Remove the system board

Use this information to remove the system board.

About this task

To avoid a shock hazard:

- Connect all power cords to a properly wired and grounded electrical outlet/source.

- Connect any equipment that will be attached to this product to properly wired outlets/sources.

- When possible, use one hand only to connect or disconnect signal cables.

- Never turn on any equipment when there is evidence of fire, water, or structural damage.

- The device might have more than one power cord, to remove all electrical current from the device, ensure that all power cords are disconnected from the power source.

- Read the following sections to ensure that you work safely.

- Turn off the corresponding DWC tray that you are going to perform the task on.NoteIf Shared I/O adapters are installed, power off the auxiliary node (node 1/3/5/7/9/11) first, and then power off the primary node (node 2/4/6/8/10/12).

- Disconnect all external cables from the enclosure.NoteUse extra forces to disconnect QSFP cables if they are connected to the solution.

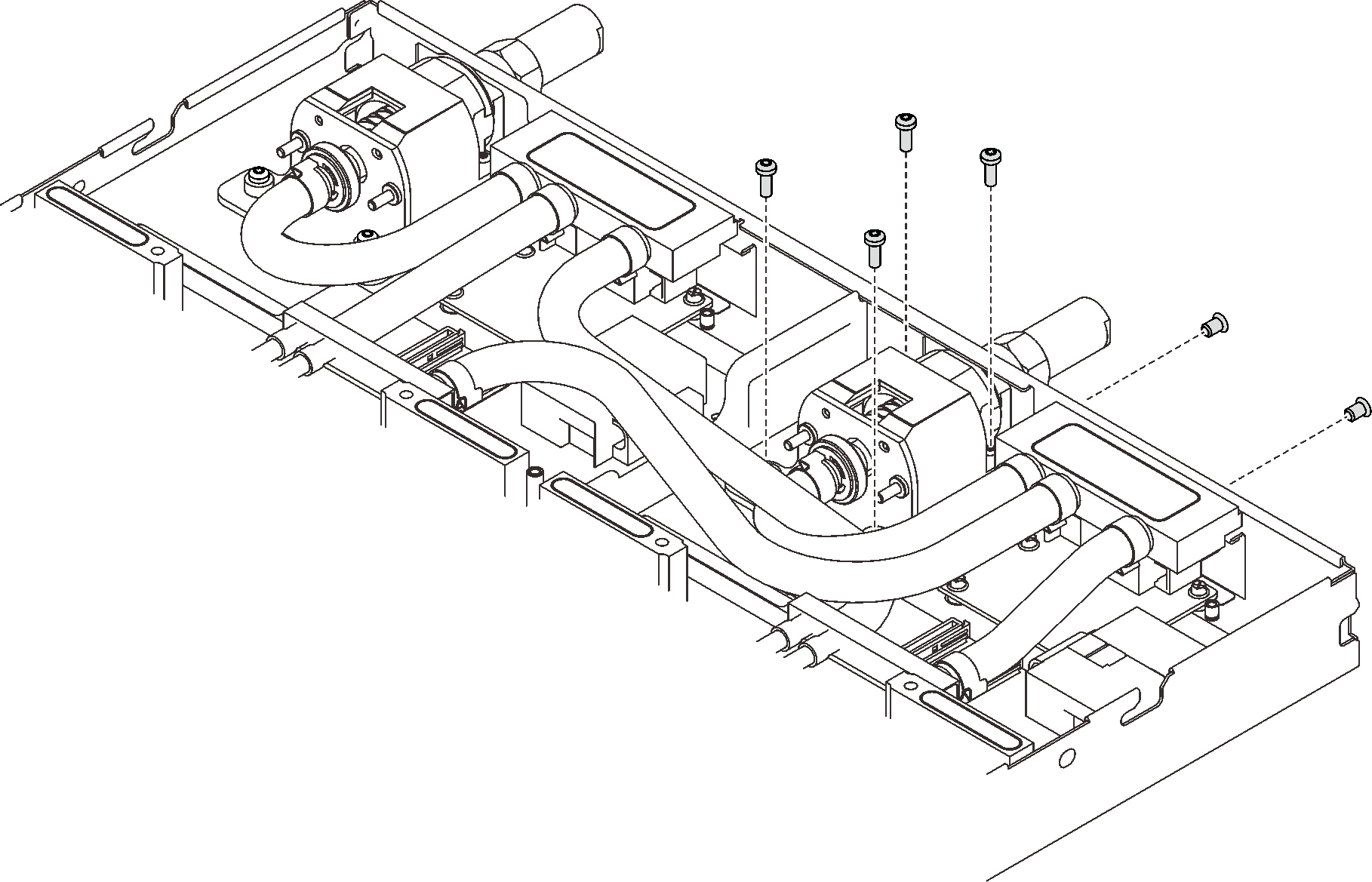

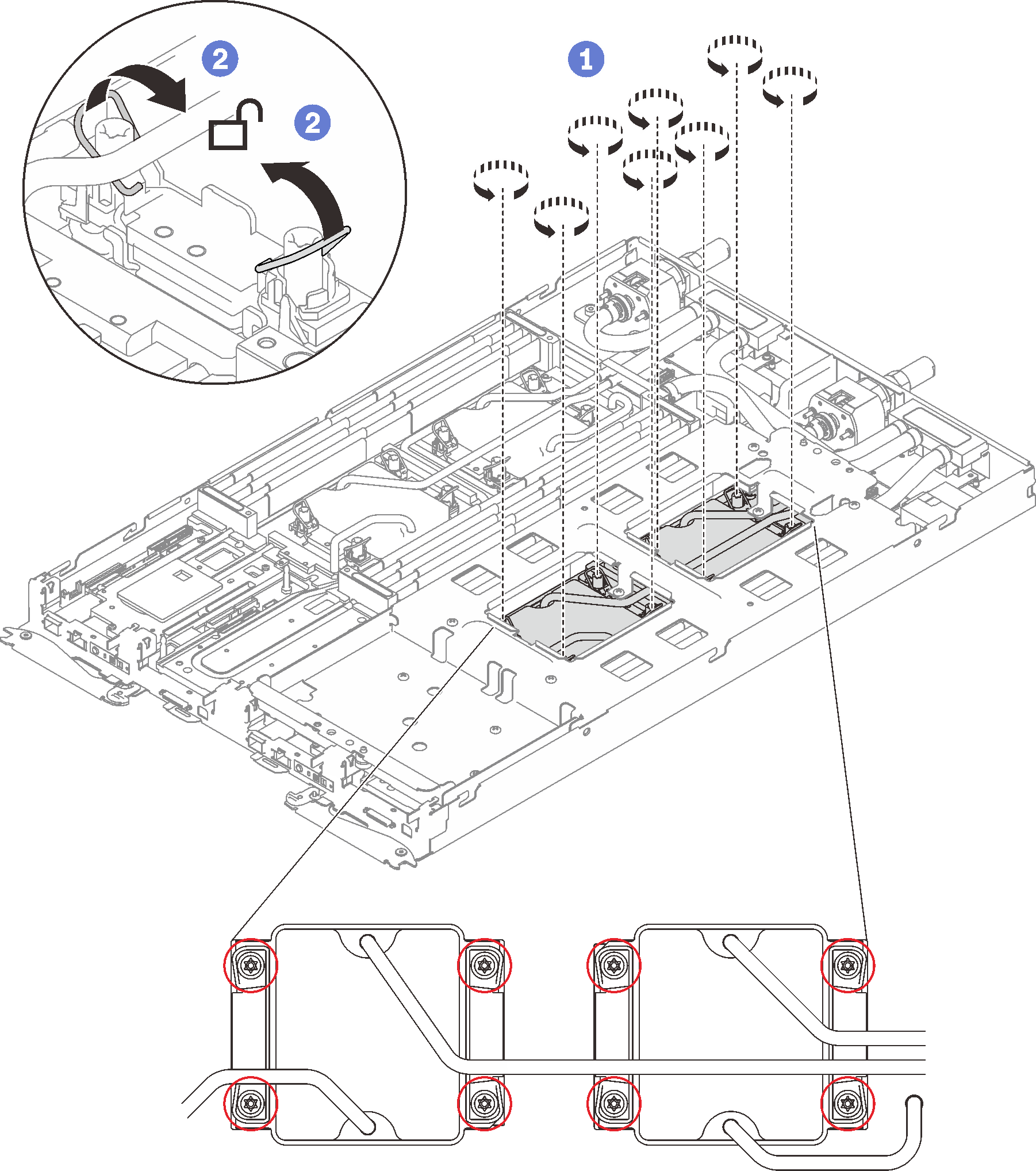

To avoid damaging the water loop, always use the water loop carrier when removing, installing or folding the water loop.

