Install the system board

Use this information to install the system board.

About this task

To avoid a shock hazard:

- Connect all power cords to a properly wired and grounded electrical outlet/source.

- Connect any equipment that will be attached to this product to properly wired outlets/sources.

- When possible, use one hand only to connect or disconnect signal cables.

- Never turn on any equipment when there is evidence of fire, water, or structural damage.

- The device might have more than one power cord, to remove all electrical current from the device, ensure that all power cords are disconnected from the power source.

- Read the following sections to ensure that you work safely.

- Turn off the corresponding DWC tray that you are going to perform the task on.NoteIf Shared I/O adapters are installed, power off the auxiliary node (node 1/3/5/7/9/11) first, and then power off the primary node (node 2/4/6/8/10/12).

- Disconnect all external cables from the enclosure.NoteUse extra forces to disconnect QSFP cables if they are connected to the solution.

To avoid damaging the water loop, always use the water loop carrier when removing, installing or folding the water loop.

Ensure you have “SD650 V2 or SD650-N V2 Neptune® DWC Waterloop Service Kit “ in hand to install components.

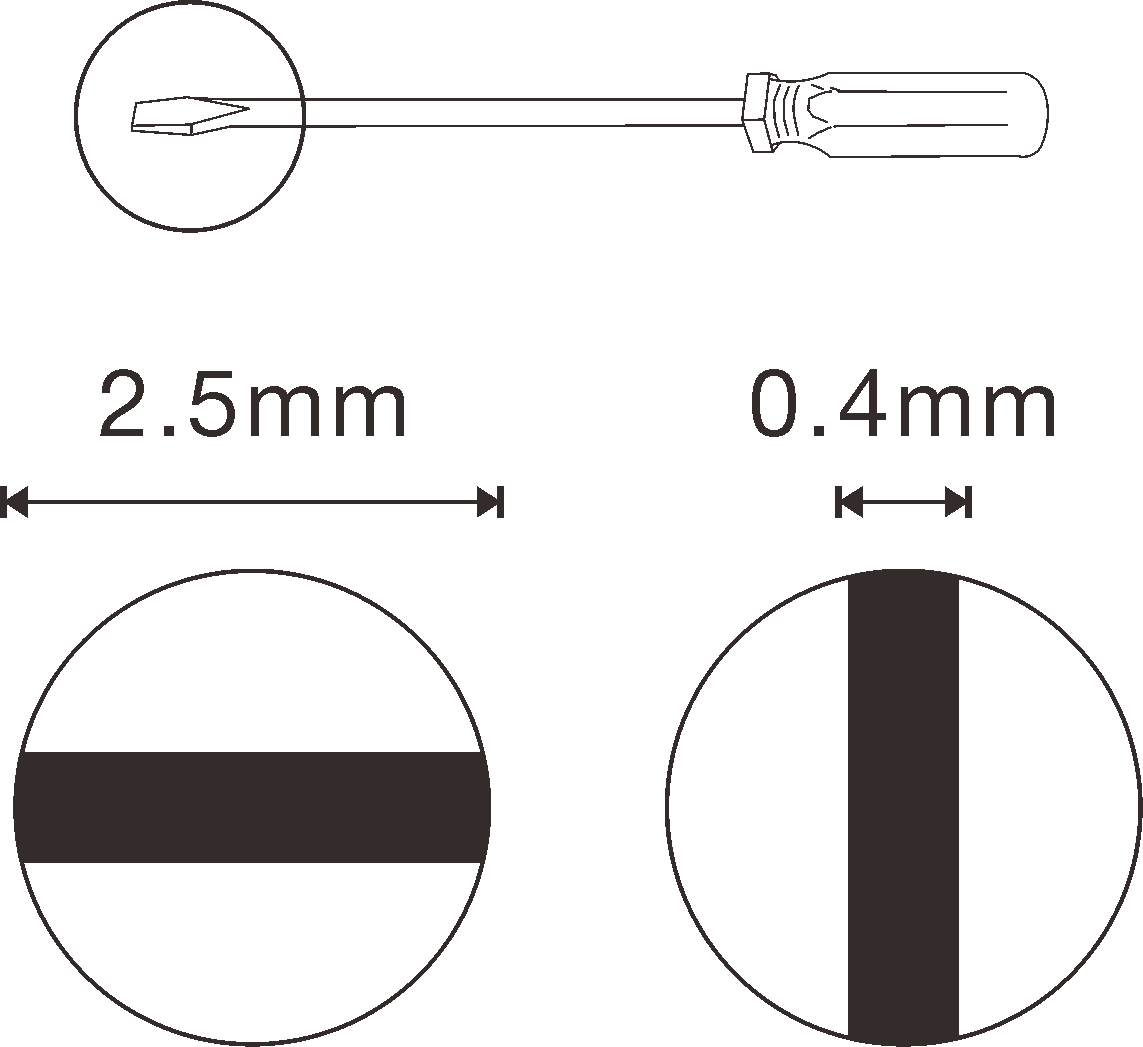

| Screwdriver type | Screw type |

| Torx T10 head screwdriver | Torx T10 screw |

| Torx T30 head screwdriver | Torx T30 screw |

| Phillips #1 head screwdriver or 3/16" hex head screwdriver | Phillips #1 screw |

| Phillips #2 head screwdriver | Phillips #2 screw |

| 3/16" hex head screwdriver | Hex head screw |

| 2.5x0.4 mm Flat head screwdriver | 2.5x0.4 mm flat head screwdriver |

Procedure

Reinstall the power distribution board (see Install the power distribution board).

Check the gap pads on the reverse side of the VR water loop, replace them with new ones if they are damaged or missing.

