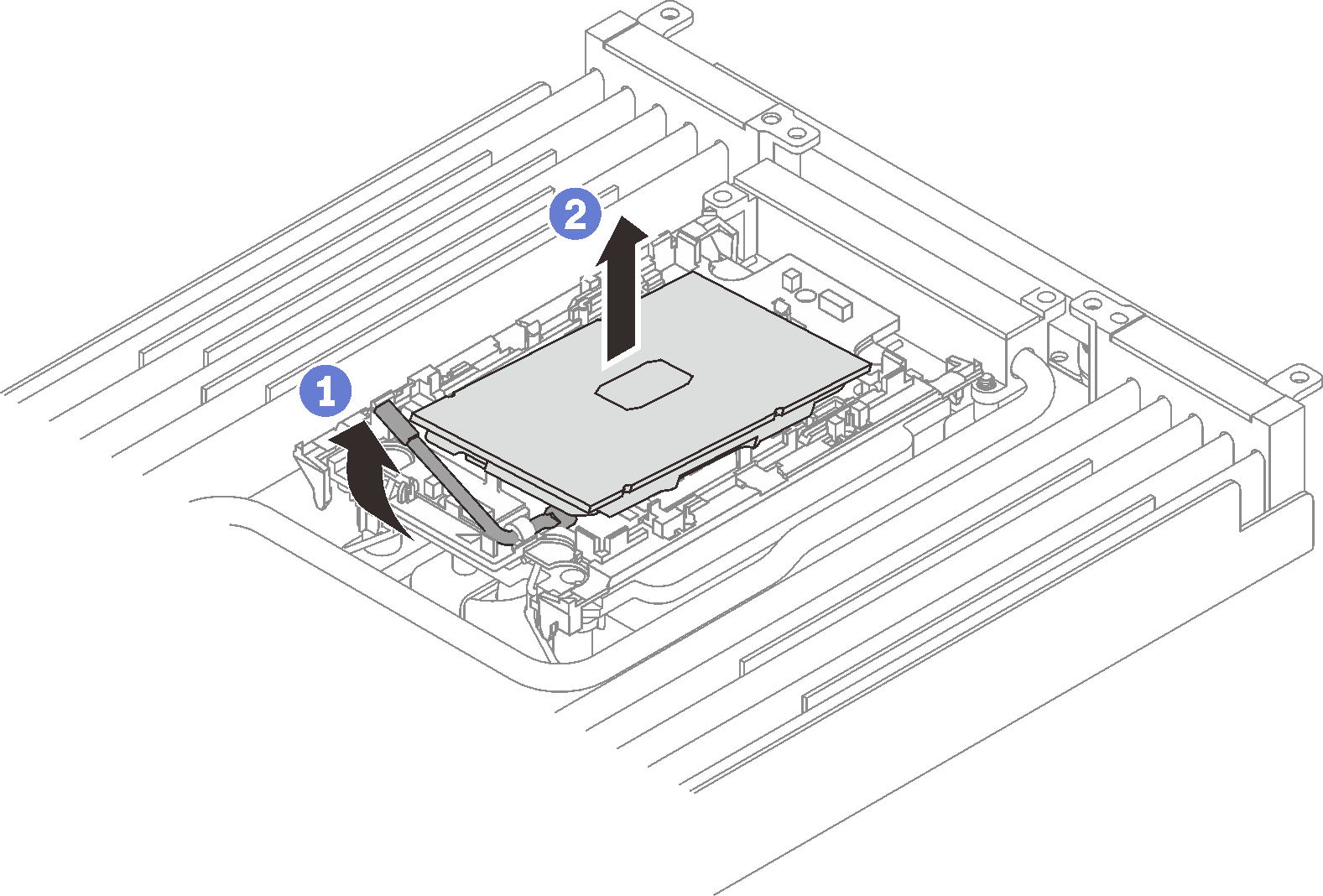

Remove a processor

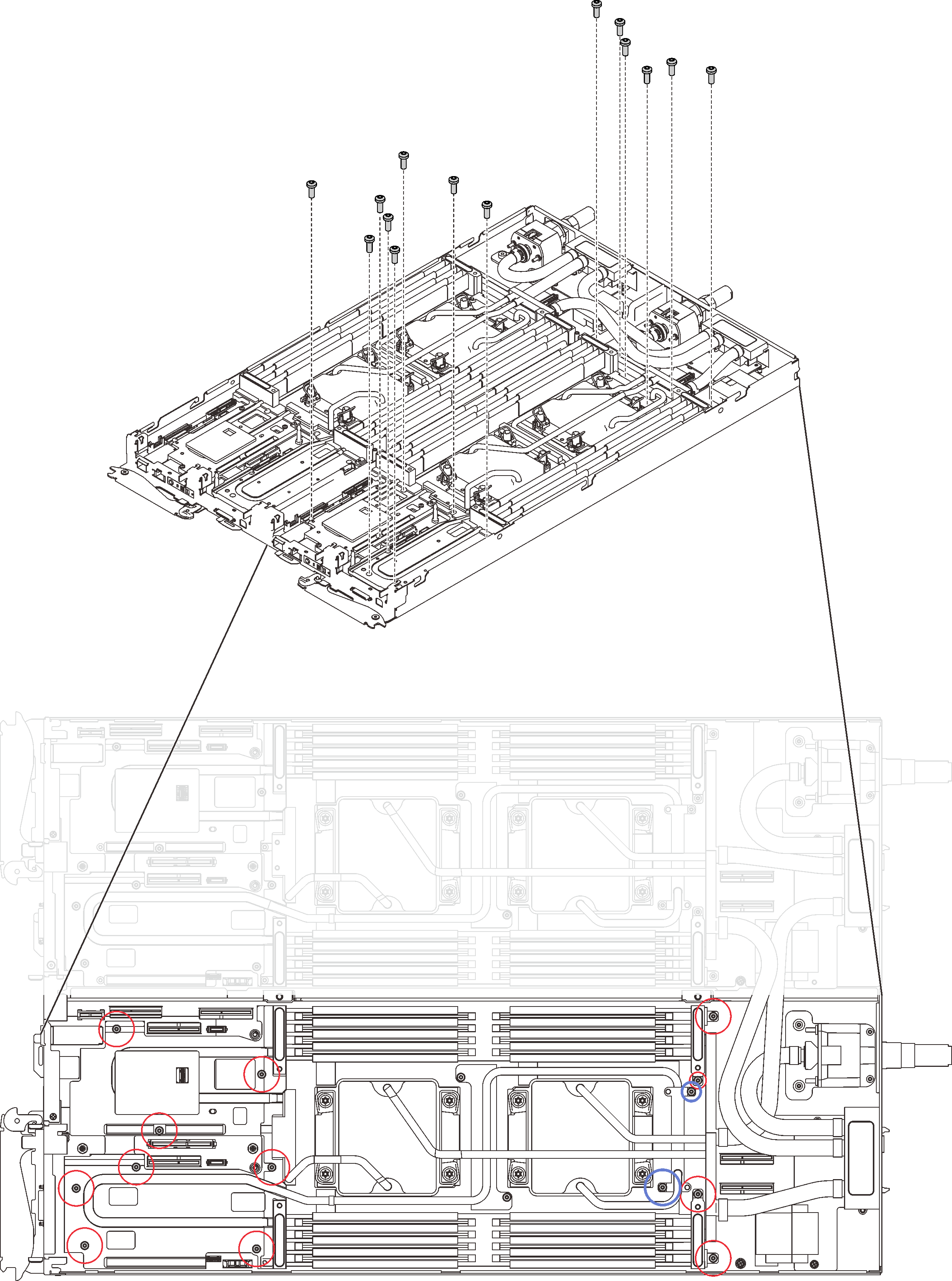