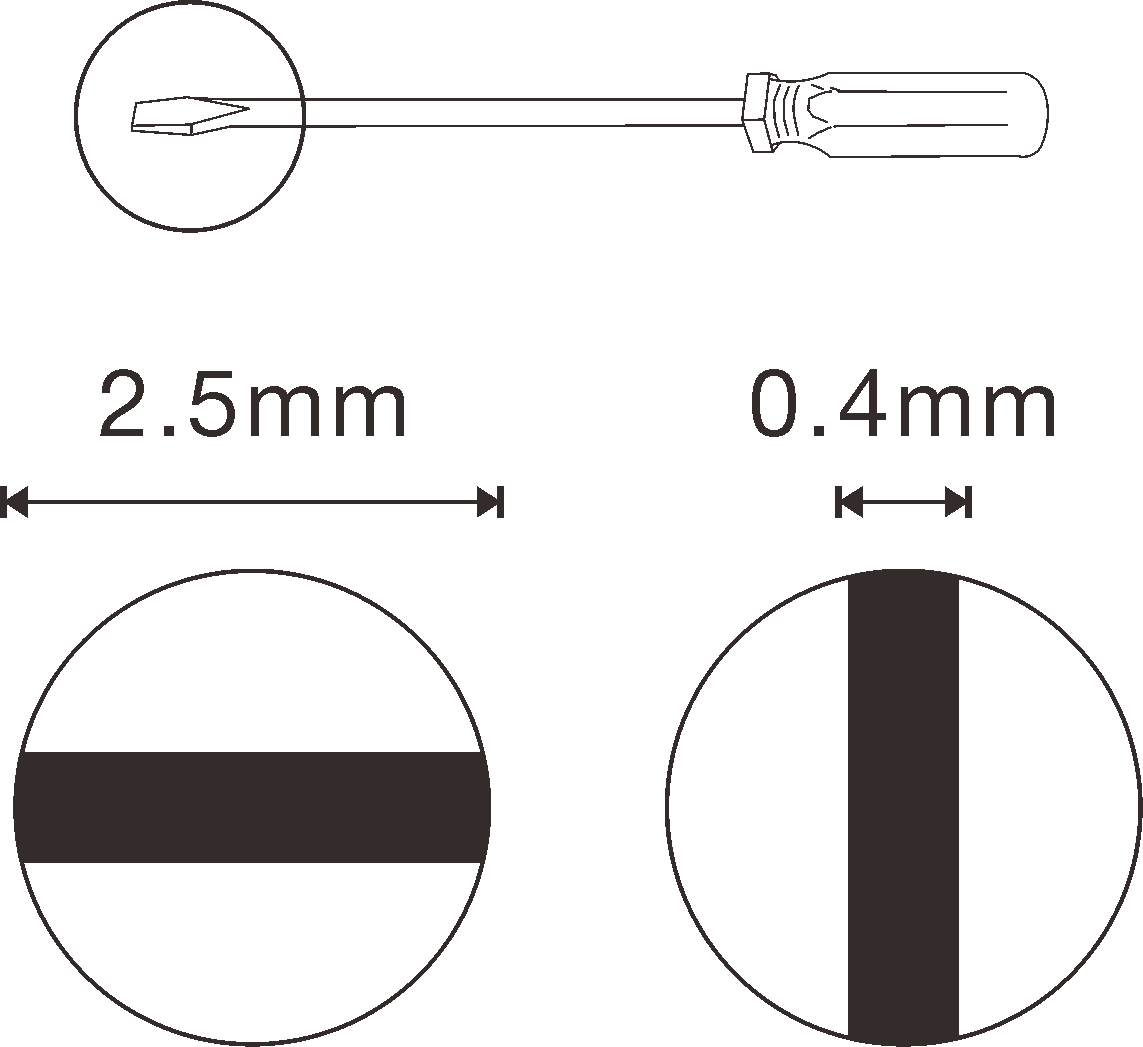

| Screwdriver type | Screw type |

| Torx T10 head screwdriver | Torx T10 screw |

| Torx T30 head screwdriver | Torx T30 screw |

| Phillips #1 head screwdriver or 3/16" hex head screwdriver | Phillips #1 screw |

