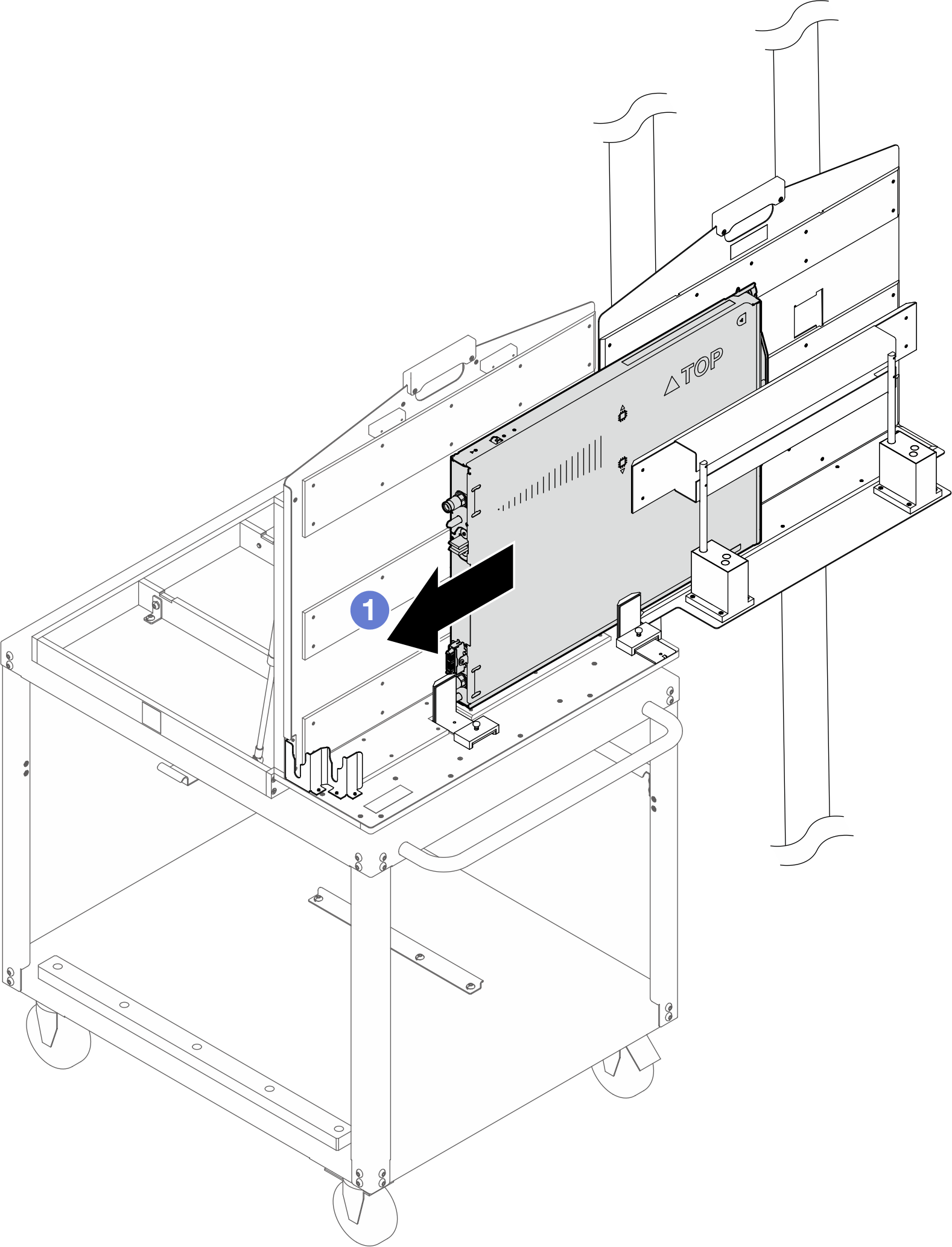

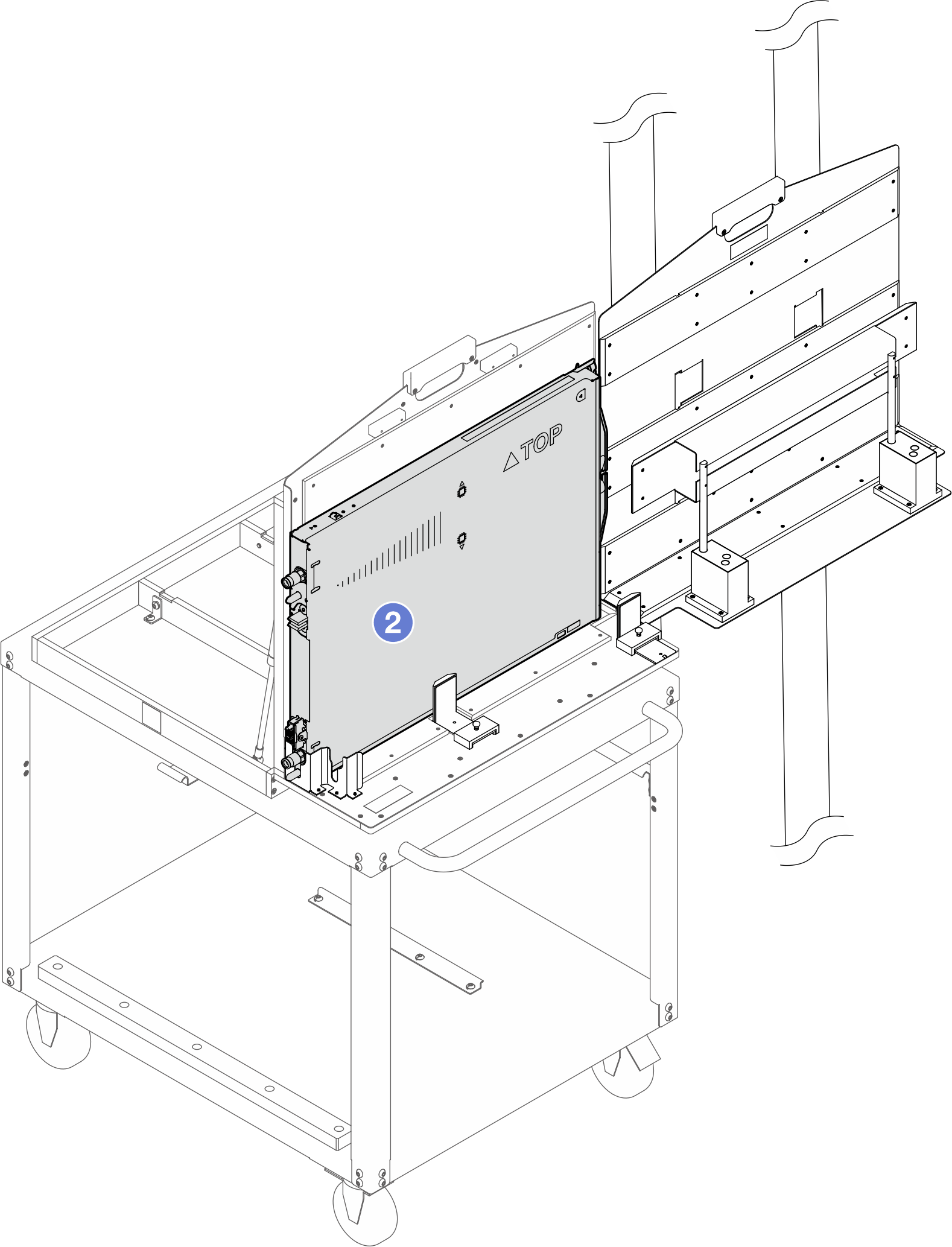

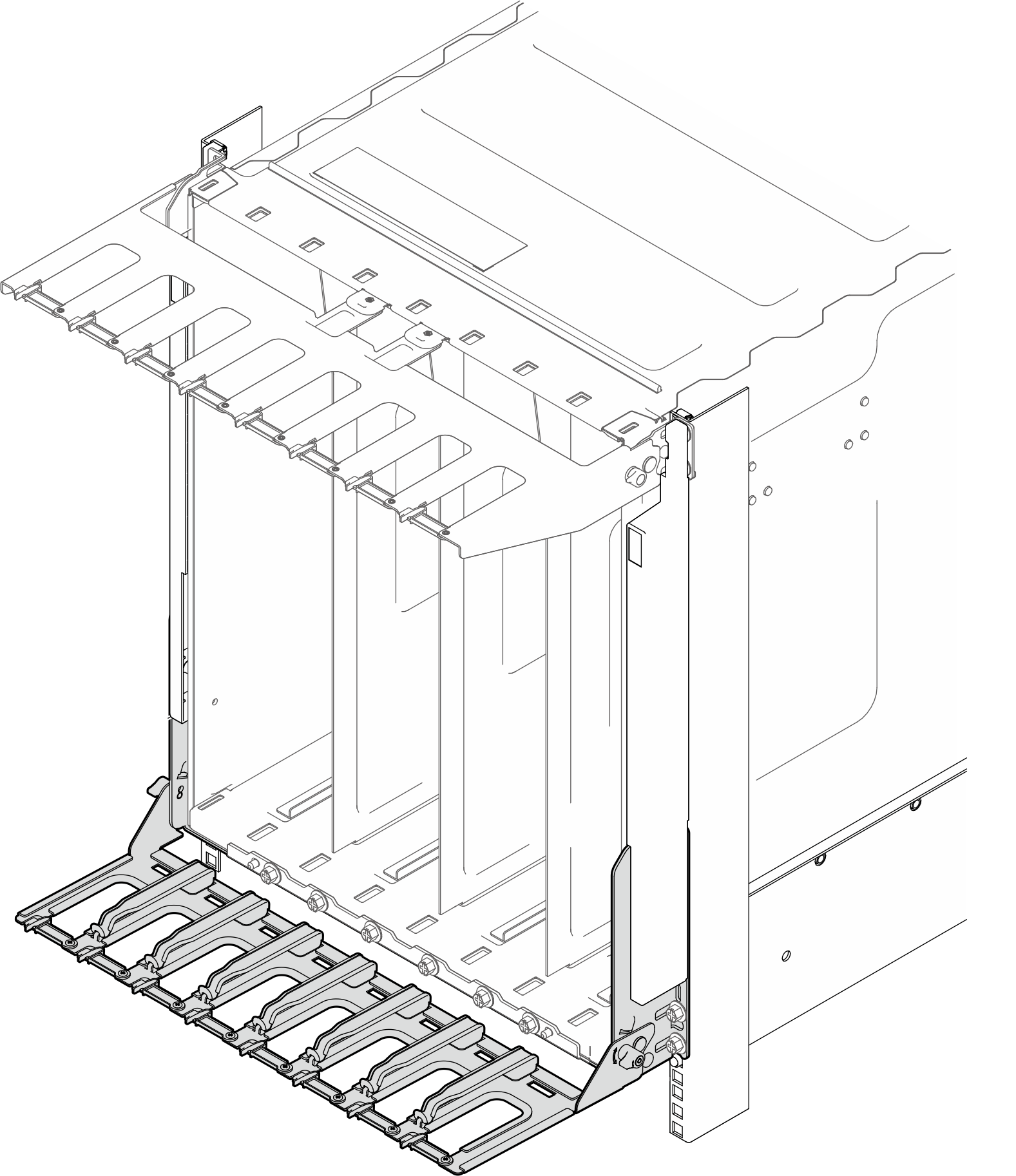

Remove a tray from the enclosure

Use this information to remove a DWC tray from the enclosure.

