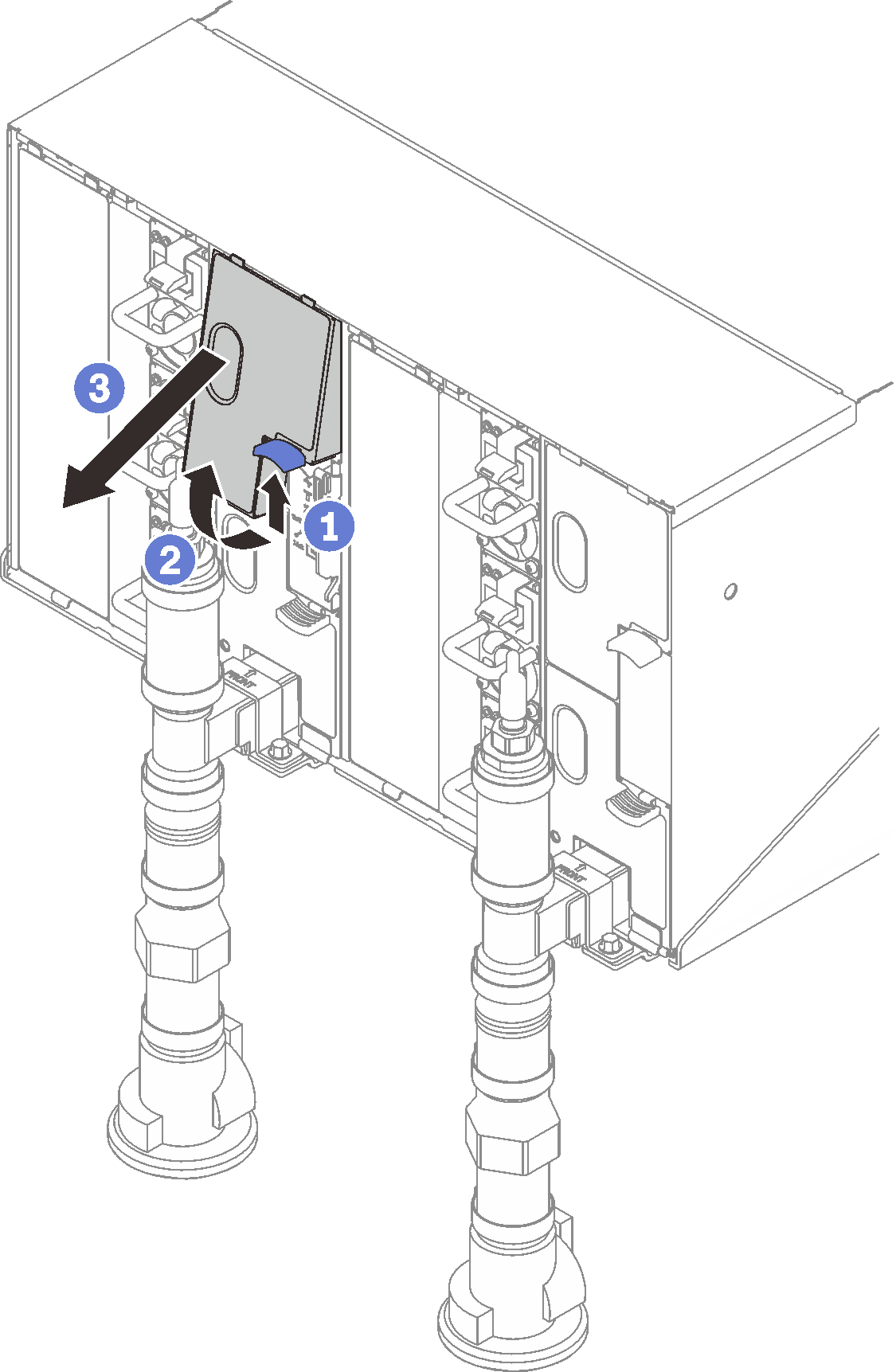

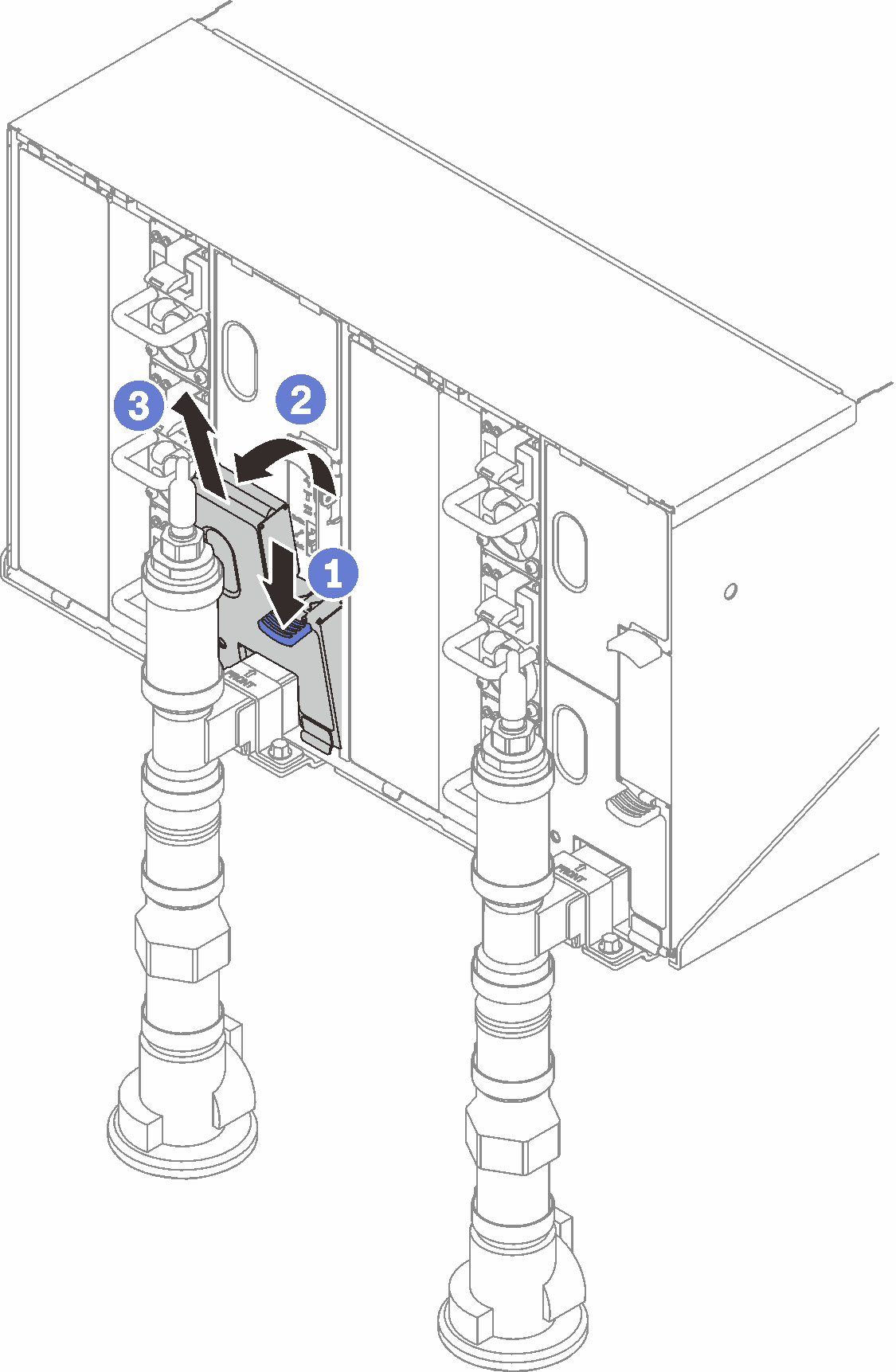

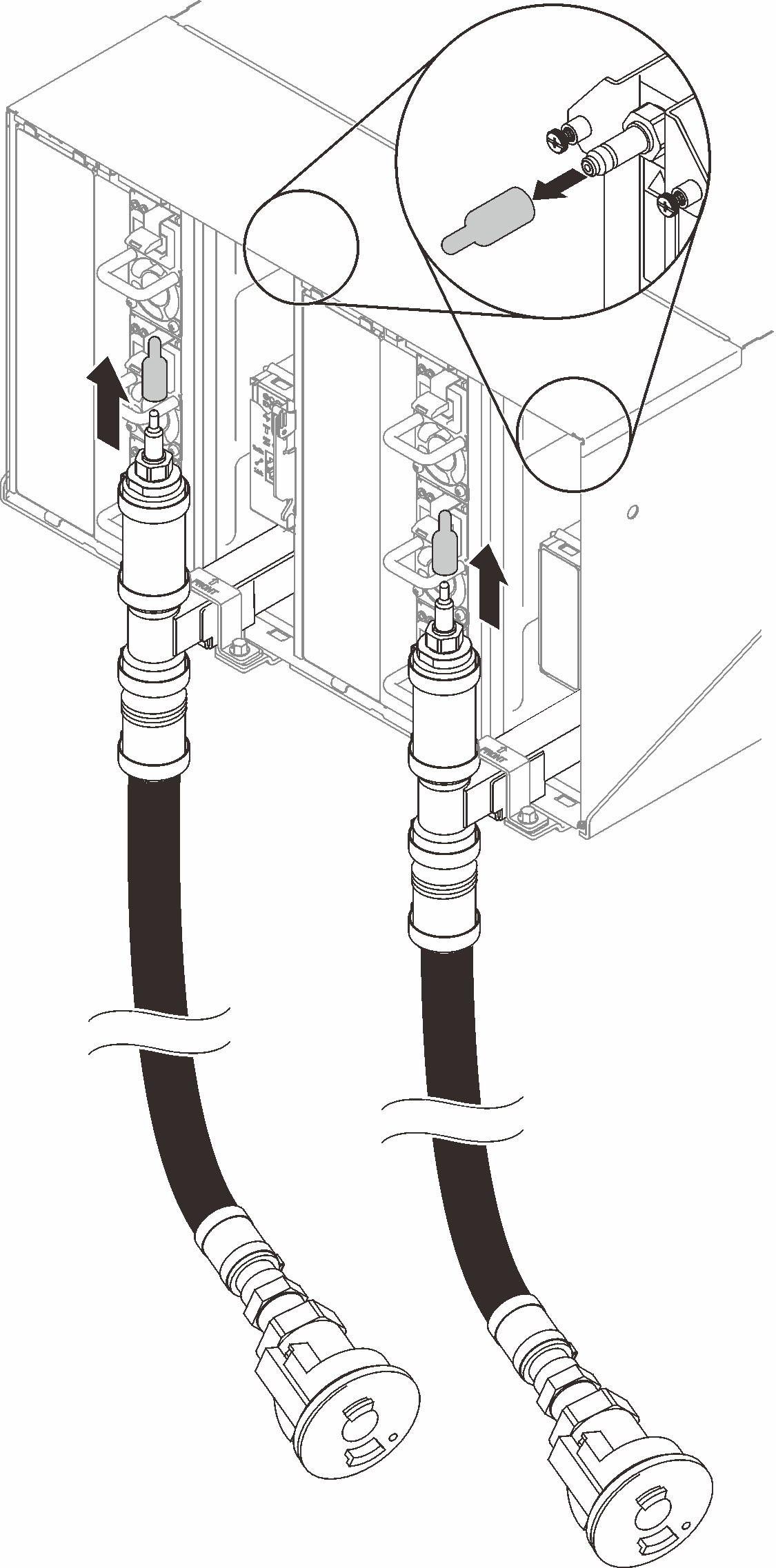

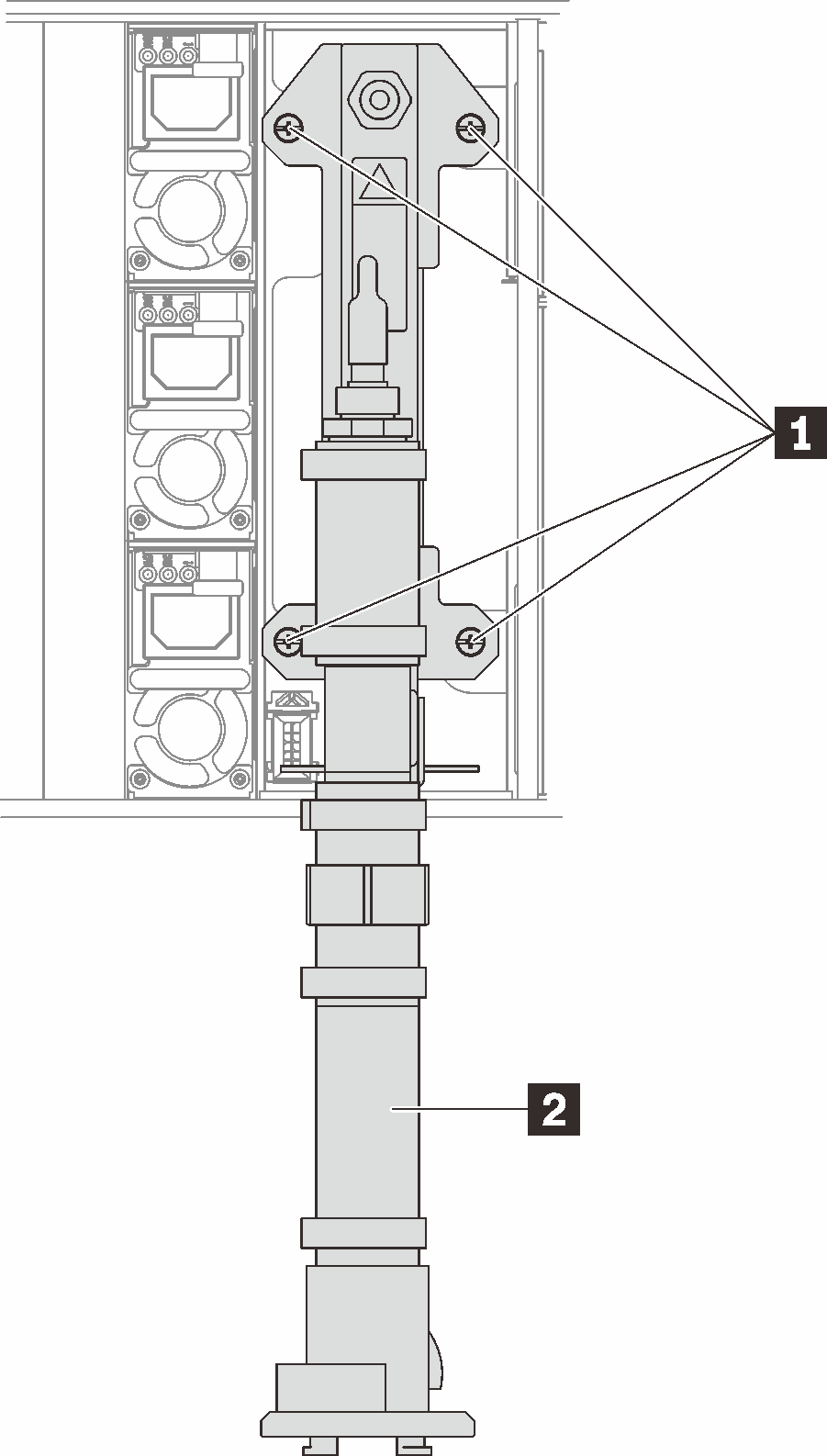

Remove the manifold

Use this information to remove the manifold.

About this task

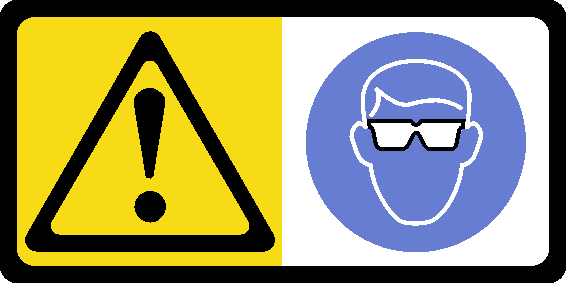

The water might cause irritation to the skin and eyes. Avoid direct contact with the lubricant.

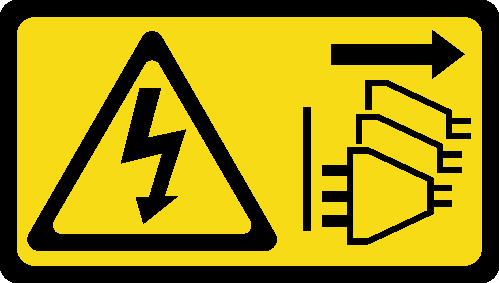

- Read the following sections to ensure that you work safely.

Ensure proper handling procedures are followed when working with any chemically treated water used in the compute rack cooling system. Ensure that material safety data sheets (MSDS) and safety information are provided by the water chemical treatment supplier and that proper personal protective equipment (PPE) is available as recommended by the water chemical treatment supplier. Protective gloves and eyewear may be recommended as a precaution.