| Phillips #2 head screwdriver | Phillips #2 screw |

| 3/16" hex head screwdriver | Hex head screw |

| 2.5x0.4 mm Flat head screwdriver | 2.5x0.4 mm flat head screwdriver |

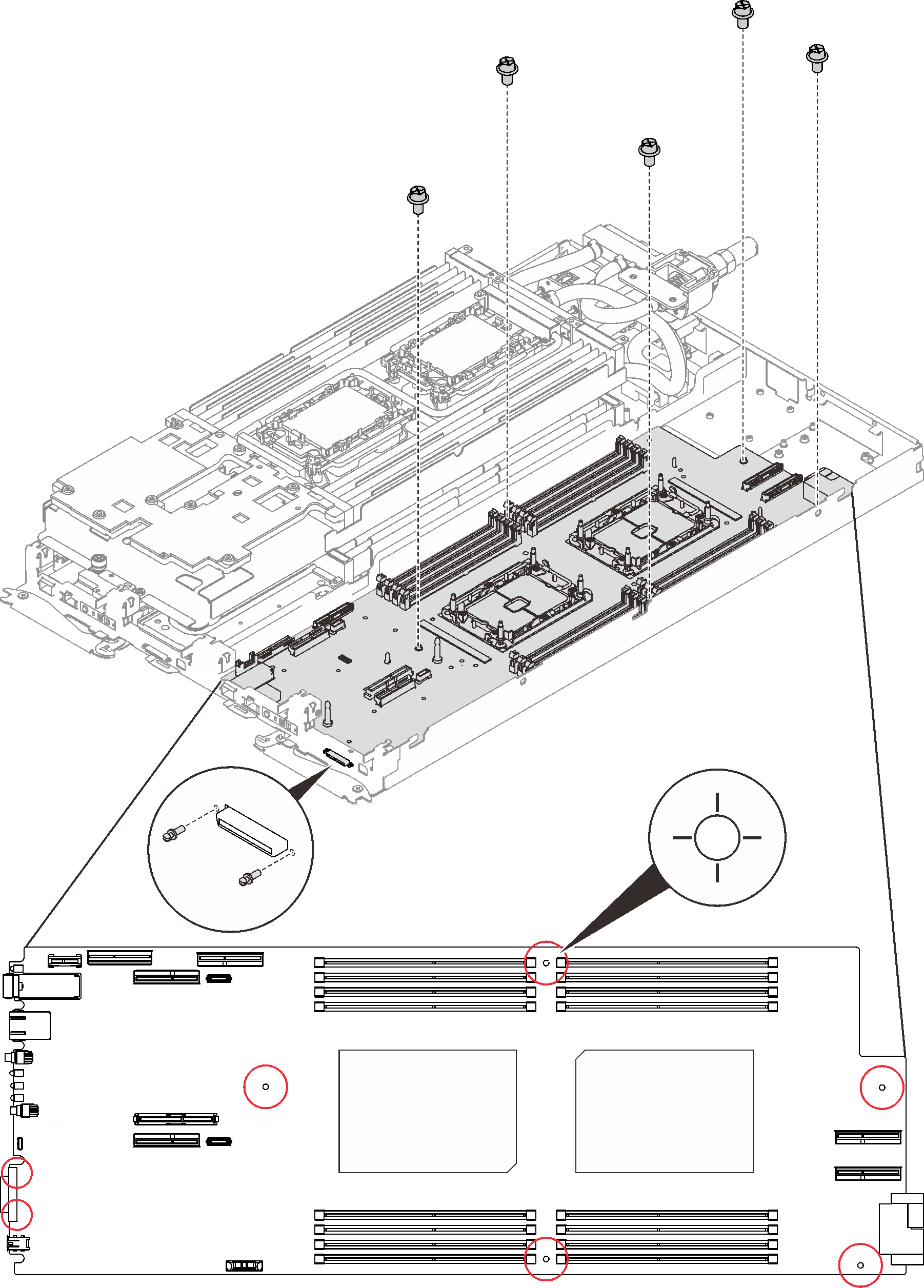

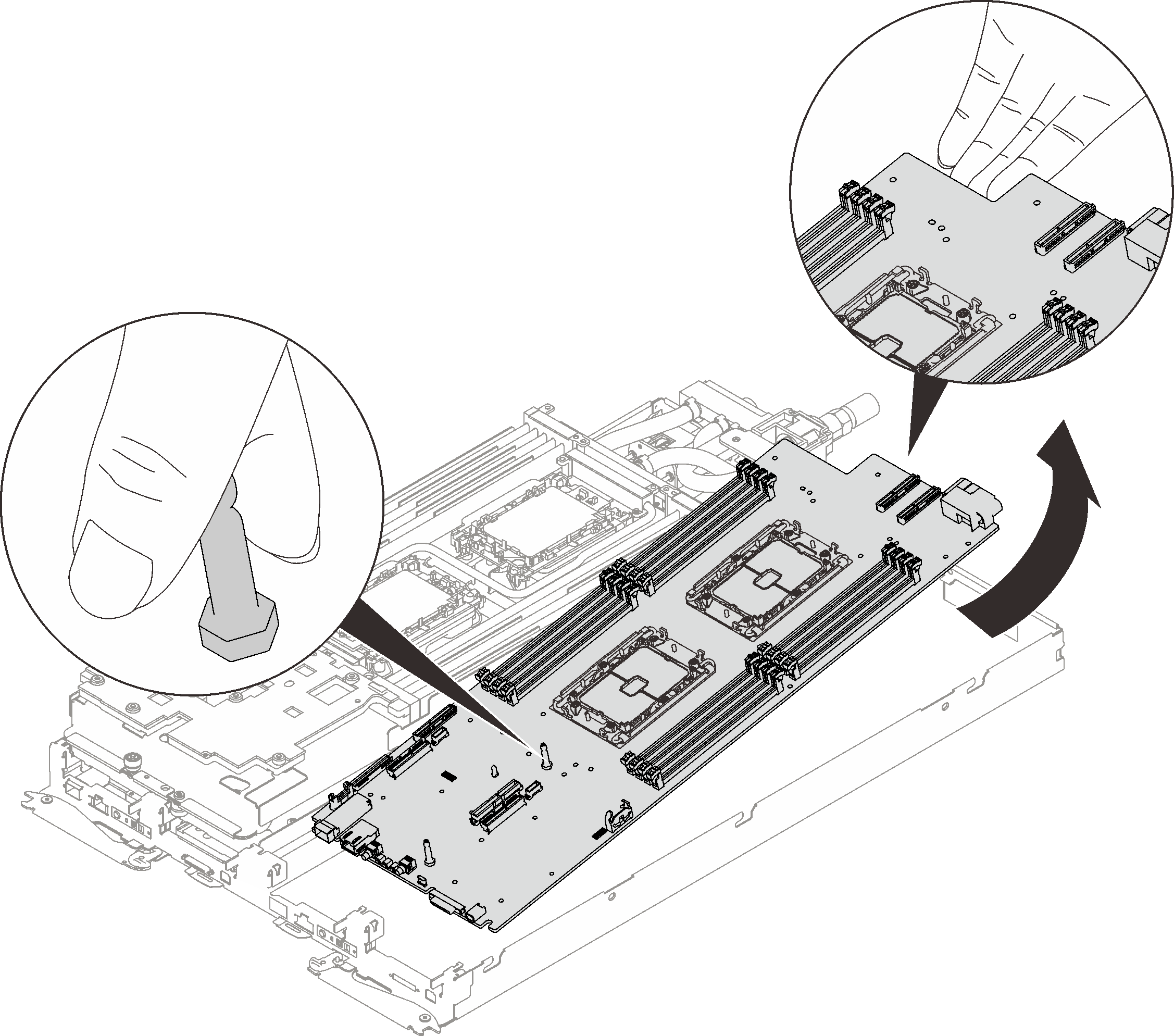

Procedure

If you are instructed to return the component or optional device, follow all packaging instructions, and use any packaging materials for shipping that are supplied to you.

Take a dust cover from the processor socket assembly on the new system board and orient it correctly above the processor socket assembly on the removed system board.

Gently press down the dust cover legs to the processor socket assembly, pressing on the edges to avoid damage to the socket pins. You might hear a click on the dust cover is securely attached.

Make sure that the dust cover is securely attached to the processor socket assembly.

