Installing a microprocessor and heat sink

Use this information to install a microprocessor and heat sink in the blade server.

Note

The optional microprocessors that IBM supports are limited by the capacity and capability of the server. Any microprocessors that you install must have the same specifications as the microprocessors that came with the blade server.

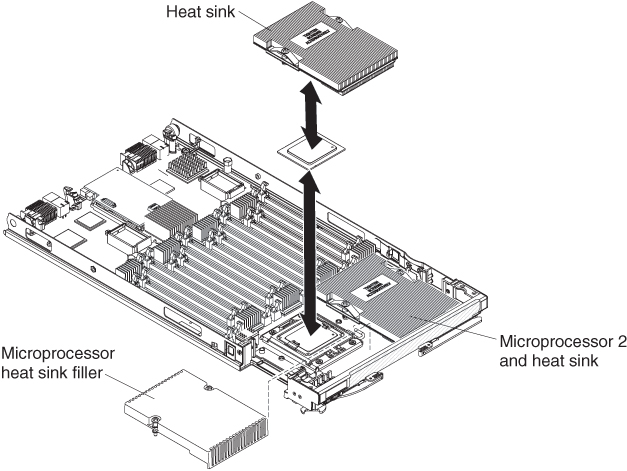

The following illustration shows how to install a microprocessor and heat sink in the blade server.

Attention

- Do not use any tools or sharp objects to lift the locking lever on the microprocessor socket. Doing so might result in permanent damage to the system board.

- Do not touch the contacts in the microprocessor socket. Touching these contacts might result in permanent damage to the system board.

To install a microprocessor and heat sink, complete the following steps:

- Before you begin, read Safety and Installation guidelines.

- If the blade server or scalable blade complex is installed in a BladeCenter chassis, remove it. See Removing the blade server from the BladeCenter chassis for instructions.

- Carefully lay the blade server on a flat, static-protective surface.

- If you are installing the microprocessor and heat sink in a blade server that is the bottom blade server in a scalable blade complex, disassemble the blade complex (see Disassembling a scalable blade complex for instructions).

- If an optional expansion unit is installed, remove the expansion unit (see Removing an expansion unit for instructions).NoteOptional expansion units are not supported when a

IBM MAX5 expansion blade is installed. - If an IBM MAX5 expansion blade is installed, remove it (see Removing an IBM MAX5 expansion blade for instructions).

- Open the blade server cover (see Removing the blade server cover for instructions).

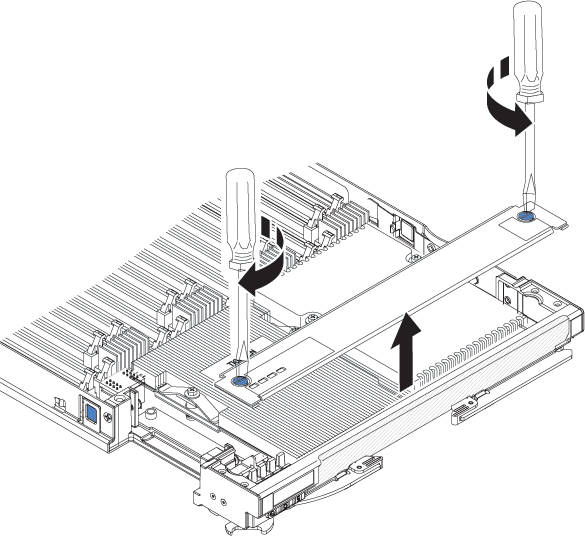

- Remove the access panel if you have the standard heat sinks installed.NoteIf you have the tall heat sinks installed, you do not need to remove the access panel.

- Using a screwdriver or a coin, turn each of the screws toward the middle of the blade server until they are in the unlocked position.

- While you lift the back of the access panel, slide the panel away from the bezel.

