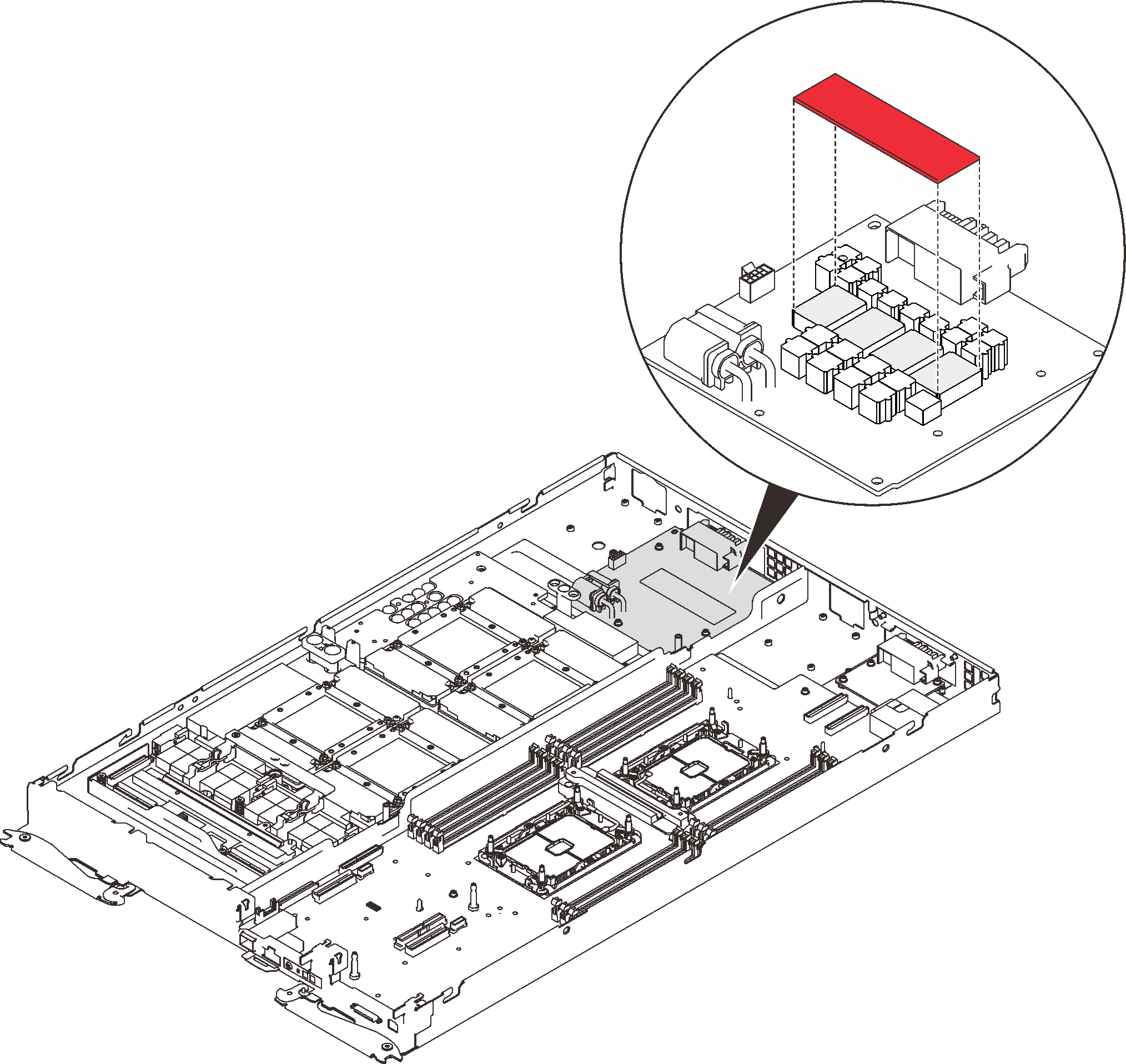

Install the retimer board

Use this information to install the retimer board.

Attention

- Read the following sections to ensure that you work safely.

A torque screwdriver is available for request if you do not have one at hand.

Note

Ensure you have “SD650 V2 or SD650-N V2 Neptune® DWC Waterloop Service Kit “ in hand to install components.