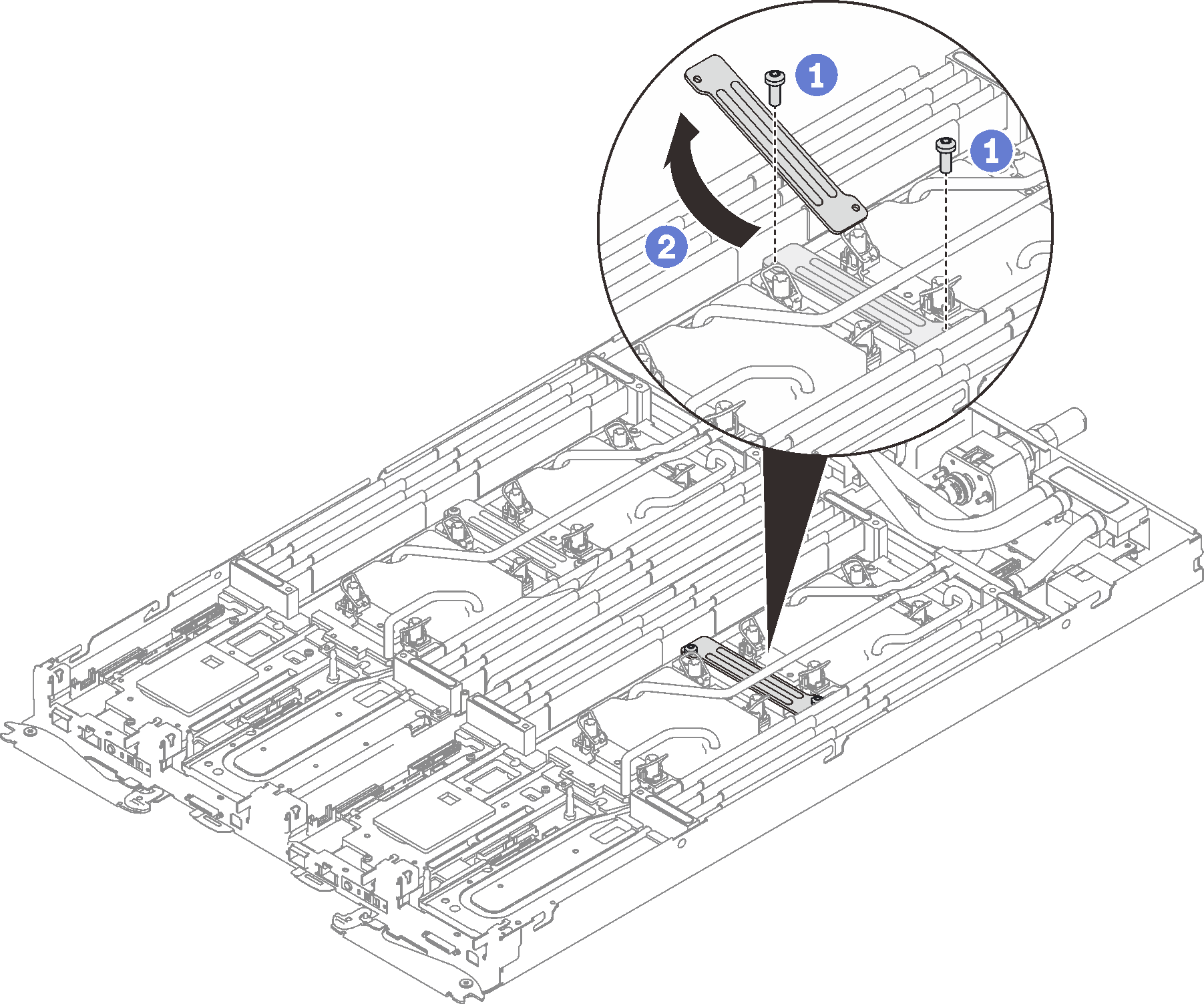

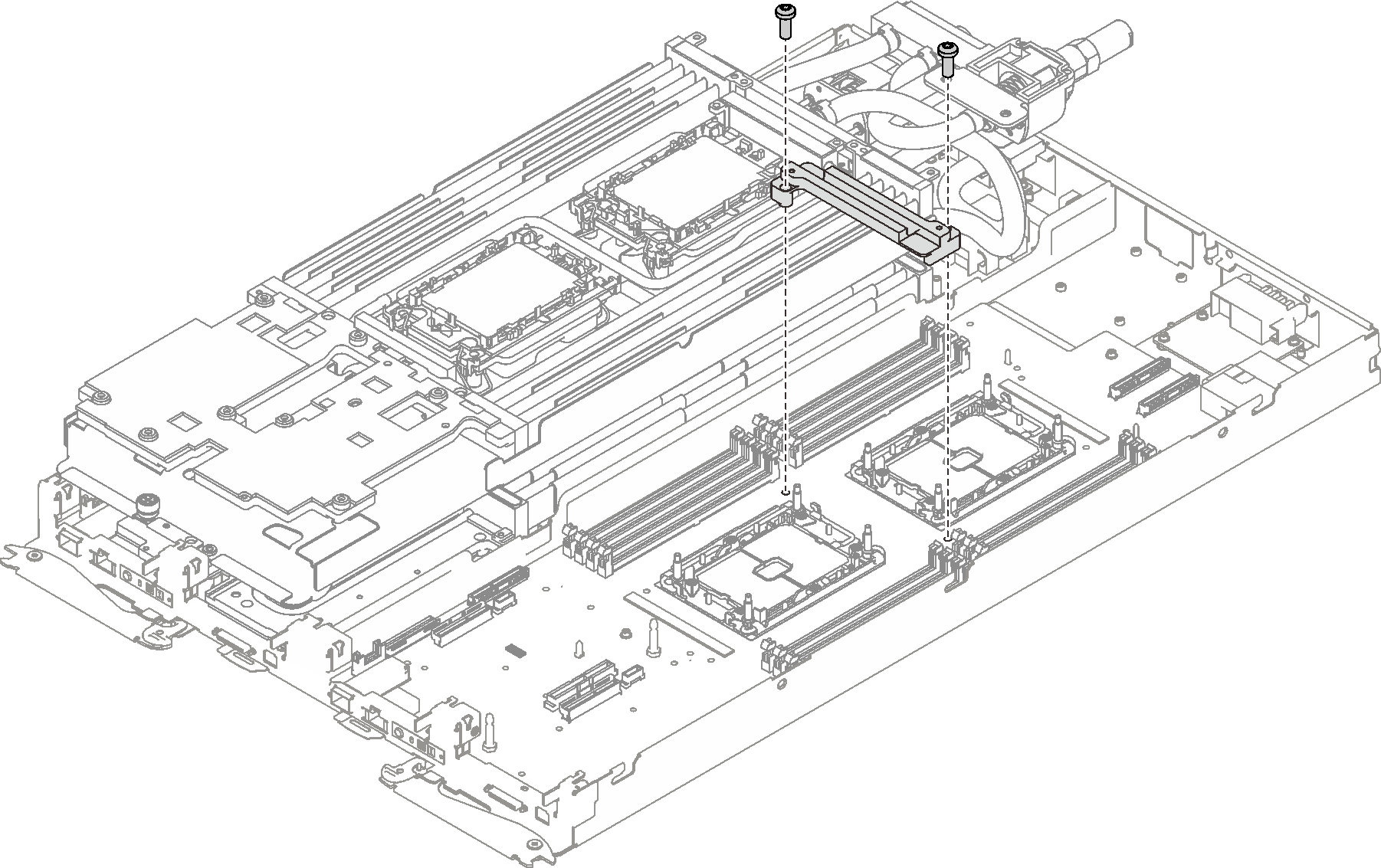

