Install a processor and heat sink

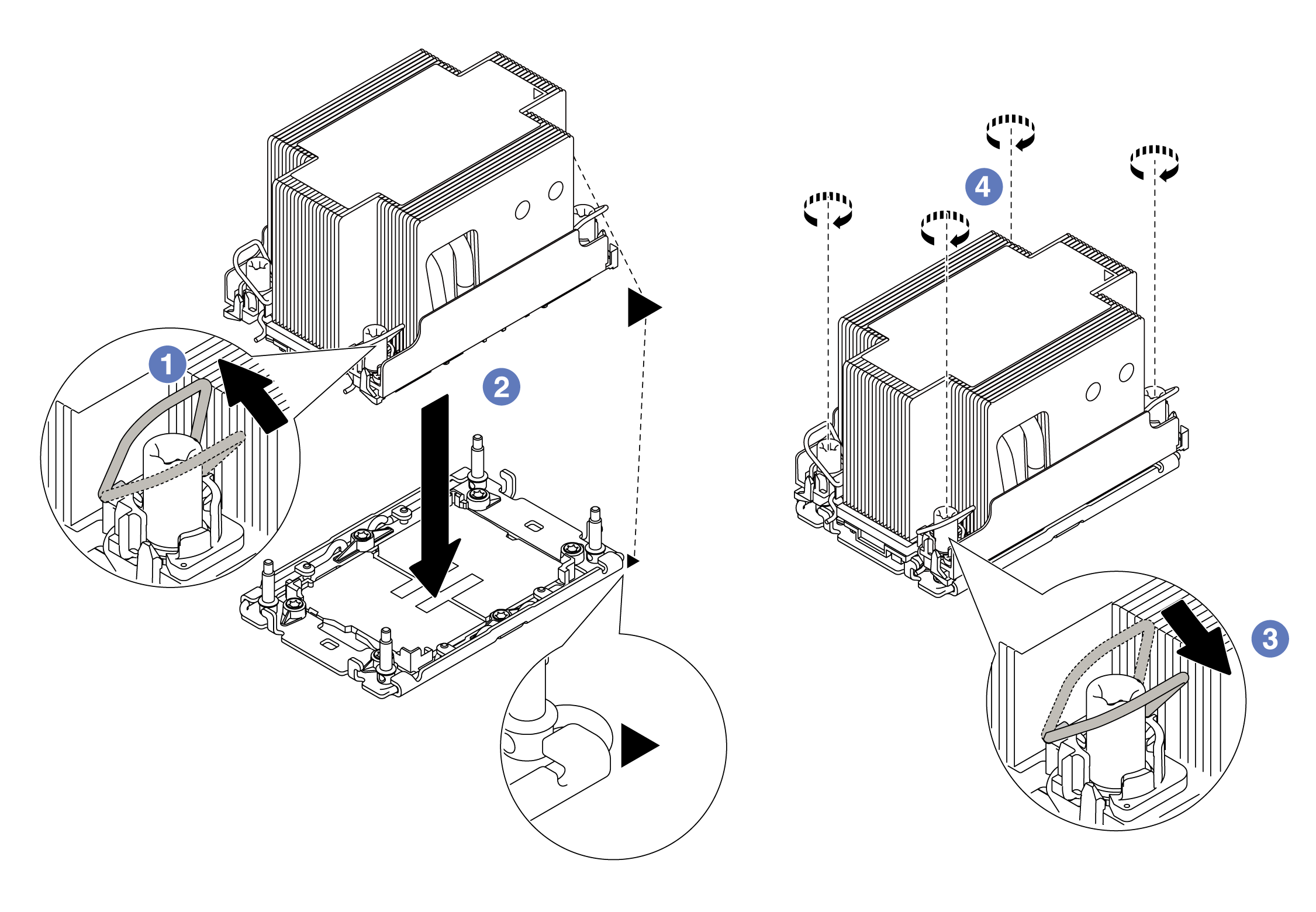

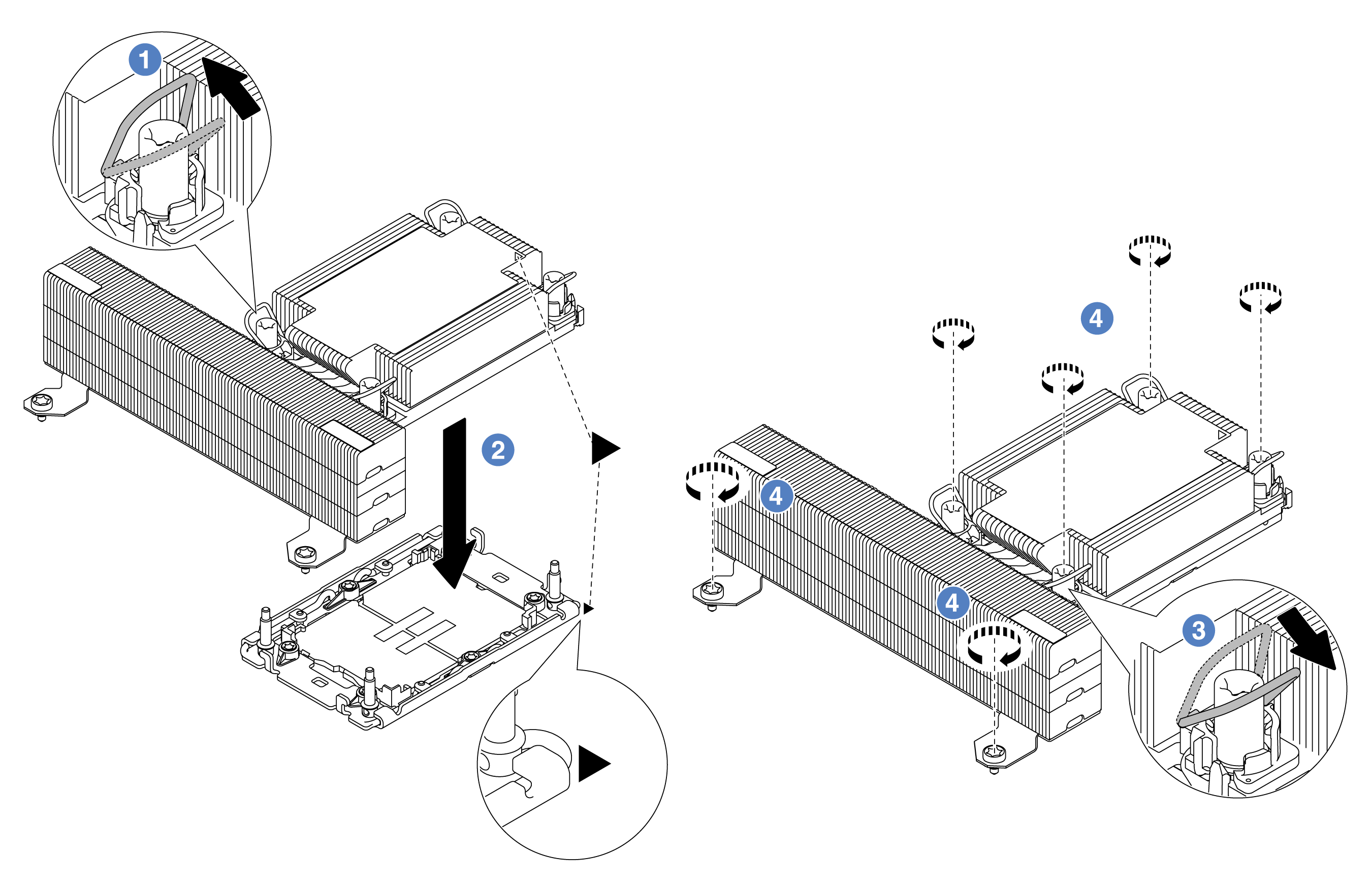

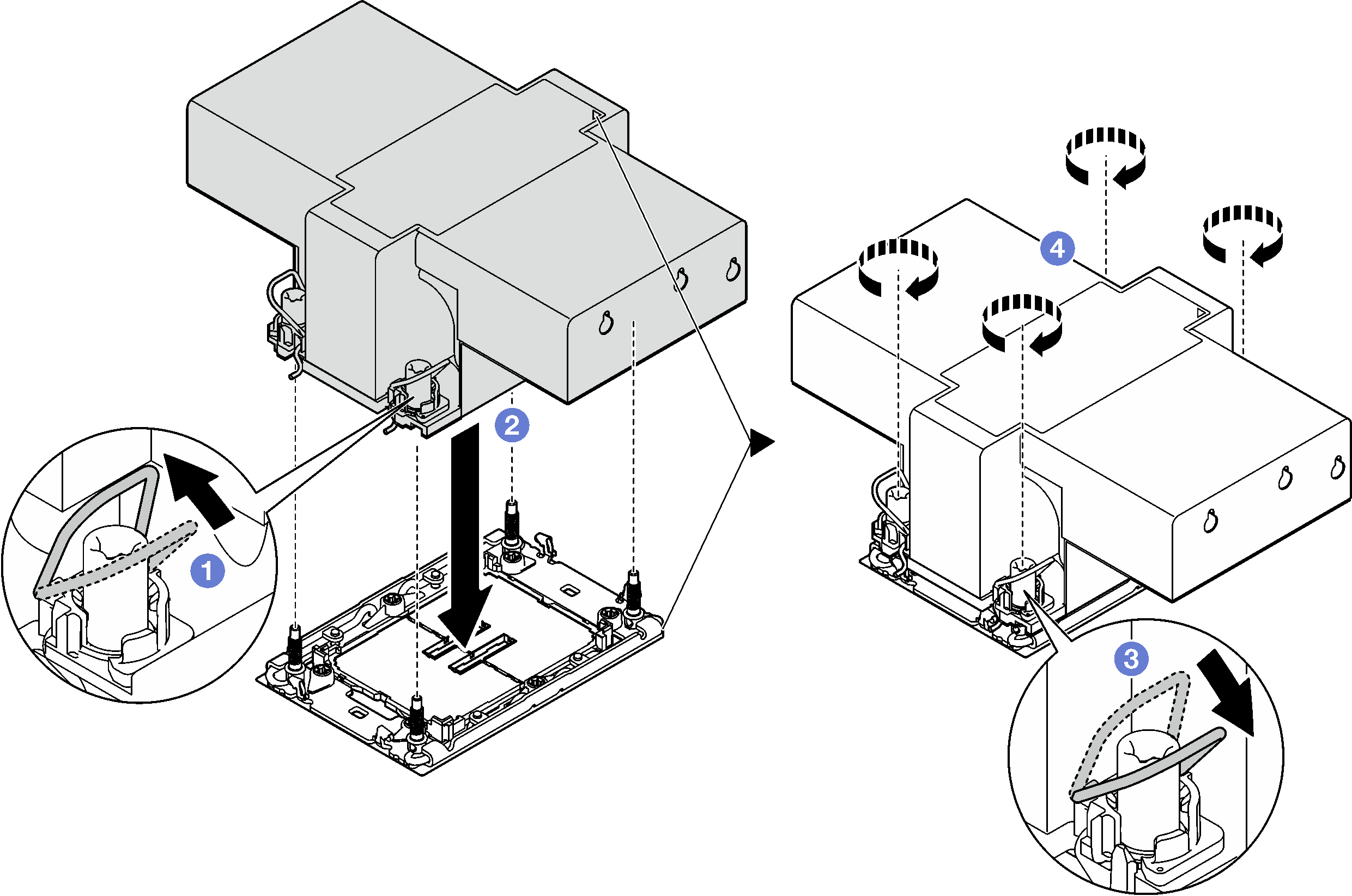

This task has instructions for installing an assembled processor and heat sink, known as a processor-heat-sink module (PHM). This task requires a Torx T30 screwdriver. This procedure must be executed by a trained technician.

About this task

Read Installation Guidelines and Safety inspection checklist to ensure that you work safely.

Power off the server and peripheral devices and disconnect the power cords and all external cables. See Power off the server.

Prevent exposure to static electricity, which might lead to system halt and loss of data, by keeping static-sensitive components in their static-protective packages until installation, and handling these devices with an electrostatic-discharge wrist strap or other grounding system.

Each processor socket must always contain a cover or a PHM. When removing a PHM, protect empty processor sockets with a cover.

Do not touch the processor socket or processor contacts. Processor-socket contacts are very fragile and easily damaged. Contaminants on the processor contacts, such as oil from your skin, can cause connection failures.