Procedure

After you finish

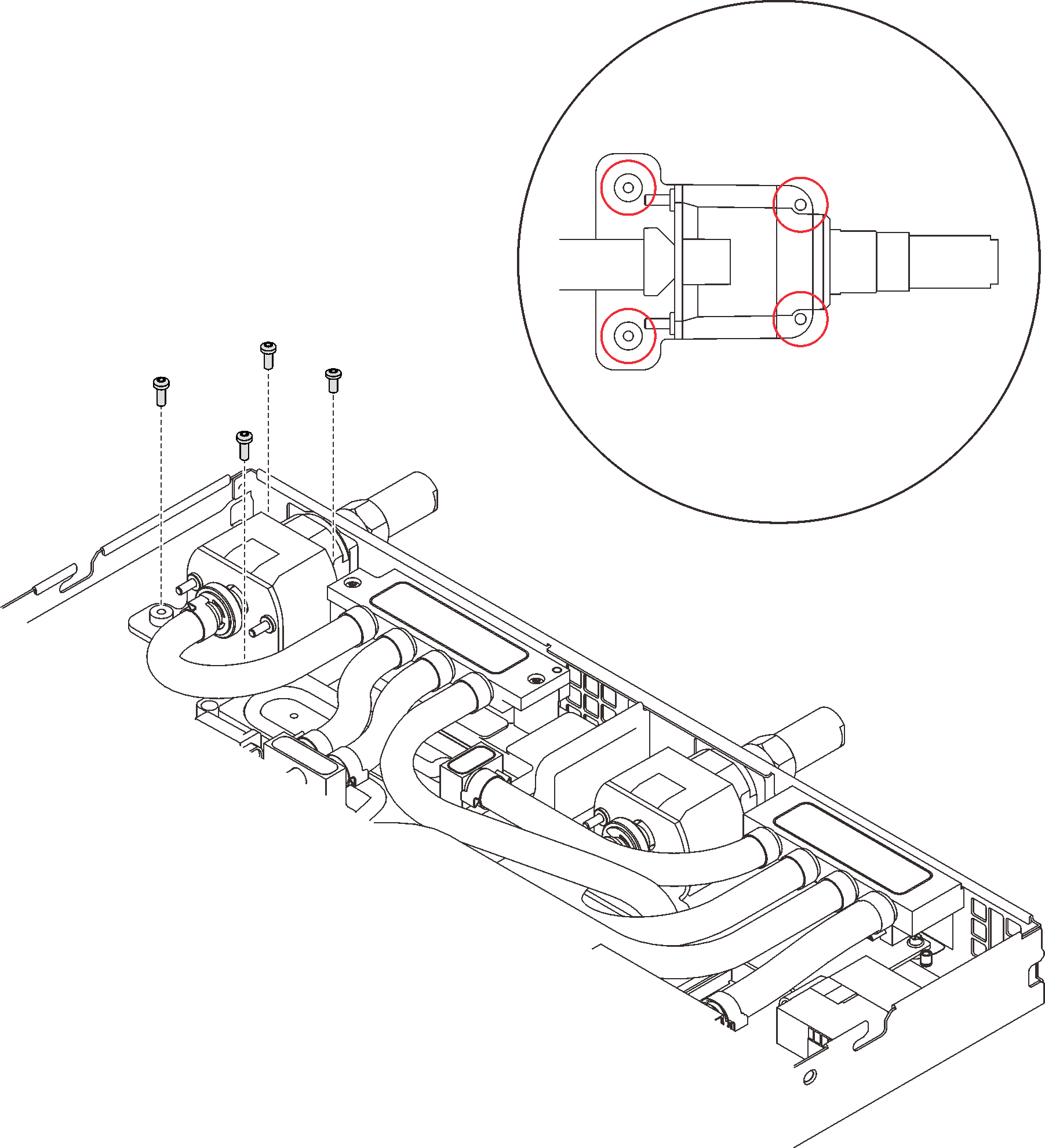

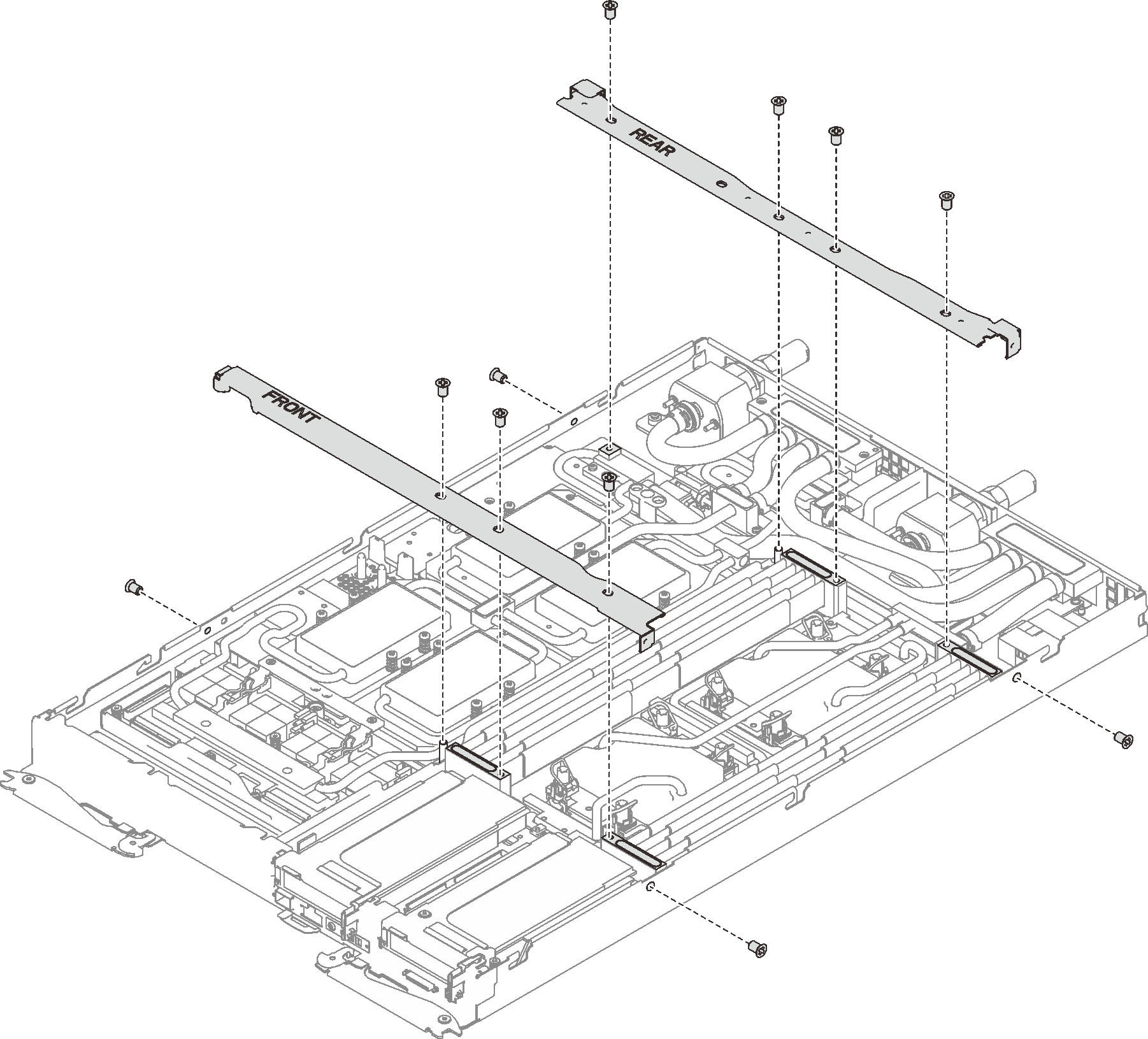