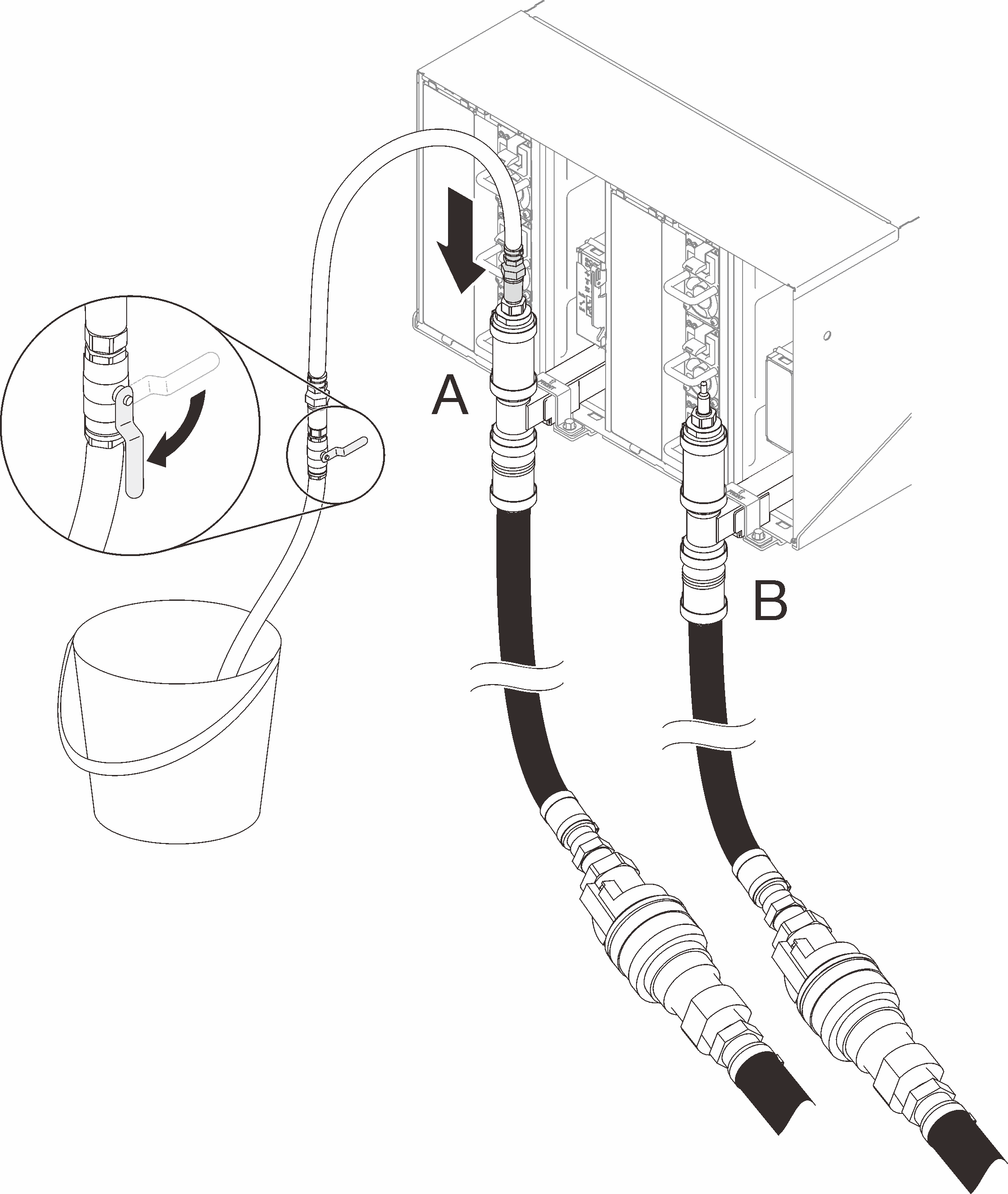

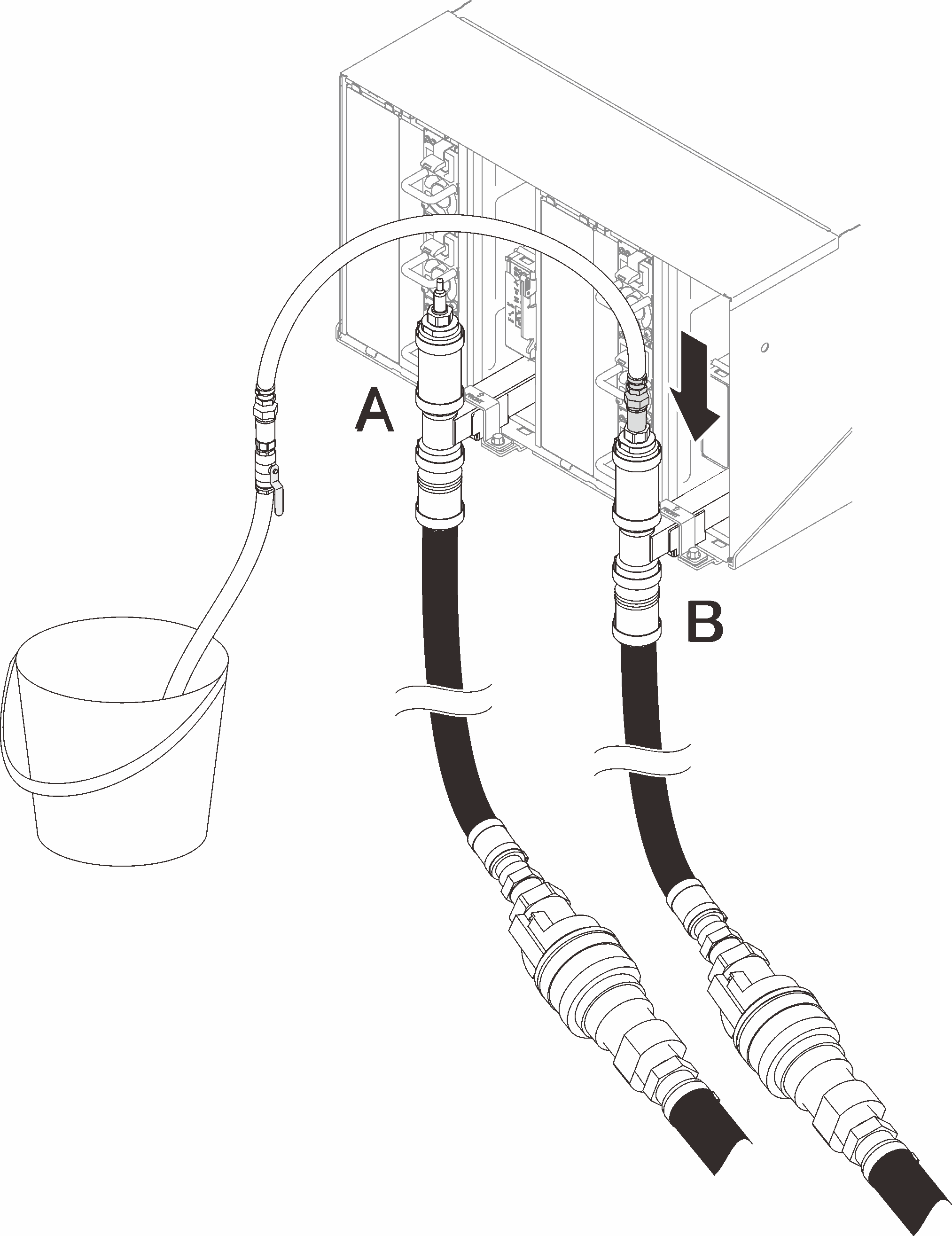

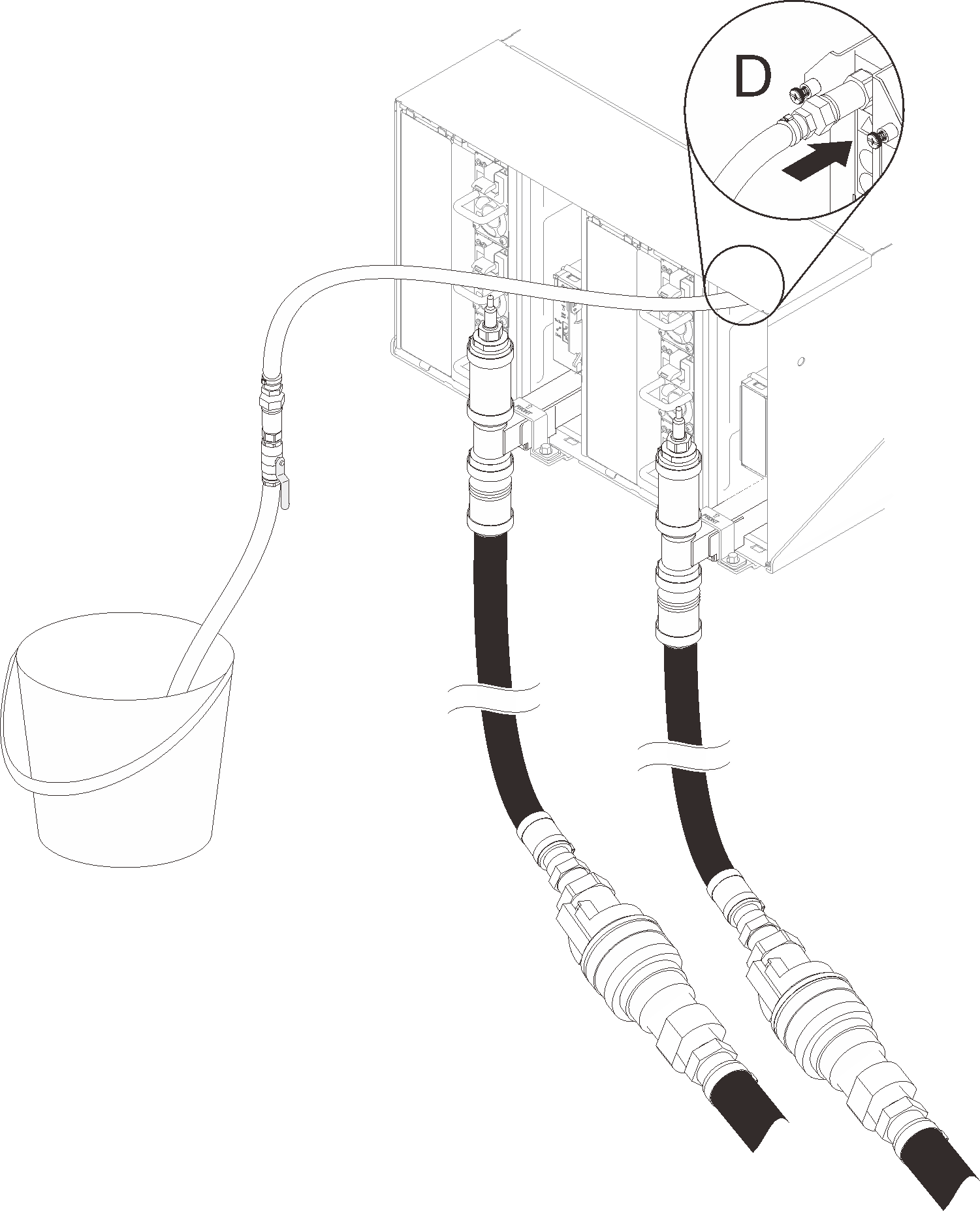