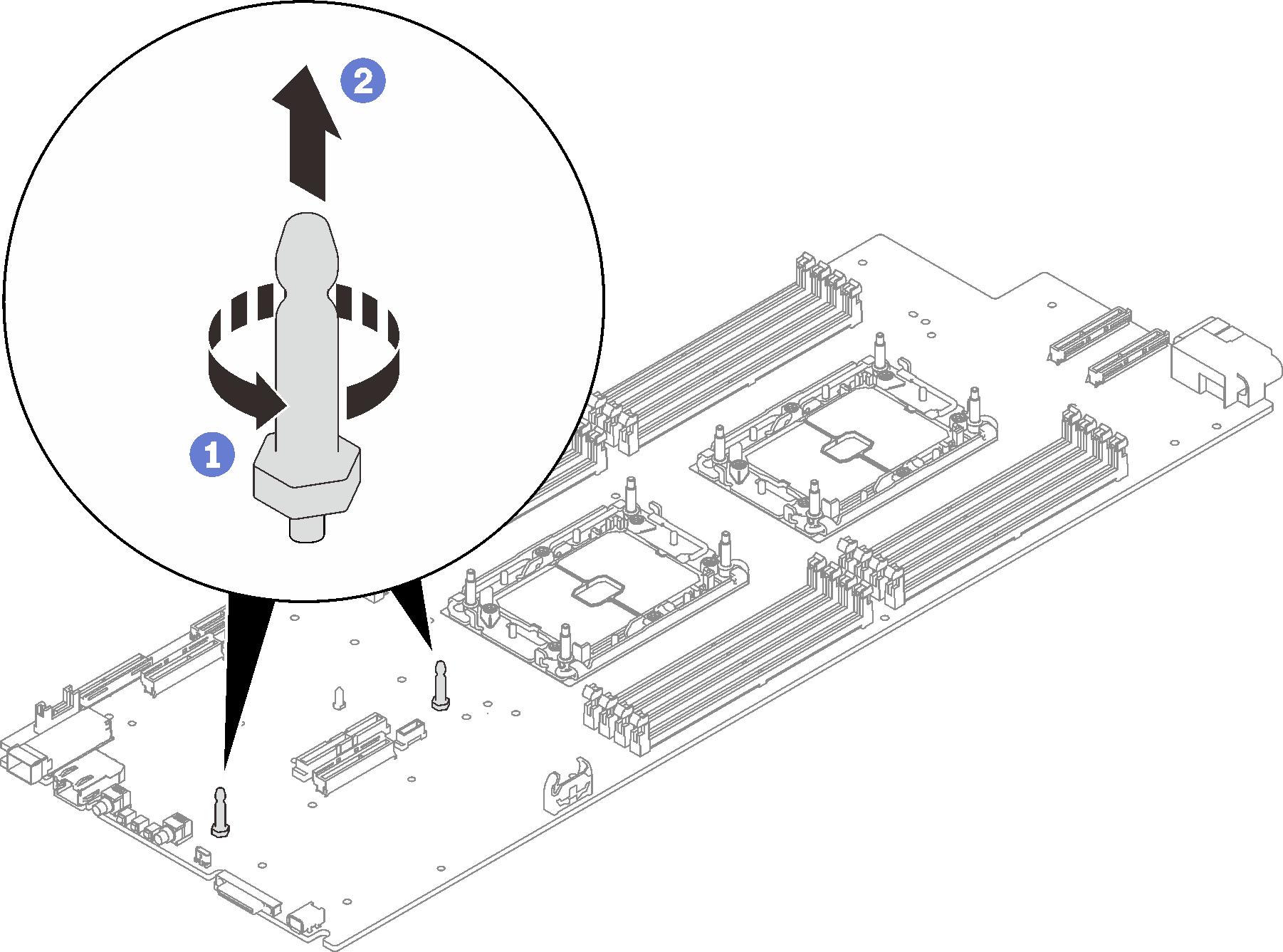

Remove the two guide pins out of the system board.