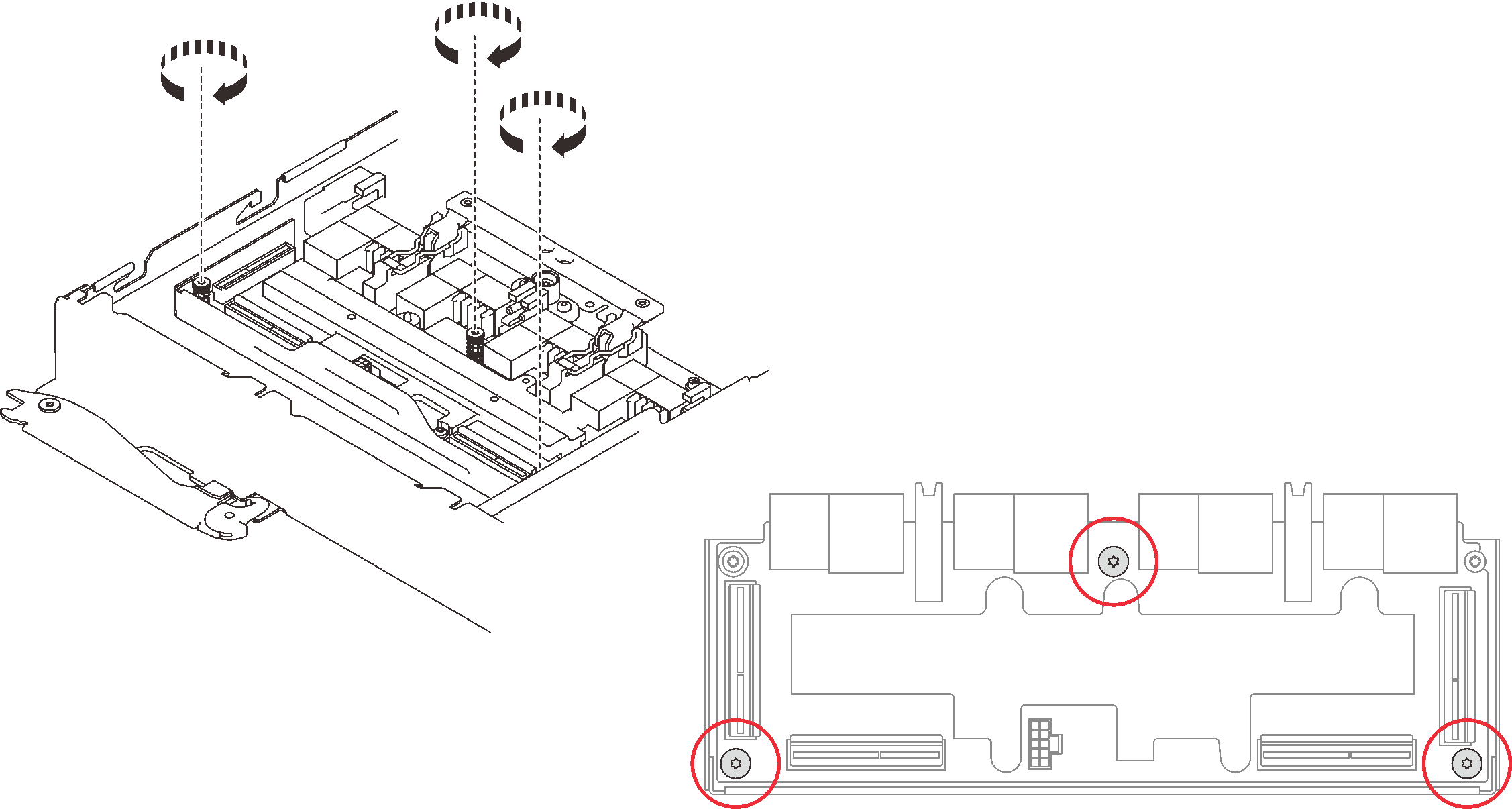

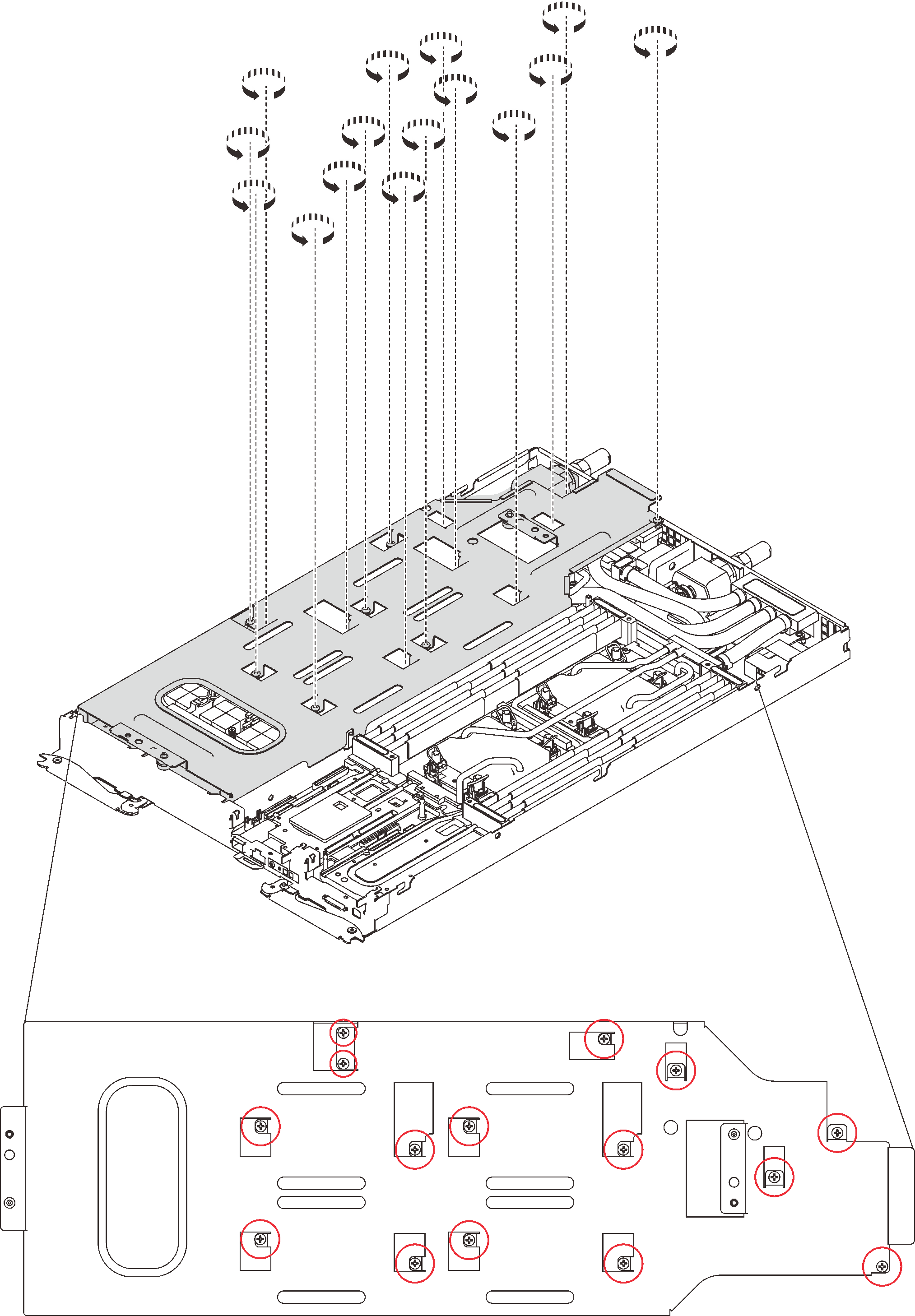

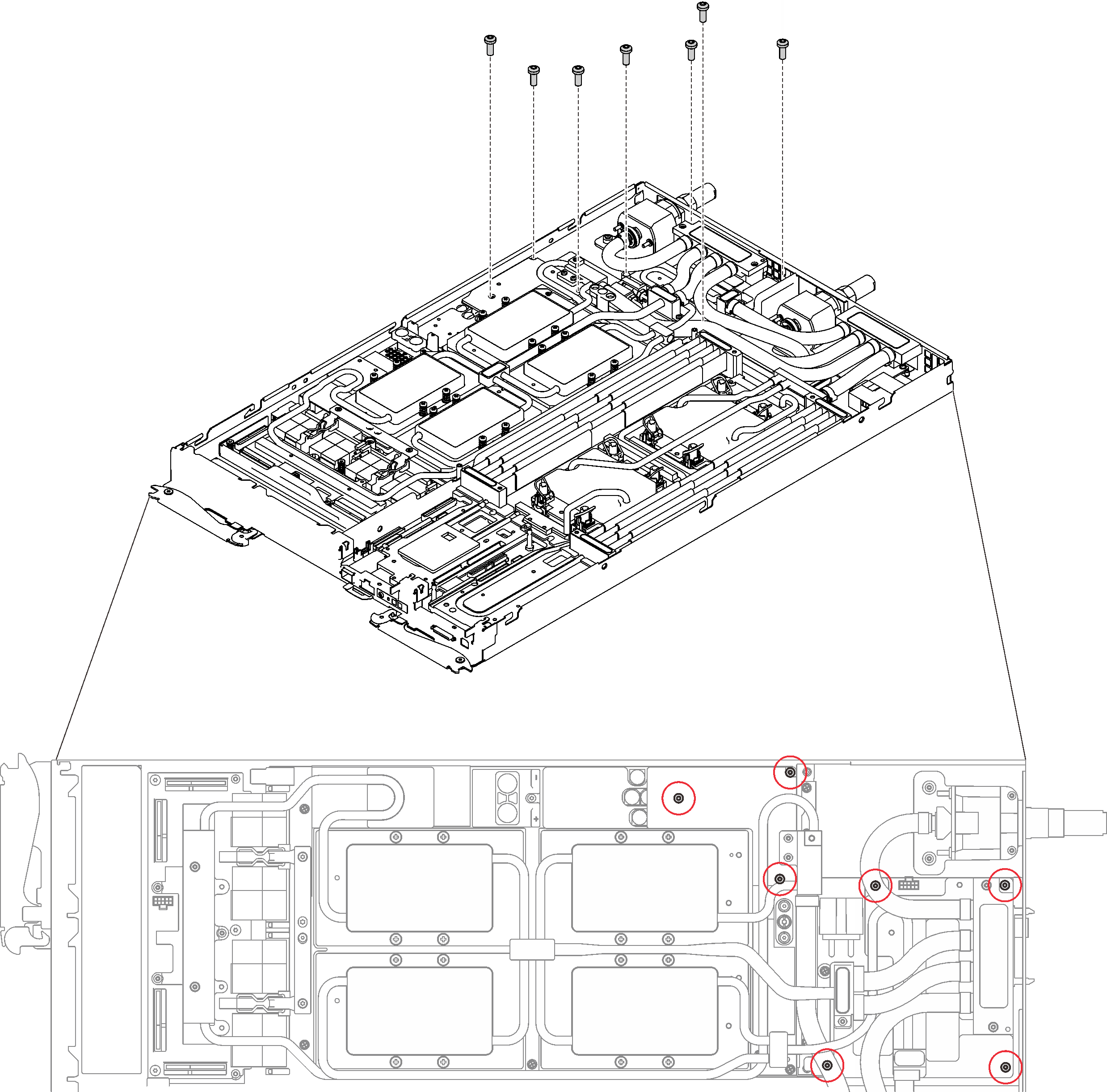