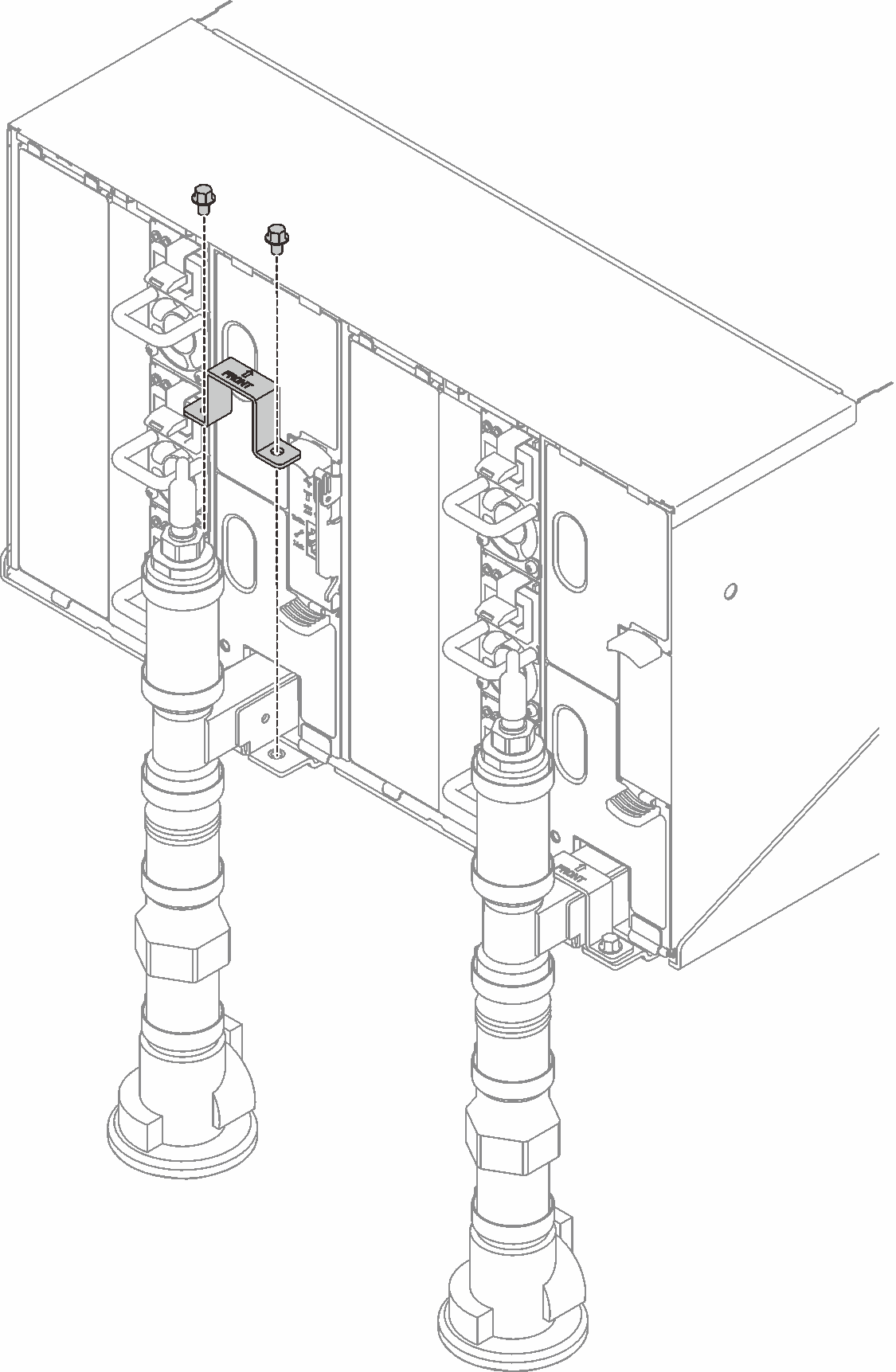

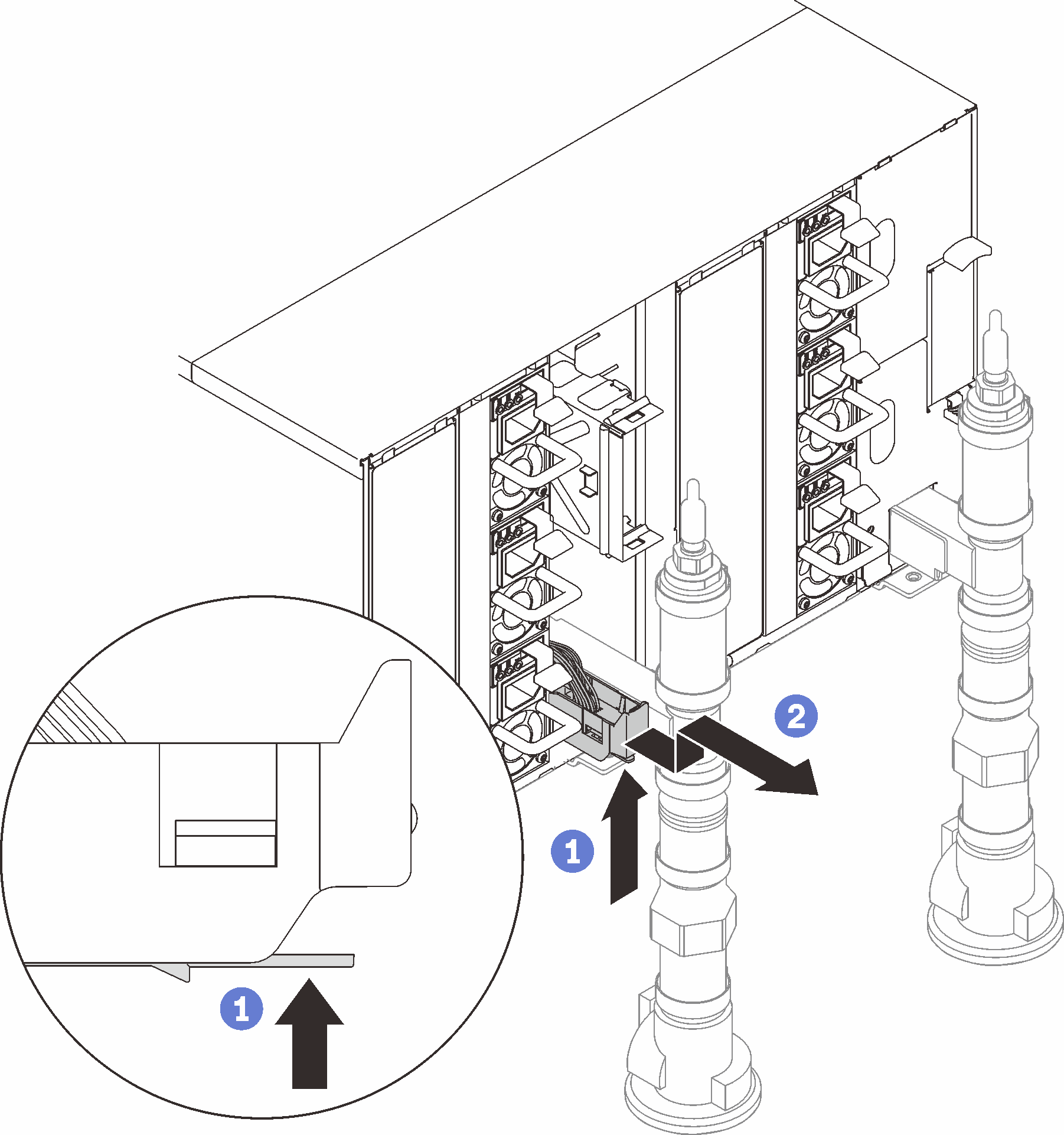