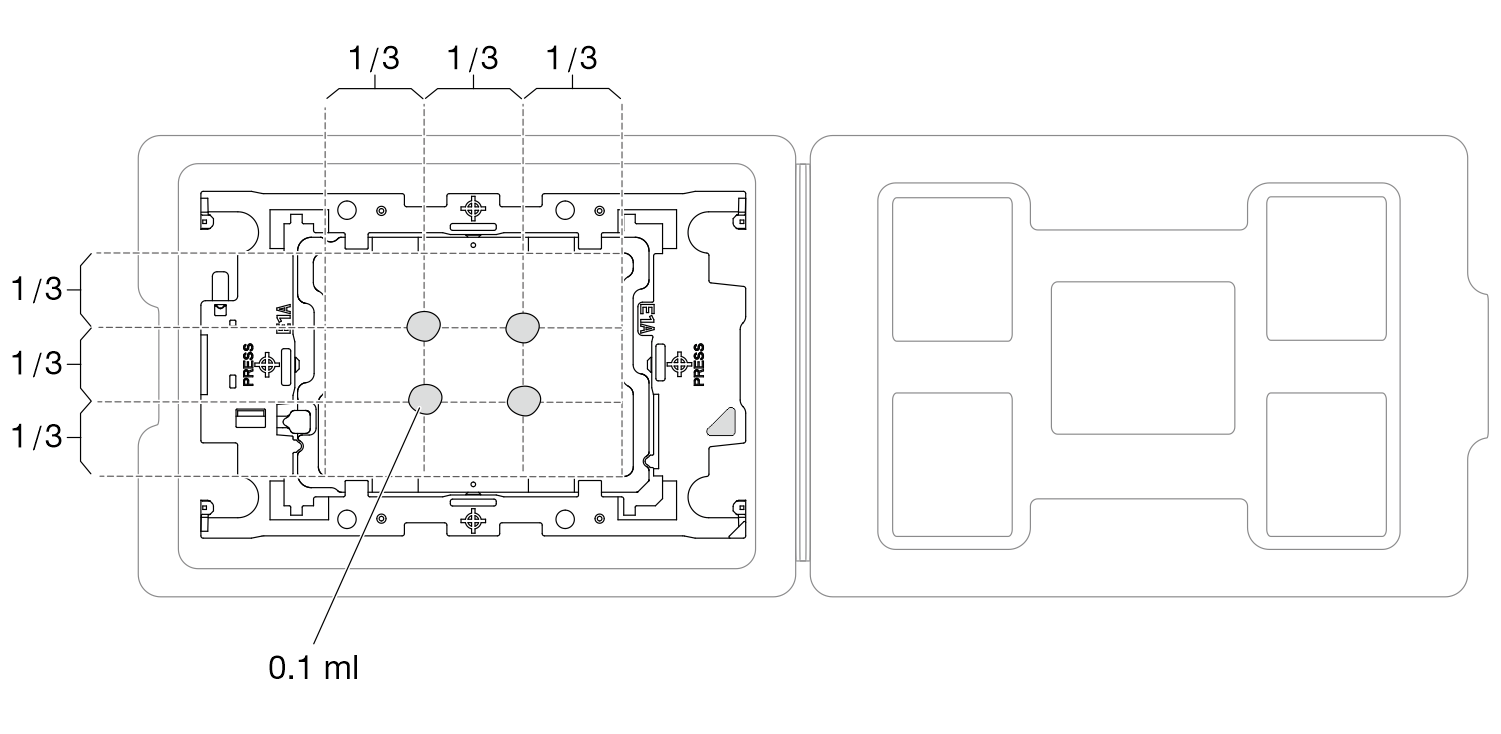

Do not allow the thermal grease on the processor or heat sink to come in contact with anything. Contact with any surface can compromise the thermal grease, rendering it ineffective. Thermal grease can damage components, such as the electrical connectors in the processor socket.

Remove and install only one PHM at a time. If the system supports multiple processors, install the PHMs starting with the first processor socket.