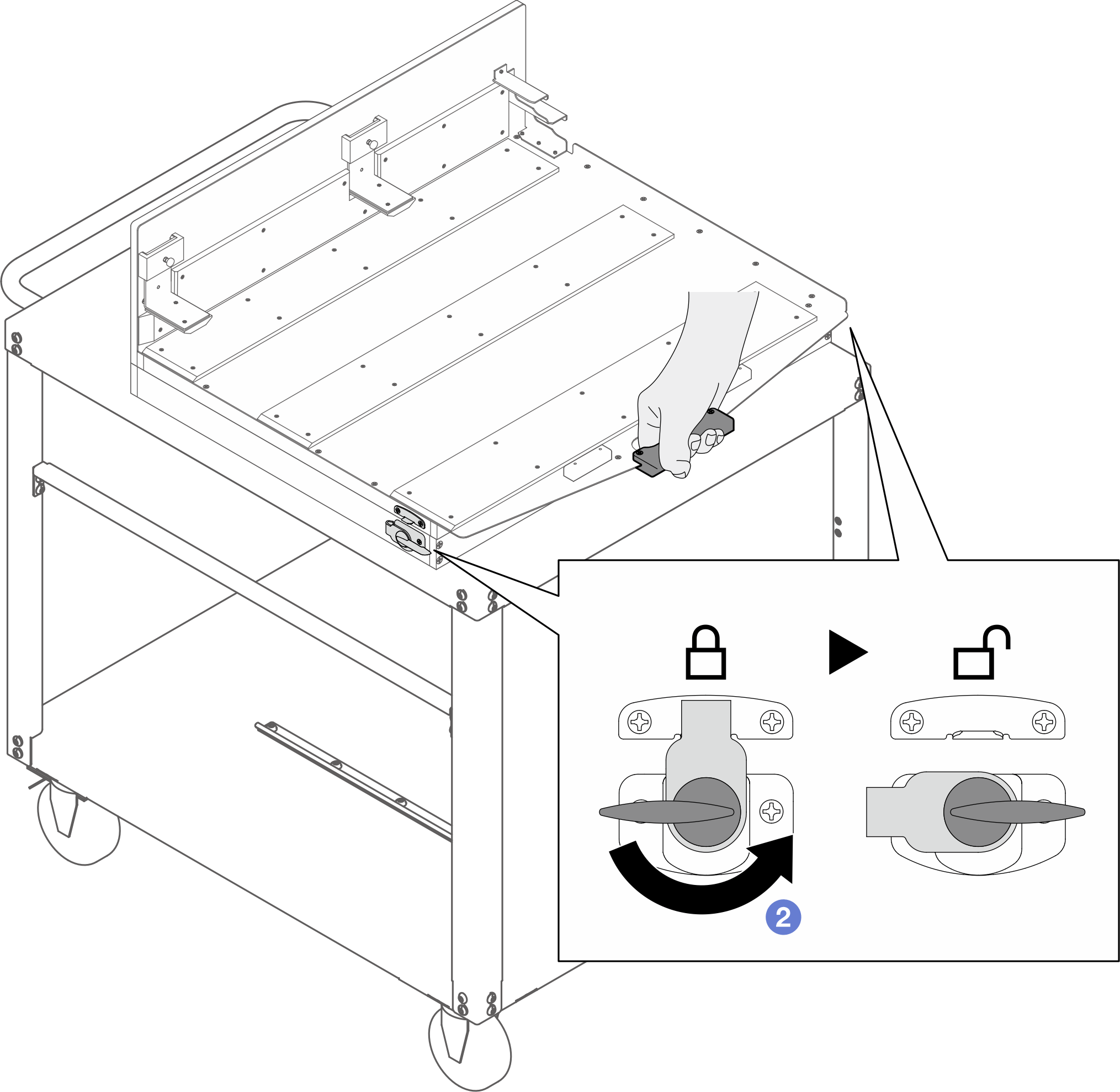

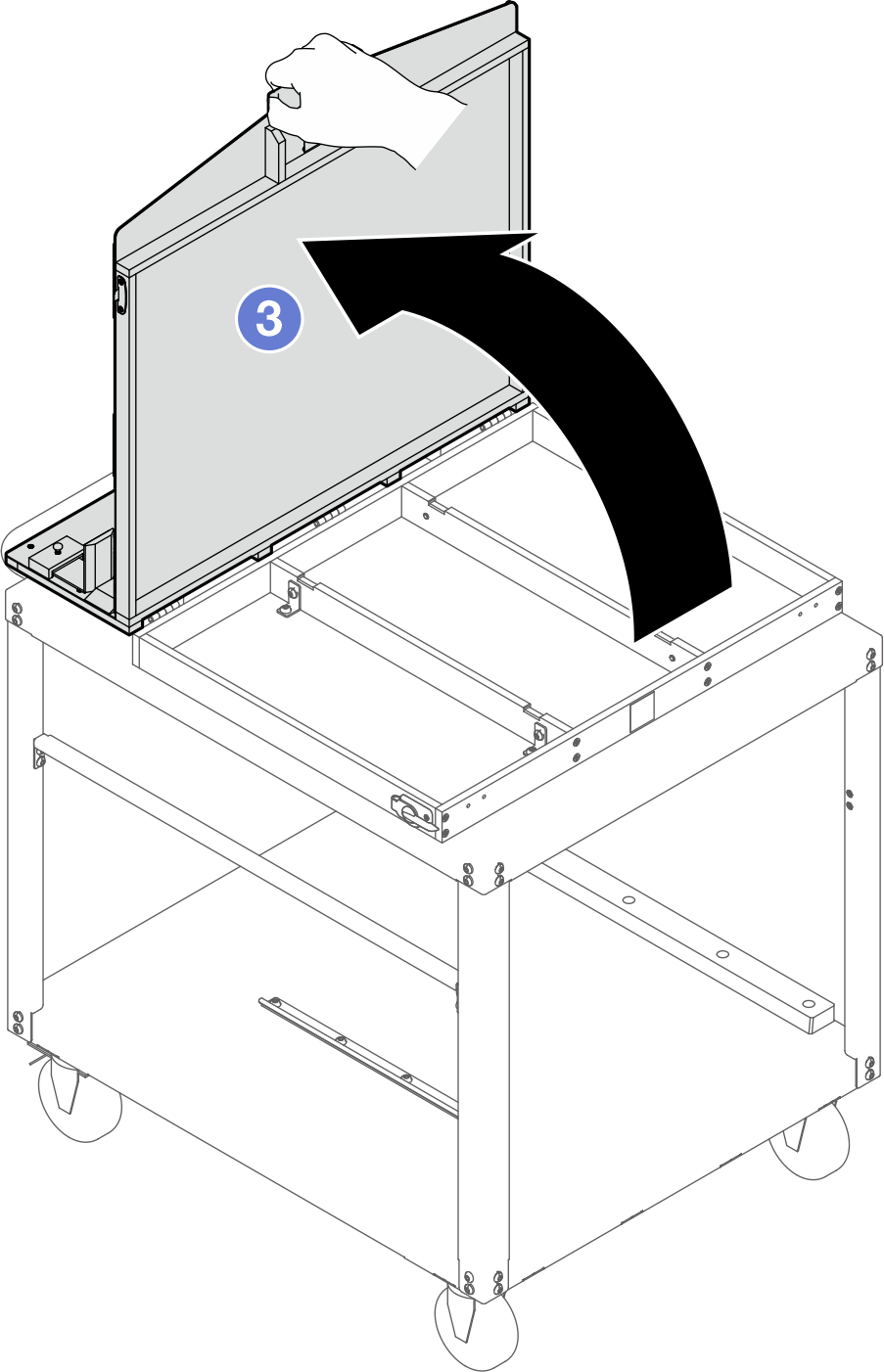

About this task

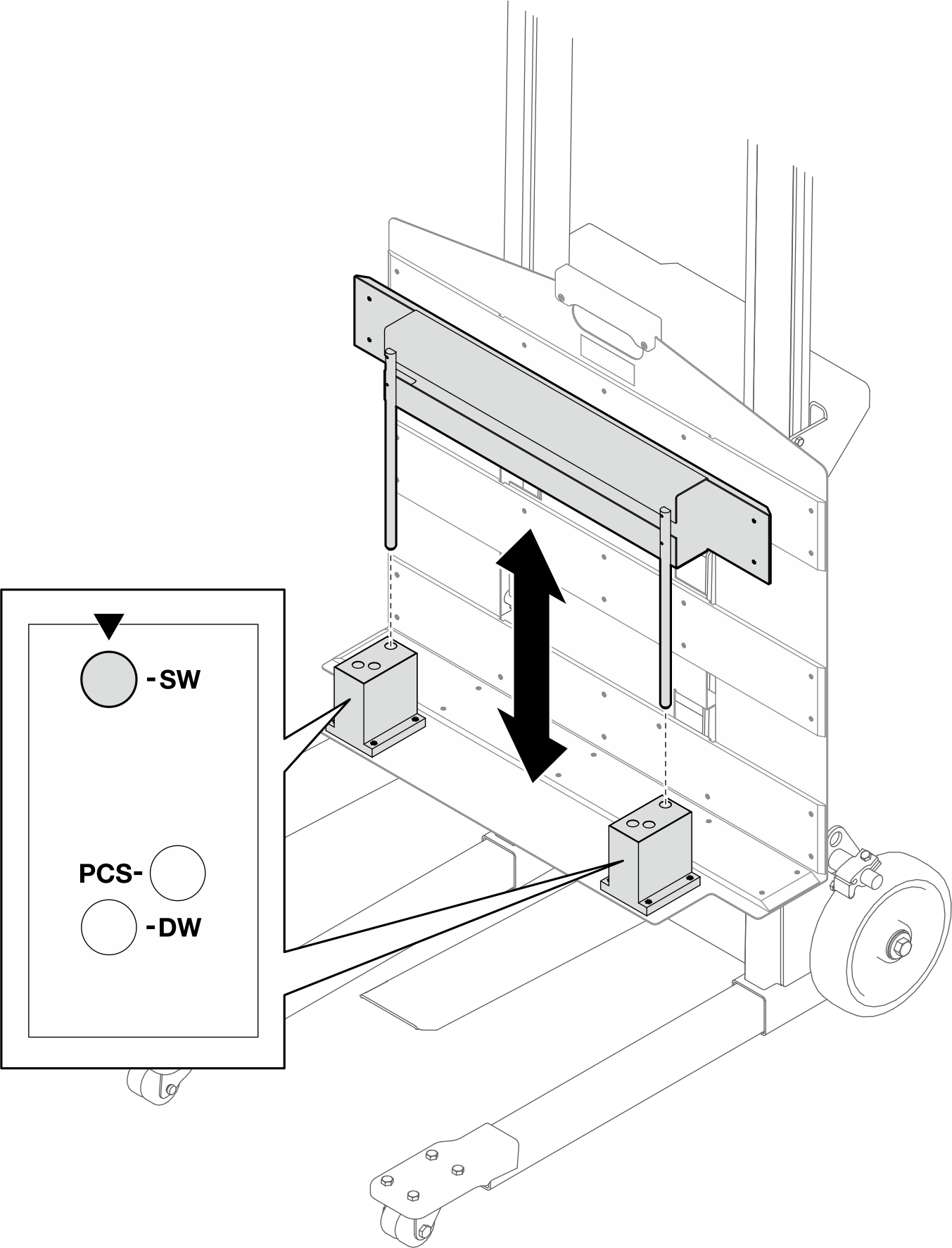

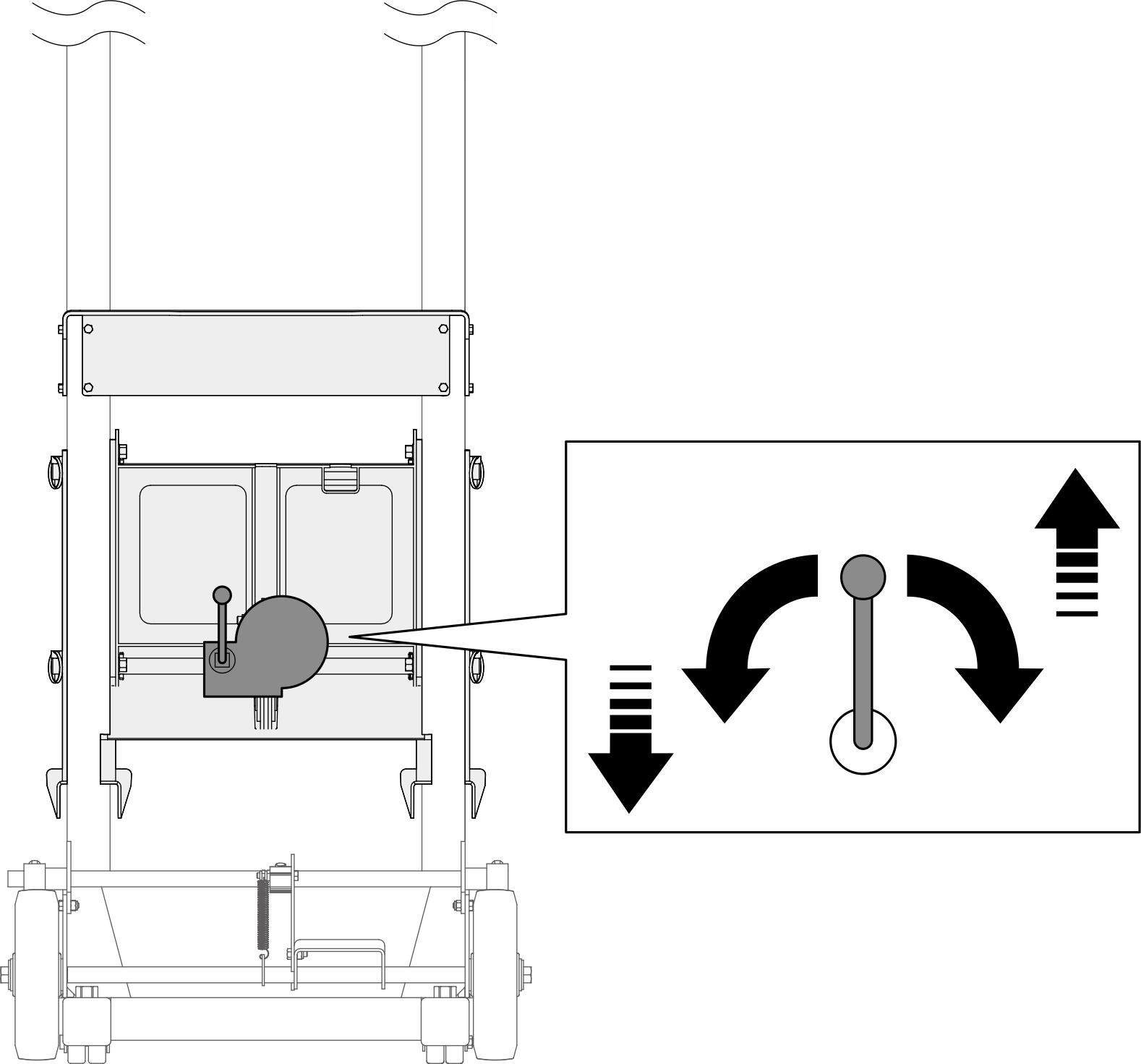

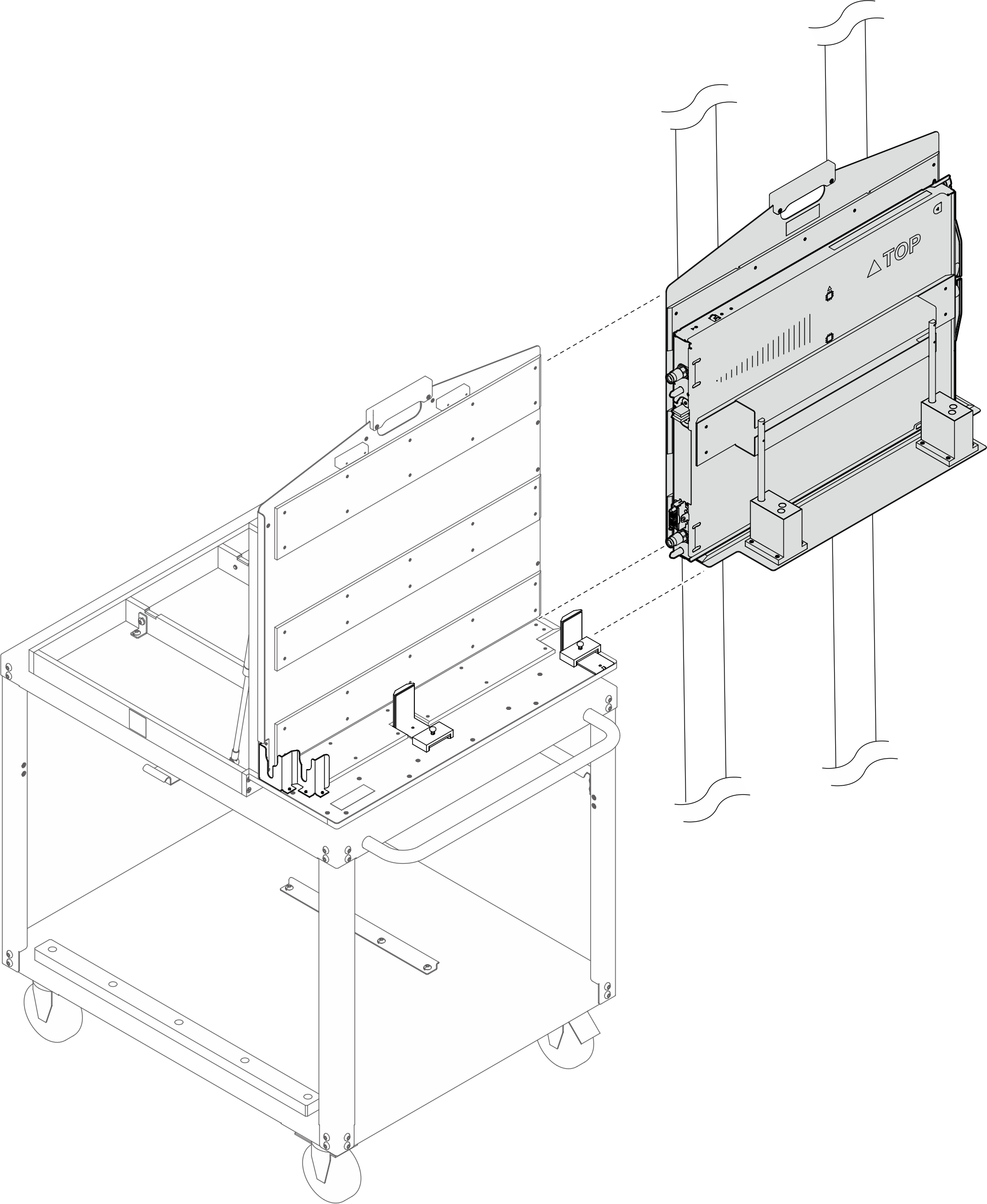

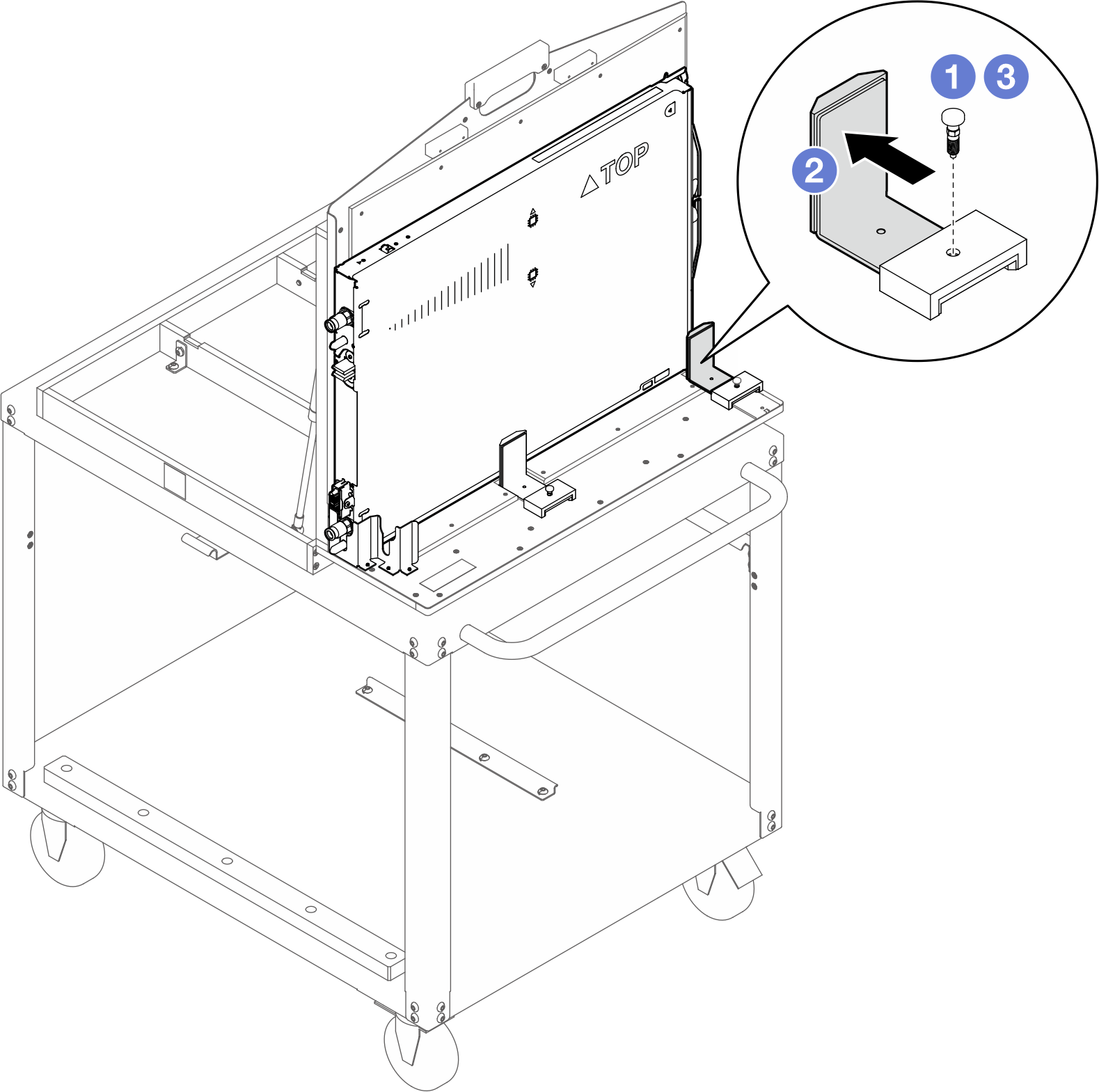

