Install the water loop in SD650 V2 tray

Use this information to install the water loop in SD650 V2 tray.

About this task

- Read the following sections to ensure that you work safely.

- Turn off the corresponding DWC tray that you are going to perform the task on.NoteIf Shared I/O adapters are installed, power off the auxiliary node (node 1/3/5/7/9/11) first, and then power off the primary node (node 2/4/6/8/10/12).

- Disconnect all external cables from the enclosure.NoteUse extra forces to disconnect QSFP cables if they are connected to the solution.

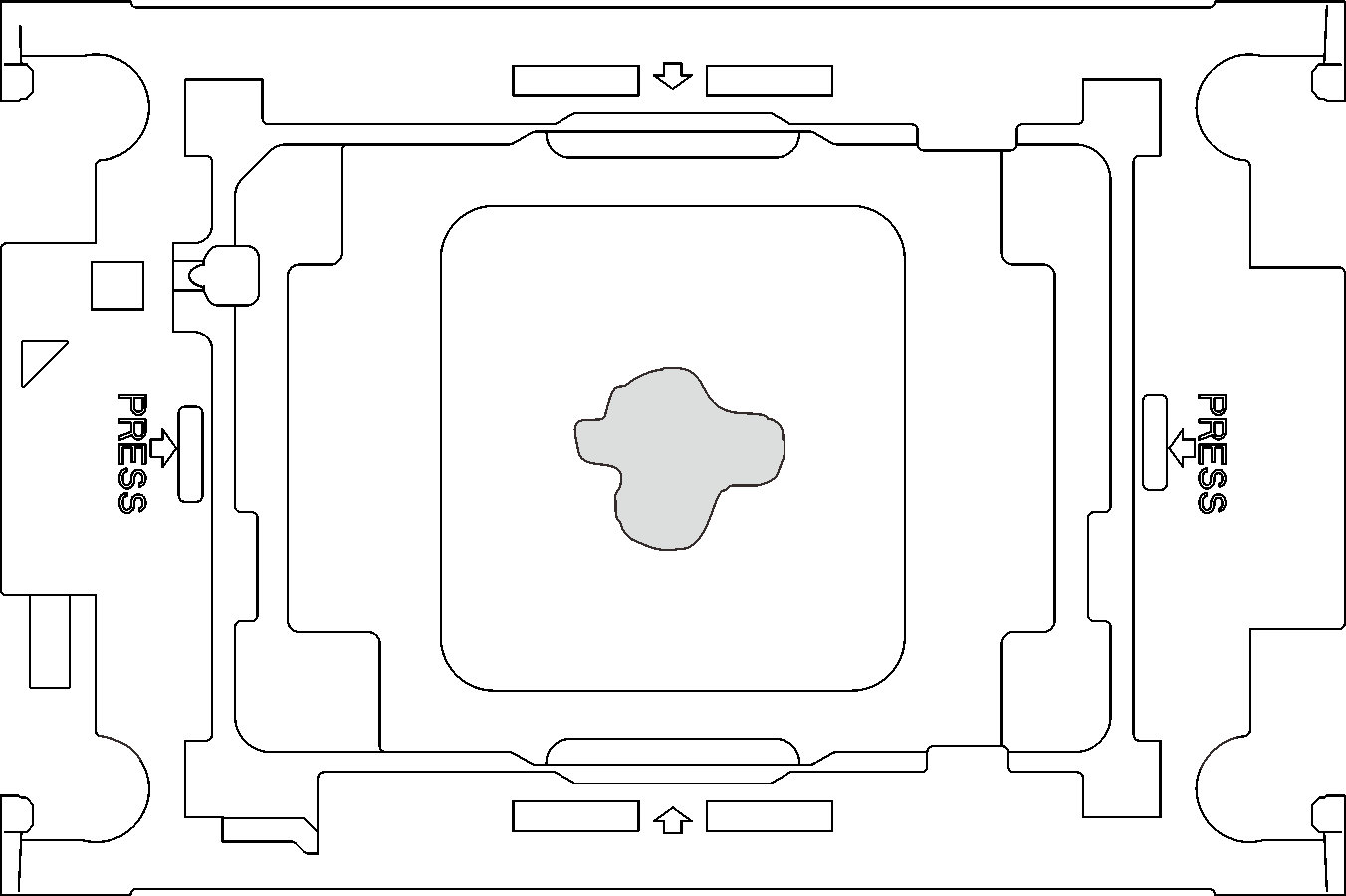

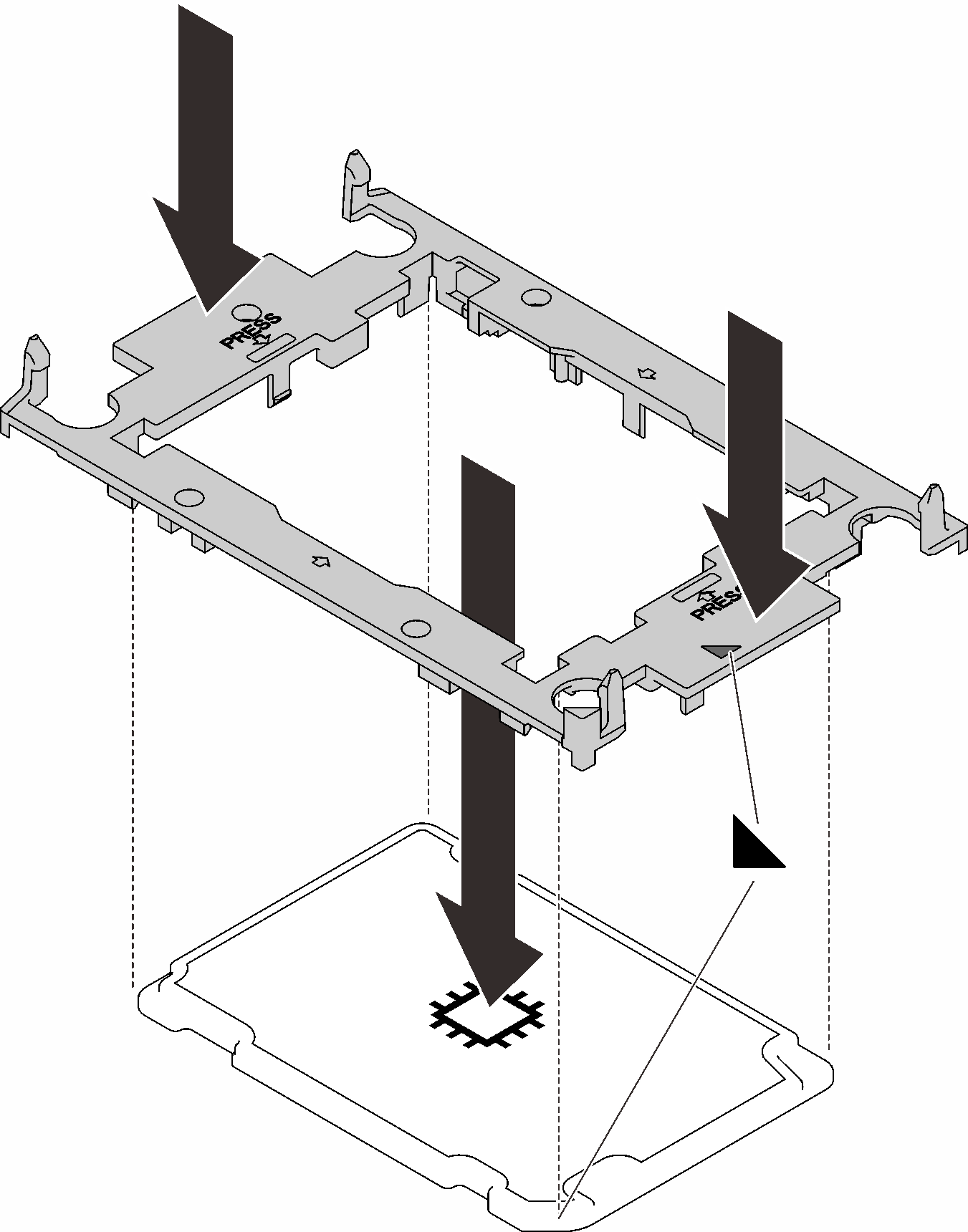

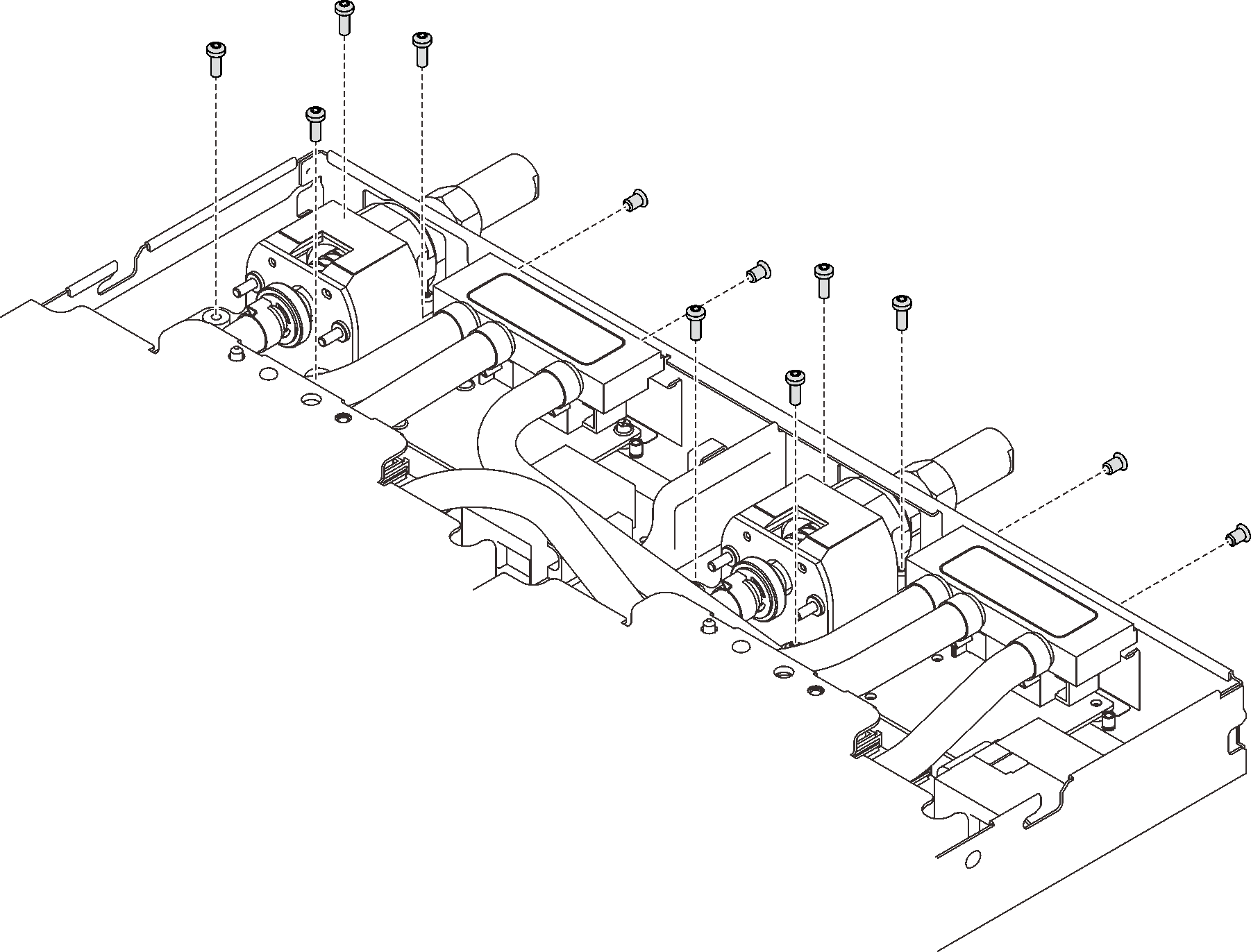

To avoid damaging the water loop, always use the water loop carrier when removing, installing or folding the water loop.

