Install a CX-7 heat sink

Follow the instructions in this section to install a CX-7 heat sink. The procedure must be executed by a trained technician.

About this task

Attention

- Read Installation Guidelines and Safety inspection checklist to ensure that you work safely.

- Power off the server and peripheral devices and disconnect the power cords and all external cables. See Power off the server.

- Prevent exposure to static electricity, which might lead to system halt and loss of data, by keeping static-sensitive components in their static-protective packages until installation, and handling these devices with an electrostatic-discharge wrist strap or other grounding system.

Important

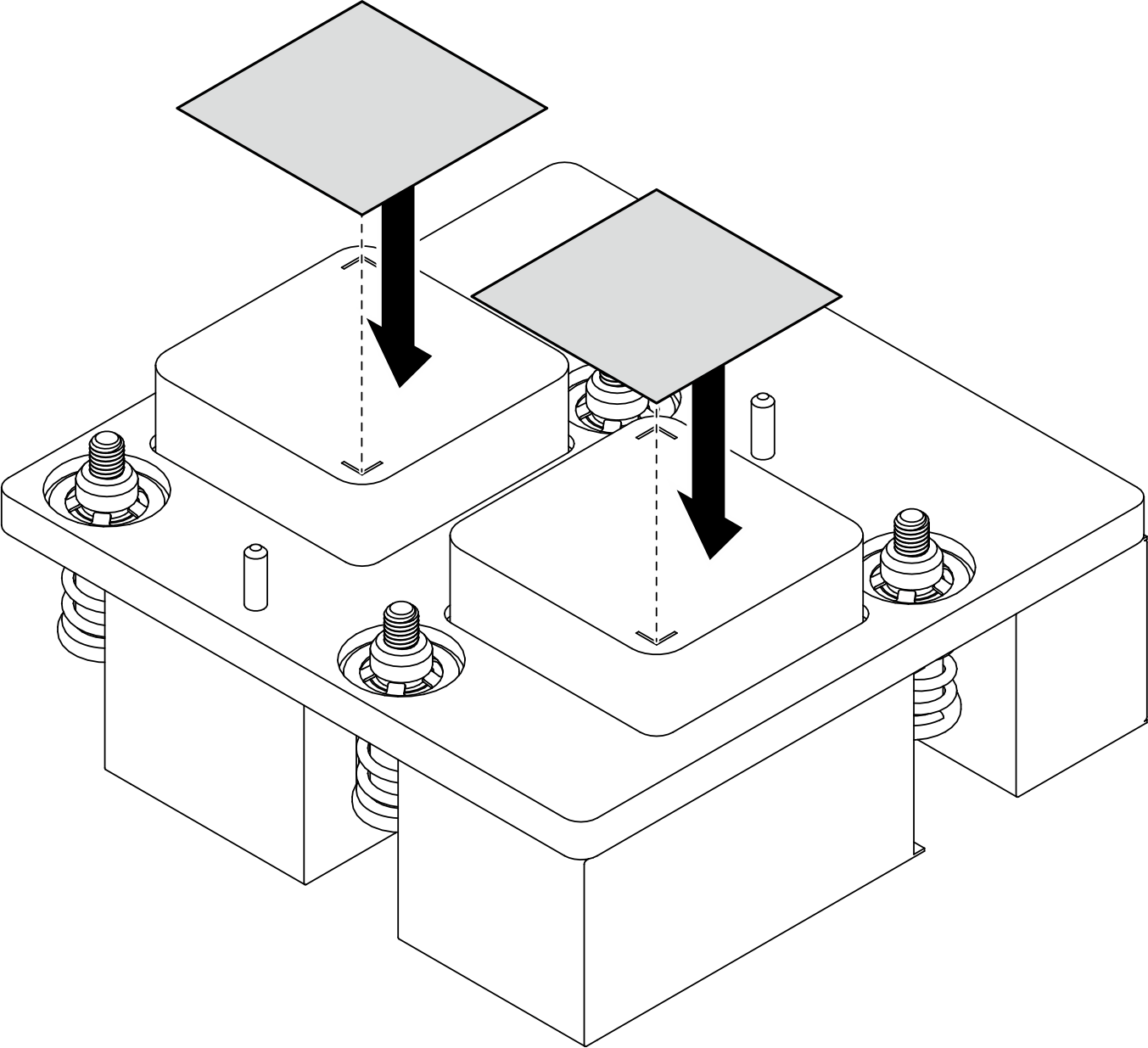

Putty pad/phase change material (PCM) replacement guidelines

- Before replacing the putty pad/PCM, gently clean the hardware surface with an alcohol cleaning pad.

- Hold the putty pad/PCM carefully to avoid deformation. Make sure no screw hole or opening is blocked by the putty pad/PCM.