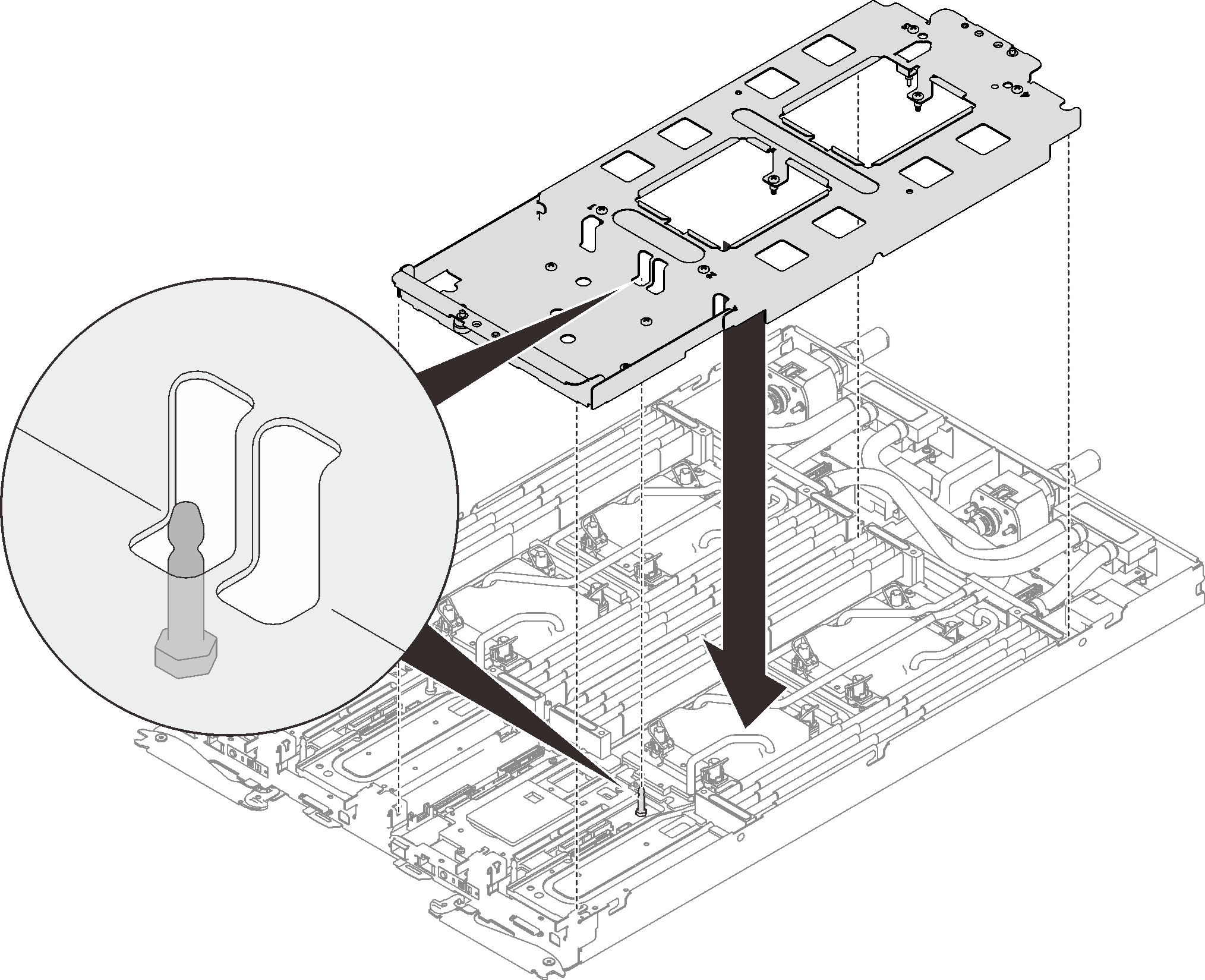

Figure 13. Guide pins removal

Recycle the unit in compliance with local regulations.

Demo video