Ensure you have “SD650 V2 or SD650-N V2 Neptune® DWC Waterloop Service Kit “ in hand to install components.

| Screwdriver Type | Screw Type |

| Torx T10 head screwdriver | Torx T10 screw |

| Torx T30 head screwdriver | Torx T30 screw |

| Phillips #1 head screwdriver or 3/16" hex head screwdriver | Phillips #1 screw |

| Phillips #2 head screwdriver | Phillips #2 screw |

Procedure

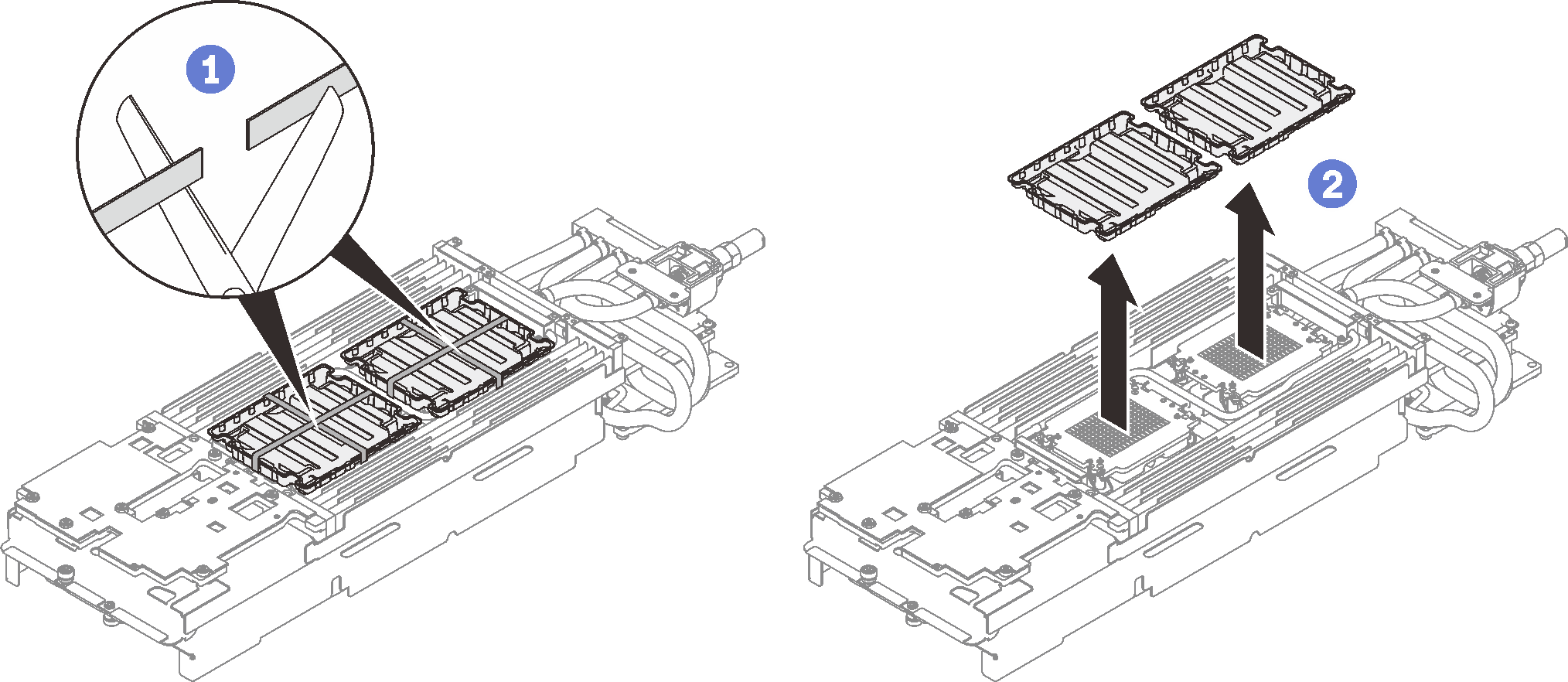

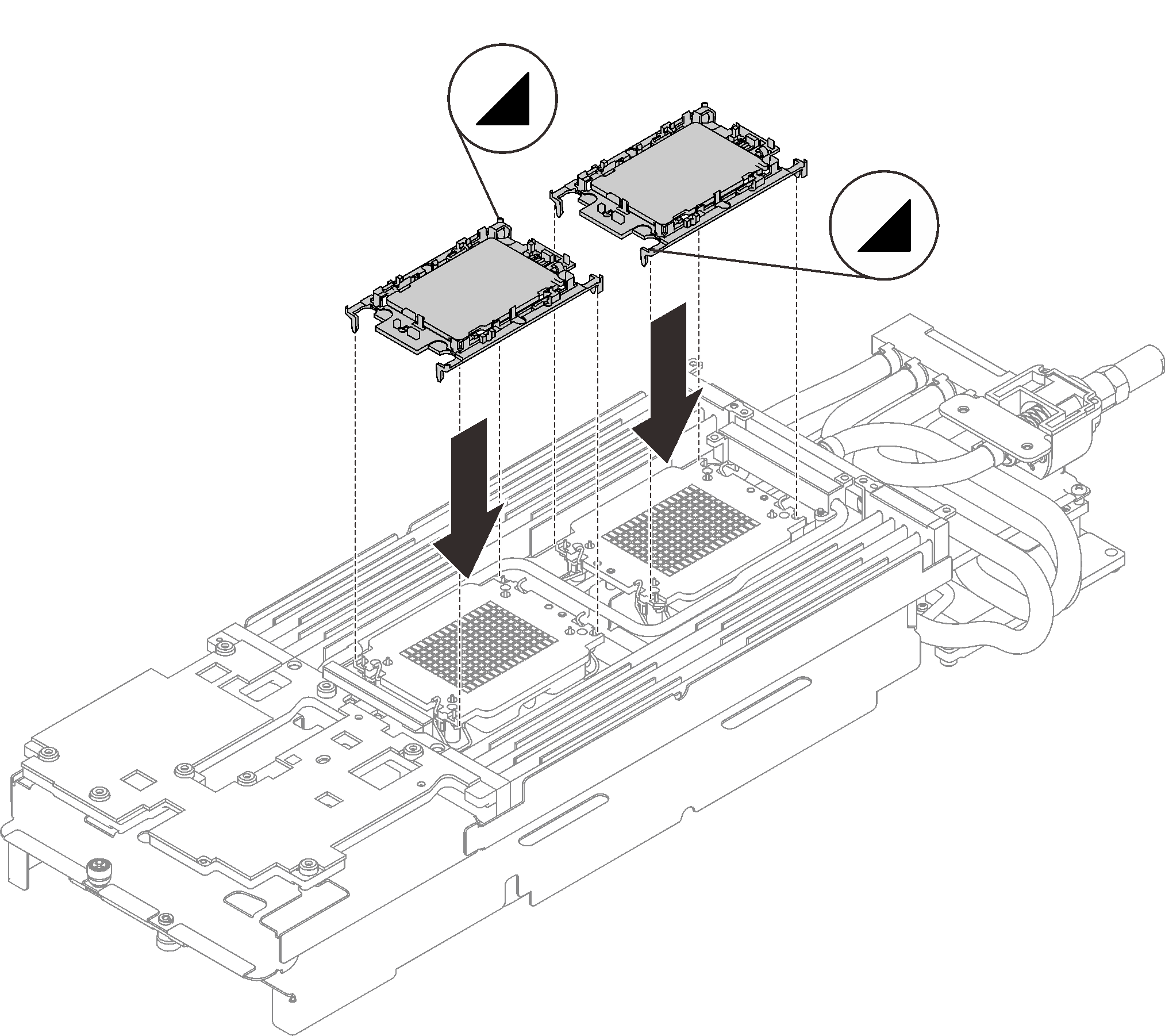

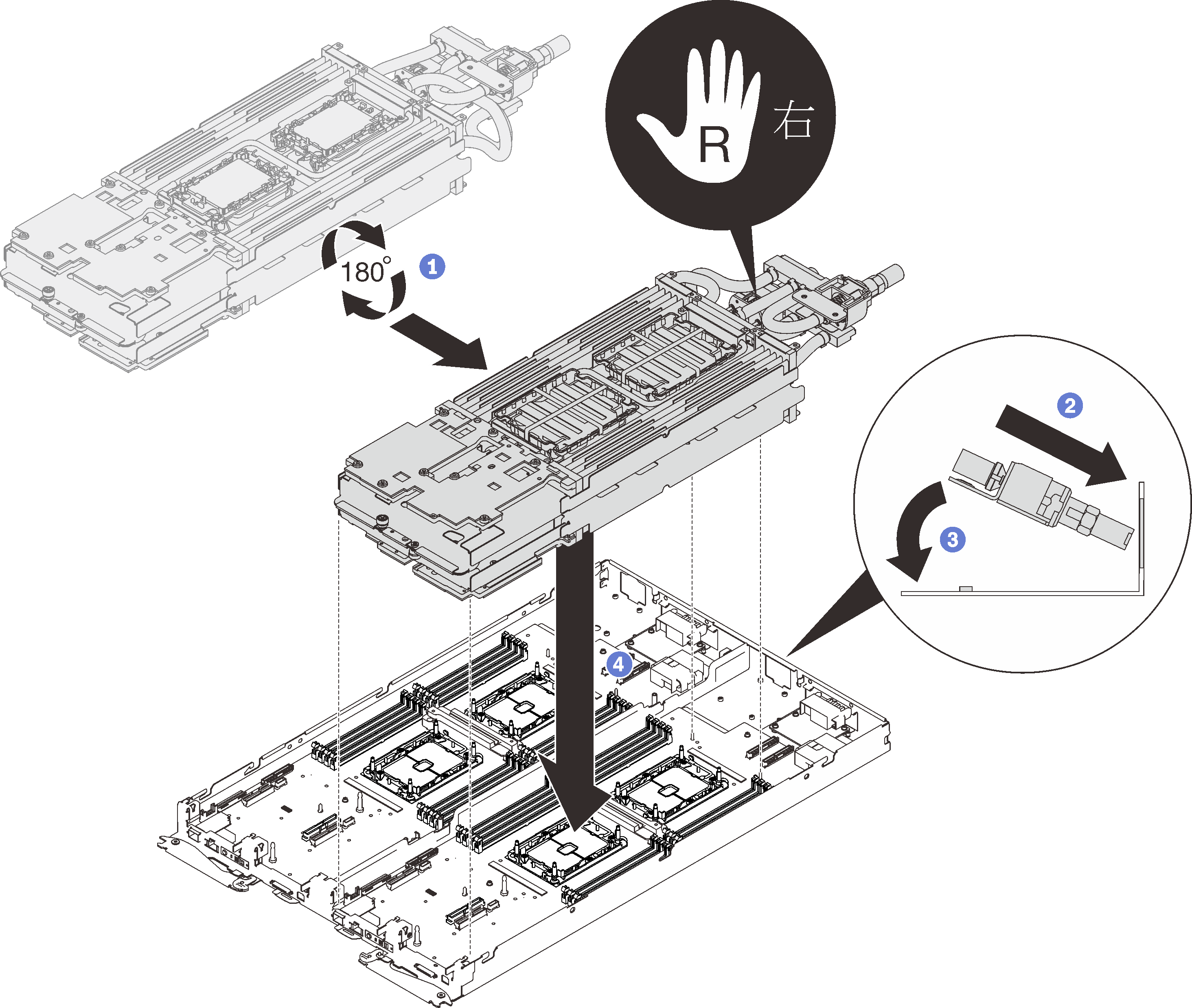

Reinstall DIMMs for both nodes (see Install a memory module).

Reinstall DIMM combs. (see Install a DIMM comb).