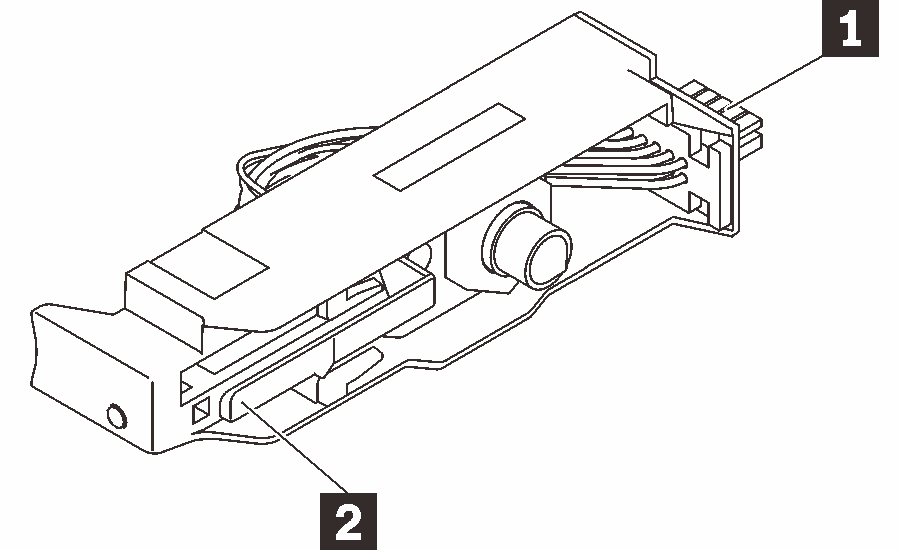

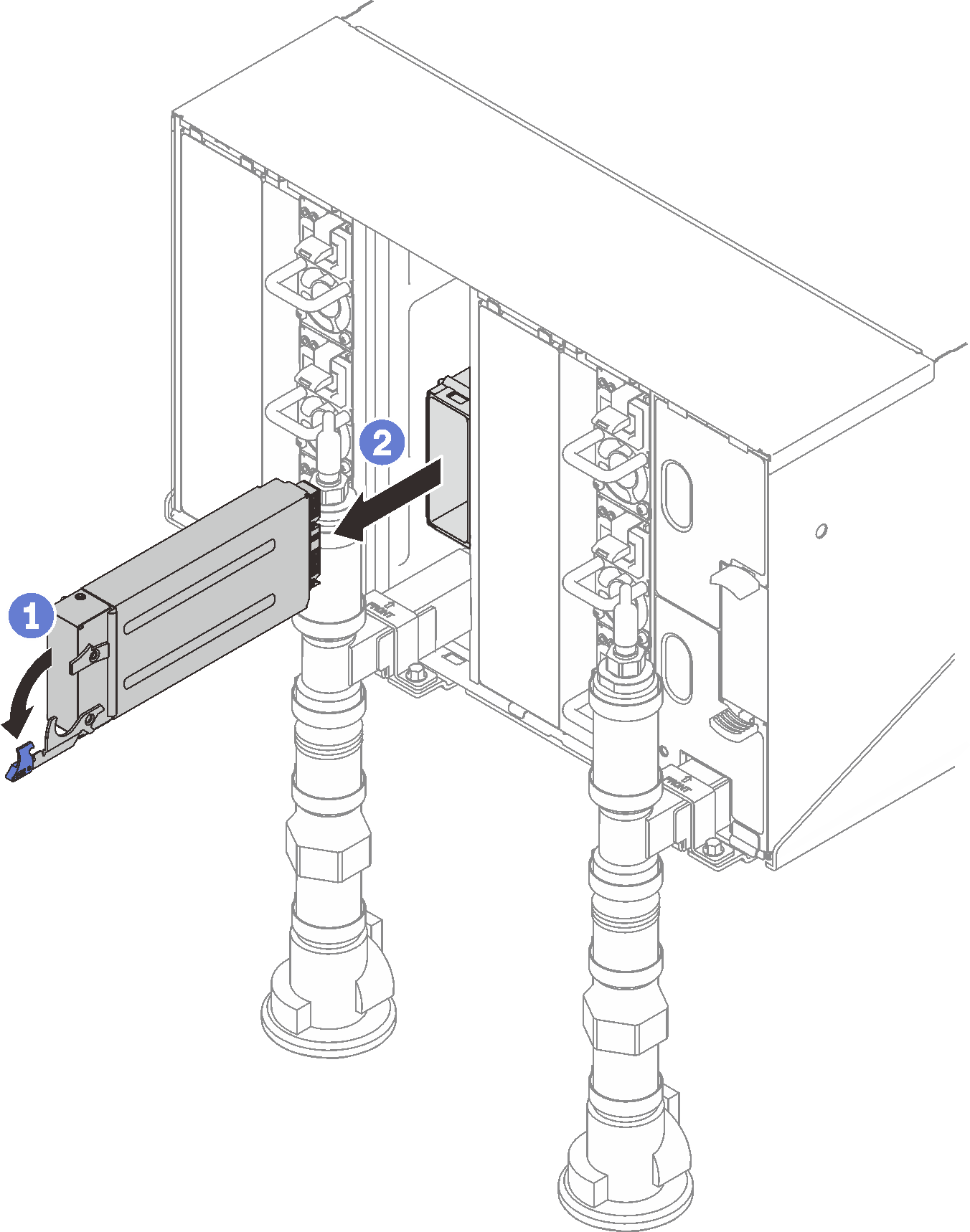

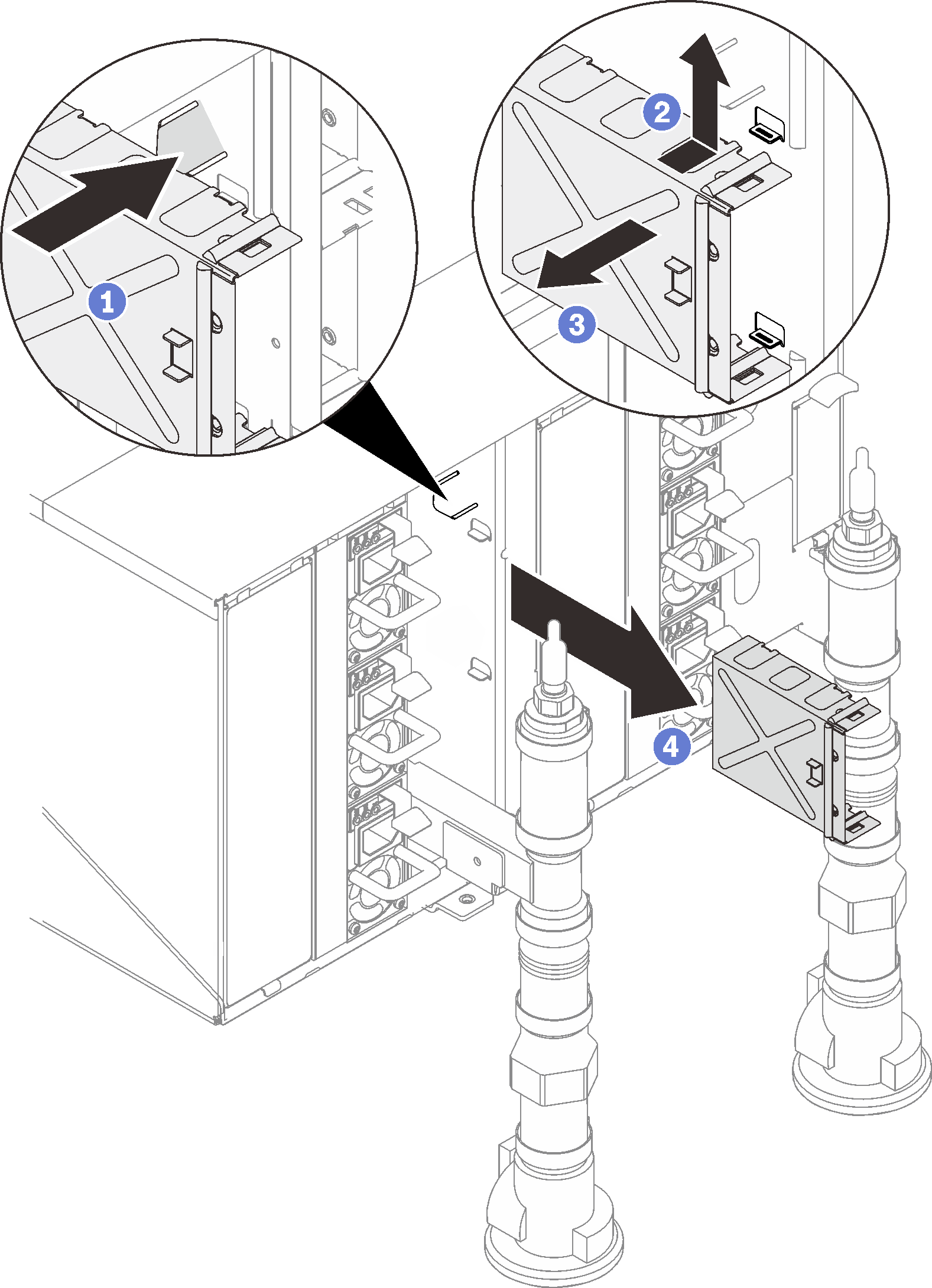