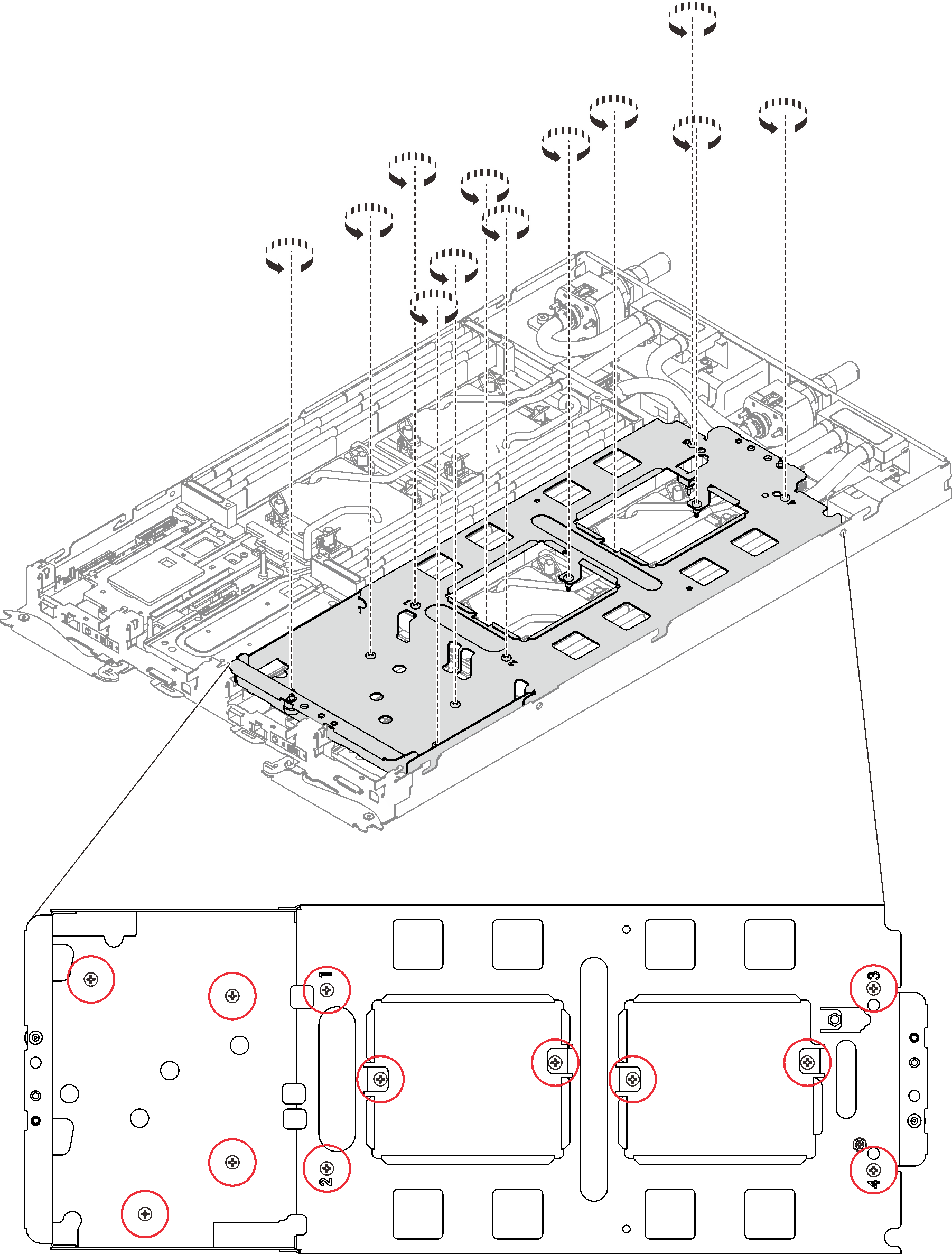

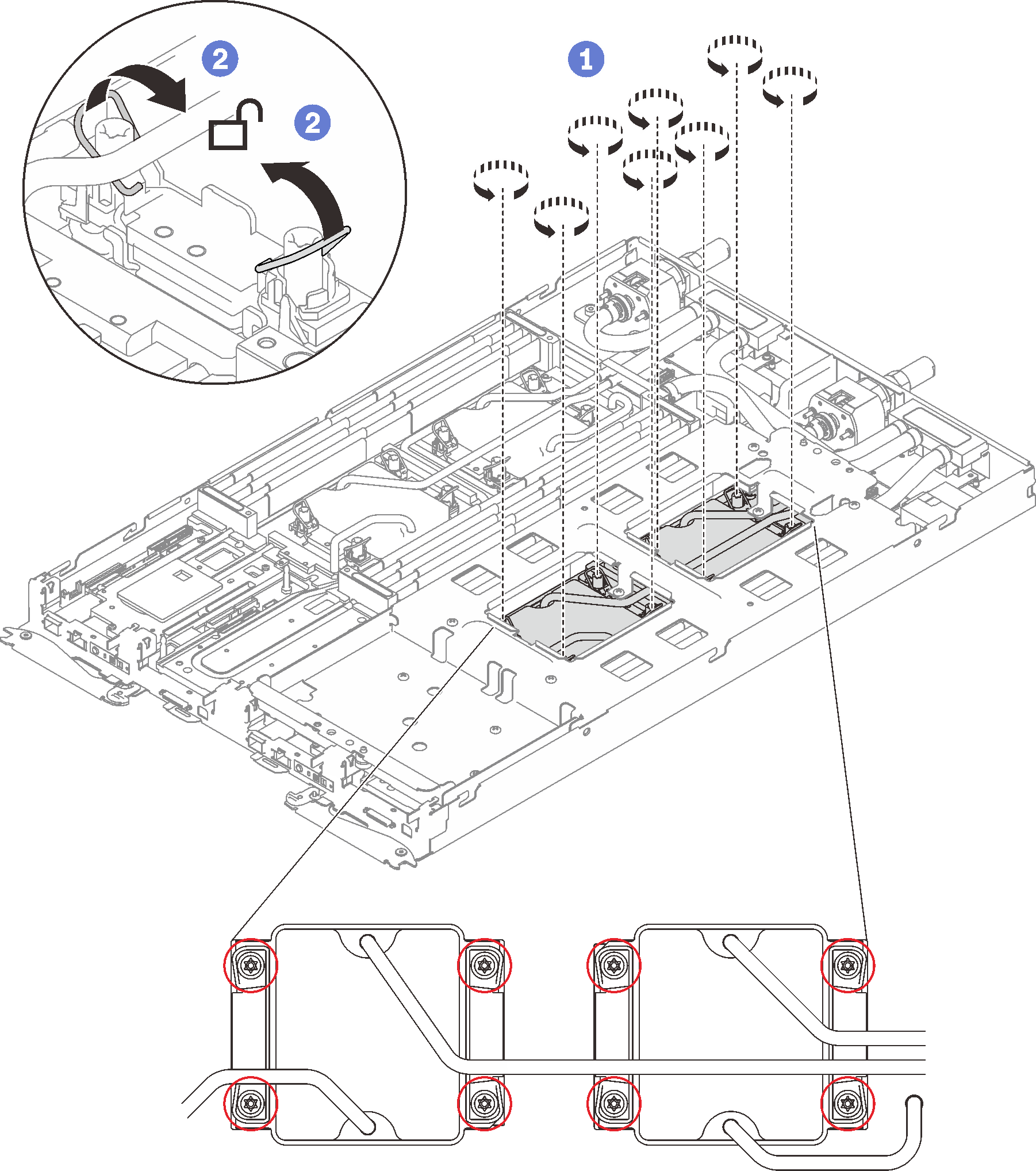

This task has instructions for removing an assembled processor. This task requires a Torx T30 driver.