Reinstall M.2 backplanes (see Install the M.2 backplane).

Reinstall drive cage assemblies if applicable (see Install a drive cage assembly).

Reinstall PCIe rise assemblies if applicable (see Install a PCIe adapter).

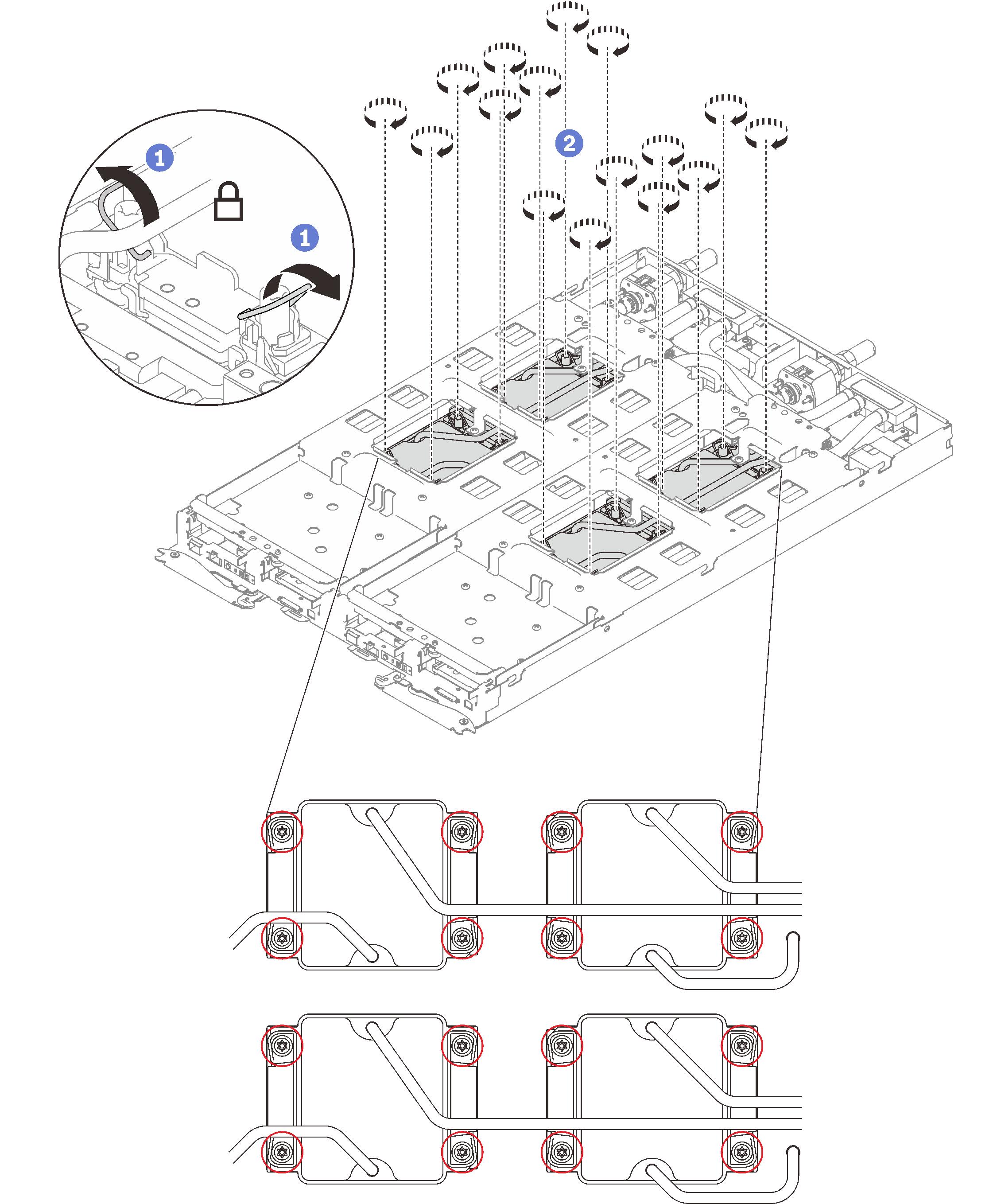