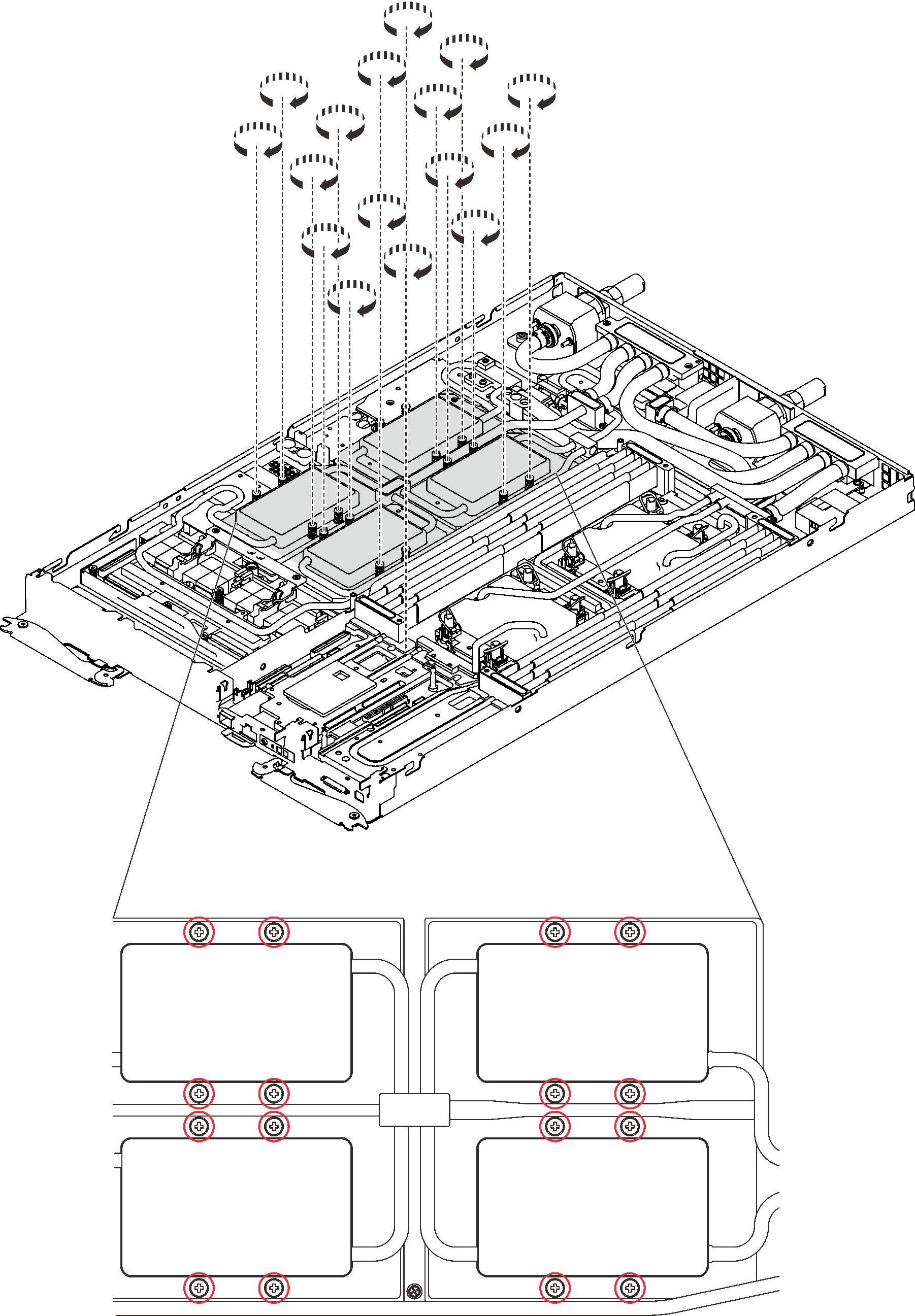

Reinstall the front and the rear cross braces (14x Phillips #1 screws).