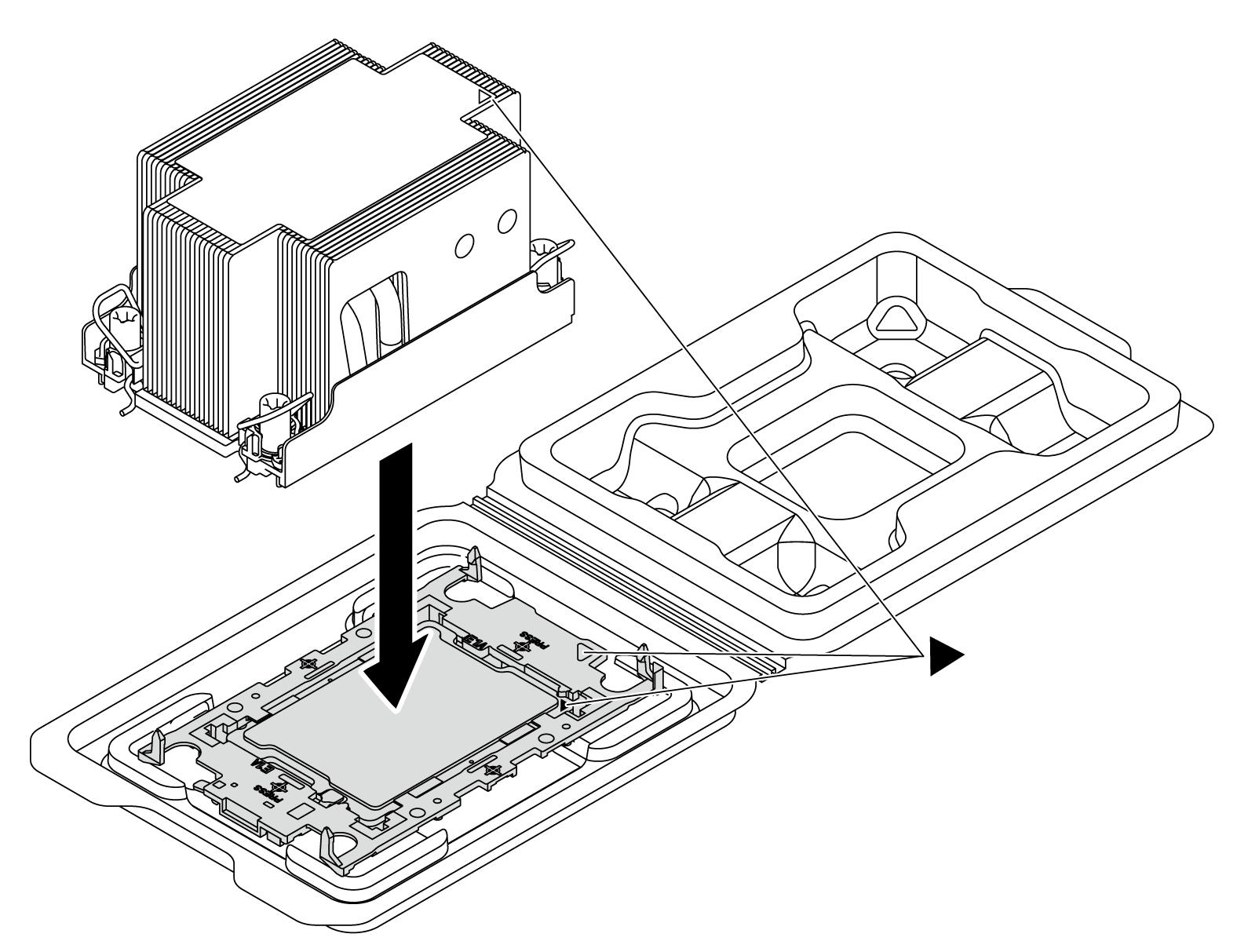

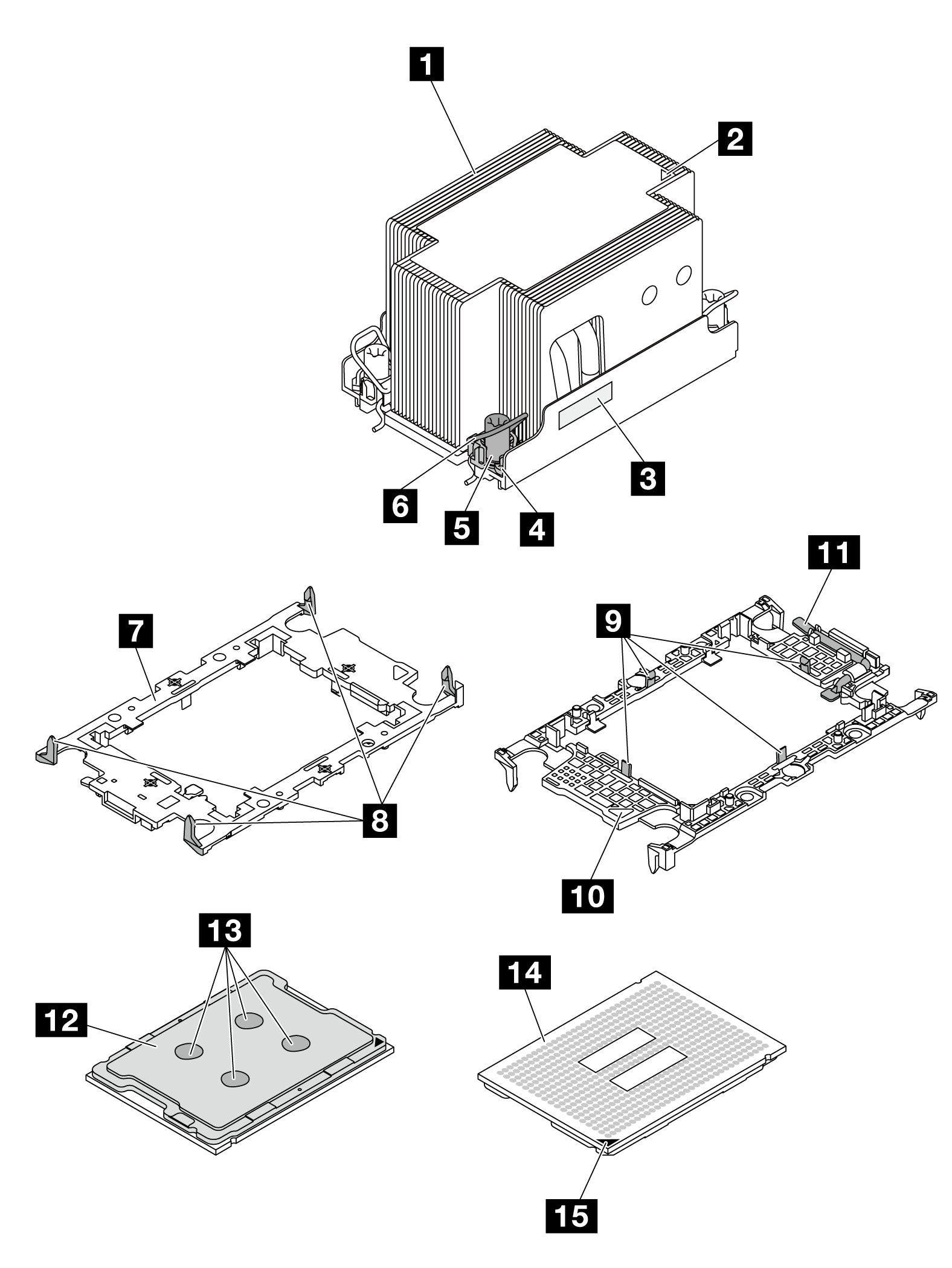

The heat sink, processor, and processor carrier for your system might be different from those shown in the illustrations.