Figure 4. VR water loop - Gap pads

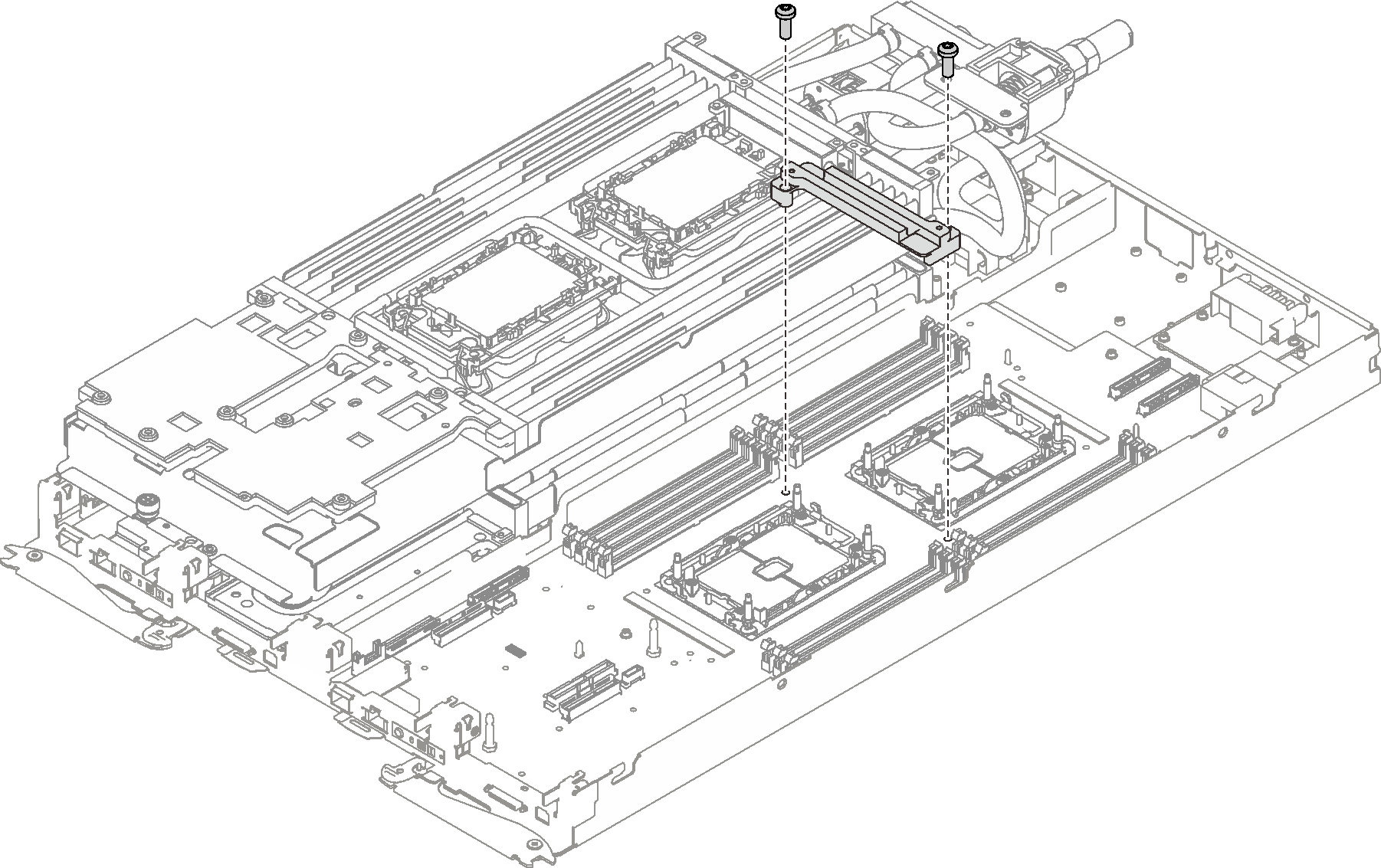

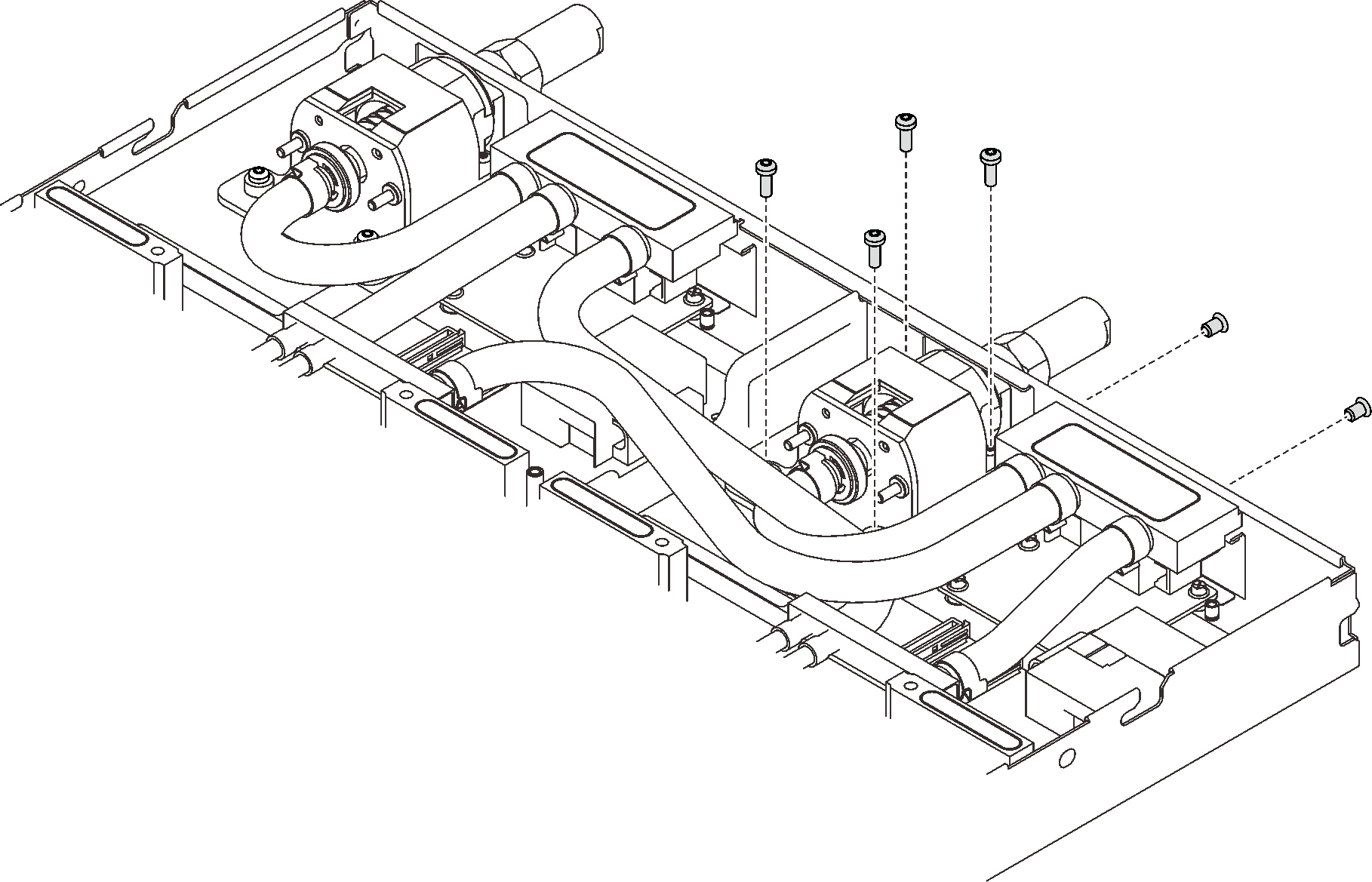

Align the VR water loop trough with the holes on the system board; then, fasten the two Torx T10 screws (per node).

