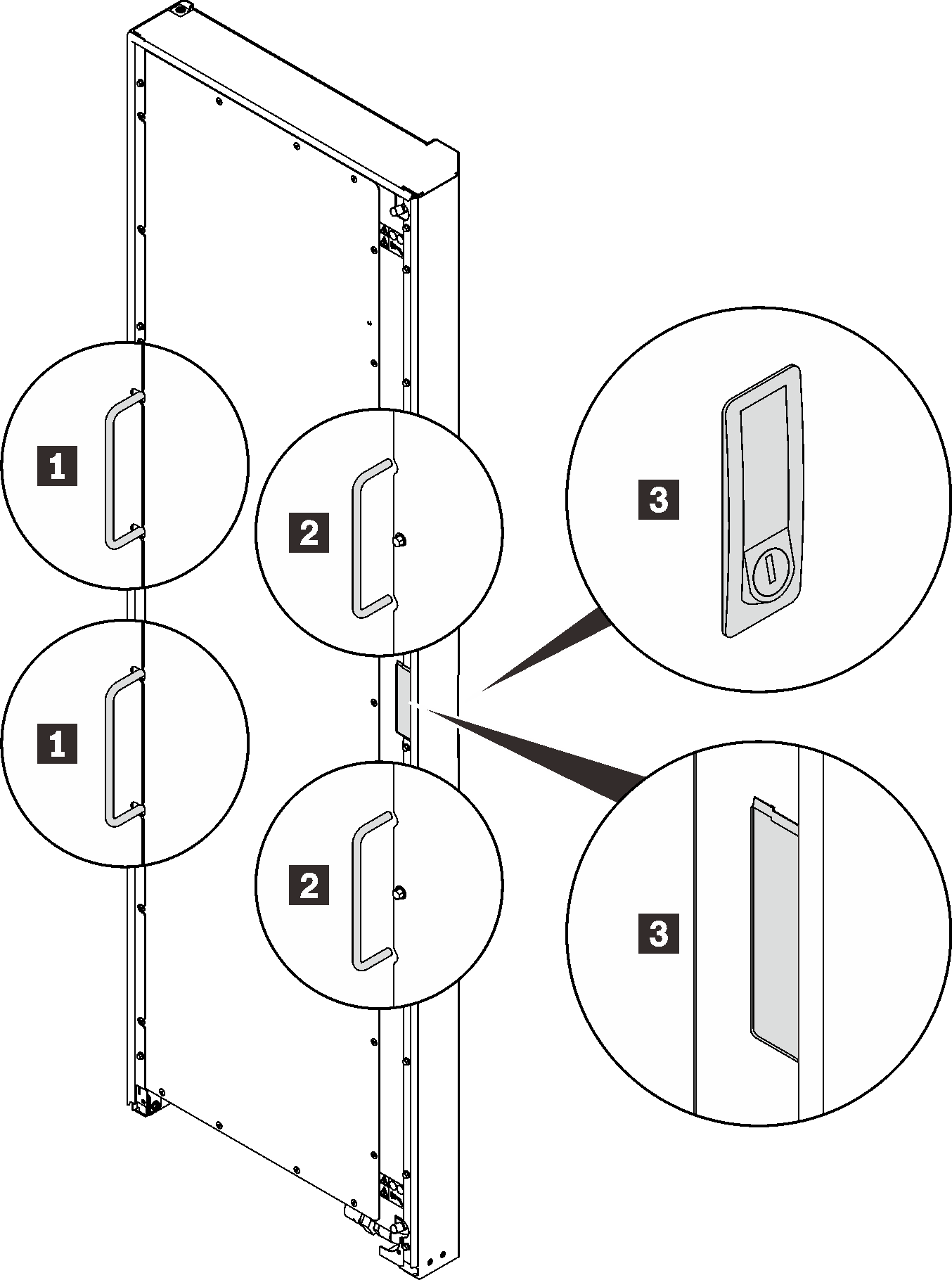

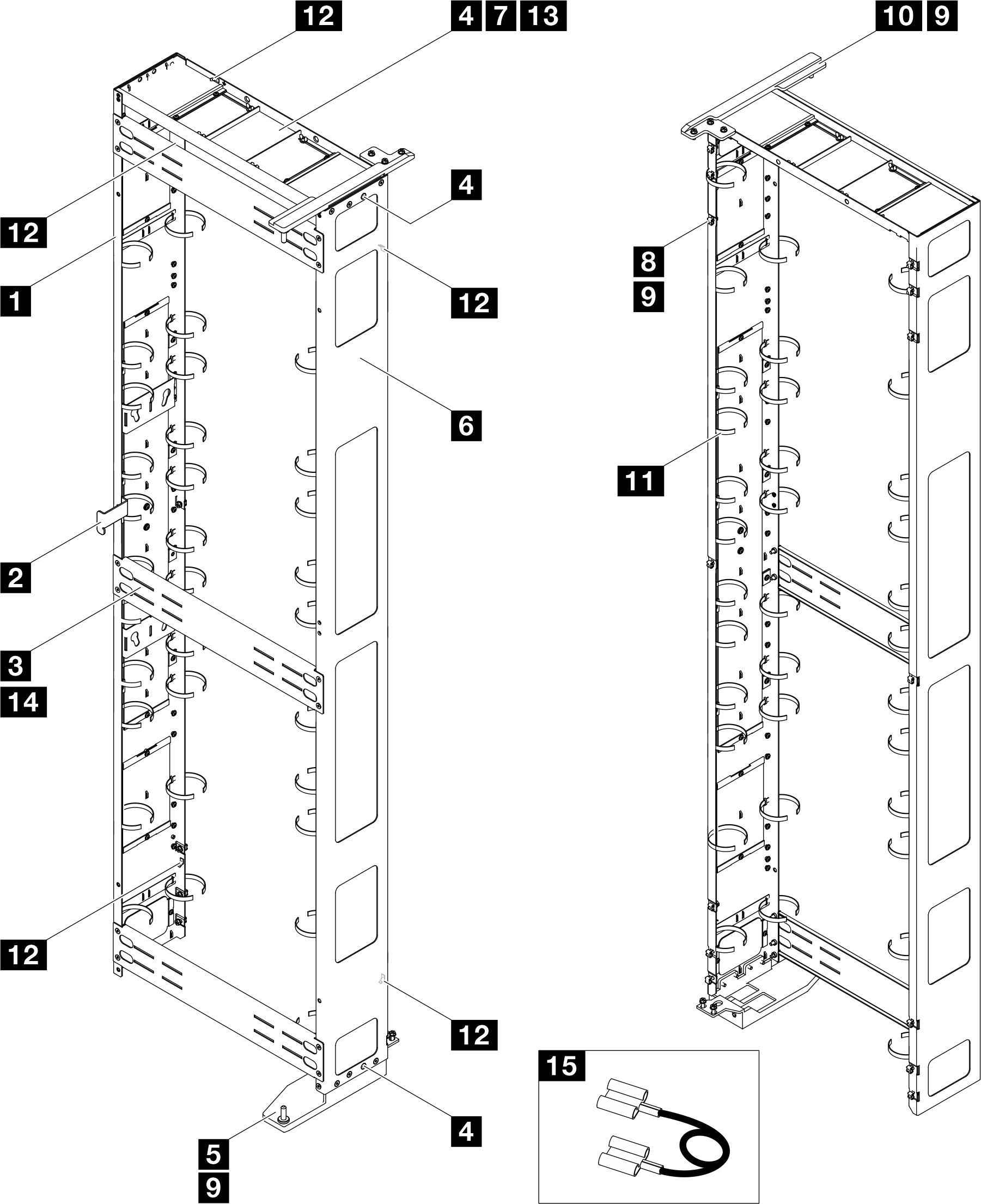

- 拡張キットには、以下のコンポーネントが追加の袋が付属しています。図 2. 部品

番号 説明 数量 番号 説明 数量 1 左側の拡張パネル 1 9 M6 x 16 mm 六角頭フランジねじ 21 2 ラッチ・プレート 1 10 RDHX 用上部ヒンジ 1 3 サポート・ブラケット 3 11 ケーブル・ストラップ・モジュール 123 2 4 M6 x 16 mm マイナス・ソケット・キャップねじ 10 12 接地プレート 5 5 RDHX 用下部ヒンジ 1 13 M4 x 6 mm マイナス・ソケット・キャップねじ 4 6 右側の拡張パネル 1 14 M6 x 12 mm マイナス・ソケット・キャップねじ 12 7 拡張トップ・カバー 1 15 接地線 4 3 8 M6 ケージ・ナット 14 - 1 ケーブル・ストラップは取り外し可能なため、必要に応じて拡張パネルからストラップを取り外してください。