Figure 17. Cross brace installation

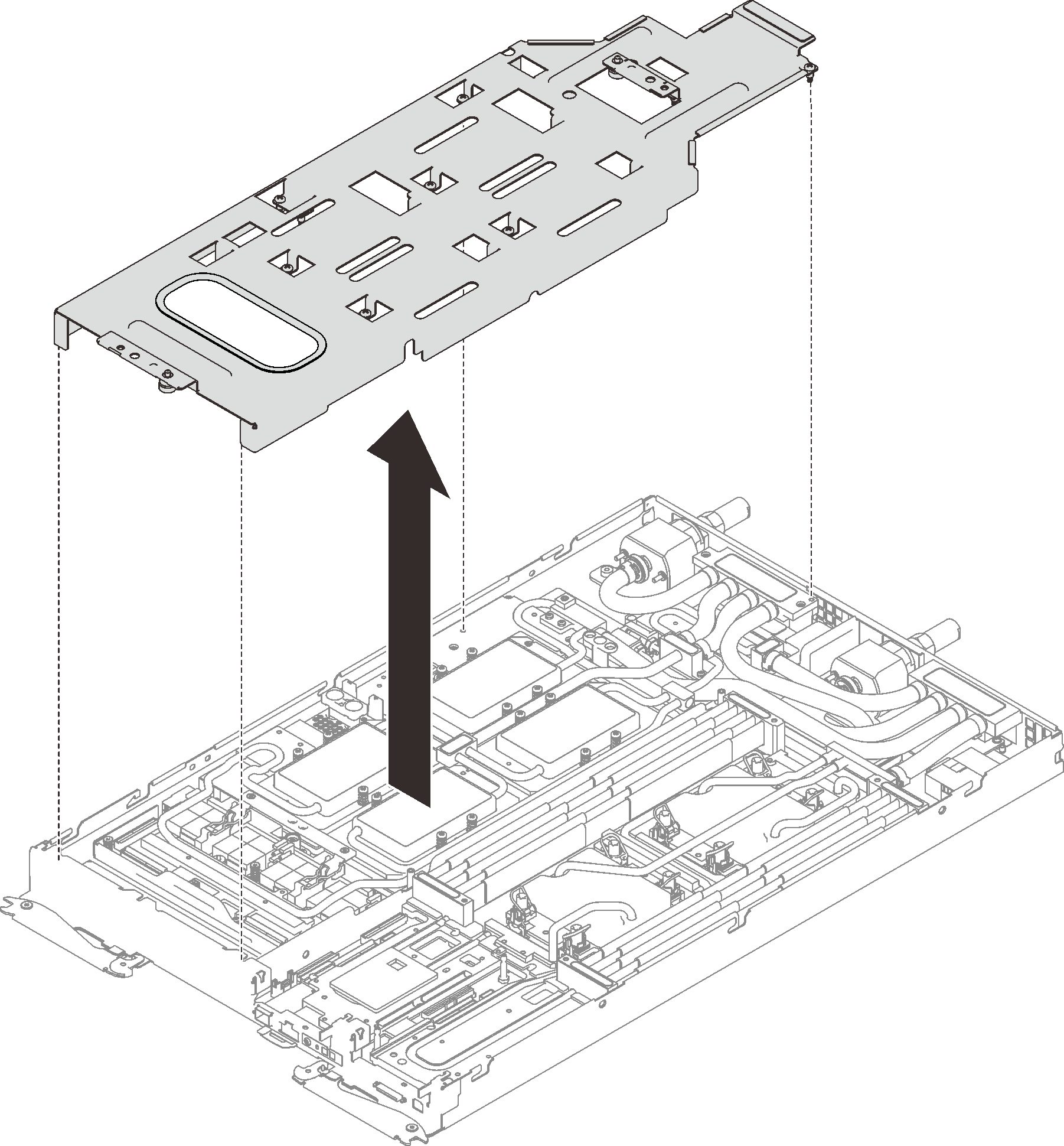

Reinstall the tray cover (see Install the tray cover).

Reinstall the tray (see Install a DWC tray in the enclosure).

NoteFor safety, use the lift tool to install the tray into the rack.- Connect all required external cables to the enclosure.NoteUse extra forces to connect QSFP cables to the enclosure if Mellanox ConnectX-6 adapters are installed.

Check the power LED on each node to make sure it changes from fast blink to slow blink to indicate all nodes are ready to be powered on.