Figure 5. VR water loop trough installation

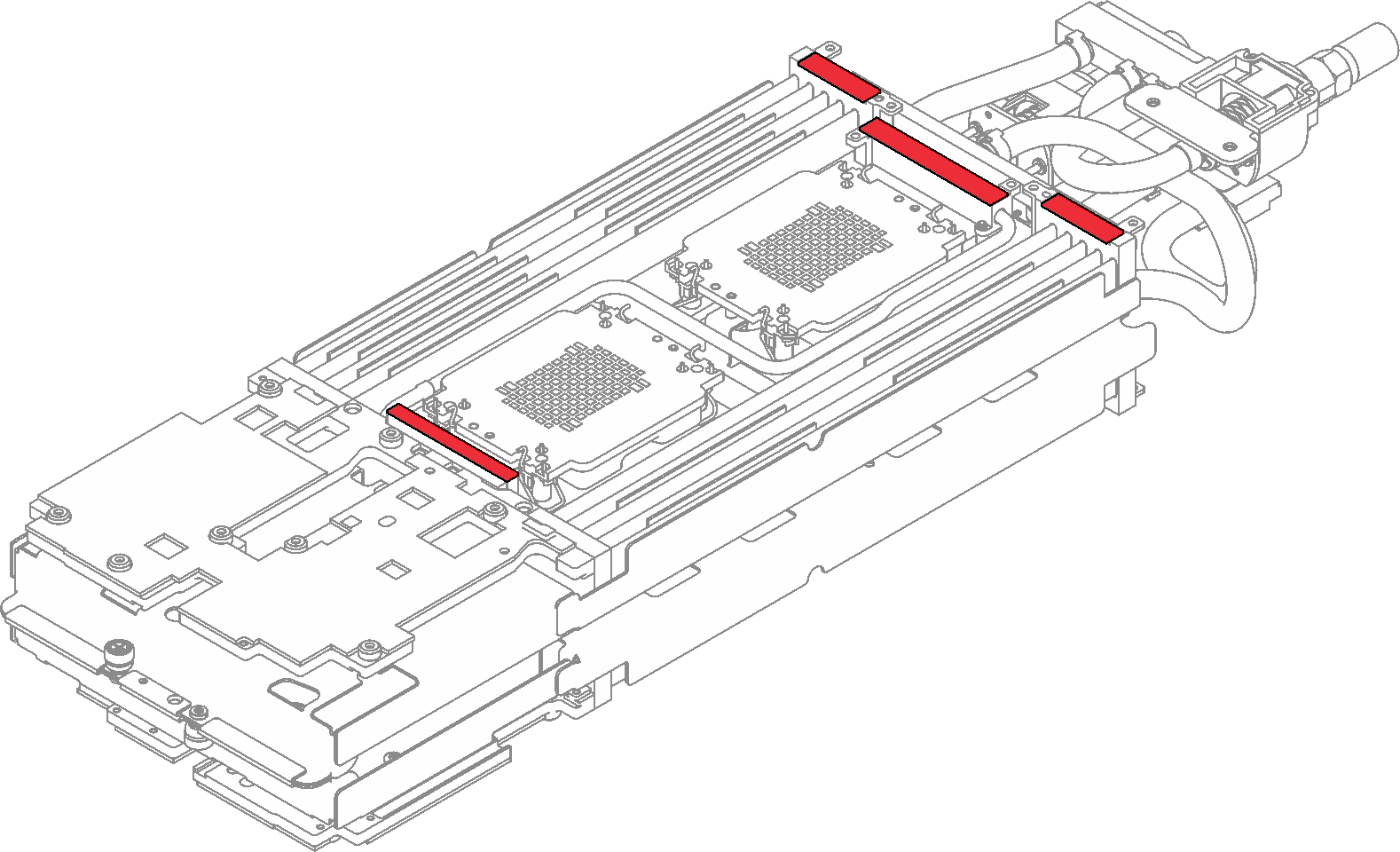

Check the gap pads on the water loop, if any of them are damaged or missing, replace them with the new ones.