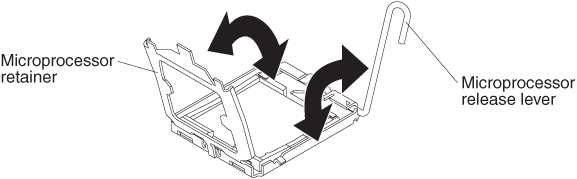

- Open the microprocessor socket release lever and retainer.

- Rotate the release lever on the microprocessor socket from its closed and locked position until it stops in the fully open position (approximately a 135° angle).

- Rotate the microprocessor retainer on the microprocessor socket from its closed position until it stops in the fully open position (approximately a 135° angle).

- If a dust cover is installed over the microprocessor socket, lift the dust cover from the socket and store it in a safe place.

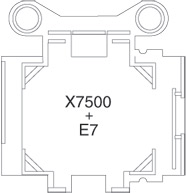

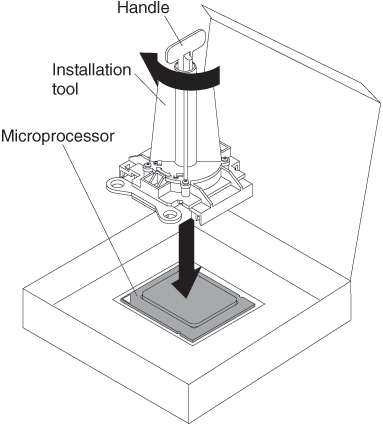

- Install the microprocessor in the microprocessor installation tool.AttentionIf you are installing E7 series microprocessors in the blade server, you must use the microprocessor installation tool with the text “X7500 + E7” on the bottom of the tool (see the following illustration). Tools that do not have this text on the bottom will not work correctly with the E7 series microprocessors.

- Remove the static-protective bag and the foam surrounding the bag from the box.

- Touch the static-protective bag that contains the new microprocessor to any unpainted surface on the BladeCenter chassis or any unpainted metal surface on any other grounded rack component.

- Carefully remove the microprocessor from the static-protective bag, touching only the edges of the microprocessor.

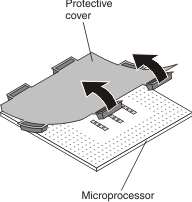

- If there is a plastic protective cover on the bottom of the microprocessor, carefully remove it.

- Put the microprocessor back in the box, component side down, on the solid piece of foam.

- Twist the handle of the installation tool counterclockwise so that it is in the open position.

- Using the triangle on the microprocessor to align it with the installation tool, place the microprocessor on the underside of the tool.

- Twist the handle of the installation tool clockwise to secure the microprocessor in the tool.NoteYou can pick up or release the microprocessor by twisting the microprocessor installation tool handle.

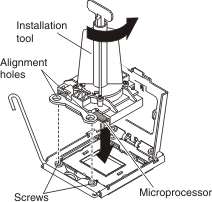

- Carefully place the microprocessor into the microprocessor socket, using the alignment tabs on the microprocessor with the alignment notches in the microprocessor socket as a guide.

The alignment holes on the tool will not sit flush on the microprocessor bracket screws. However, the holes can be used as a guide to ensure the proper alignment between the microprocessor installation tool and the microprocessor bracket.

Attention- Do not press the microprocessor into the socket.

- Do not touch exposed pins of the microprocessor socket.

- Make sure that the microprocessor is oriented and aligned correctly in the socket before you try to close the microprocessor retainer.

- Do not touch the thermal material on the bottom of the heat sink or on top of the microprocessor. Touching the thermal material will contaminate it. If the thermal material on the microprocessor or heat sink becomes contaminated, contact your service technician.

- Carefully close the microprocessor retainer.

- Rotate the locking lever on the microprocessor socket to the closed and locked position. Make sure that the lever is secured in the locked position by pressing the tab on the microprocessor socket.

- If you are reinstalling a heat sink that was removed from the blade server, complete the following steps:Attention

- Do not touch the thermal material on the bottom of the heat sink. Touching the thermal material will contaminate it. If the thermal material on the microprocessor or heat sink becomes contaminated, contact your service technician.