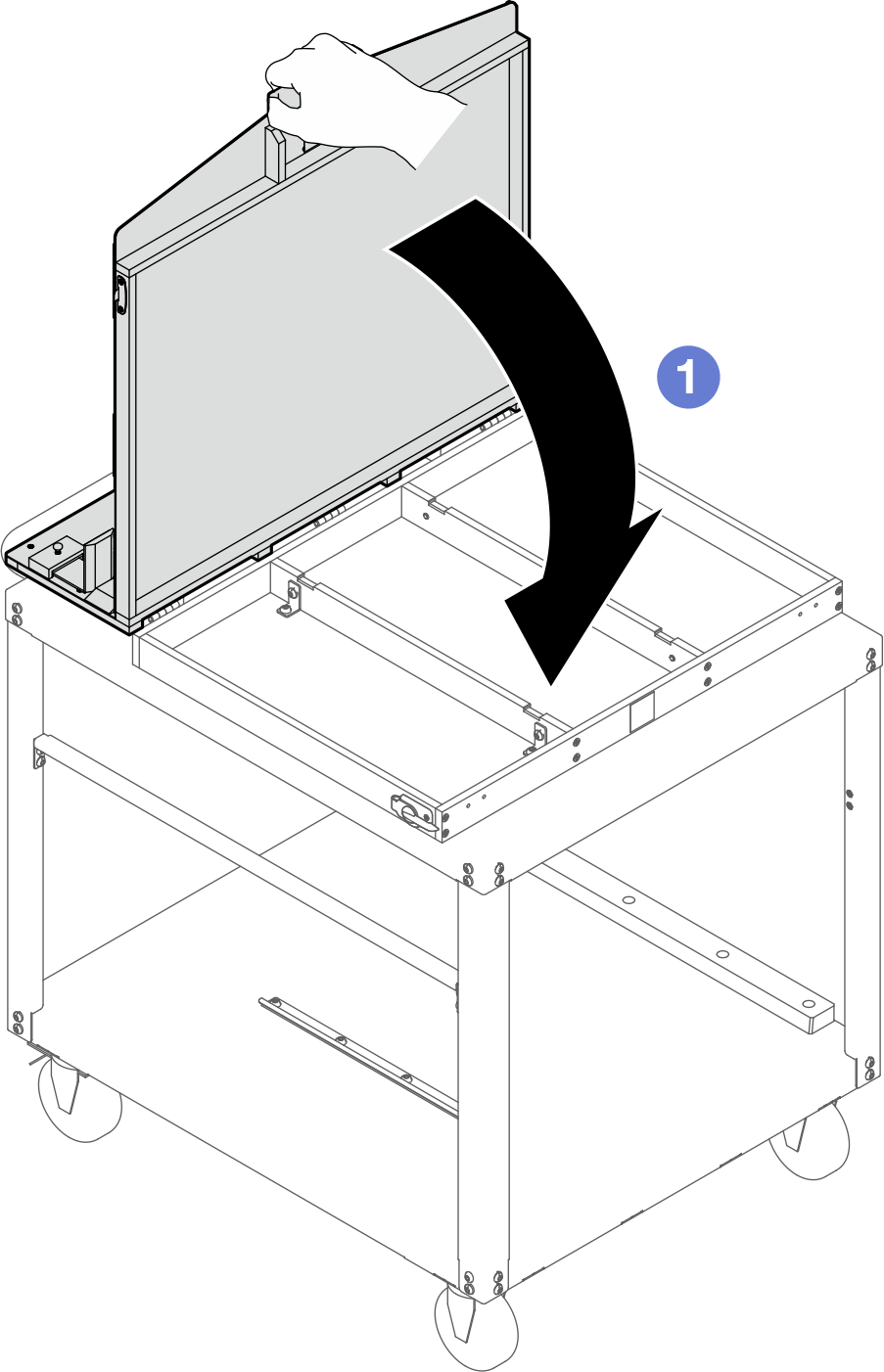

Lift tool assembly

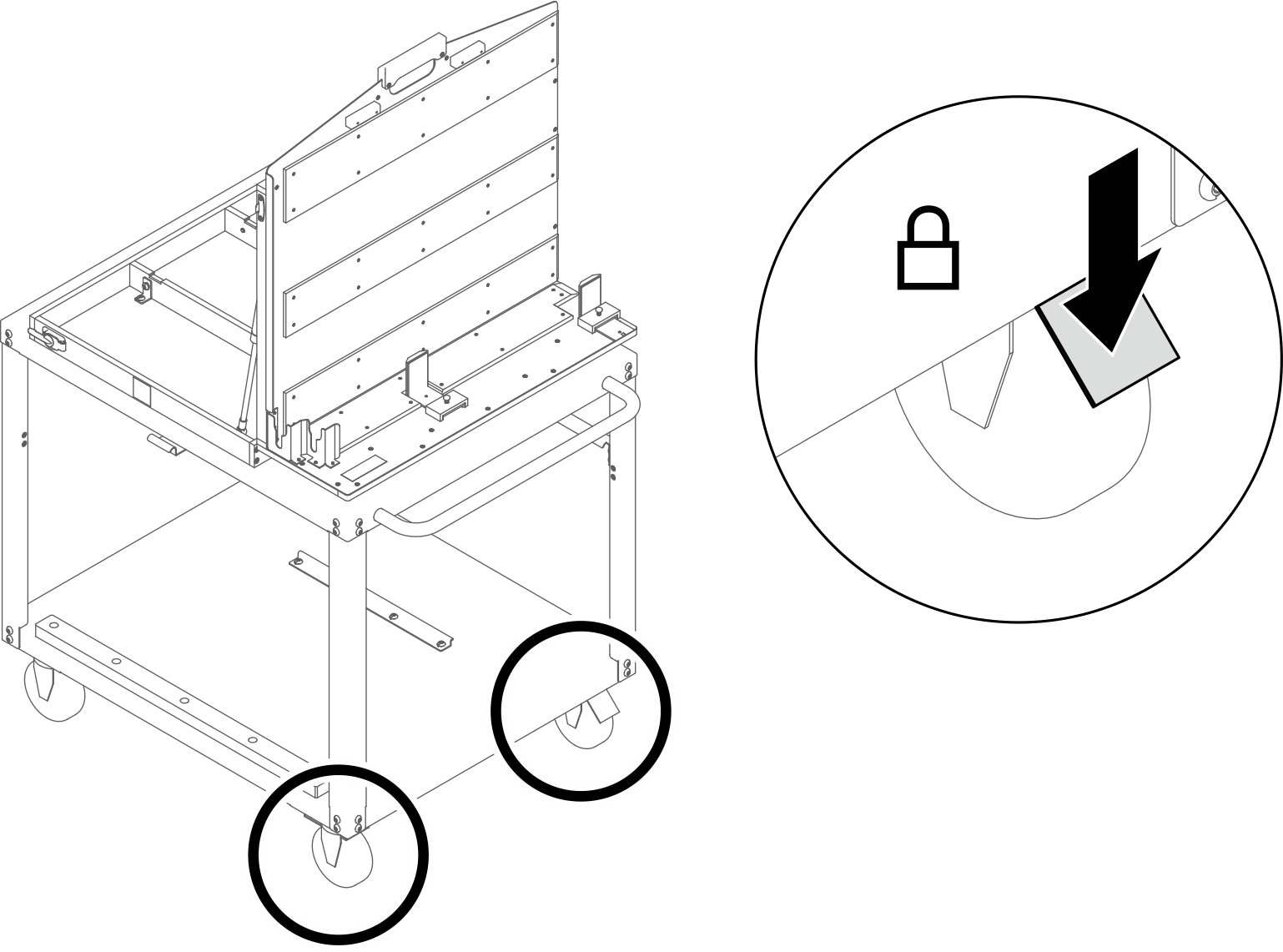

Genie GL-8 lift tool installed with the lift tool fixture. The foot-release brake should also be attached to the lift tool.