Figure 6. Water loop - Gap pads

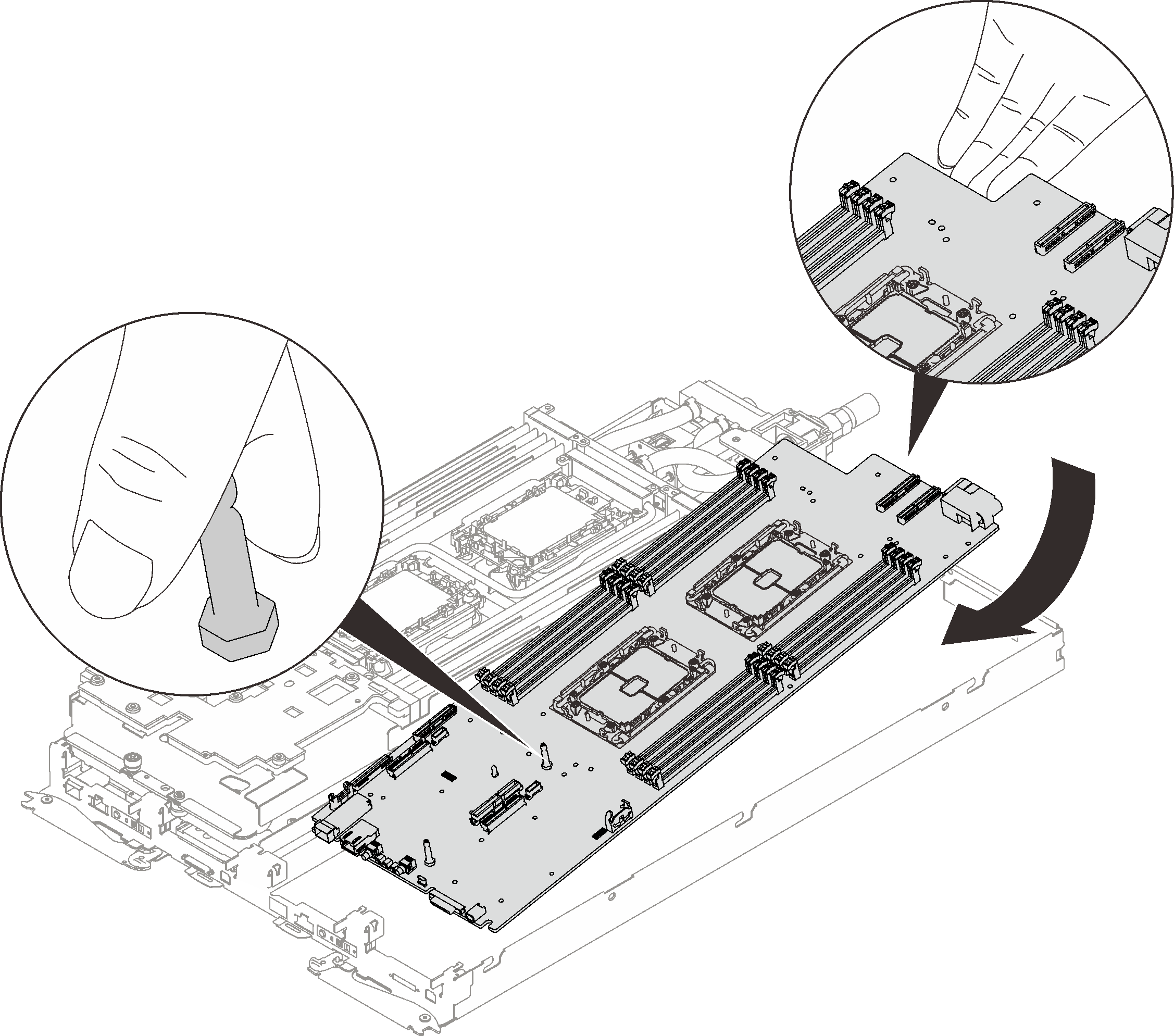

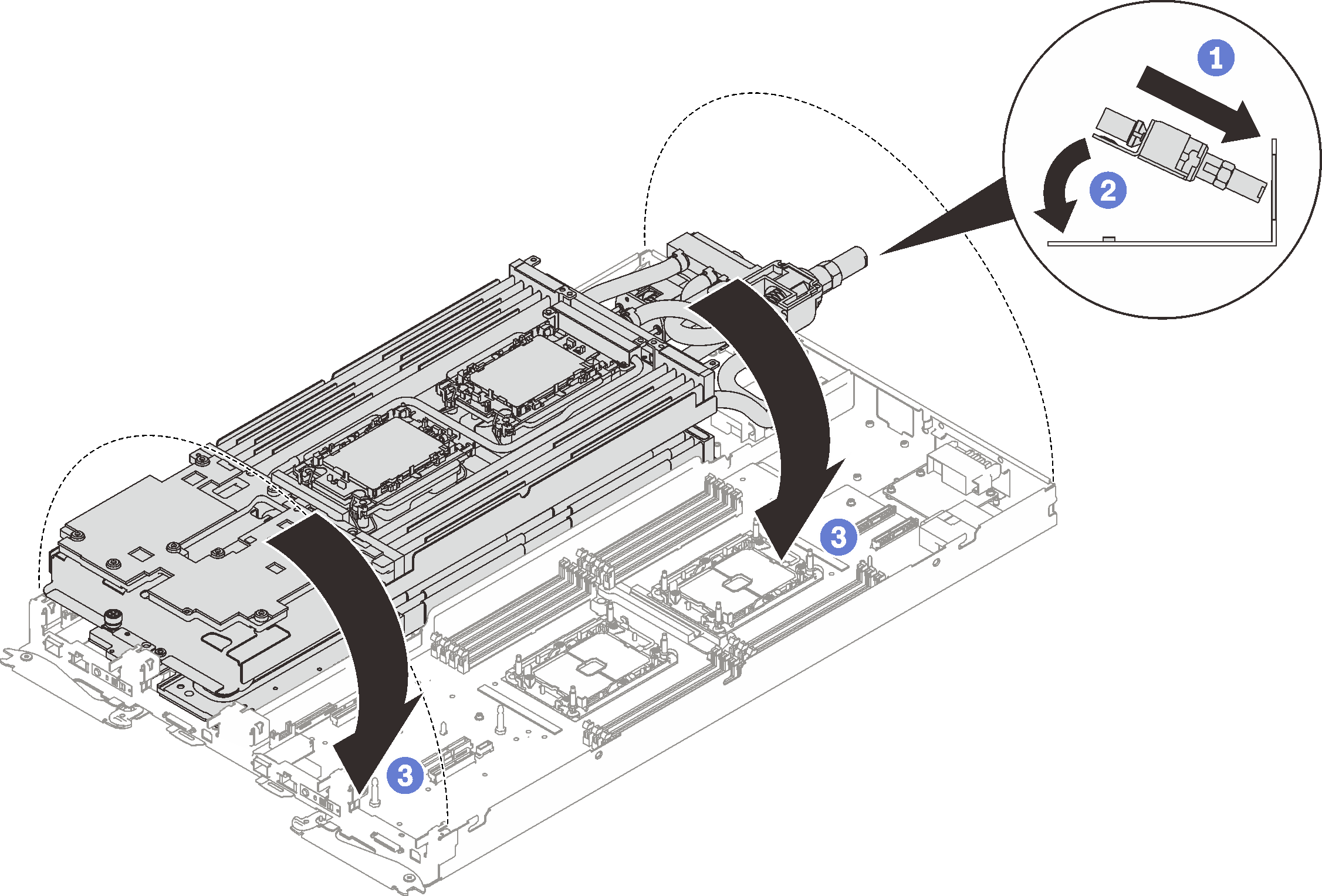

- Reinstall the water loop.

❶ Carefully rotate the top side of the water loop.

❷ Carefully insert the quick connect into the tray opening as shown.

❸ Carefully position the water loop on two guide pins near the rear of the node; then, gently put the water loop down and ensure it is firmly seated on the system board.

Figure 7. Water loop installation

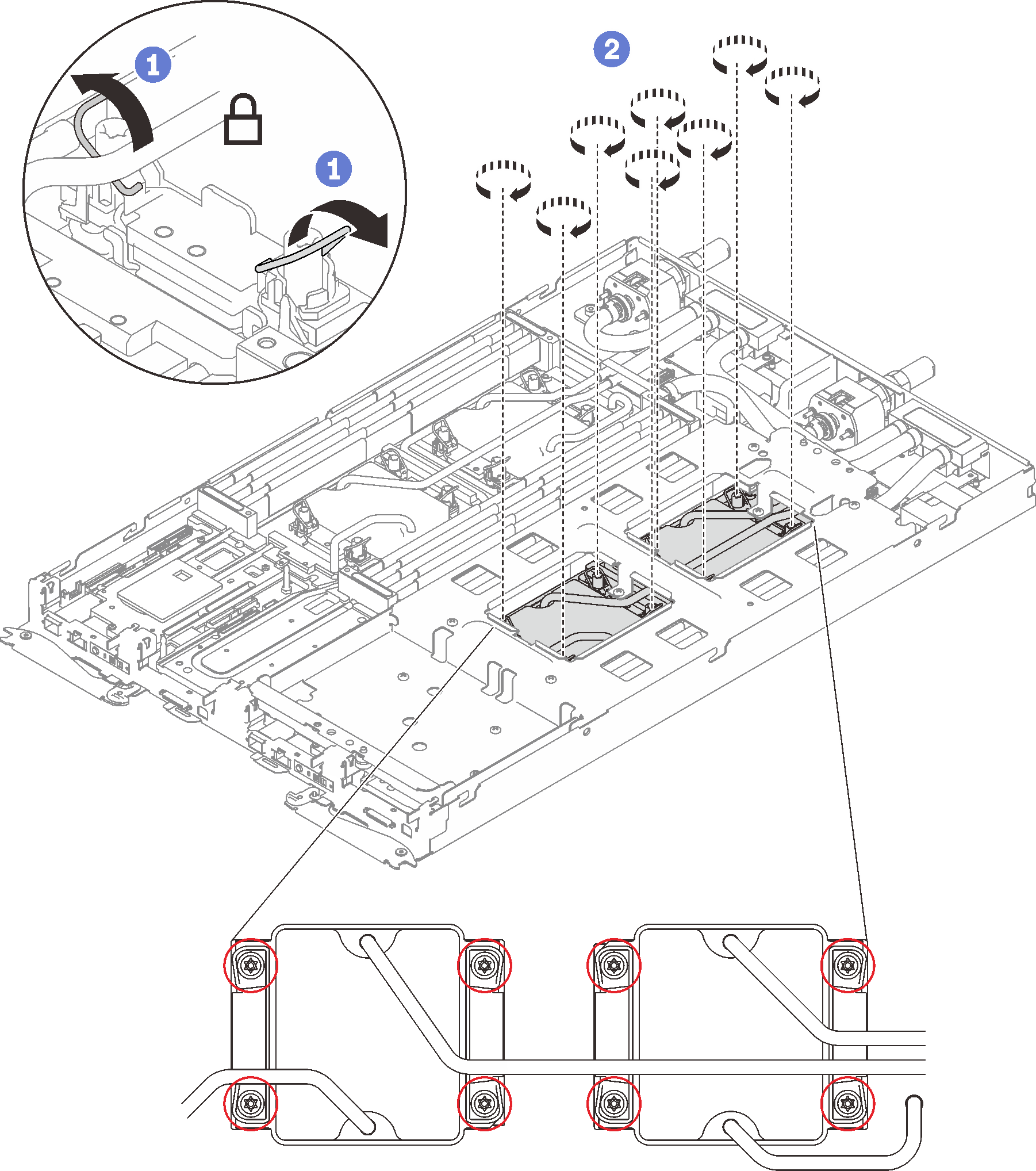

- Ensure the processors are secured properly.

❶ Rotate anti-tilt wire bails (8x anti-tilt wire bails per node) outwards to the locked position.