Demo video

Give documentation feedback

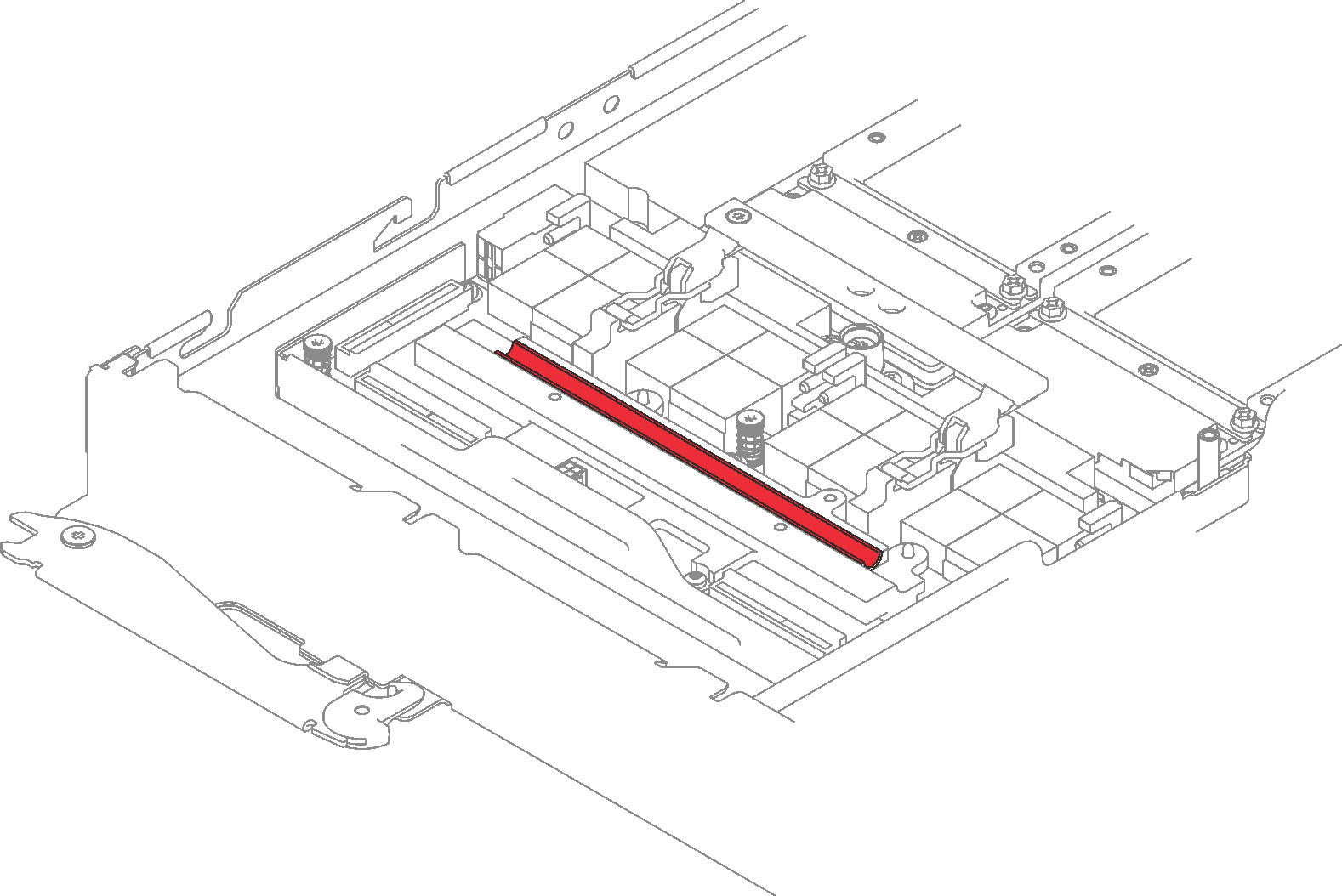

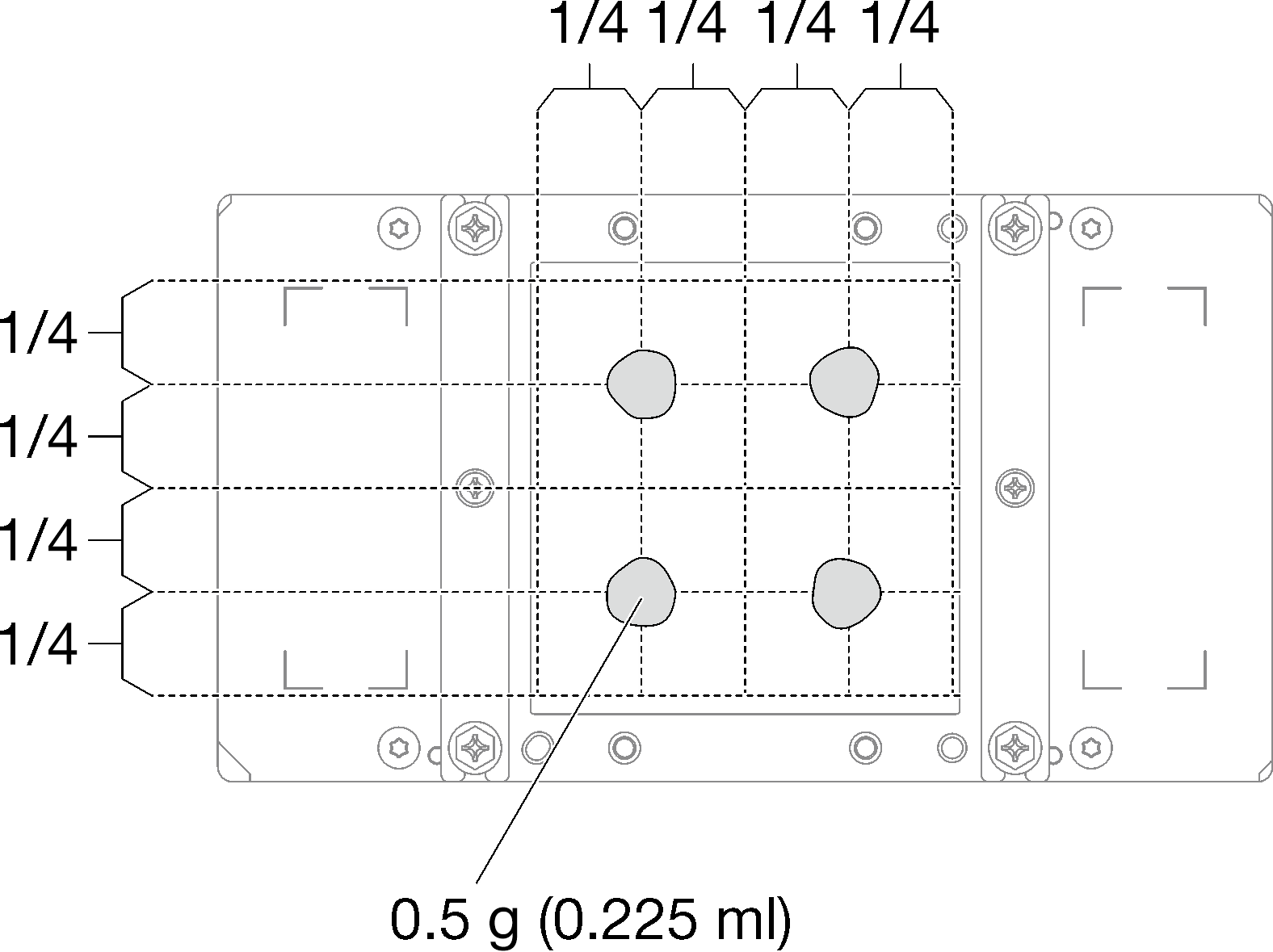

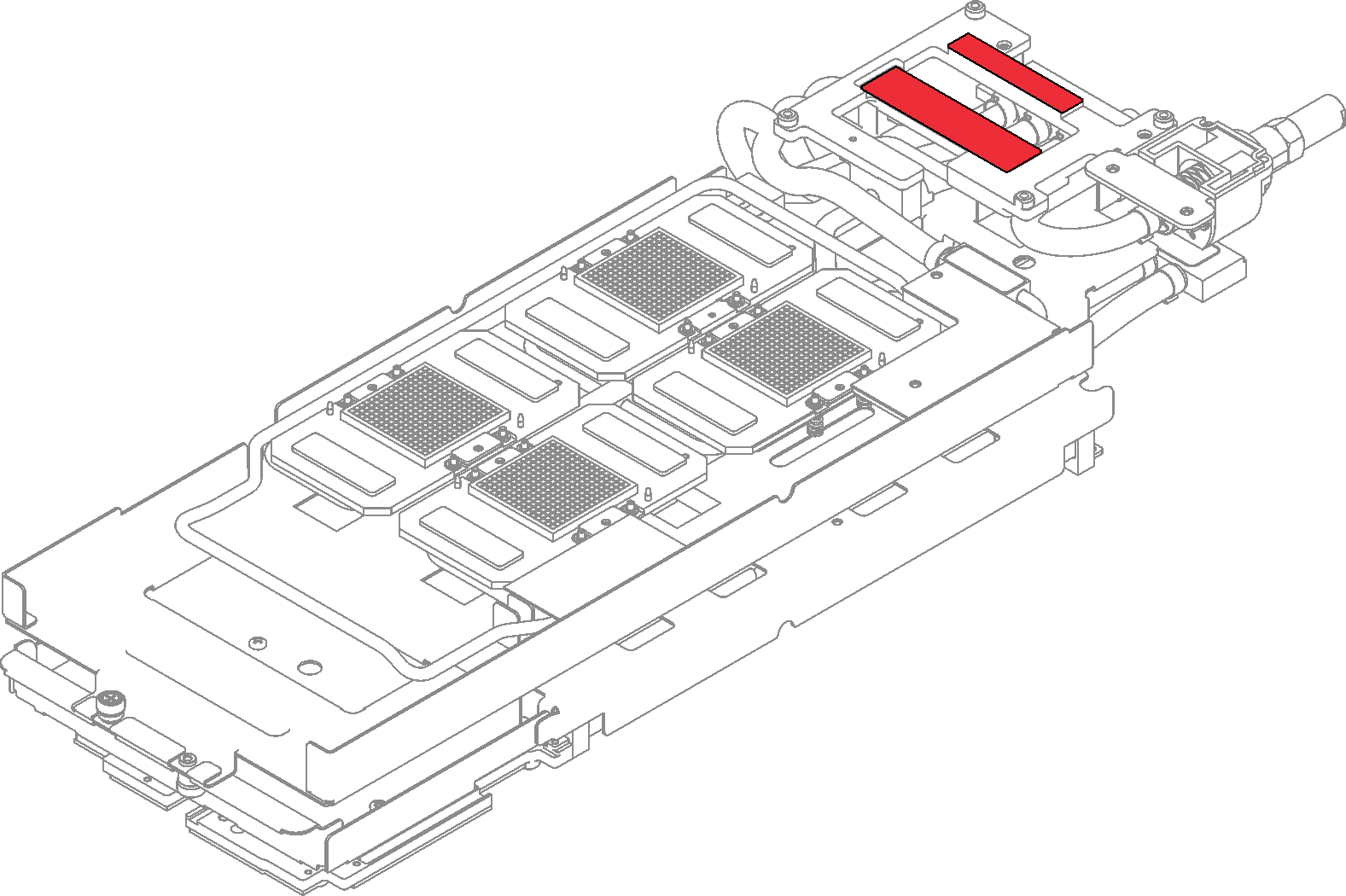

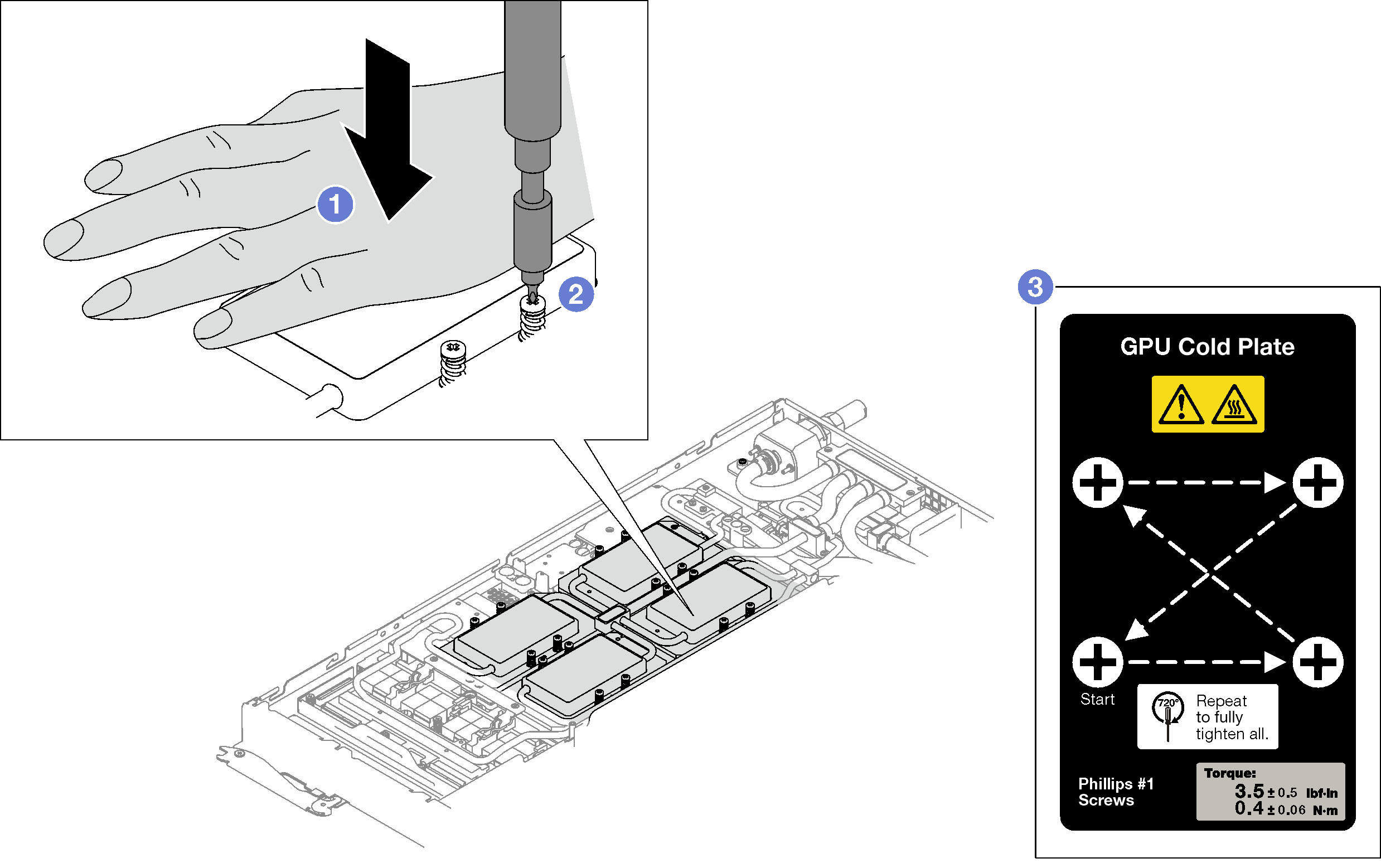

Push down the GPU cold plate with your palm to reduce the gap between the GPU cold plate and the GPU.

Push down the GPU cold plate with your palm to reduce the gap between the GPU cold plate and the GPU. Press the torque screwdriver against the screw so that the screw is engaged with the GPU.

Press the torque screwdriver against the screw so that the screw is engaged with the GPU. Follow the screw sequence specified on the GPU cold plate label, and fasten each screw for 720 degrees with a torque screwdriver set to the proper torque.

Follow the screw sequence specified on the GPU cold plate label, and fasten each screw for 720 degrees with a torque screwdriver set to the proper torque.

Make sure that the GPU cold plate is lowered into the node and its surface is flat without tilting. If the GPU cold plate is tilted, unfasten the screws, and repeat Step 1 to Step 3.

Make sure that the GPU cold plate is lowered into the node and its surface is flat without tilting. If the GPU cold plate is tilted, unfasten the screws, and repeat Step 1 to Step 3. Repeat Step 3 until the screws are fully tightened.