About this task

- Read the following sections to ensure that you work safely.

- Turn off the corresponding DWC tray that you are going to perform the task on.NoteIf Shared I/O adapters are installed, power off the auxiliary node (node 1/3/5/7/9/11) first, and then power off the primary node (node 2/4/6/8/10/12).

- Disconnect all external cables from the enclosure.NoteUse extra forces to disconnect QSFP cables if they are connected to the solution.

If the Intel® Xeon® Platinum 8368Q processor is installed, the supported water temperature is 2°C - 35°C (35.6°F - 95°F).

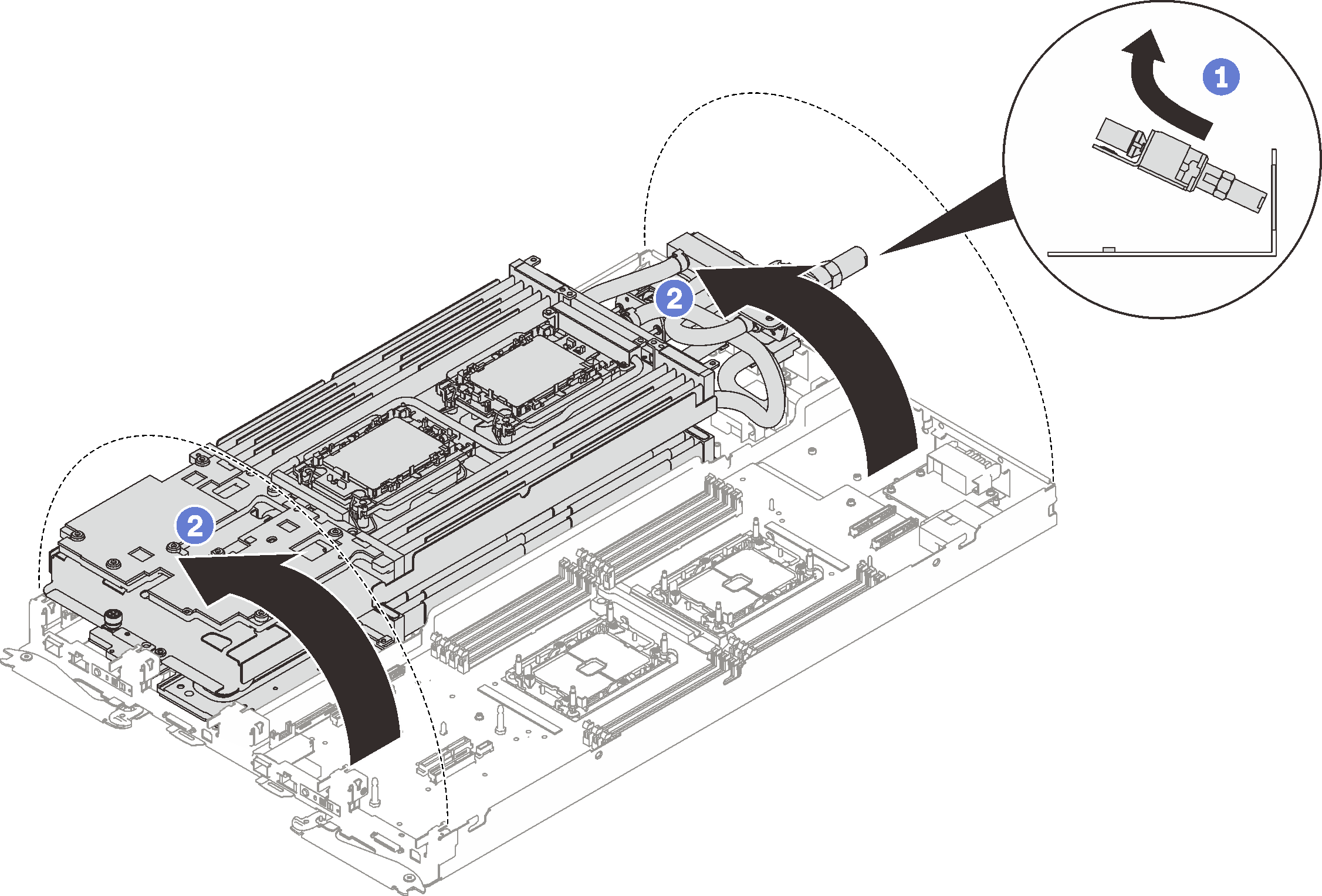

Each processor socket must always contain a cover. When removing or installing a processor, protect empty processor sockets with a cover.

Do not touch the processor socket or processor contacts. Processor-socket contacts are very fragile and easily damaged. Contaminants on the processor contacts, such as oil from your skin, can cause connection failures.