❷ Fully tighten all Torx T30 captive screws (8x Torx T30 captive screws per node) on cold plates in the installation sequence shown on the cold plate label (with a torque screwdriver sets to the proper torque).

NoteFor reference, the torque required for the screws to be fully tightened/removed is 1.1-1.15 newton-meters, 9.8-10.2 inch-pounds.AttentionTo prevent damage to components, make sure that you follow the indicated tightening sequence.

Figure 8. Processors installation

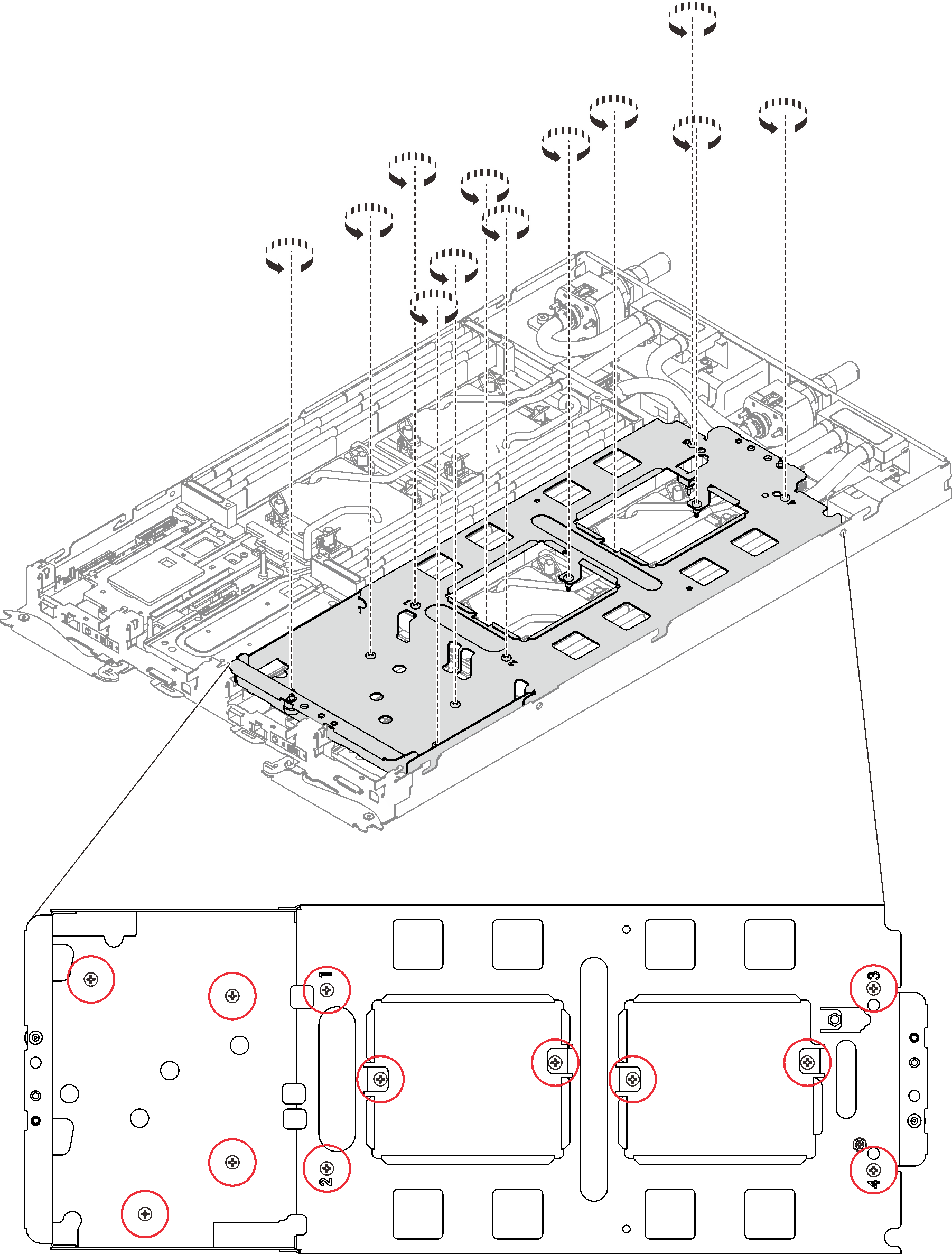

Loosen water loop carrier screws (12x Phillips #2 screws per node).

Figure 9. Loosening water loop carrier screws

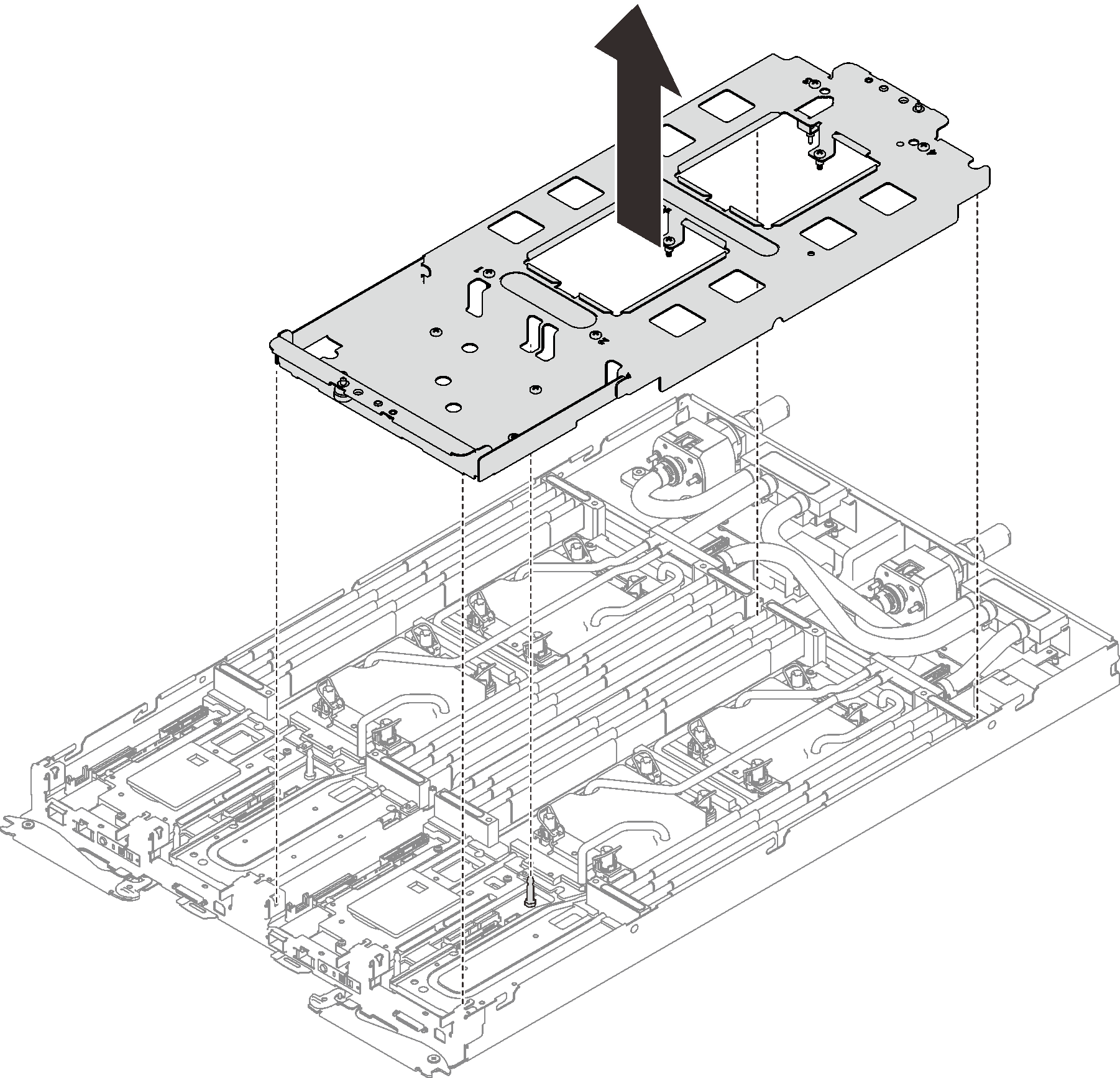

Carefully lift the water loop carrier up and away from the water loop.