PHMs are keyed for the socket where they can be installed and for their orientation in the socket.

See Lenovo ServerProven website for a list of processors supported for your server. All processors must have the same speed, number of cores, and frequency.

Before you install a new PHM or replacement processor, update your system firmware to the latest level. See Update the firmware.

| 1 Heat sink | 9 Clips to secure processor in carrier |

| 2 Heat sink triangular mark | 10 Carrier triangular mark |

| 3 Processor identification label | 11 Processor ejector handle |

| 4 Nut and wire bail retainer | 12 Processor heat spreader |

| 5 Torx T30 nut | 13 Thermal grease |

| 6 Anti-tilt wire bail | 14 Processor contacts |

| 7 Processor carrier | 15 Processor triangular mark |

| 8 Clips to secure carrier to heat sink |

Go to Drivers and Software download website for ThinkSystem SR650 V3 to see the latest firmware and driver updates for your server.

Go to Update the firmware for more information on firmware updating tools.

Procedure

After you finish

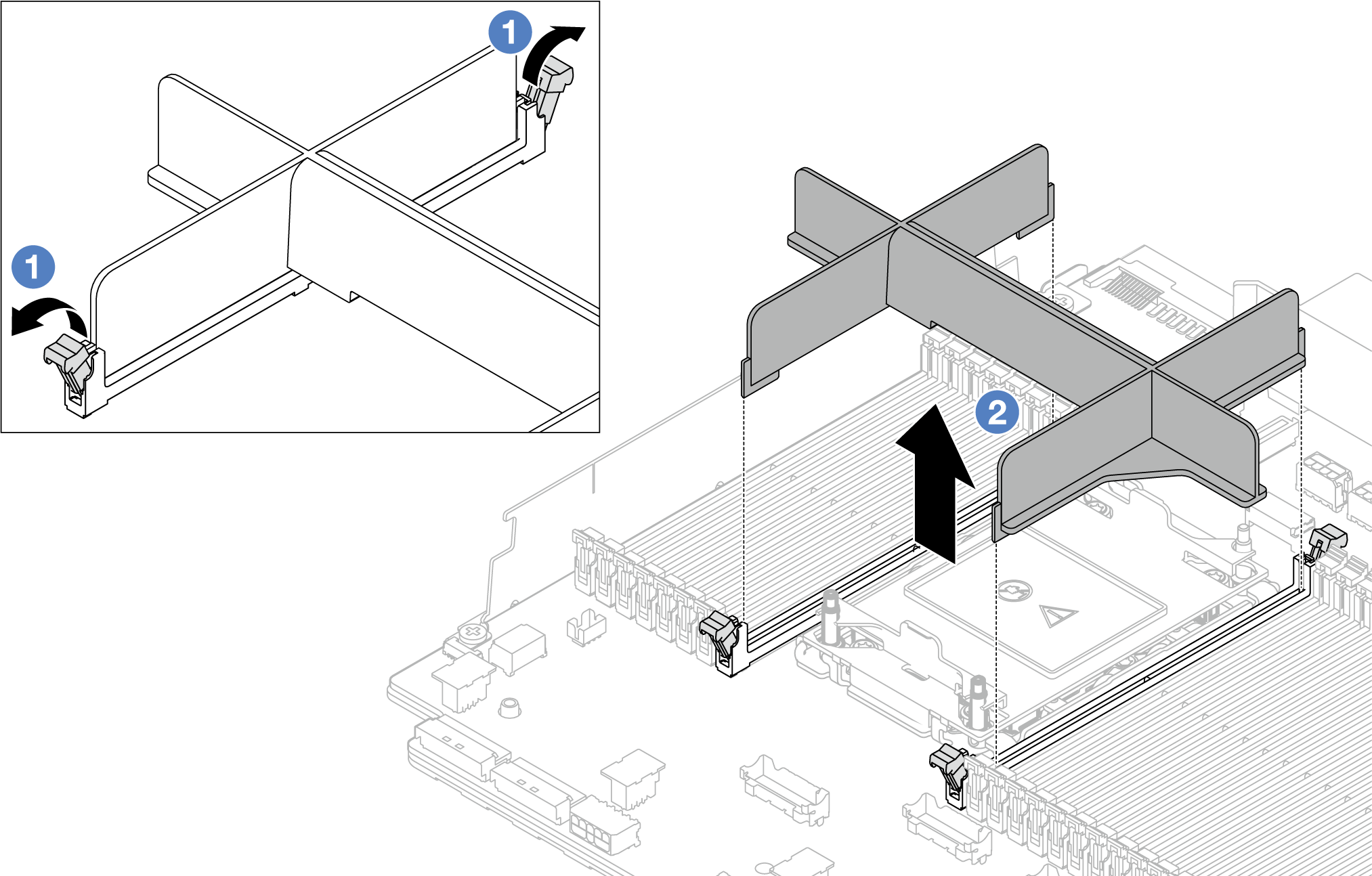

Complete the parts replacement. See Complete the parts replacement.

To enable Intel® On Demand Suite to the new processor, or to transfer Intel® On Demand Suite from the defective processor to the new processor, refer to Enable Intel® On Demand.