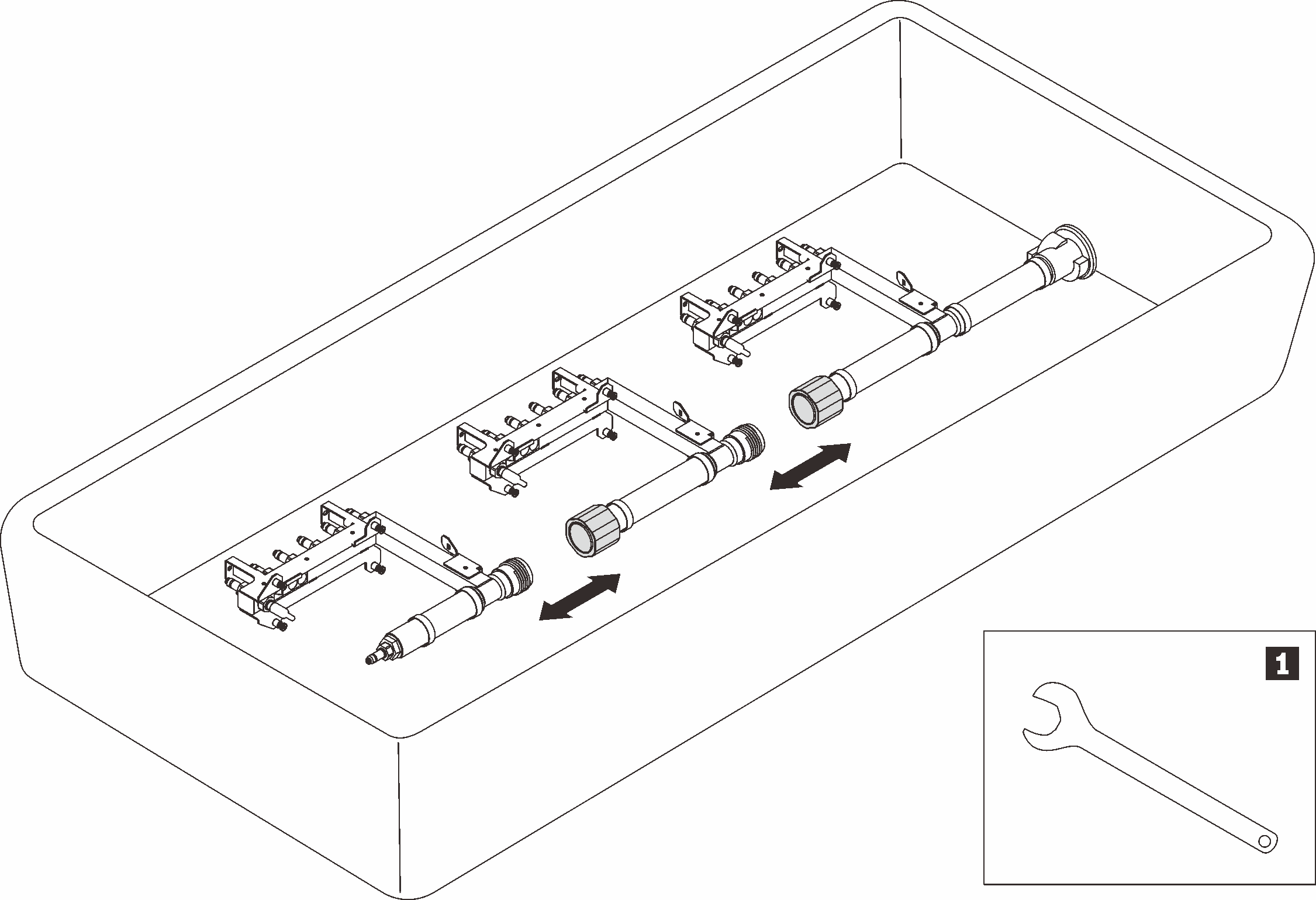

Procedure

If you are instructed to return the component or optional device, follow all packaging instructions, and use any packaging materials for shipping that are supplied to you.

Demo video