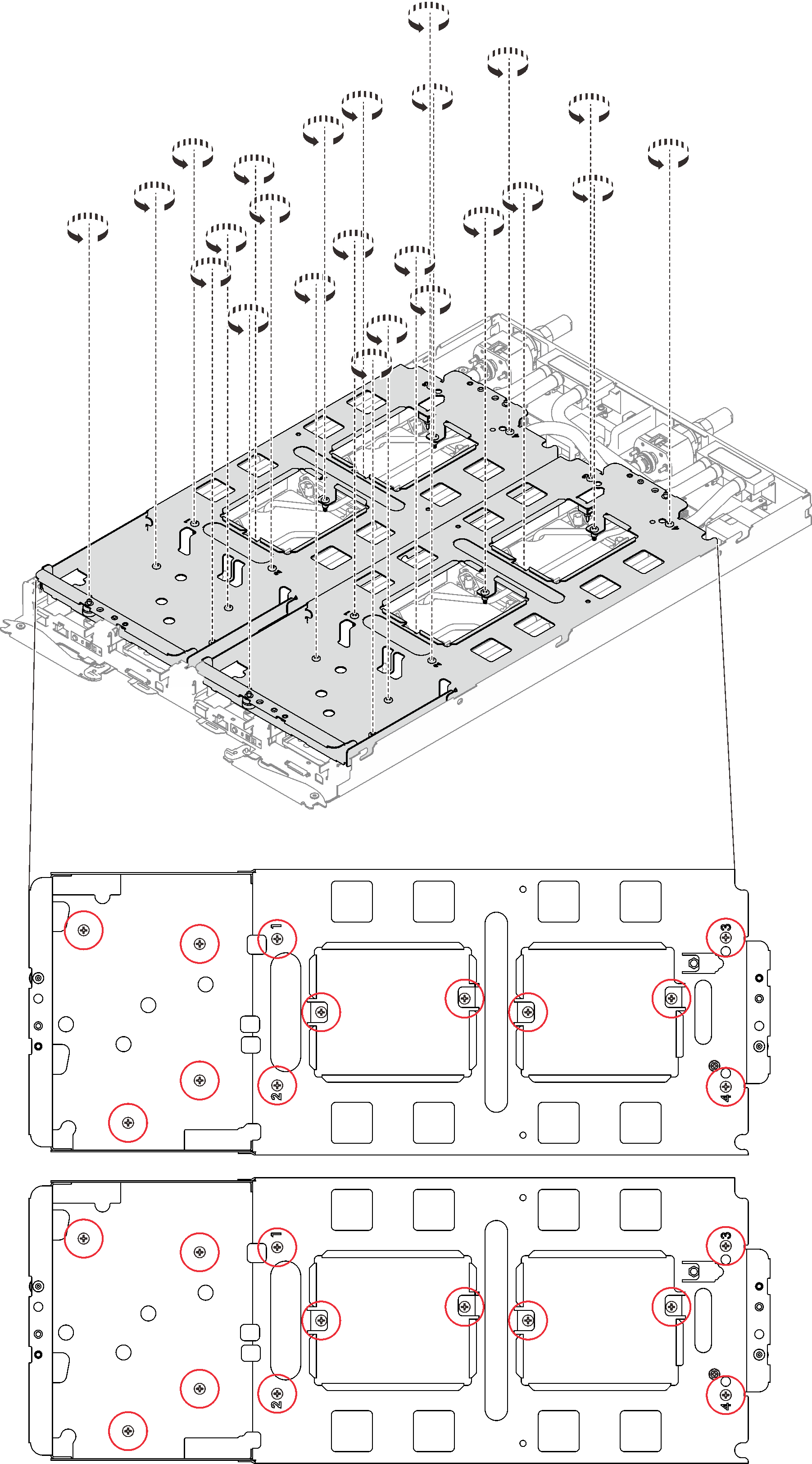

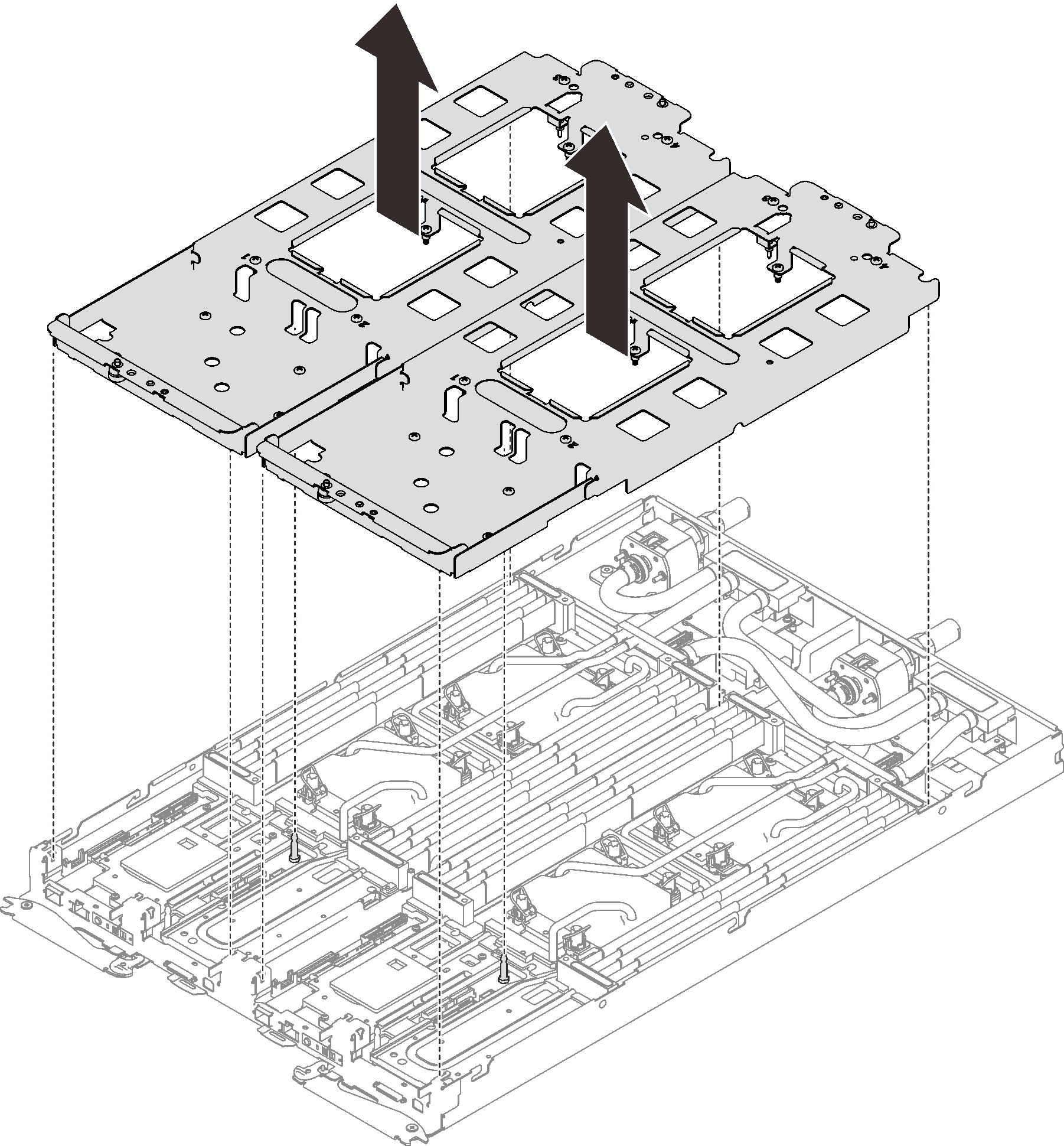

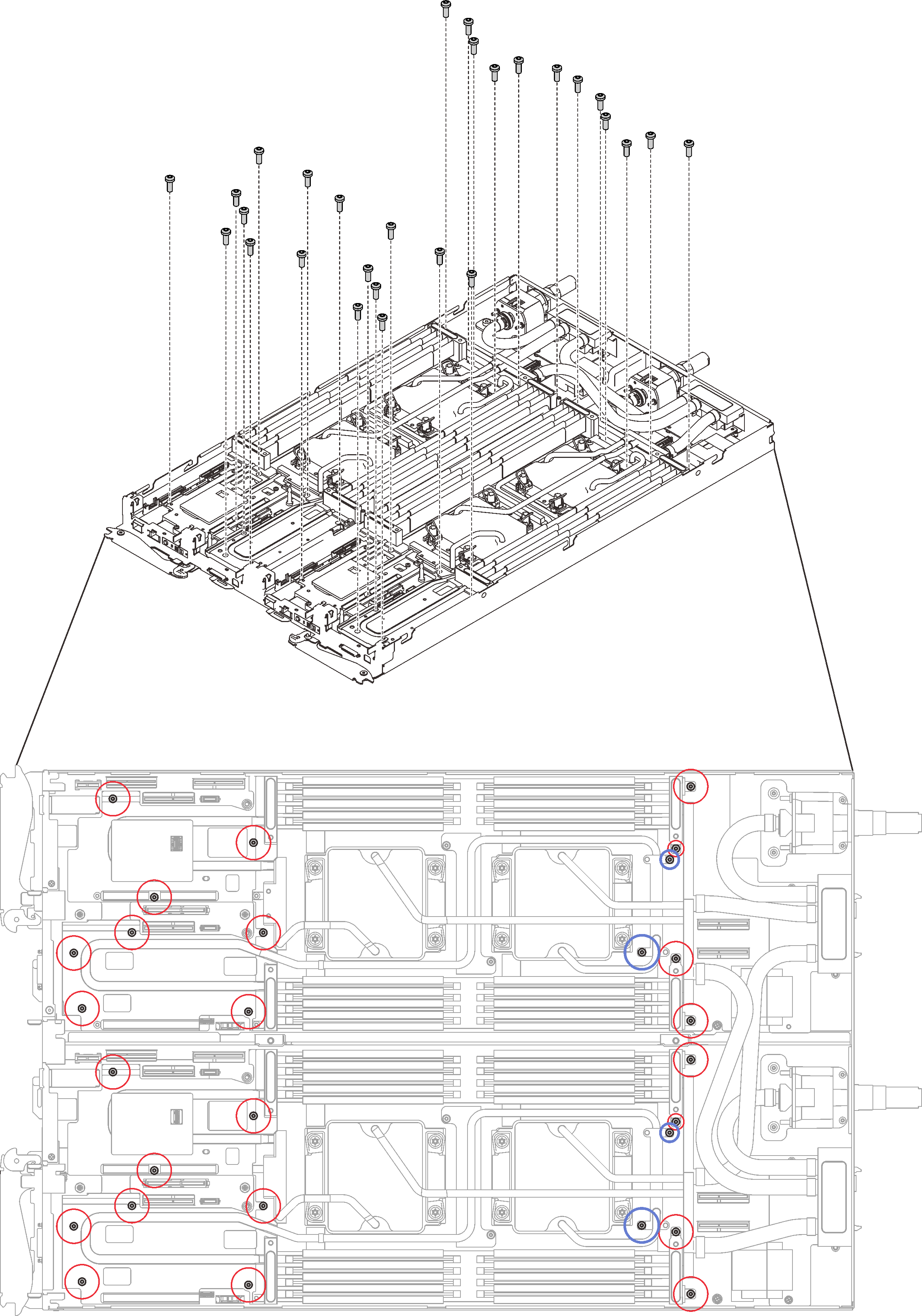

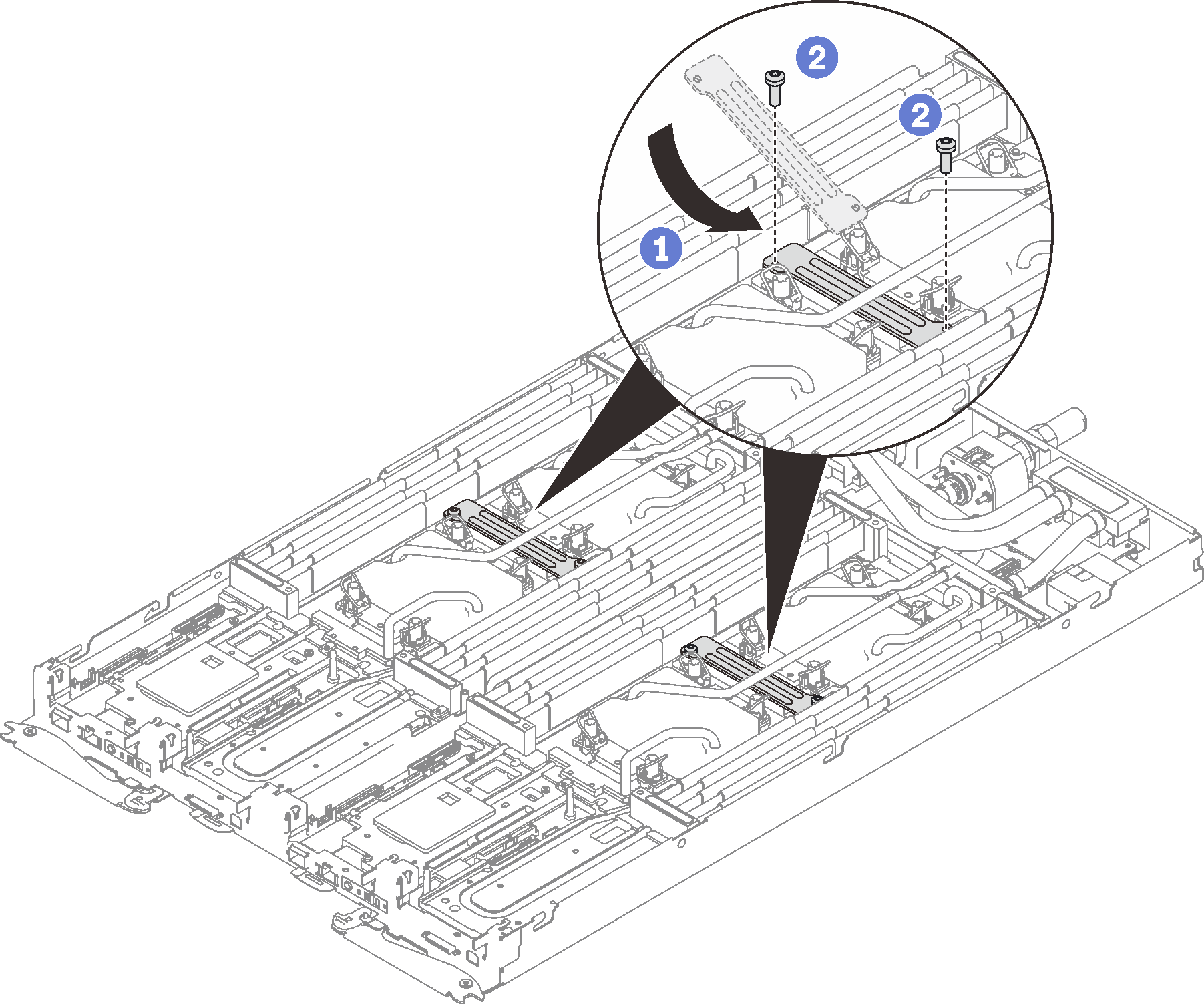

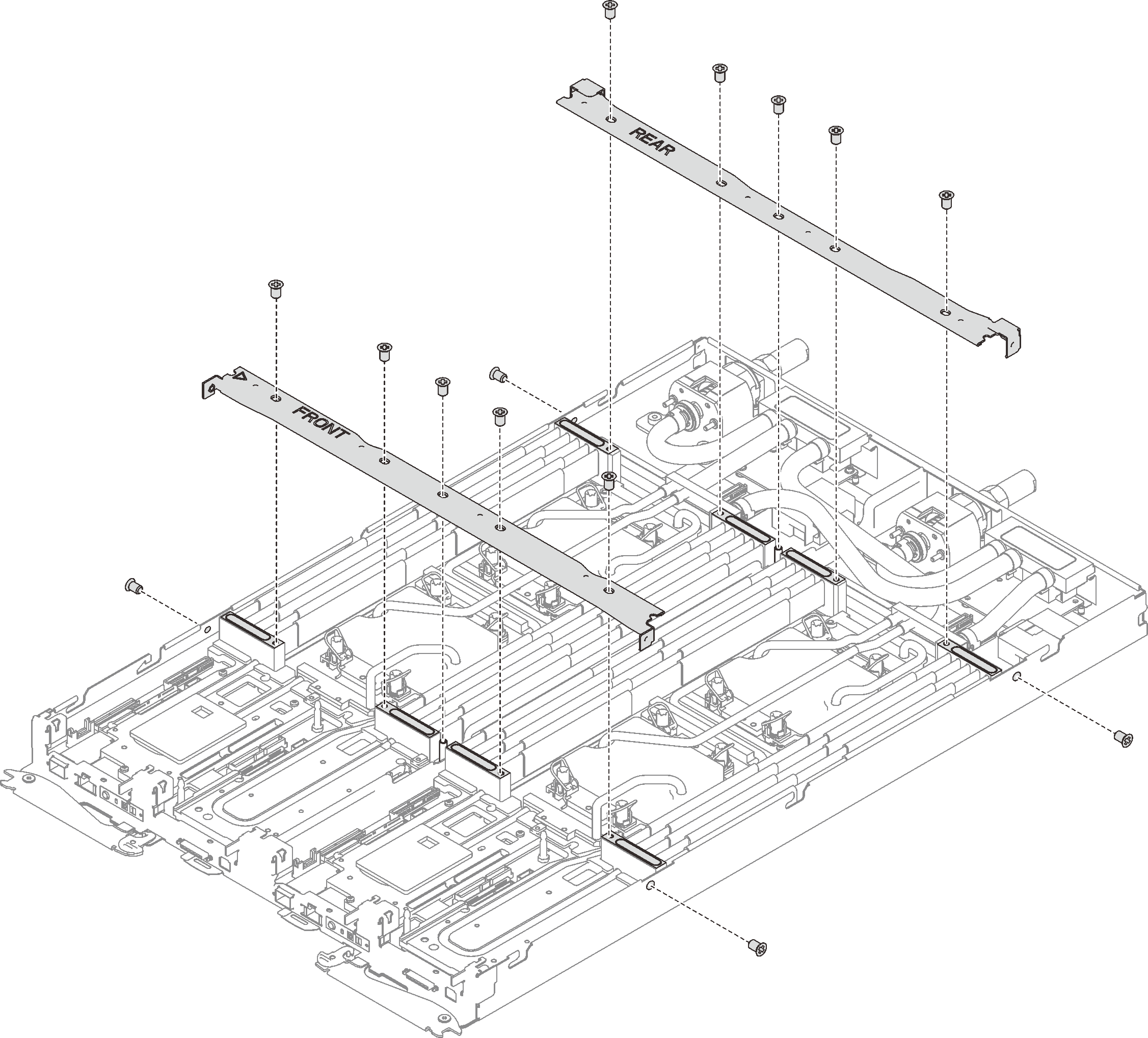

Reinstall the front and the rear cross braces (14x Phillips #1 screws).

Figure 17. Cross brace installation

Reinstall the tray cover (see Install the tray cover).

Reinstall the tray (see Install a DWC tray in the enclosure).

NoteFor safety, use the lift tool to install the tray into the rack.- Connect all required external cables to the enclosure.NoteUse extra forces to connect QSFP cables to the enclosure if Mellanox ConnectX-6 adapters are installed.

Check the power LED on each node to make sure it changes from fast blink to slow blink to indicate all nodes are ready to be powered on.

Demo video