For assembling instructions, see Setting up the lift tool assembly

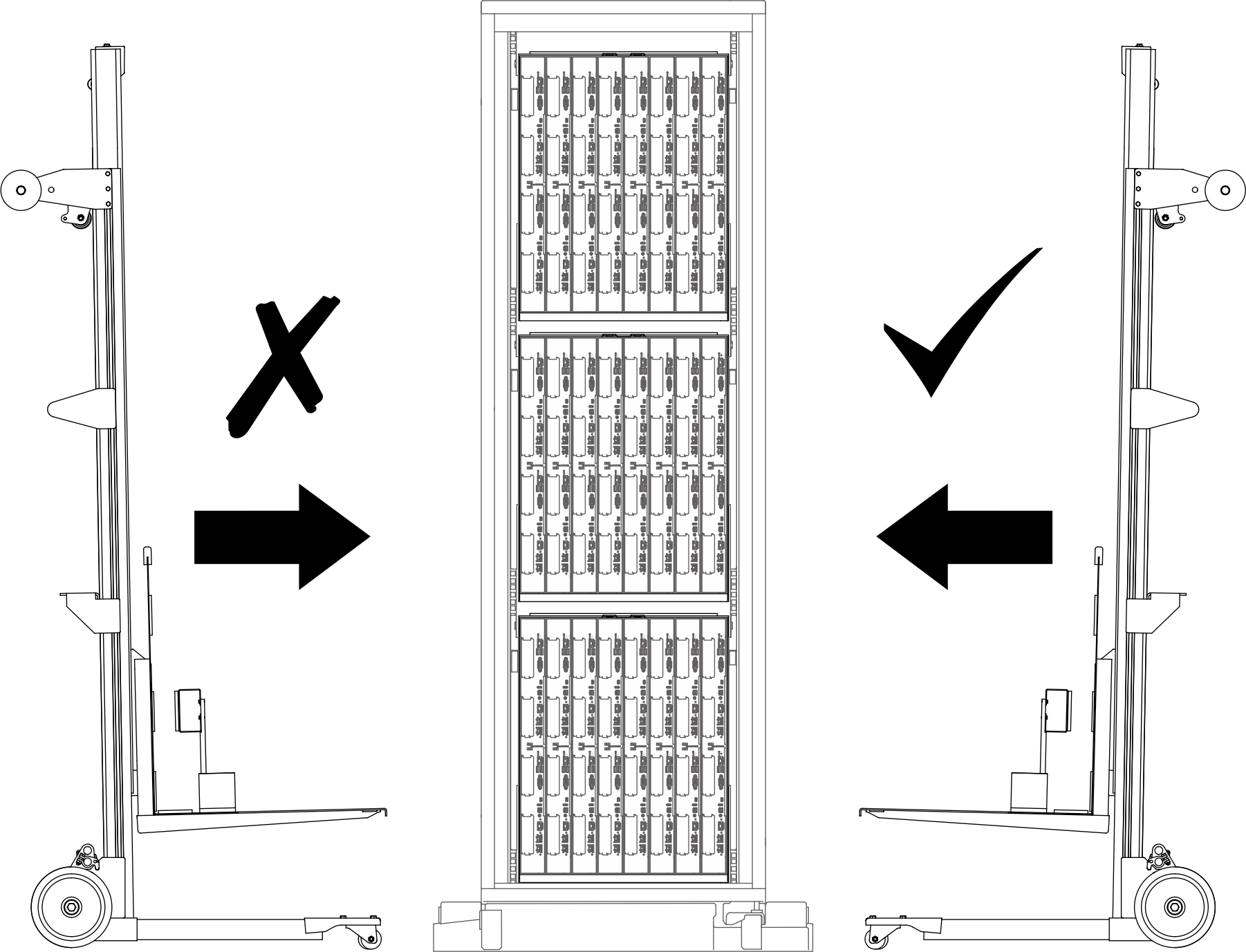

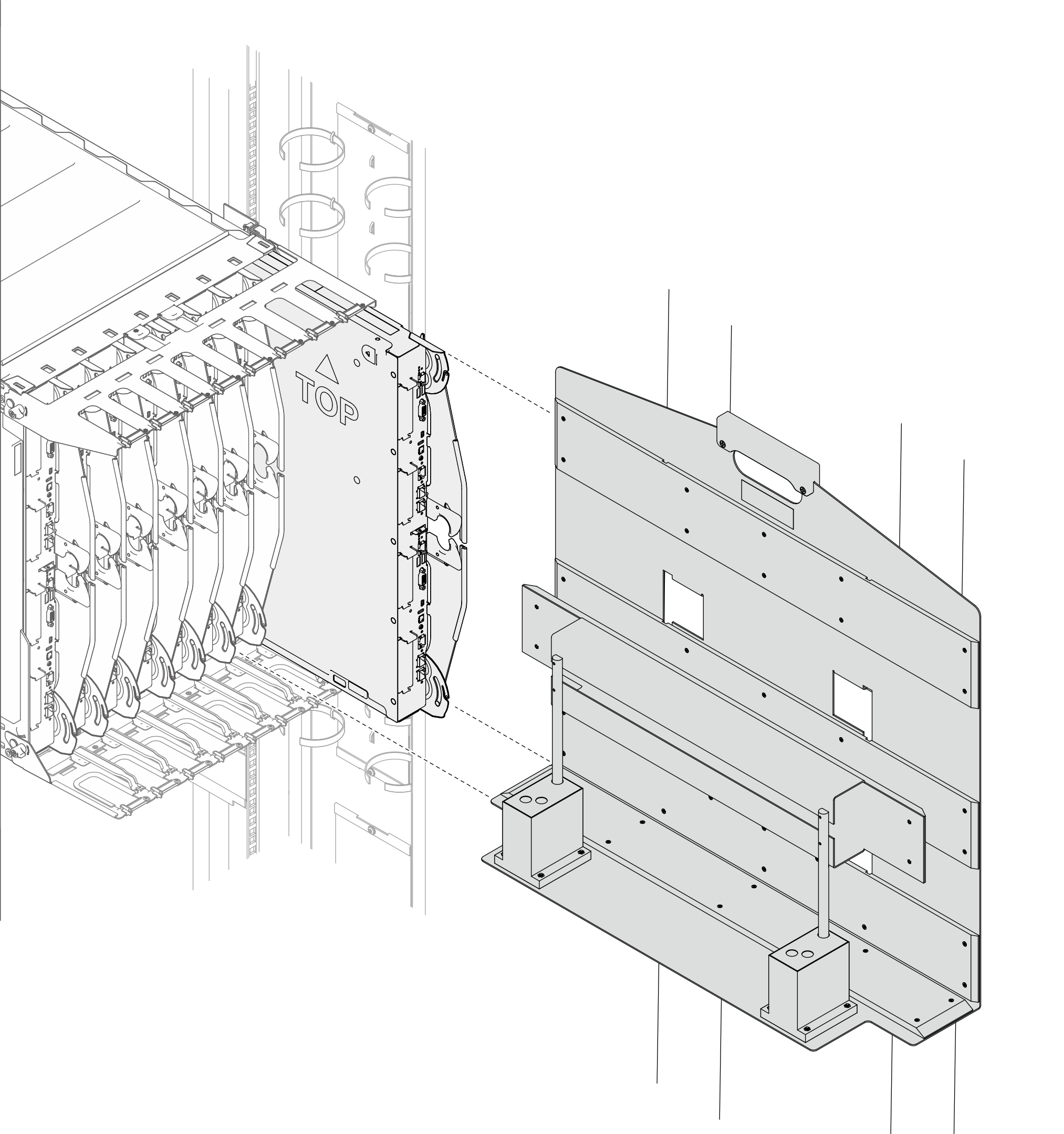

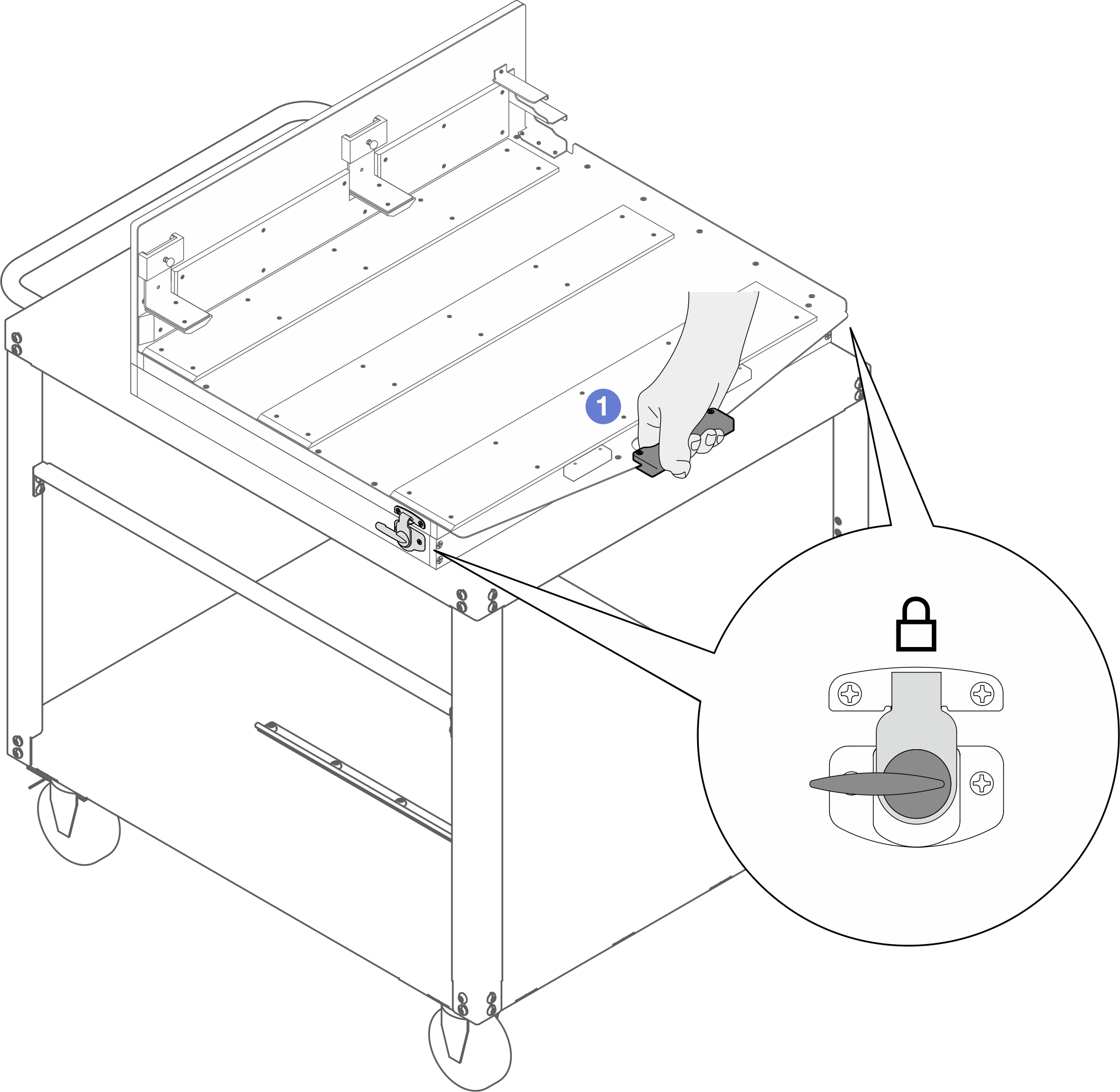