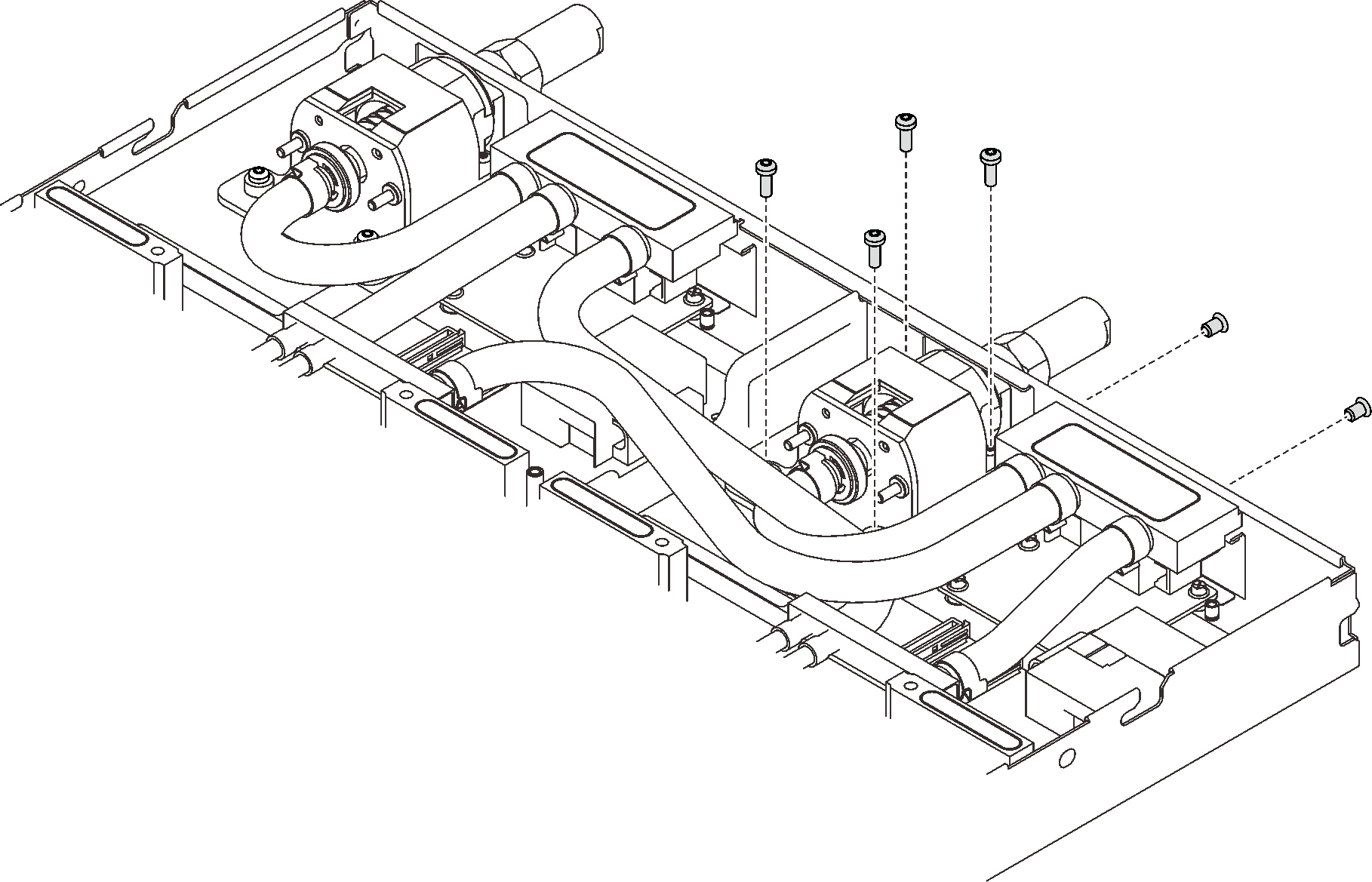

Do not allow the thermal grease on the processor or water loop to come in contact with anything. Contact with any surface can compromise the thermal grease, rendering it ineffective. Thermal grease can damage components, such as electrical connectors in the processor socket. Do not remove the grease cover from the cold plate until you are instructed to do so.