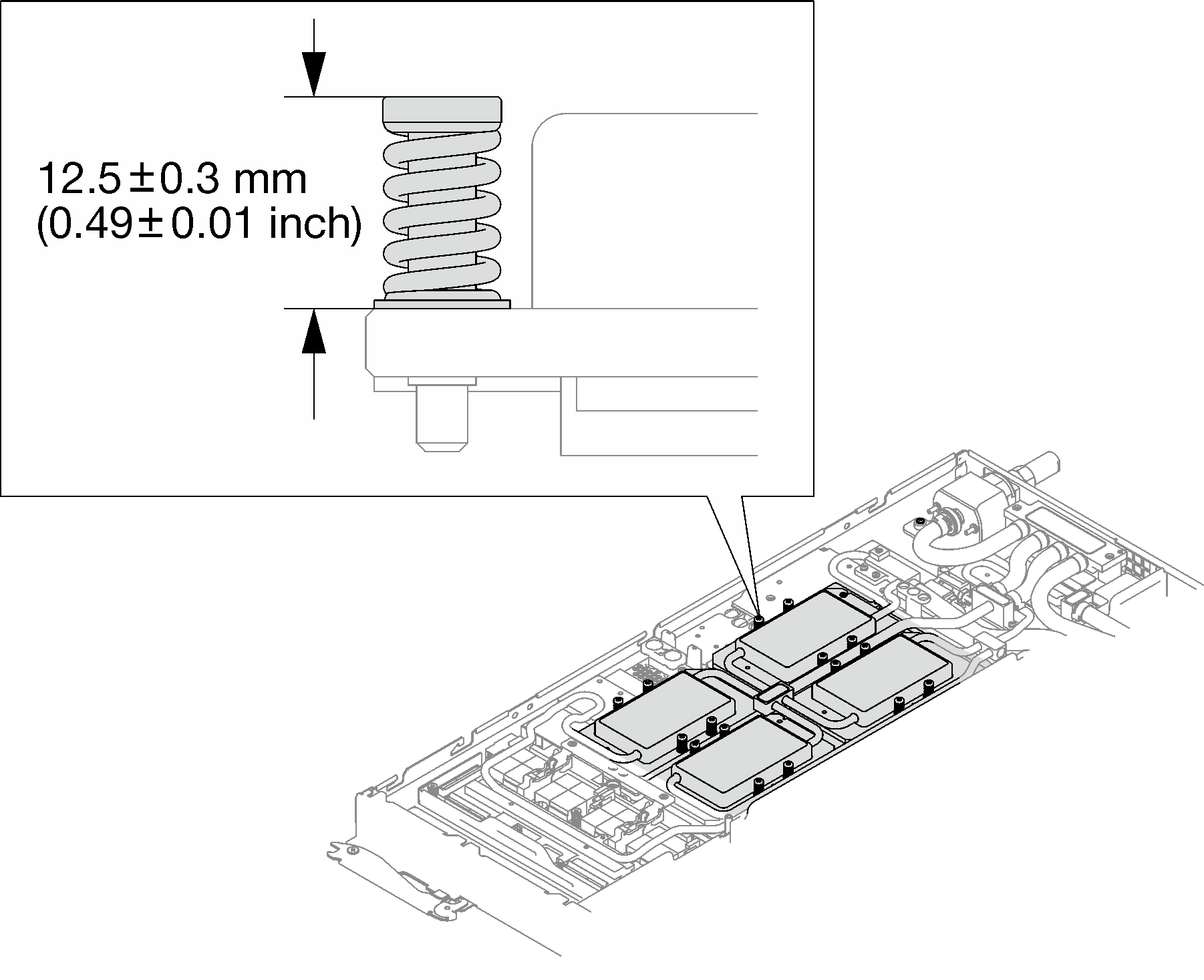

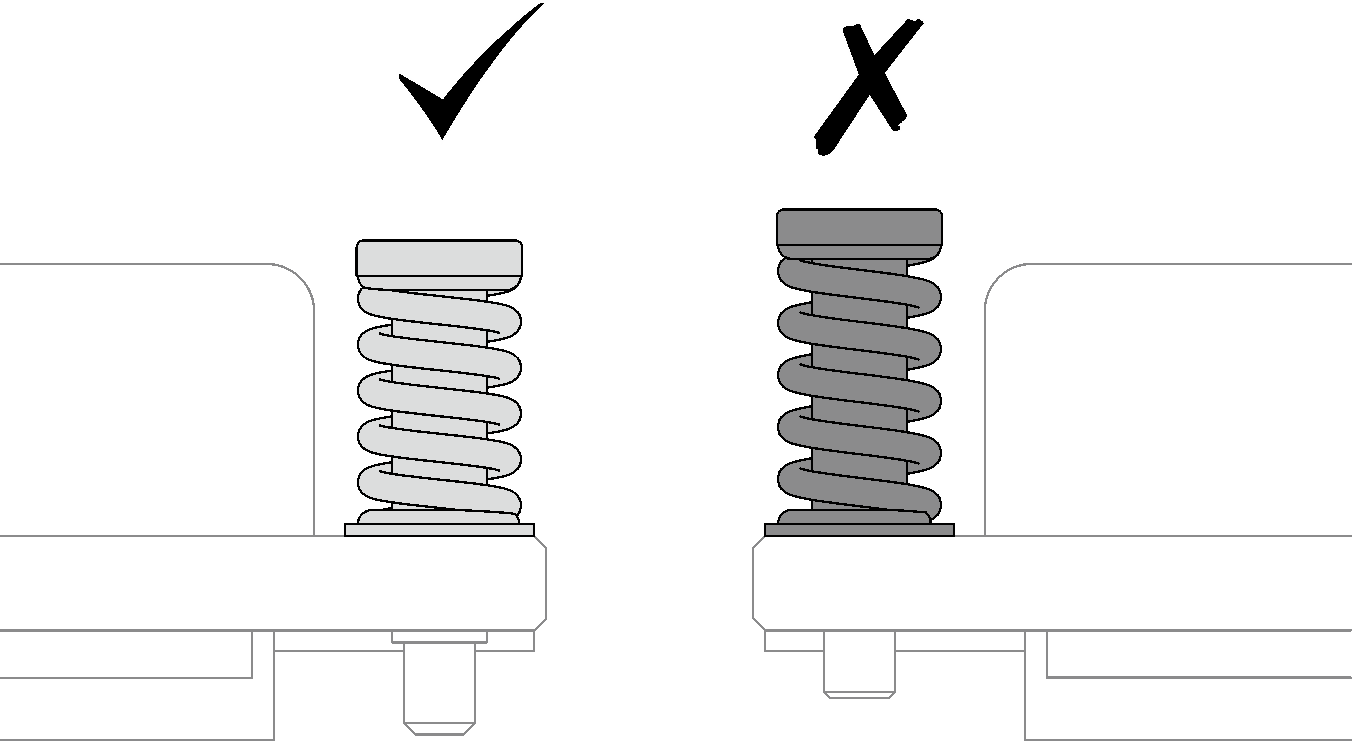

Repeat Step 3 until the screws are fully tightened. Make sure the height of each screw is 12.5±0.3 millimeter (0.49±0.01 inch) and is fully compressed. If not, repeat the GPU cold plate installation steps.

Make sure the height of each screw is 12.5±0.3 millimeter (0.49±0.01 inch) and is fully compressed. If not, repeat the GPU cold plate installation steps.