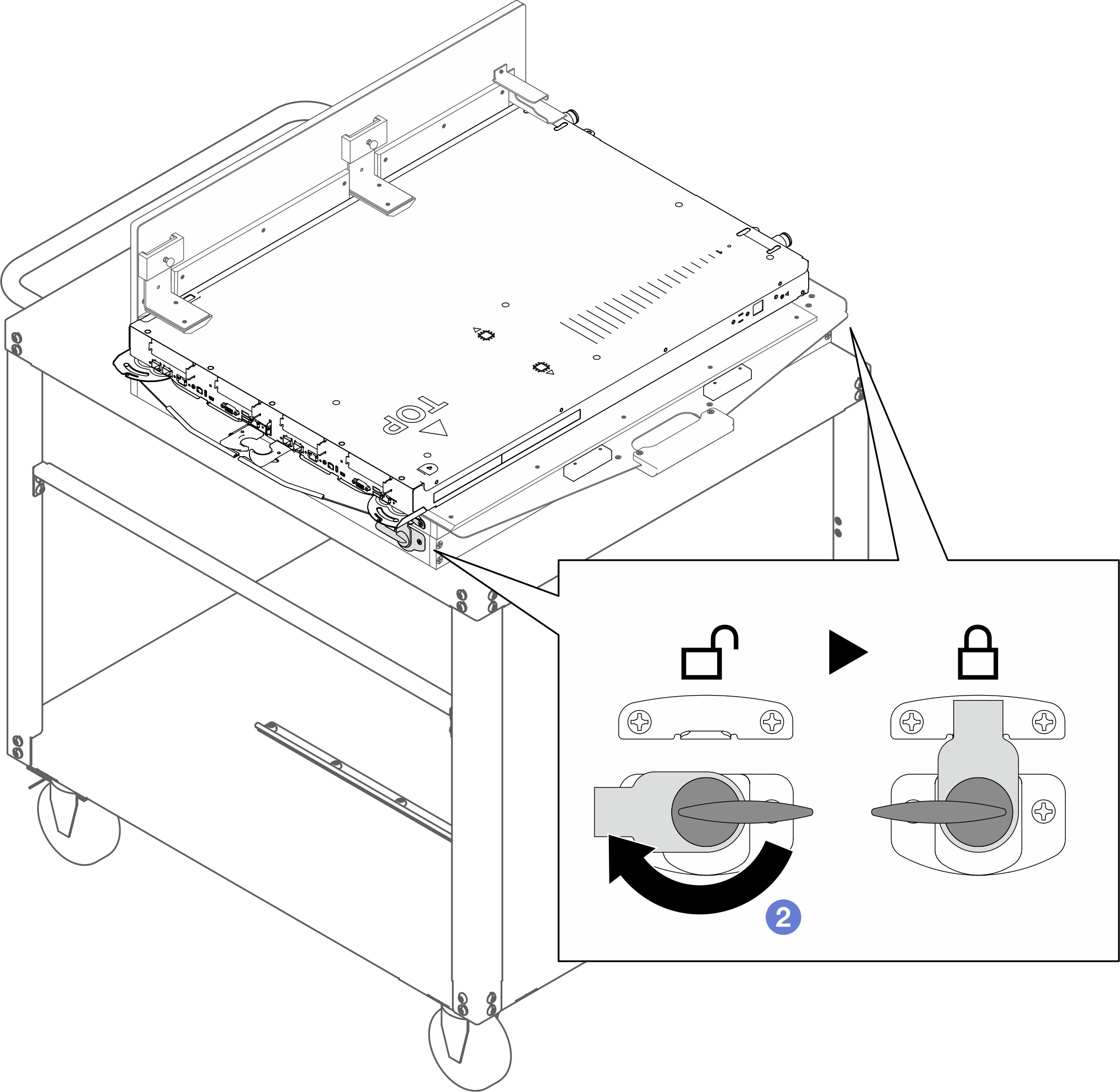

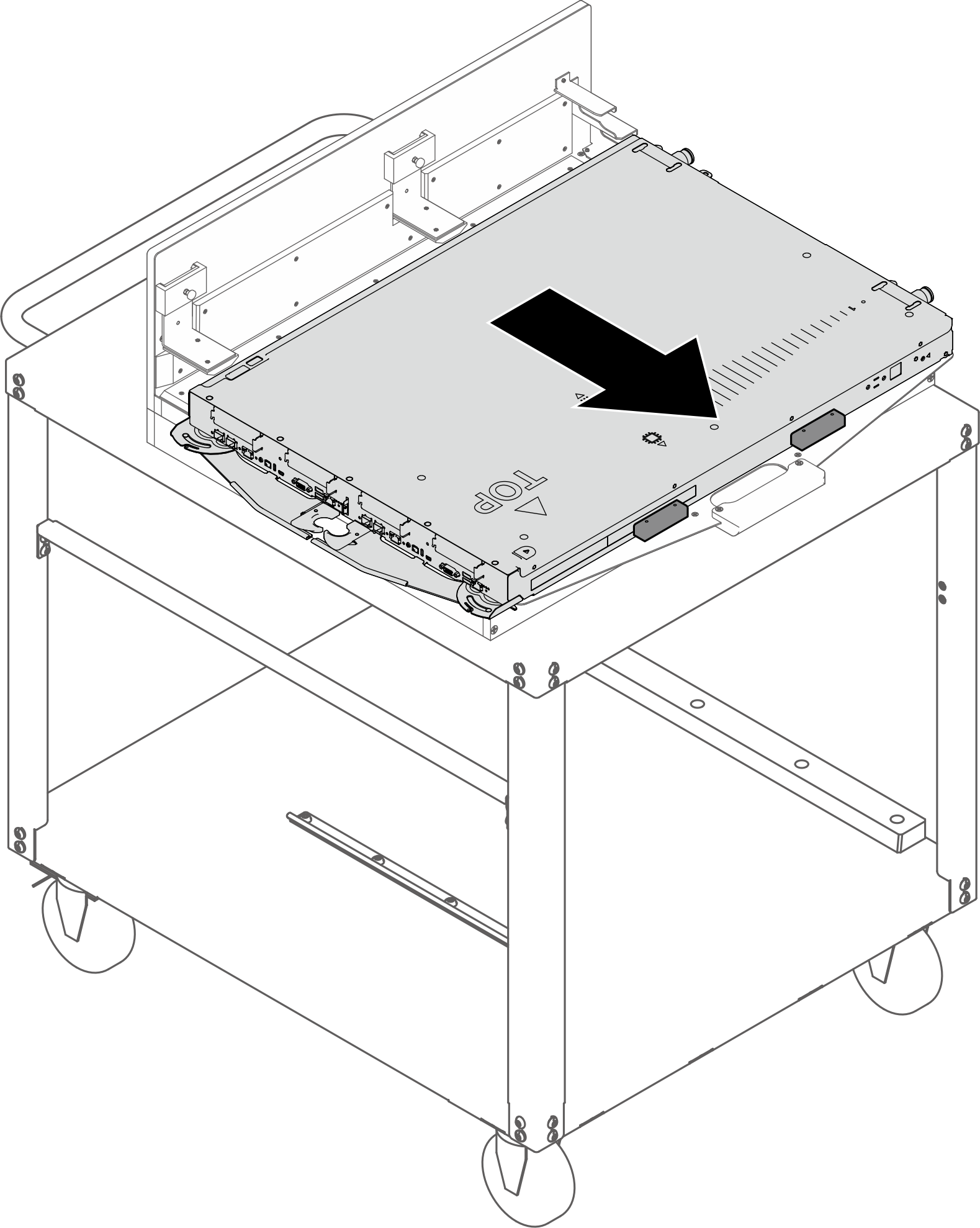

Rotate fixture cart assembly

Rotate fixture installed on the customized cart.