Demo video

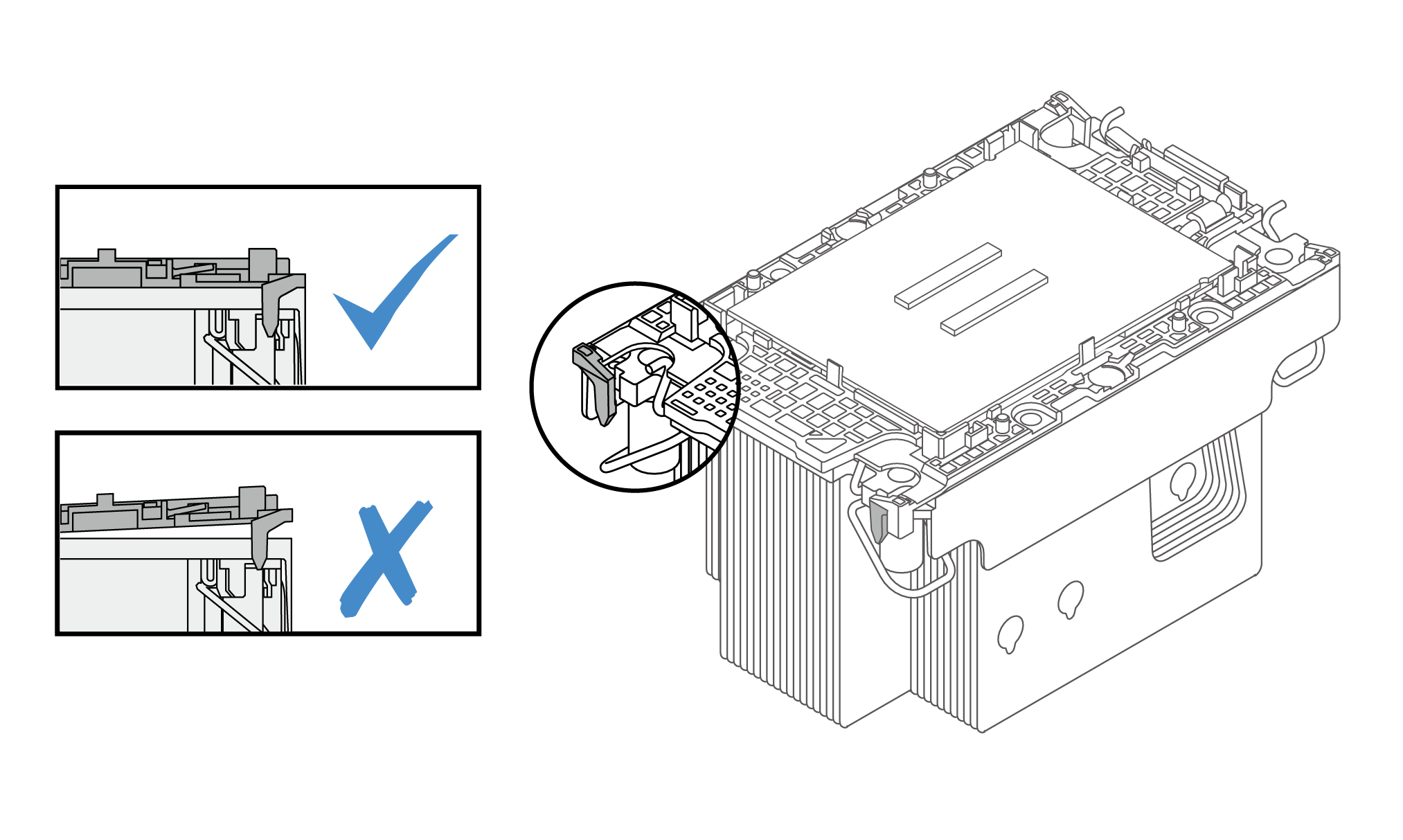

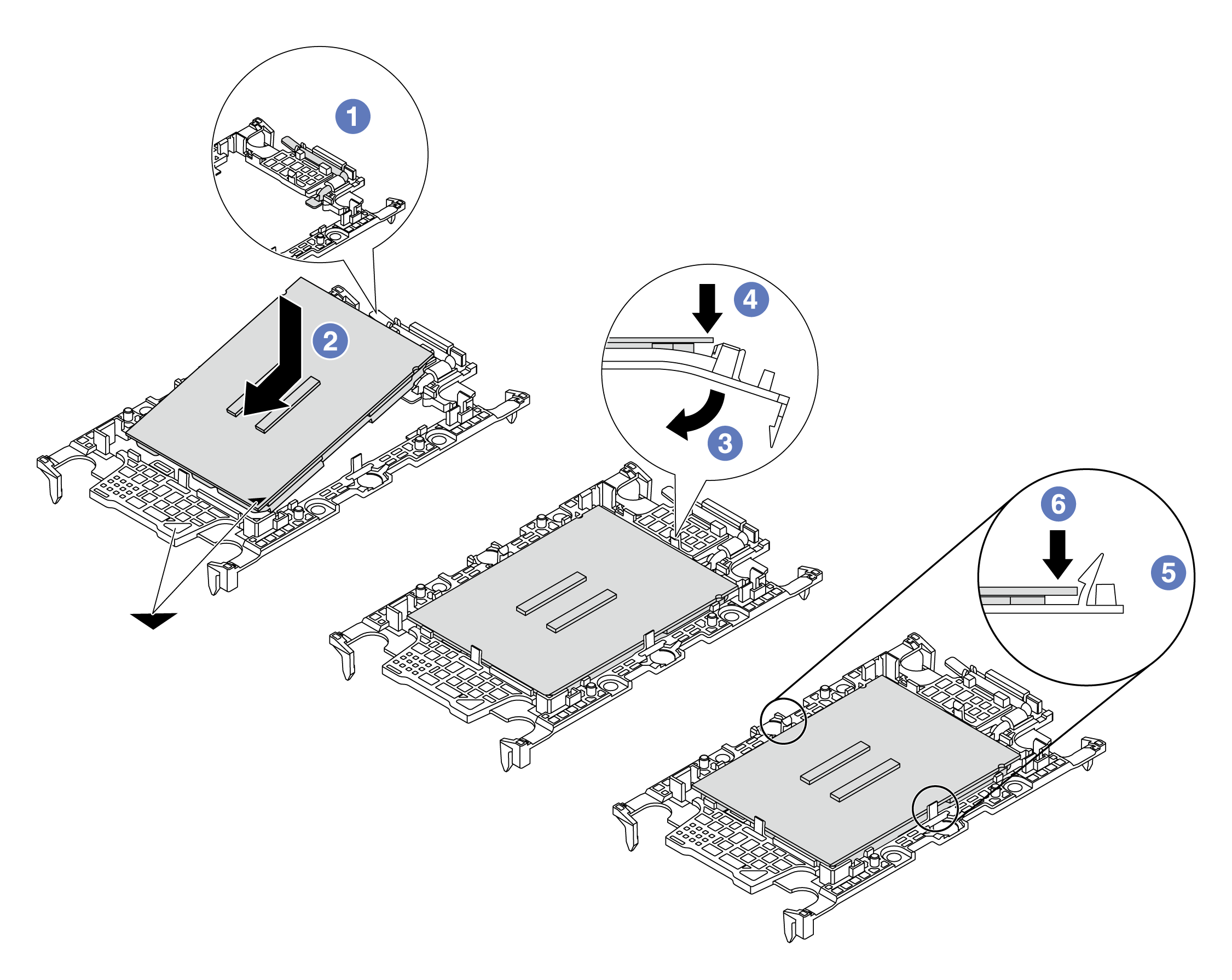

Make sure the handle on the carrier is in the closed position.

Make sure the handle on the carrier is in the closed position. Align the processor on the new carrier so that the triangular marks align; then, insert the marked end of the processor into the carrier.

Align the processor on the new carrier so that the triangular marks align; then, insert the marked end of the processor into the carrier. Hold the inserted end of the processor in place; then, pivot the unmarked end of the carrier down and away from the processor.

Hold the inserted end of the processor in place; then, pivot the unmarked end of the carrier down and away from the processor. Press the processor and secure the unmarked end under the clip on the carrier.

Press the processor and secure the unmarked end under the clip on the carrier. Carefully pivot the sides of the carrier down and away from the processor.

Carefully pivot the sides of the carrier down and away from the processor. Press the processor and secure the sides under the clips on the carrier.

Press the processor and secure the sides under the clips on the carrier.