- Do not use expired putty pad/PCM. Check the expiry date on putty pad/PCM package. If the putty pads/PCM are expired, acquire new ones to properly replace them.

Note

Make sure you have the required tools listed below available to properly replace the component:

- Torx T15 bit

- Torque screwdriver

- Alcohol cleaning pad

- SR675 V3 CX-7 heat sink putty pad kit

Procedure

After you finish

- Reinstall the CX-7 assembly. See Install the CX-7 assembly.

- Reconnect the cables to the CX-7 carrier board and the CX-7 mezz board. See CX-7 carrier board cable routing and OSFP port card cable routing for more information.CAUTION

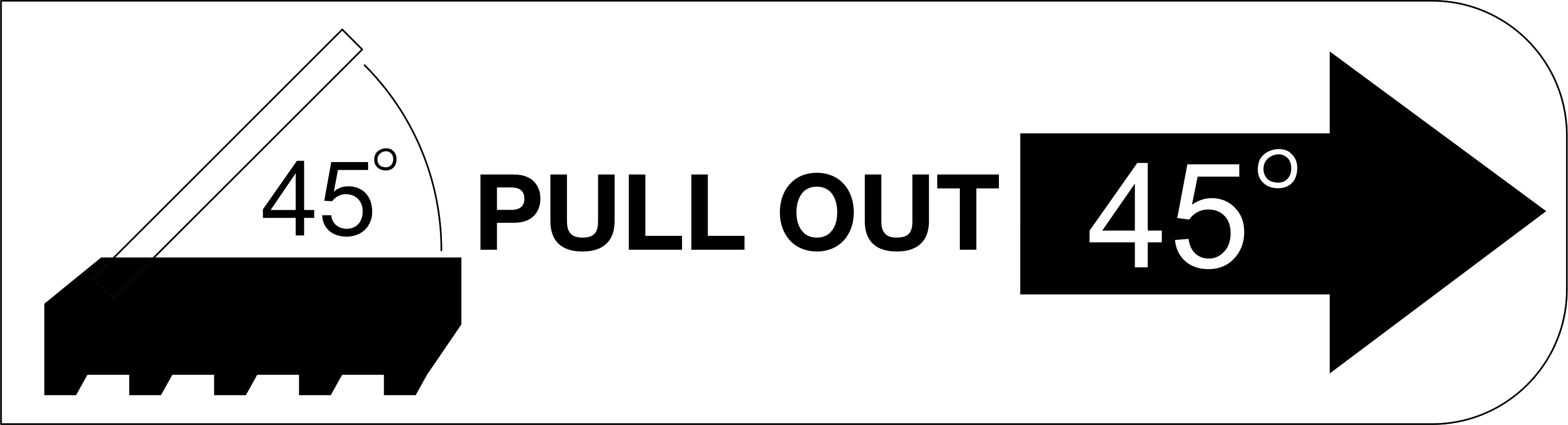

- Hold the cable connector at 45 degree angle when inserting it into the port.

- Have extremely precaution when reseating the connectors that have a 45 degree label on them as they are fragile and will get damage if not installed in the correct 45 degree angle.

- Complete the parts replacement. See Complete the parts replacement.