- Do not touch exposed pins of the microprocessor socket.

- Make sure that the thermal material is still on the bottom of the heat sink and on the top of the microprocessor.

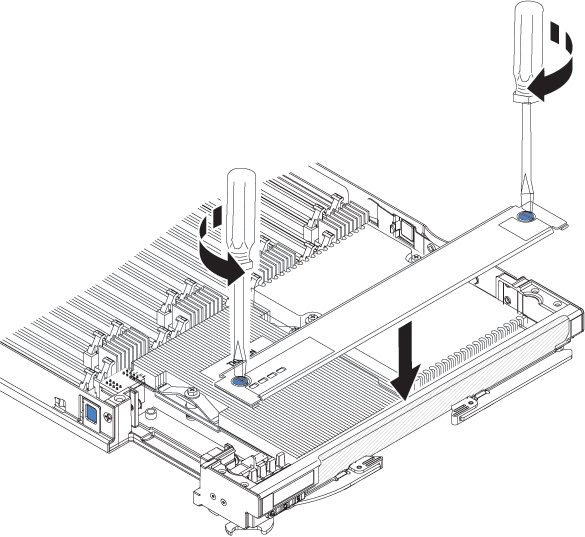

- Align and place the heat sink on top of the microprocessor in the retention bracket, thermal material side down. Press firmly on the heat sink.

- Align the three screws on the heat sink with the holes on the heat-sink retention module.

- Press firmly on the captive screws and tighten them with a screwdriver, alternating among the screws until they are tight. If possible, each screw should be rotated two full rotations at a time. Repeat until the screws are tight. Do not overtighten the screws by using excessive force. If you are using a torque wrench, tighten the screws to 1.13 ± 0.13 Newton-meters (Nm) (10 ± 0.15 in-lbs).

- If you are installing a new heat sink, complete the following steps:Attention

- Do not set down the heat sink after you remove the plastic cover.

- Do not touch the thermal material on the bottom of the heat sink. Touching the thermal material will contaminate it. If the thermal material on the microprocessor or heat sink becomes contaminated, contact your service technician.

- Do not touch exposed pins of the microprocessor socket.

- Remove the plastic protective cover from the bottom of the heat sink.

- Align and place the heat sink on top of the microprocessor in the retention bracket, thermal material side down. Press firmly on the heat sink.

- Align the screws on the heat sink with the holes on the heat-sink retention module.

- Press firmly on the captive screws and tighten them with a screwdriver, alternating among the screws until they are tight. If possible, each screw should be rotated two full rotations at a time. Repeat until the screws are tight. Do not overtighten the screws by using excessive force. If you are using a torque wrench, tighten the screws to 8.5 Newton-meters (Nm) to 13 Nm (6.3 foot-pounds to 9.6 foot-pounds).

- Make sure that, at a minimum, memory modules are installed in DIMM connectors 1 and 4. See Installing a DIMM - BladeCenter HX5 for more information on installing a memory module.

- Install the access panel if you have standard heat sinks installed.NoteIf you have the tall heat sinks installed, you do not need to install the access panel.

- Make sure that the screws on the access panel are in the open position (the screw insert is parallel to the side of the access panel).

- Slide the back of the cover under the blade server bezel, aligning the screws with the slots on the blade server.

- Using a screwdriver or a coin, turn each of the screws away from the middle of the blade server until it is in the locked position.

- If the blade server is part of a scalable blade complex, assemble the scalable blade complex (see Assembling a scalable blade complex for instructions).

- Install the IBM MAX5 expansion blade if you removed one (see Installing an IBM MAX5 expansion blade for instructions).

- Install the optional expansion unit, if you removed one from the blade server (see Installing an expansion unit for instructions).

- Install the cover onto the blade server (see Installing the blade server cover for instructions).

- Install the blade server or scalable blade complex into the BladeCenter chassis (see Installing a blade server in a BladeCenter chassis for instructions).

Give documentation feedback