Figure 10. Water loop carrier removal

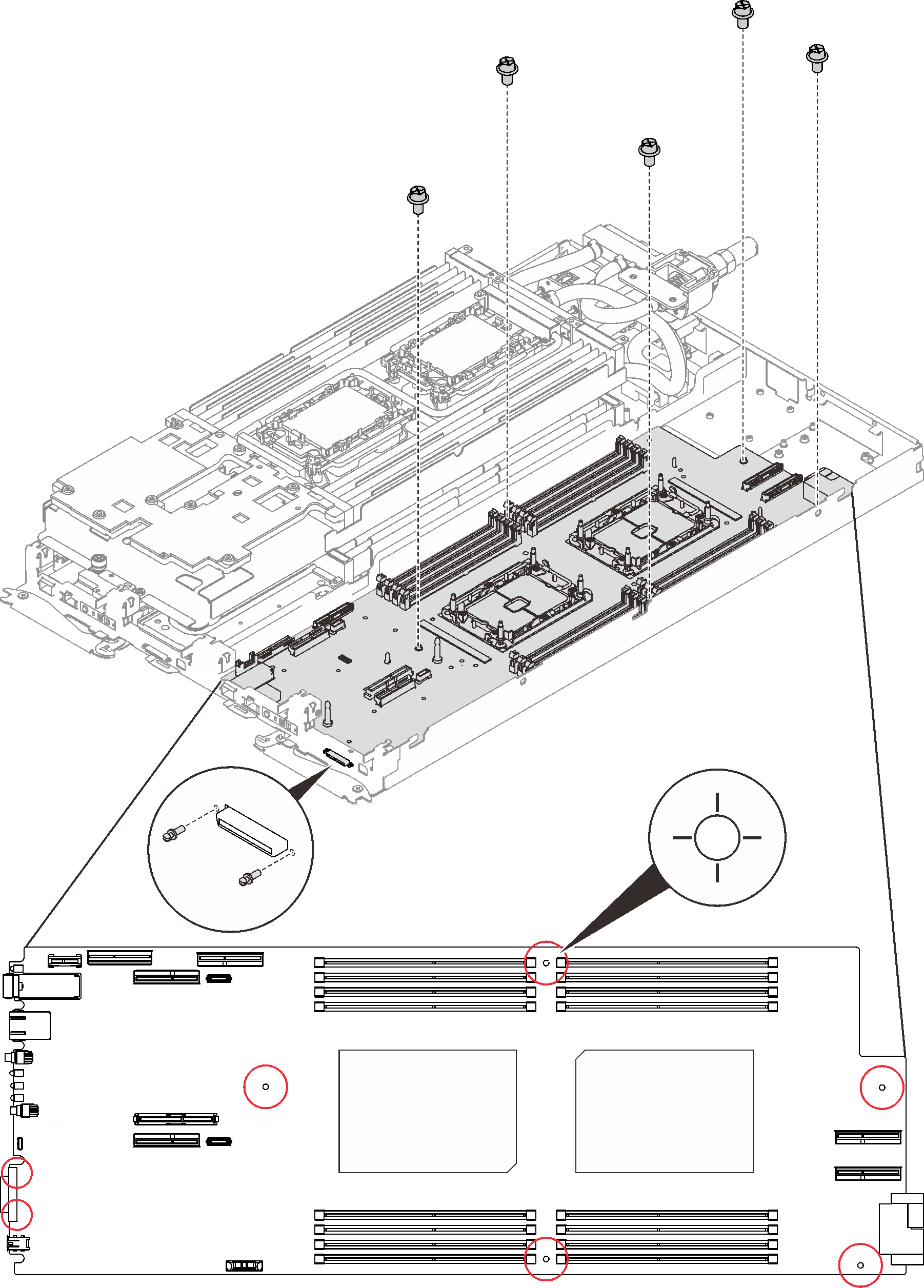

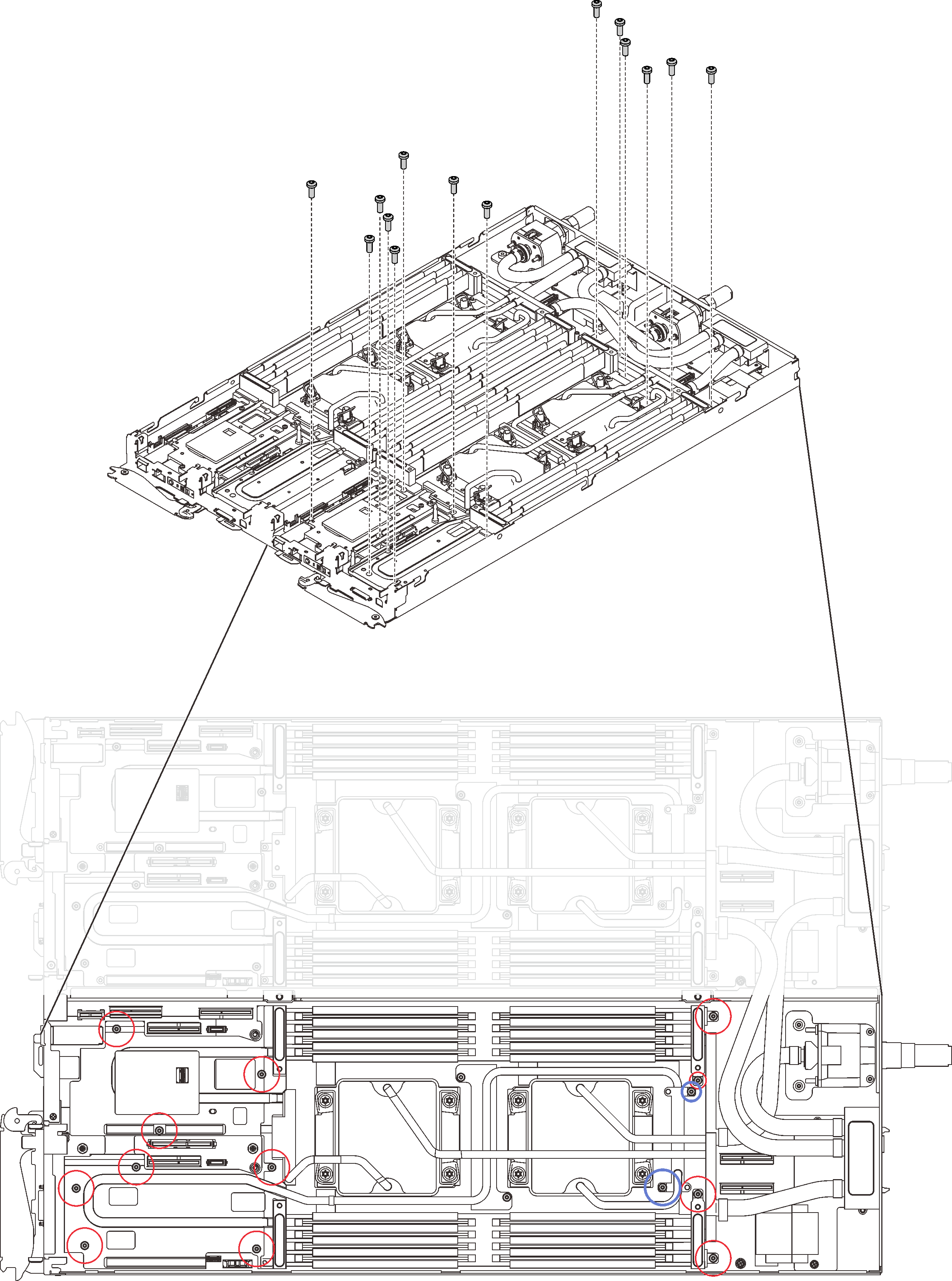

- Install the water loop screws (13x Torx T10 screws per node) with a torque screwdriver sets to the proper torque.Note

- For reference, the torque required for the screws to be fully tightened/removed is 0.5-0.6 newton-meters, 4.5-5.5 inch-pounds.

- The screw holes that are circled in blue are meant for 9.5 mm screws, while the others that are circled in red are meant for 8.0 mm ones.

Figure 11. Water loop screws installation

- Reinstall the following screws.

Four Torx T10 screws (per node) to secure the quick connect.

Two Phillips #1 screws (per node) on the rear of the node.