Demo video

Give documentation feedback

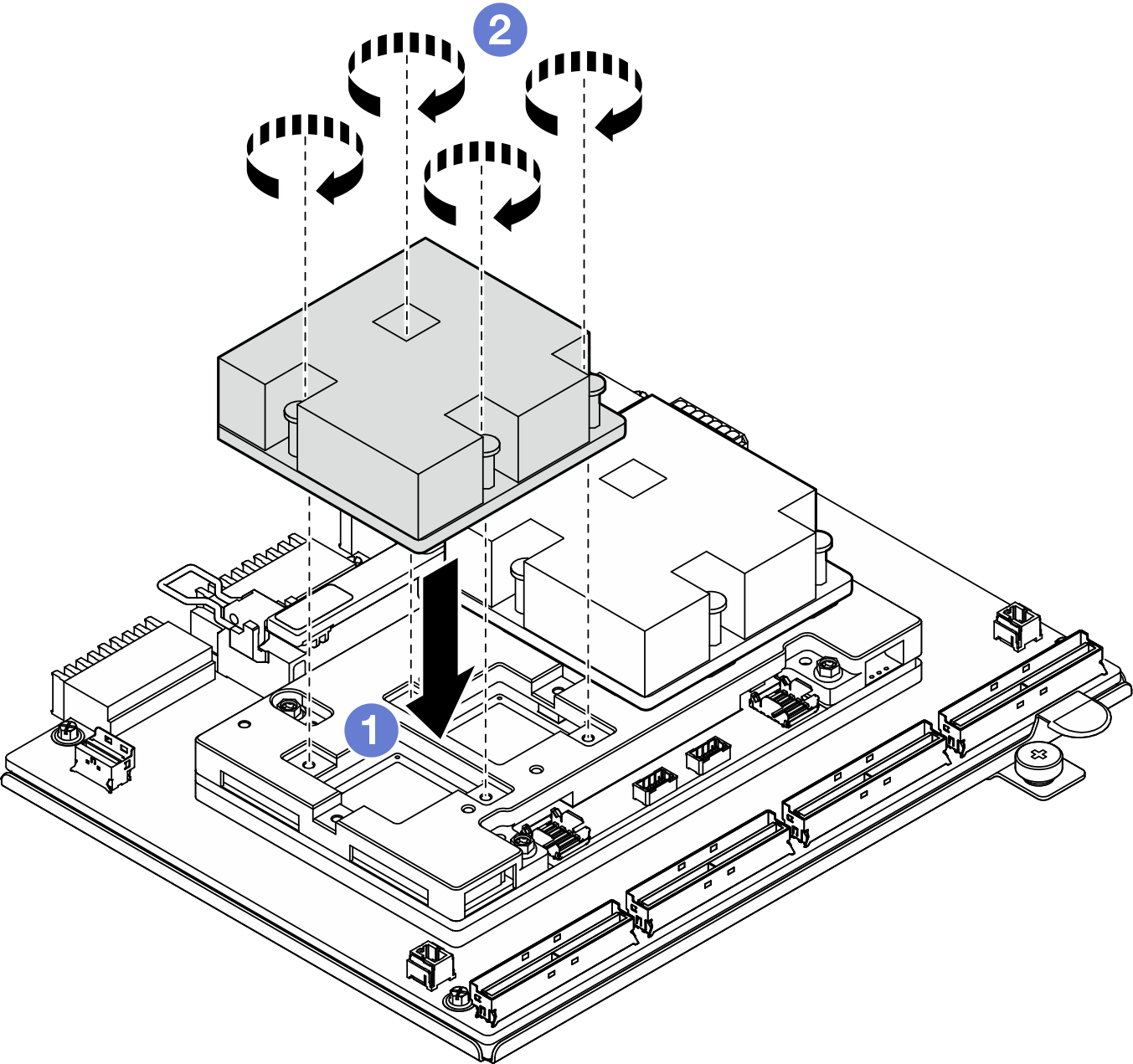

Orient the

Orient the  Fasten the four Torx T15 screws in the installation sequence shown on the

Fasten the four Torx T15 screws in the installation sequence shown on the