For assembling instructions, see Setting up the rotate fixture cart assembly

For mandatory tools ordering information, see ThinkSystem server options.

Read Installation Guidelines and Safety inspection checklist to ensure that you work safely.

Turn off the corresponding DWC tray that you are going to perform the task on.

Disconnect all external cables from the enclosure.

Use extra force to disconnect QSFP cables if they are connected to the solution.

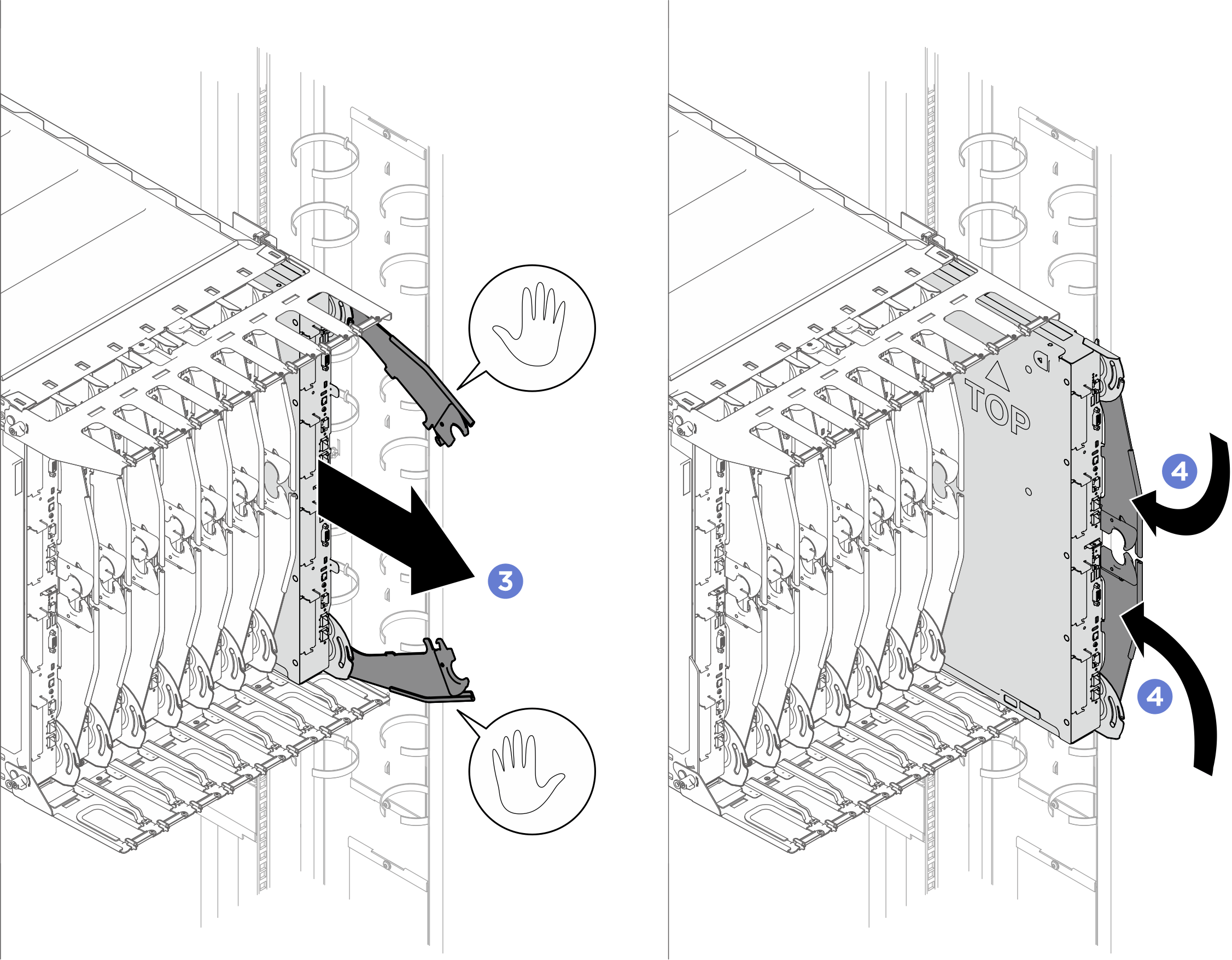

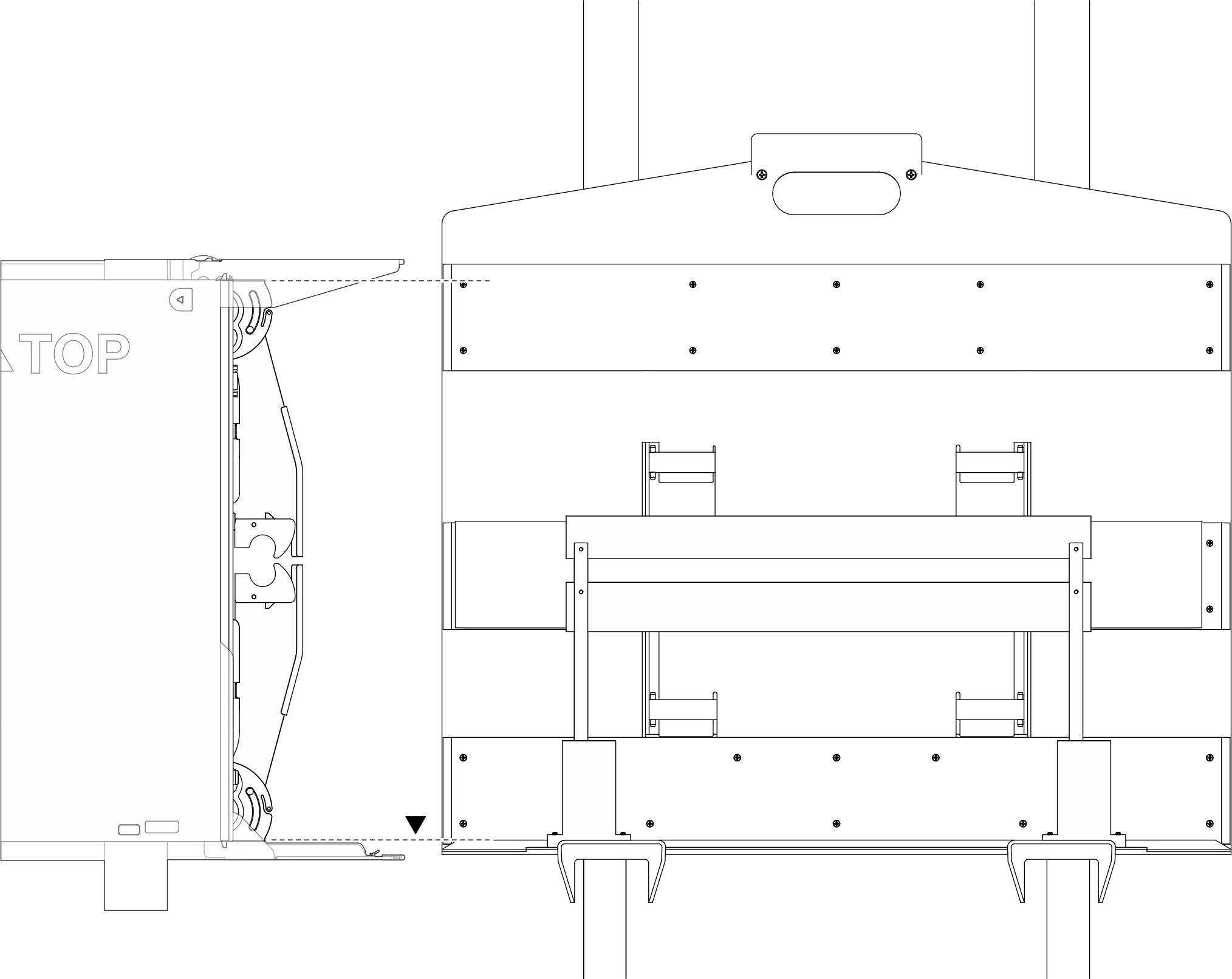

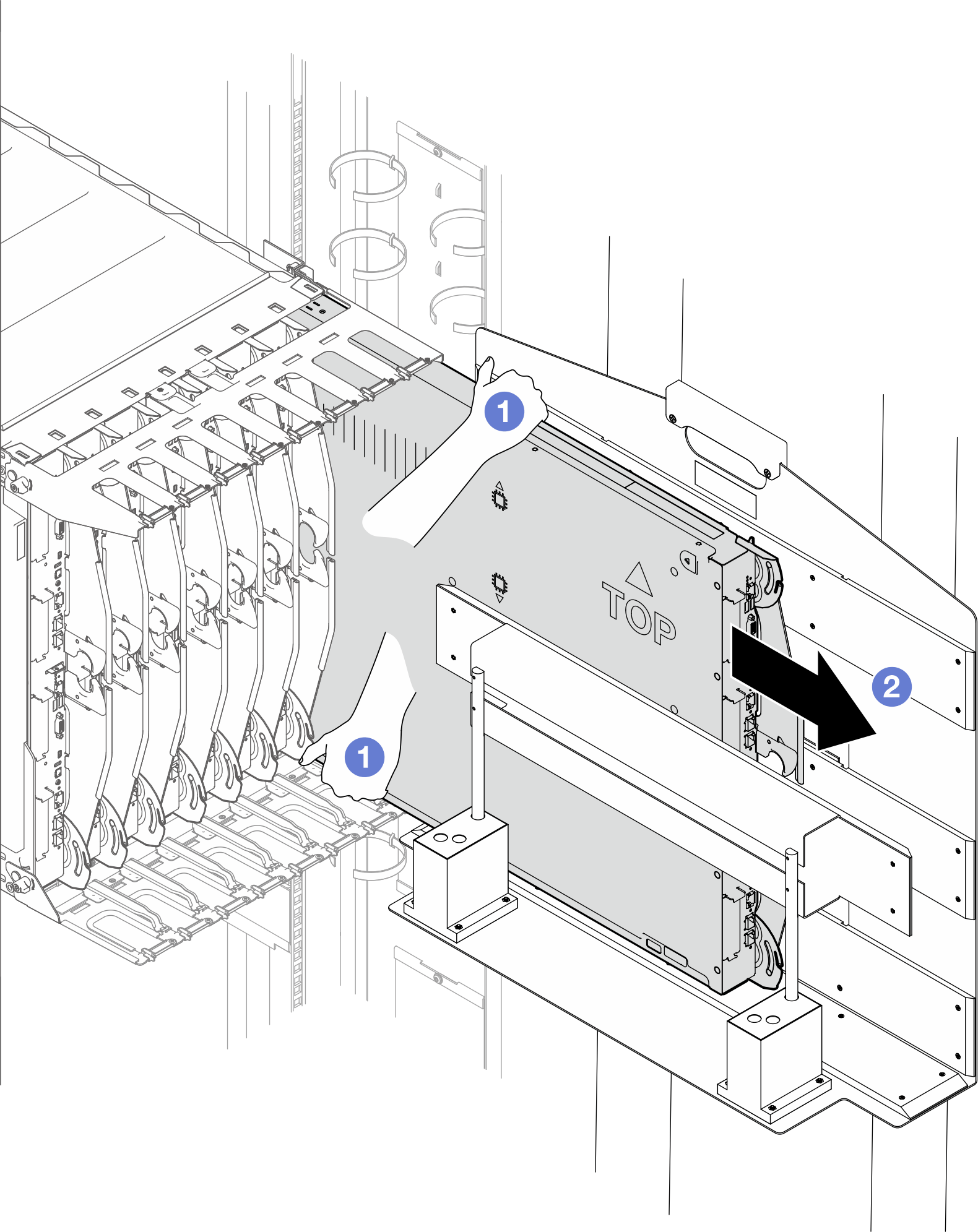

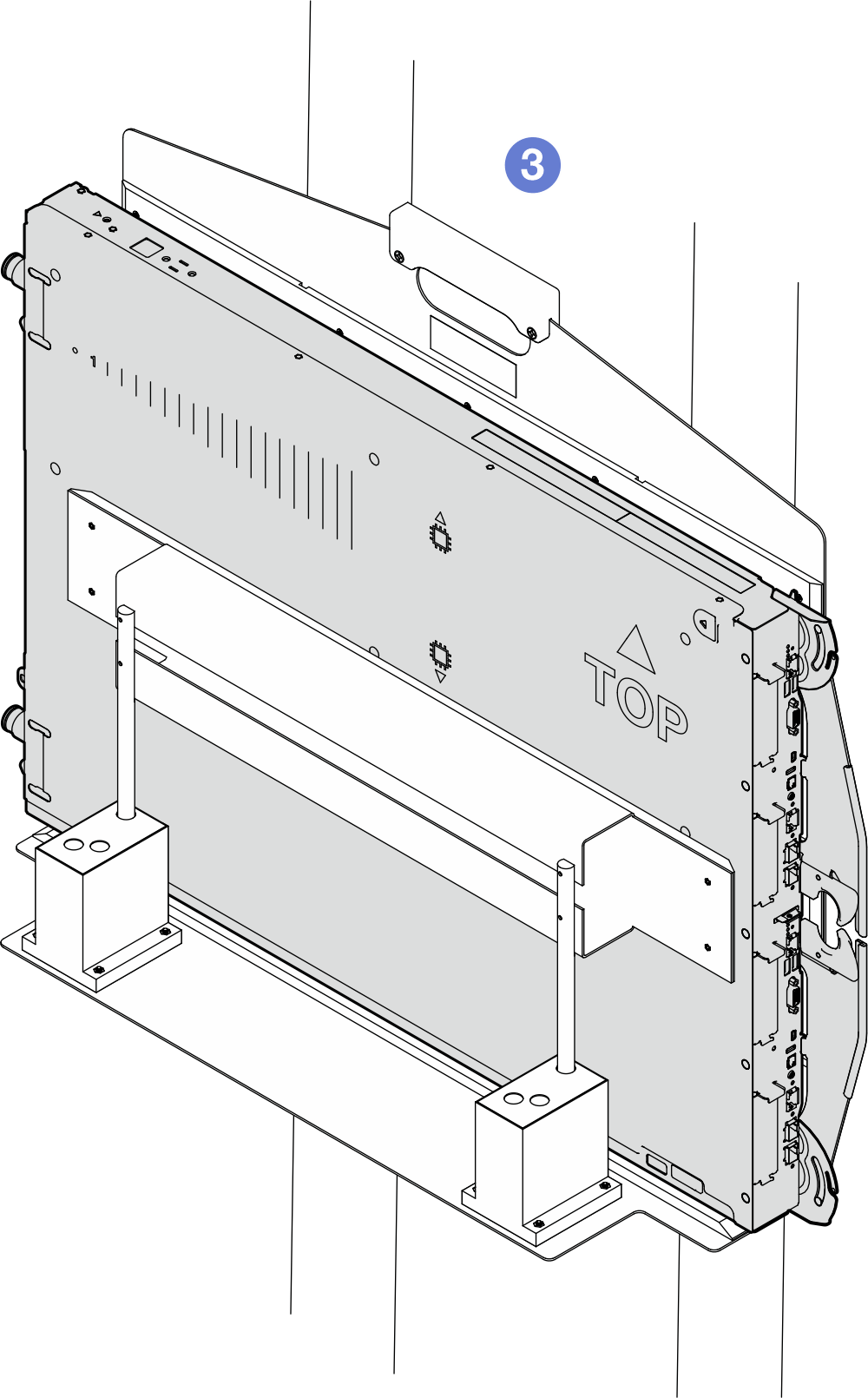

The following illustration might differ slightly from your hardware, but the removal method is the same.

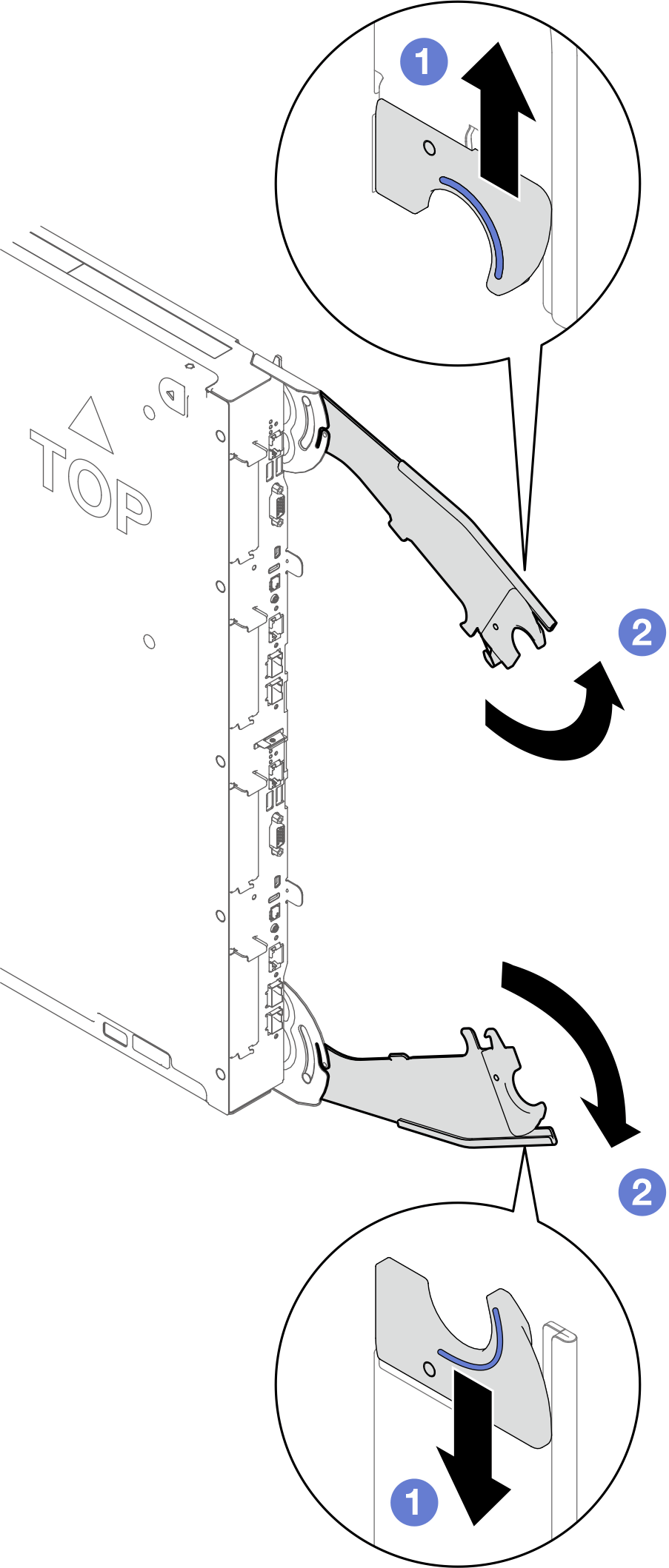

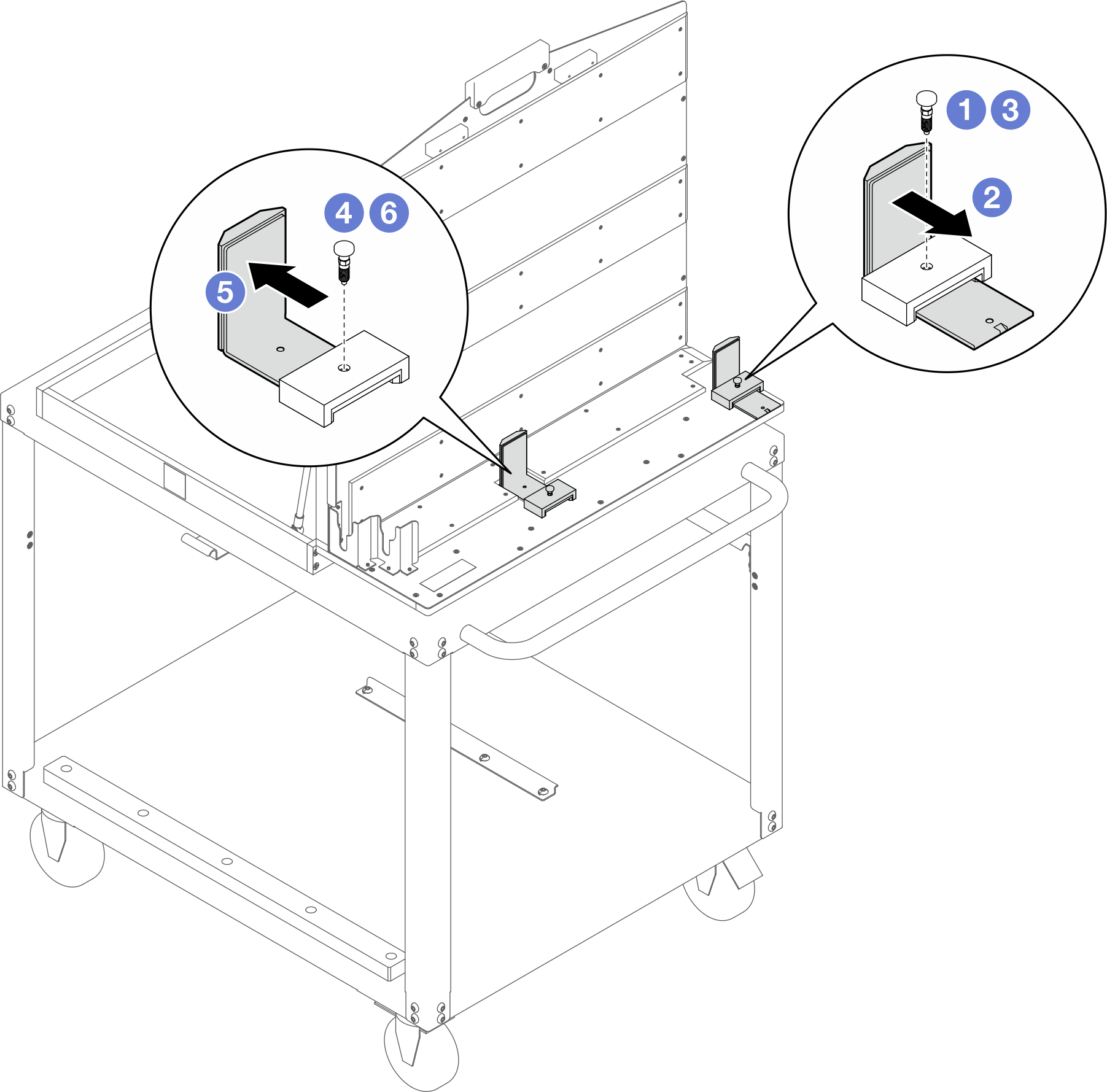

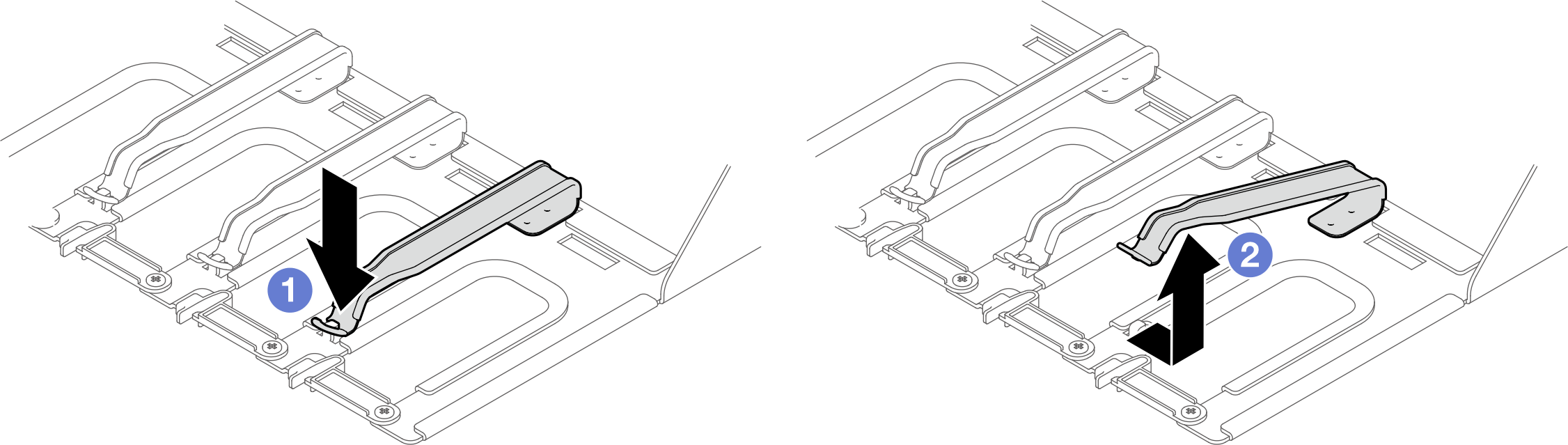

Opening the cable retainer

Press down the cable retainer.

