Installing an additional microprocessor and heat sink

Use this information to install an additional microprocessor and heat sink.

The following notes describe the type of microprocessor that the server supports and other information that you must consider when you install a microprocessor:

- The server supports Intel scalable multi-core microprocessors which are designed for the LGA 2011 socket. Scalable up to ten cores with an integrated memory controller, quick-path interconnect and shared last cache. See https://static.lenovo.com/us/en/serverproven/index.shtml for a list of supported microprocessors.

- Both microprocessors must have the same QuickPath Interconnect (QPI) link speed, integrated memory controller frequency, core frequency, power segment, cache size, and type.

- Read the documentation that comes with the microprocessor to determine whether you must update the server firmware for the server. To download the most current level of server firmware and many other code updates for your server, complete the following steps:

- Go to http://datacentersupport.lenovo.com.

- Under Product support, click System x.

- Under Popular links, click Software and device drivers.

- Click System x3650 M4 BD to display the matrix of downloadable files for the server.

- (Optional) Obtain an SMP-capable operating system. For a list of supported operating systems and optional devices, see https://static.lenovo.com/us/en/serverproven/index.shtml.

- To order additional microprocessor optional devices, contact your sales representative or reseller.

- The microprocessor speeds are automatically set for this server; therefore, you do not have to set any microprocessor frequency-selection jumpers or switches.

- If you have to replace a microprocessor, call for service.

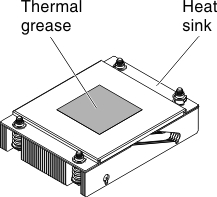

- If the thermal-grease protective cover (for example, a plastic cap or tape liner) is removed from the heat sink, do not touch the thermal grease on the bottom of the heat sink or set down the heat sink.

- Do not remove the first microprocessor from the system board to install the second microprocessor.

- A startup (boot) microprocessor must always be installed in microprocessor socket 1 on the system board.

- To ensure correct server operation when you install an additional microprocessor, use microprocessors that are compatible and install at least one DIMM in a DIMM connector for microprocessor 2.

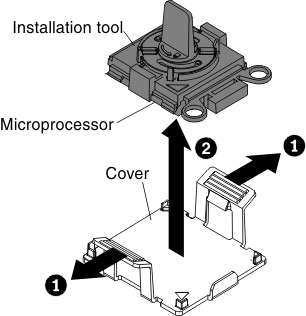

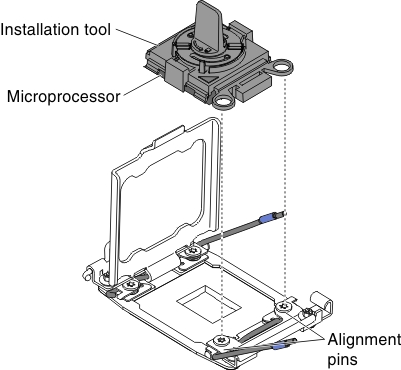

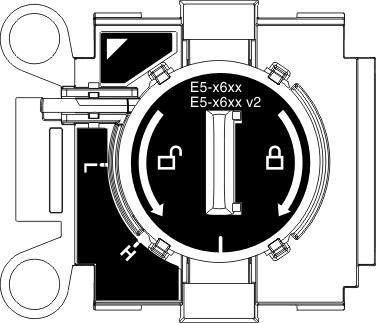

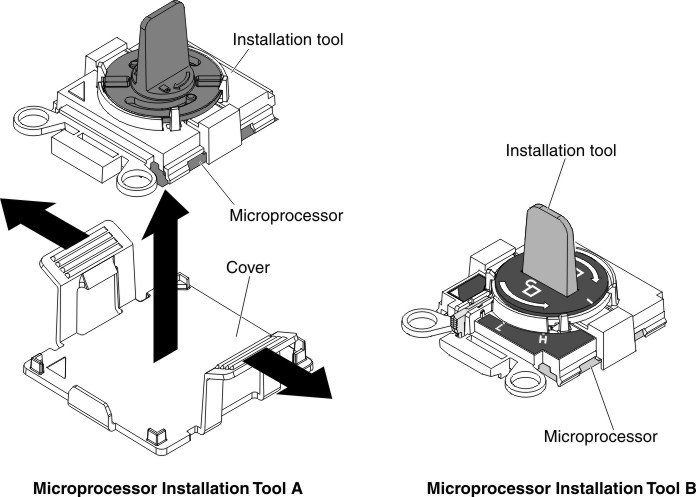

There are two types of microprocessor installation tools. The tools are similar in function and design, however Tool A has one setting for installing one size of microprocessor, and supports the following families of microprocessors: E5-26xx, E5-46xx. Installation Tool B has two settings for installing two different sizes of microprocessors. The settings that are marked on Tool B are “L” for smaller low core microprocessors, and “H” for larger high core microprocessors. Installation Tool B supports the following families of microprocessors: E5-26xx, E5-46xx, E5-26xx v2, E5-46xx v2. Microprocessor Installation Tools A and B are shown in the following illustration.

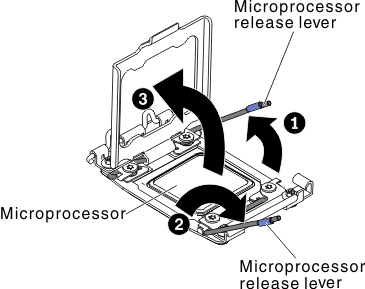

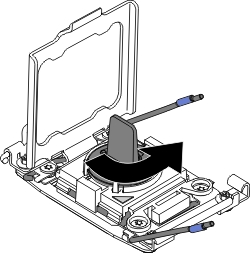

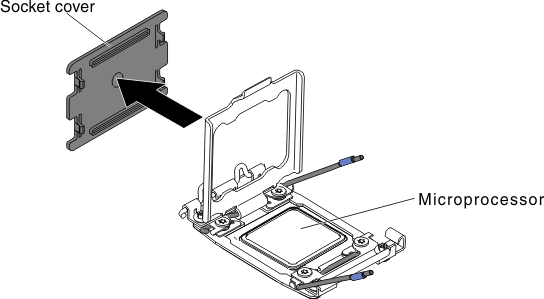

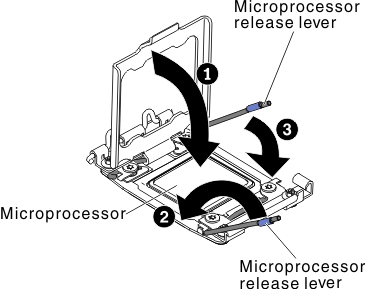

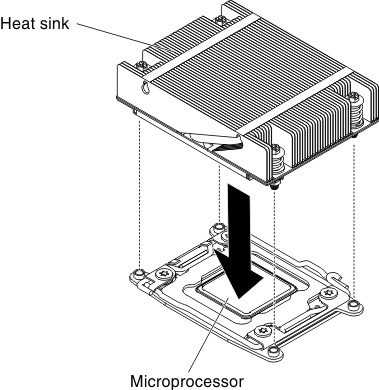

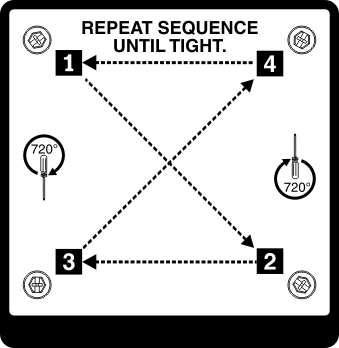

To install an additional microprocessor, complete the following steps:

If you have other devices to install or remove, do so now. Otherwise, go to Completing the installation.