Figure 12. Screws installation

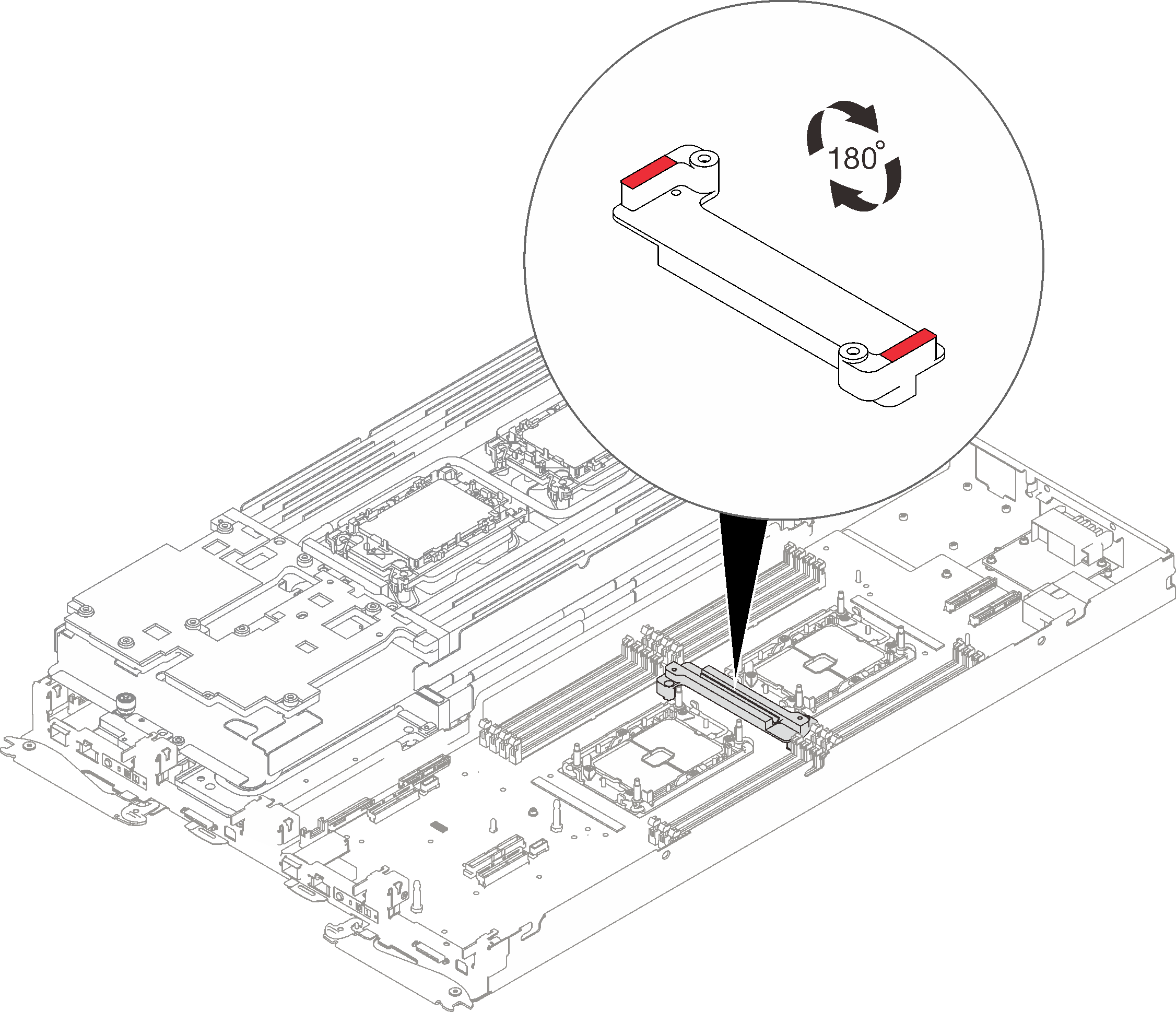

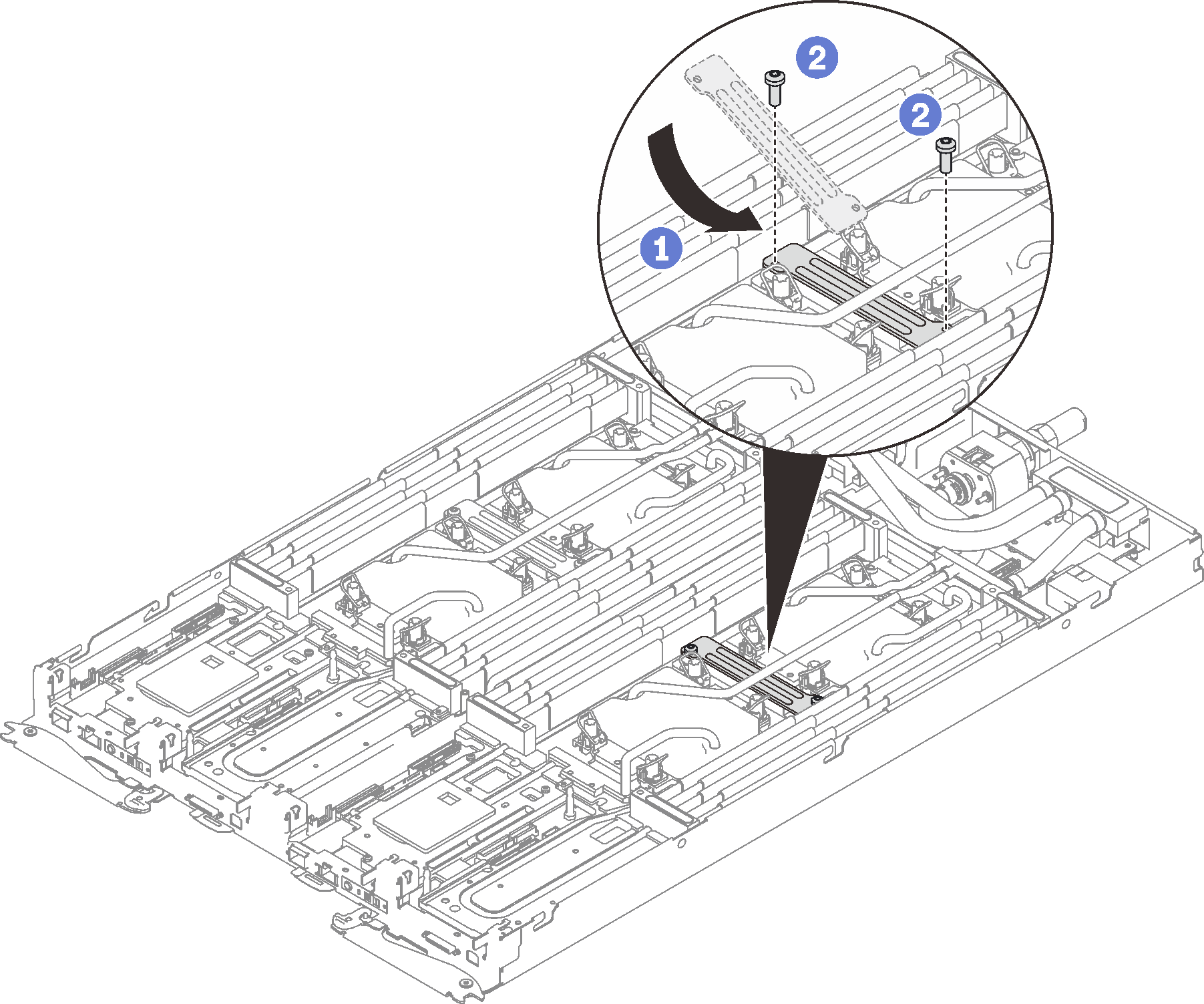

Slide the VR clamp plate into the node and install two Torx T10 screws (per node).

Figure 13. VR clamp plate installation

Reinstall DIMMs for both nodes (see Install a memory module).

Reinstall DIMM combs. (see Install a DIMM comb).

Reinstall M.2 backplanes (see Install the M.2 backplane).

Reinstall drive cage assemblies if applicable (see Install a drive cage assembly).

Reinstall PCIe rise assemblies if applicable (see Install a PCIe adapter).

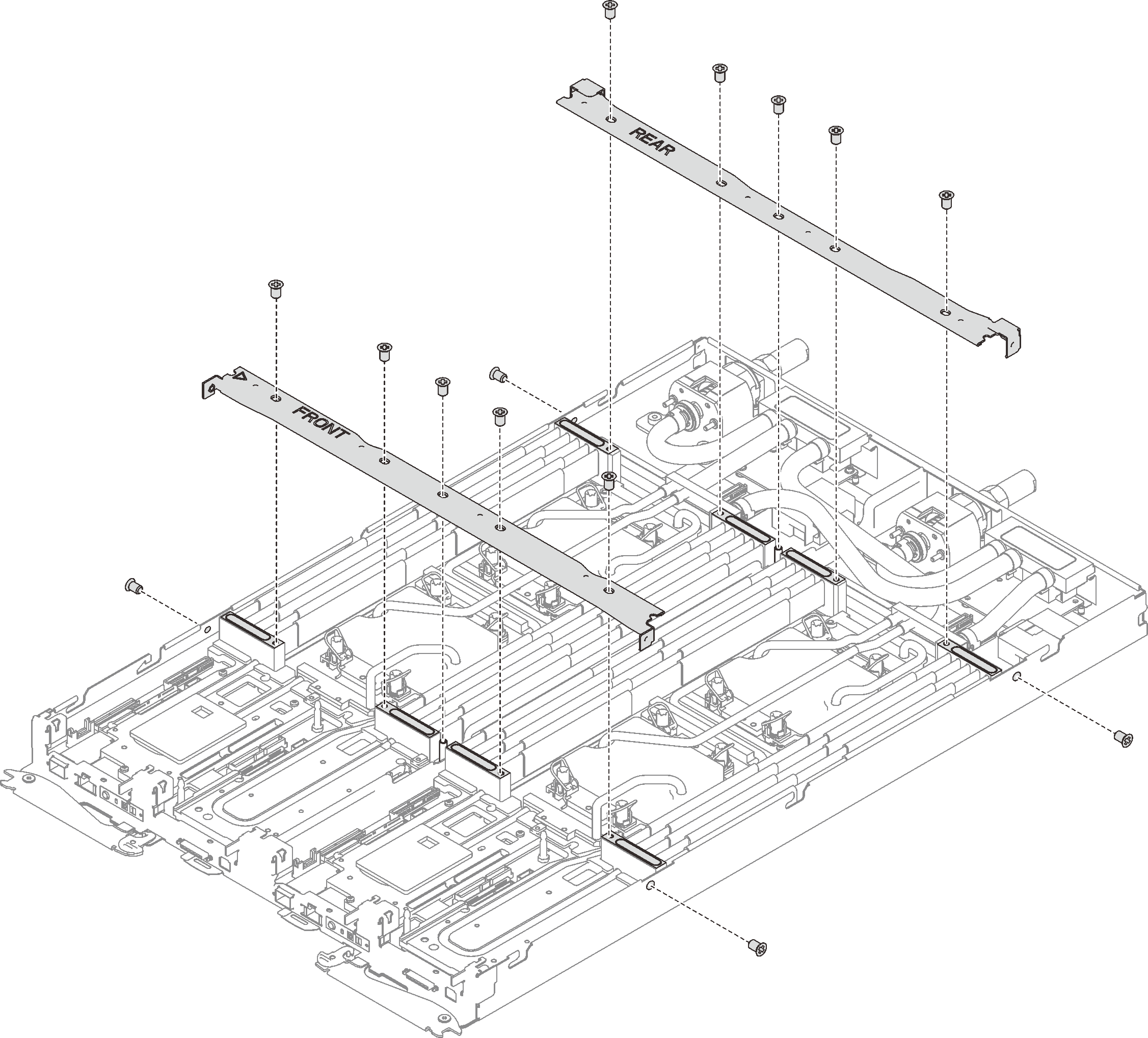

Reinstall the front and the rear cross braces (14x Phillips #1 screws).

Figure 14. Cross brace installation

Reinstall the tray cover (see Install the tray cover).

Reinstall the tray (see Install a DWC tray in the enclosure).

NoteFor safety, use the lift tool to install the tray into the rack.- Connect all required external cables to the enclosure.NoteUse extra forces to connect QSFP cables to the enclosure if Mellanox ConnectX-6 adapters are installed.

Check the power LED on each node to make sure it changes from fast blink to slow blink to indicate all nodes are ready to be powered on.

Update the Universally Unique Identifier (UUID) and DMI/SMBIOS data with new vital product data (VPD). Use the Lenovo XClarity Provisioning Manager to update the UUID and DMI/SMBIOS data. See Update the Universal Unique Identifier (UUID) and Update the asset tag.

Enable TPM/TCM. See Enable TPM/TCM

Optionally, enable Secure Boot.

Demo video