- 2 ケーブル・ストラップは、2 本以上のストラップを接続して長くすることができます。

- 3 ケーブル・ストラップを使用して、出荷前に PDU および多岐管を固定します。

- 4 接地線の一方の端を延長パネルの接地プレートに接続し、もう一方の端をラックの最も近い接地プレートに接続します。

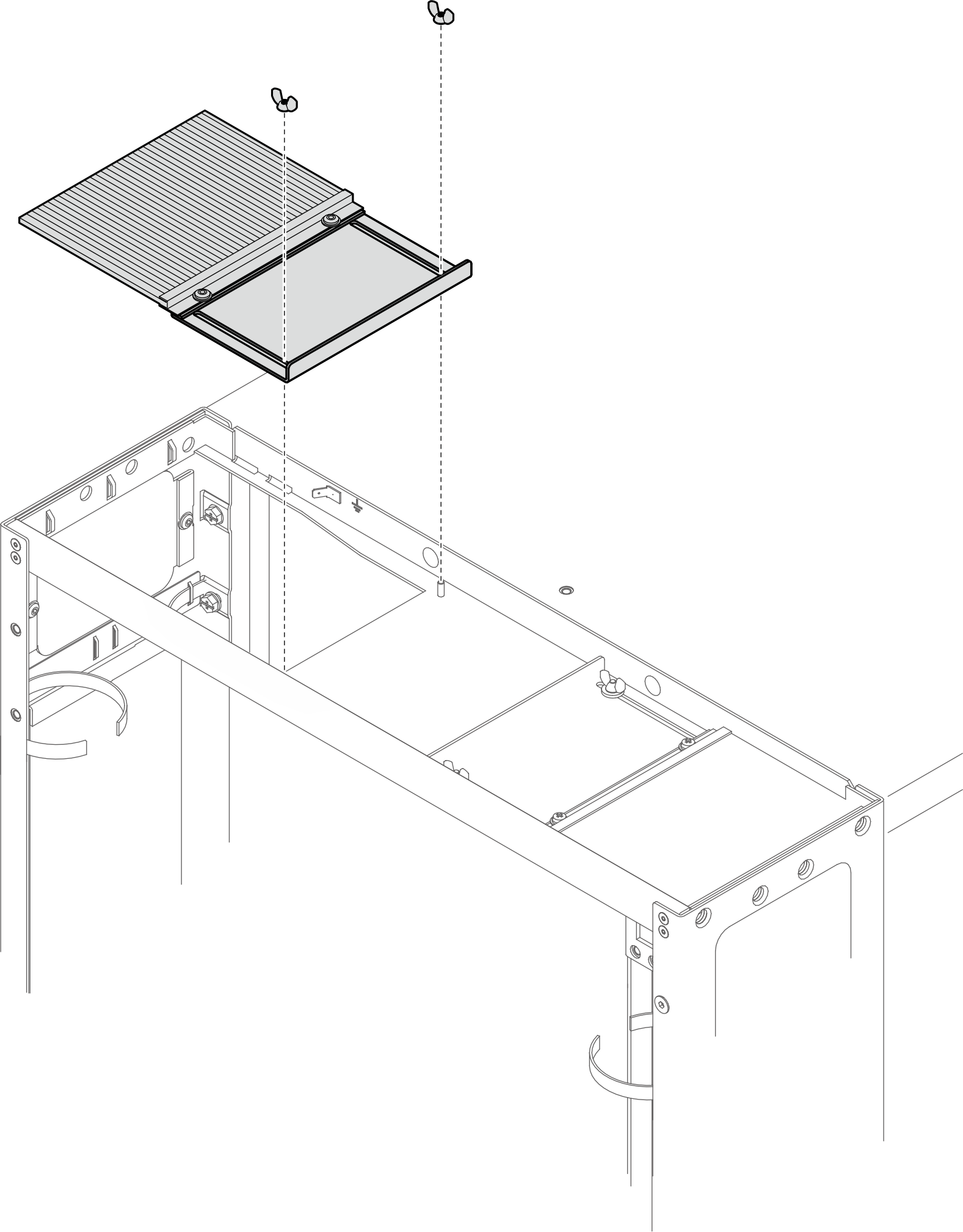

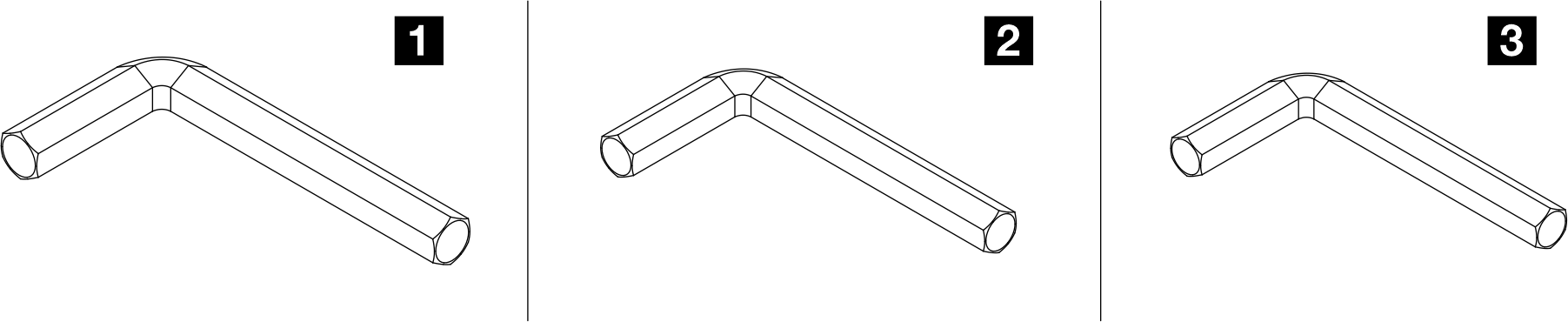

図 3. 六角アレン・レンチ

番号 説明 1 六角アレン・レンチ、4 mm 2 六角アレン・レンチ、3 mm 3 六角アレン・レンチ、2.5 mm

手順

フィードバックを送る