Press down the cable retainer. Pull the cable retainer to the right; then, pull it up.

Pull the cable retainer to the right; then, pull it up.

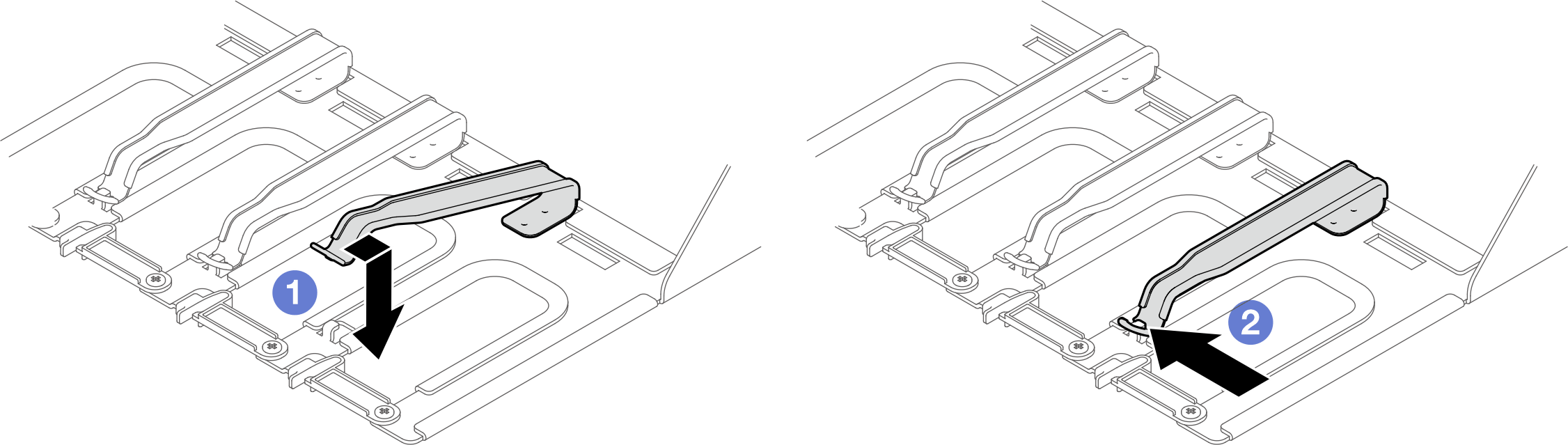

Closing the cable retainer

Pull the cable retainer to the right; then, press it down.

Pull the cable retainer to the right; then, press it down. Pull the cable retainer to the left to secure it to the support bracket.

Pull the cable retainer to the left to secure it to the support bracket.

- A video of this procedure is available at YouTube.

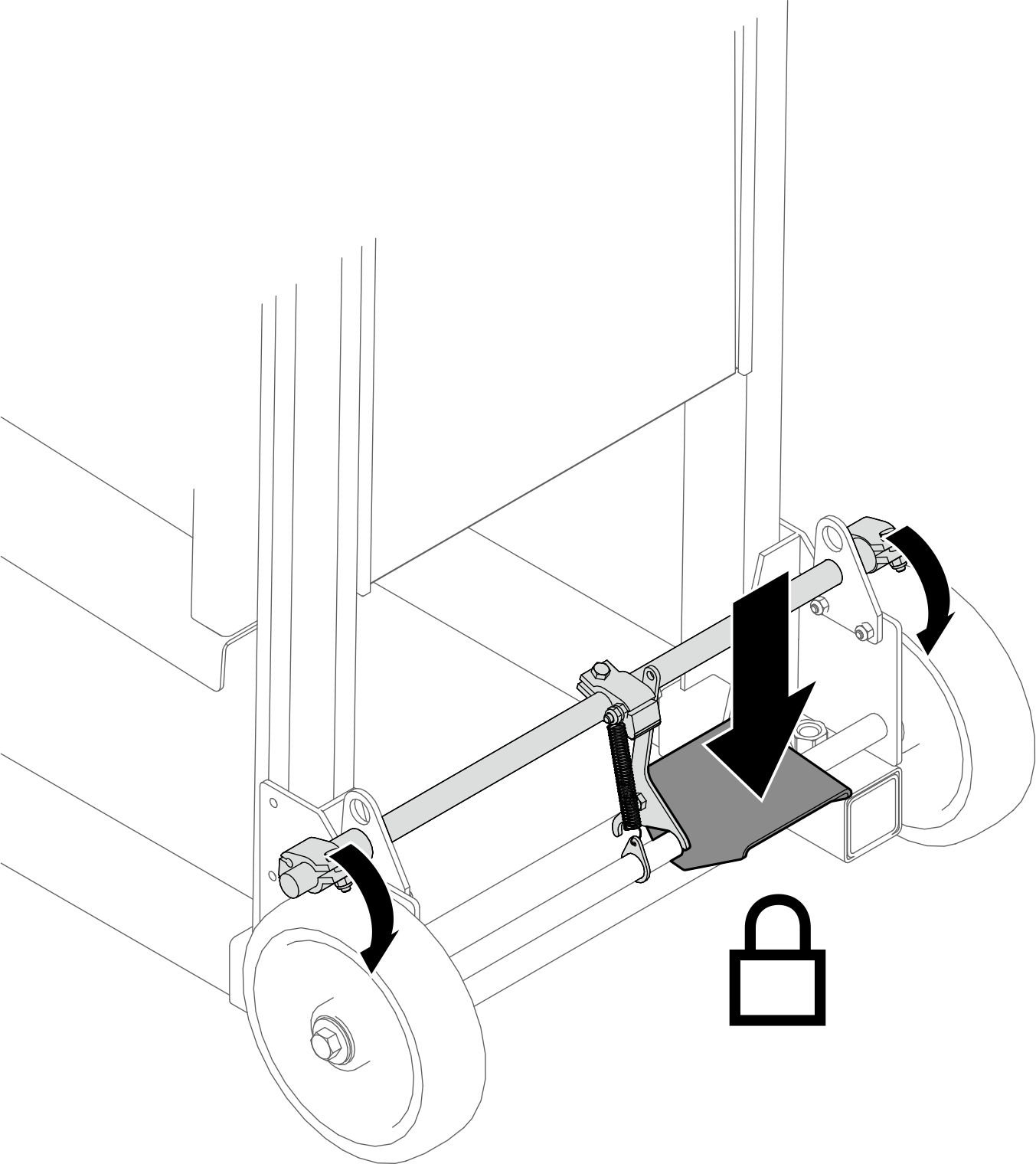

Procedure

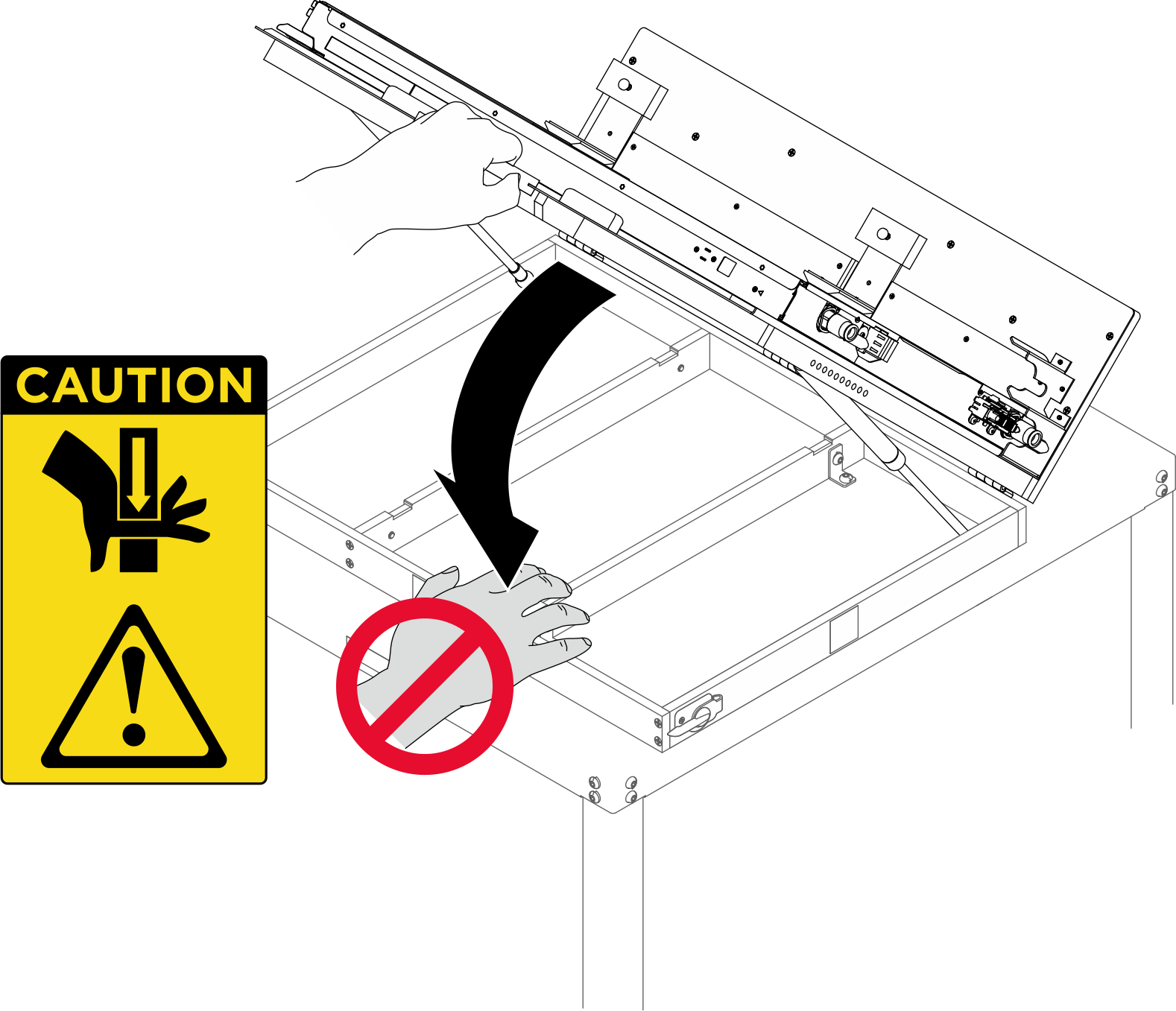

The tray might be very hot. Wait several minutes to let the tray cool before removing the tray cover.

If you are instructed to return the component or optional device, follow all packaging instructions, and use any packaging materials for shipping that are supplied to you.