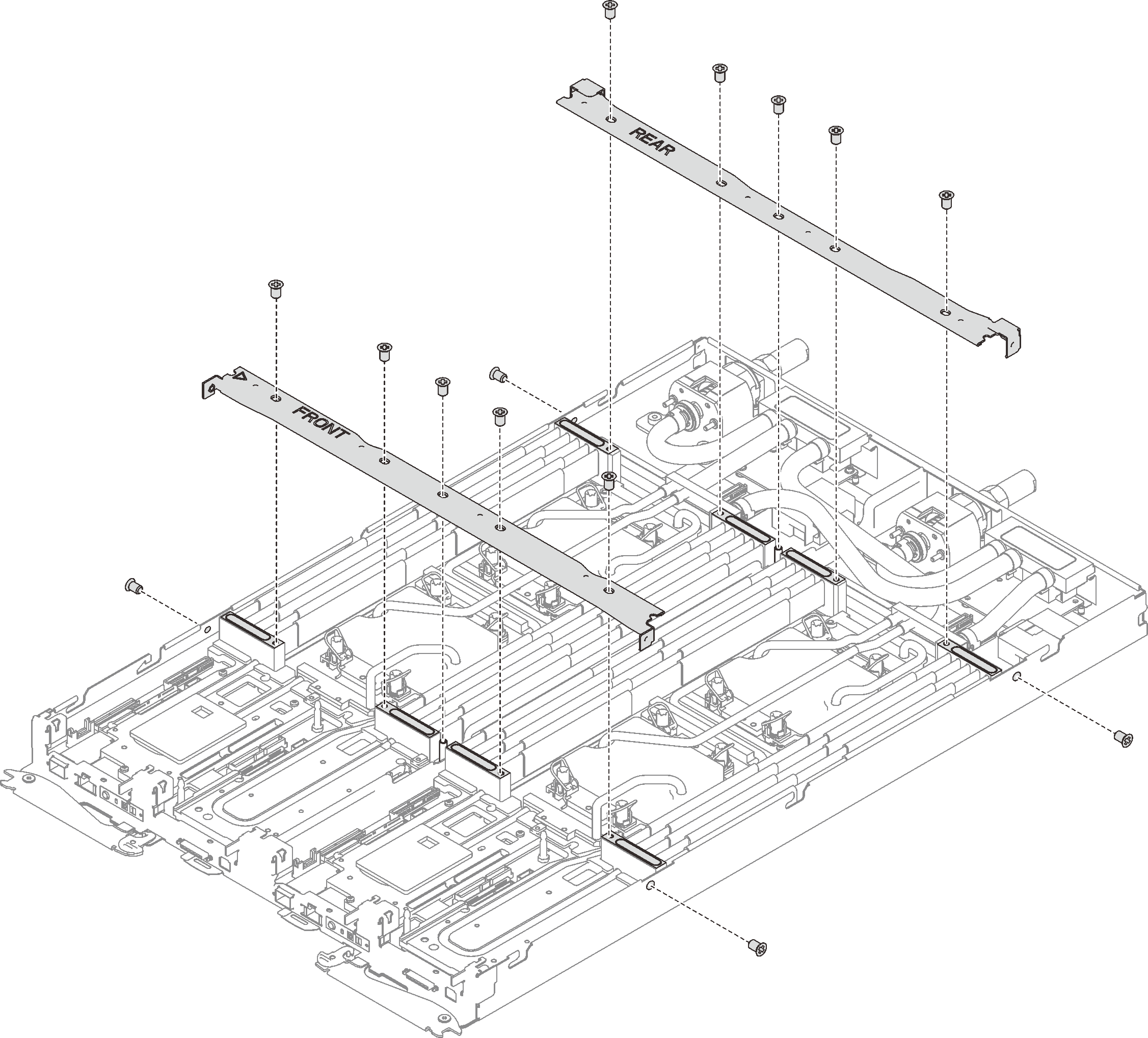

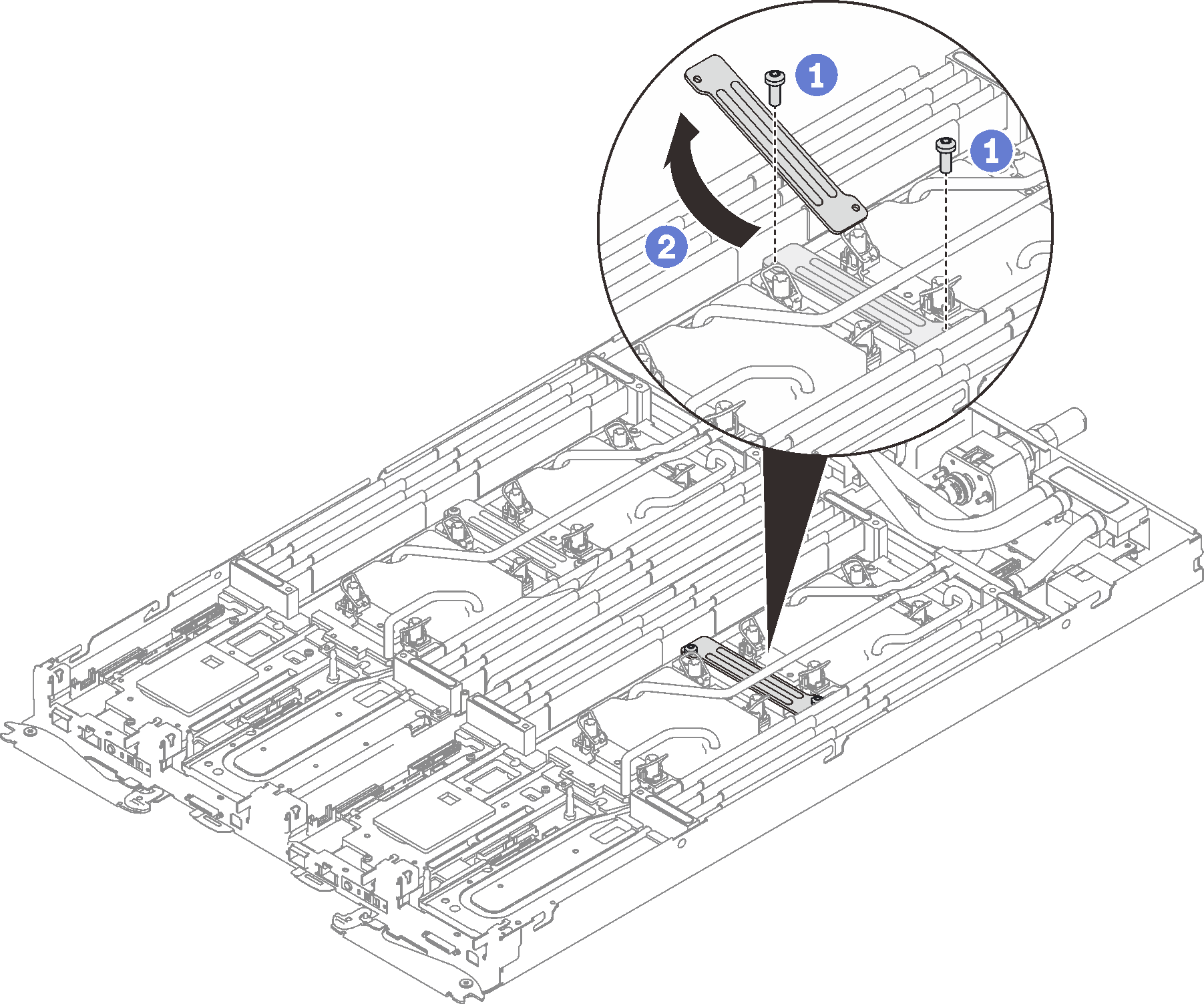

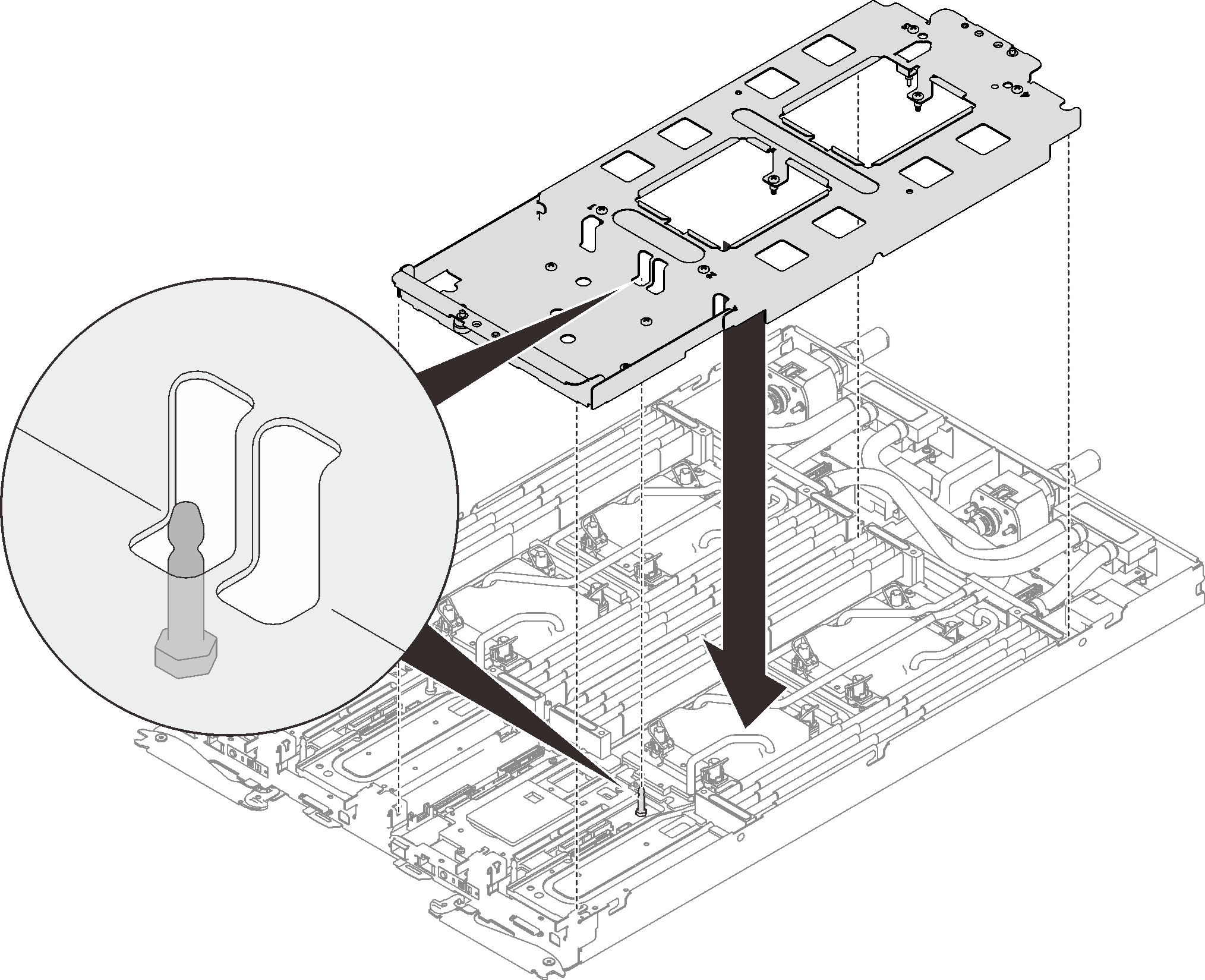

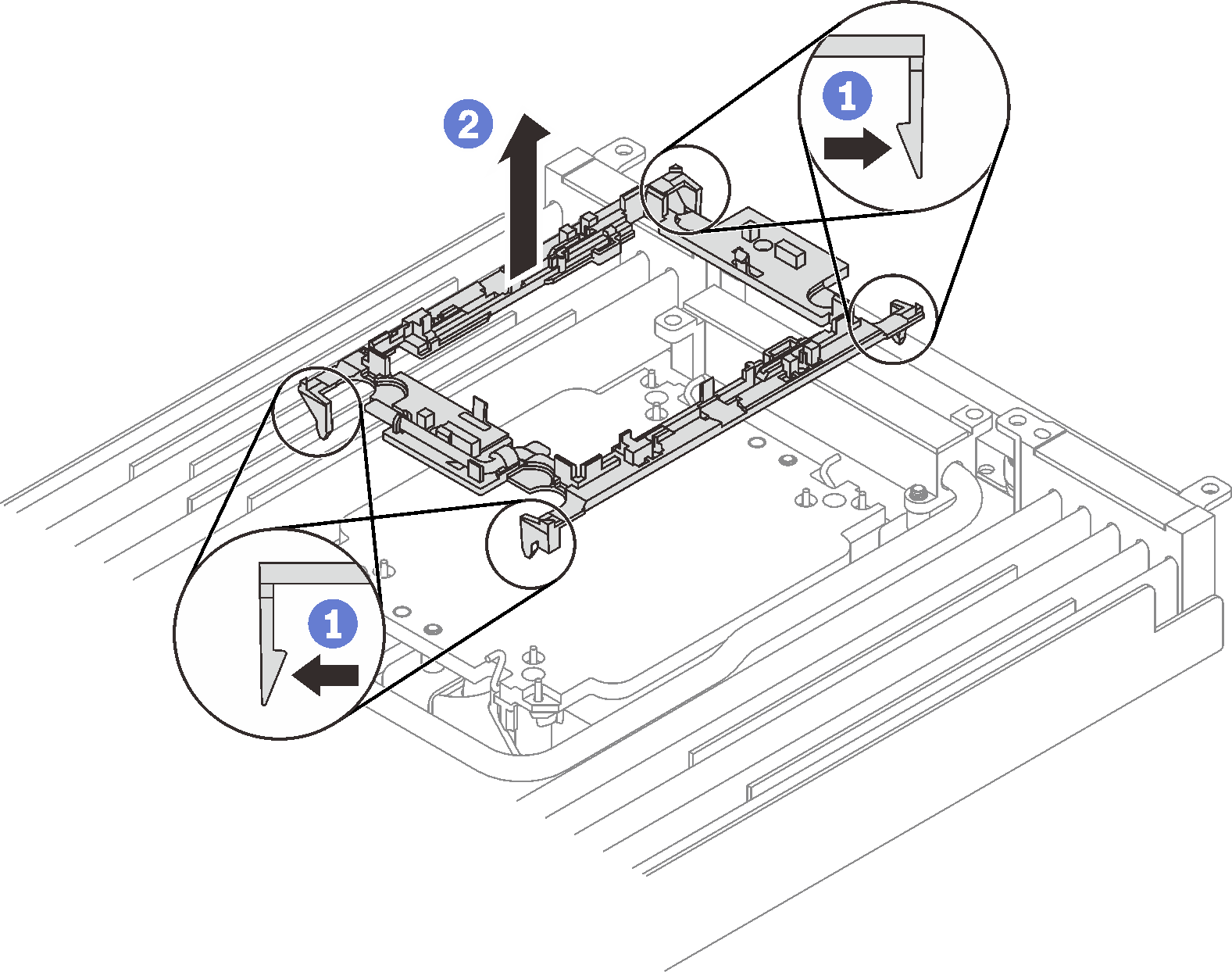

To avoid damaging the water loop, always use the water loop carrier when removing, installing or folding the water loop.

Before you install a new or replace a processor, update your system firmware to the latest level. See Update the firmware.

To avoid damaging the water loop, always use the water loop carrier when removing, installing or folding the water loop.

| Screwdriver Type | Screw Type |

| Torx T10 head screwdriver | Torx T10 screw |

| Torx T30 head screwdriver | Torx T30 screw |

| Phillips #1 head screwdriver or 3/16" hex head screwdriver | Phillips #1 screw |

| Phillips #2 head screwdriver | Phillips #2 screw |

Procedure

If you are instructed to return the component or optional device, follow all packaging instructions, and use any packaging materials for shipping that are supplied to you.

Demo video