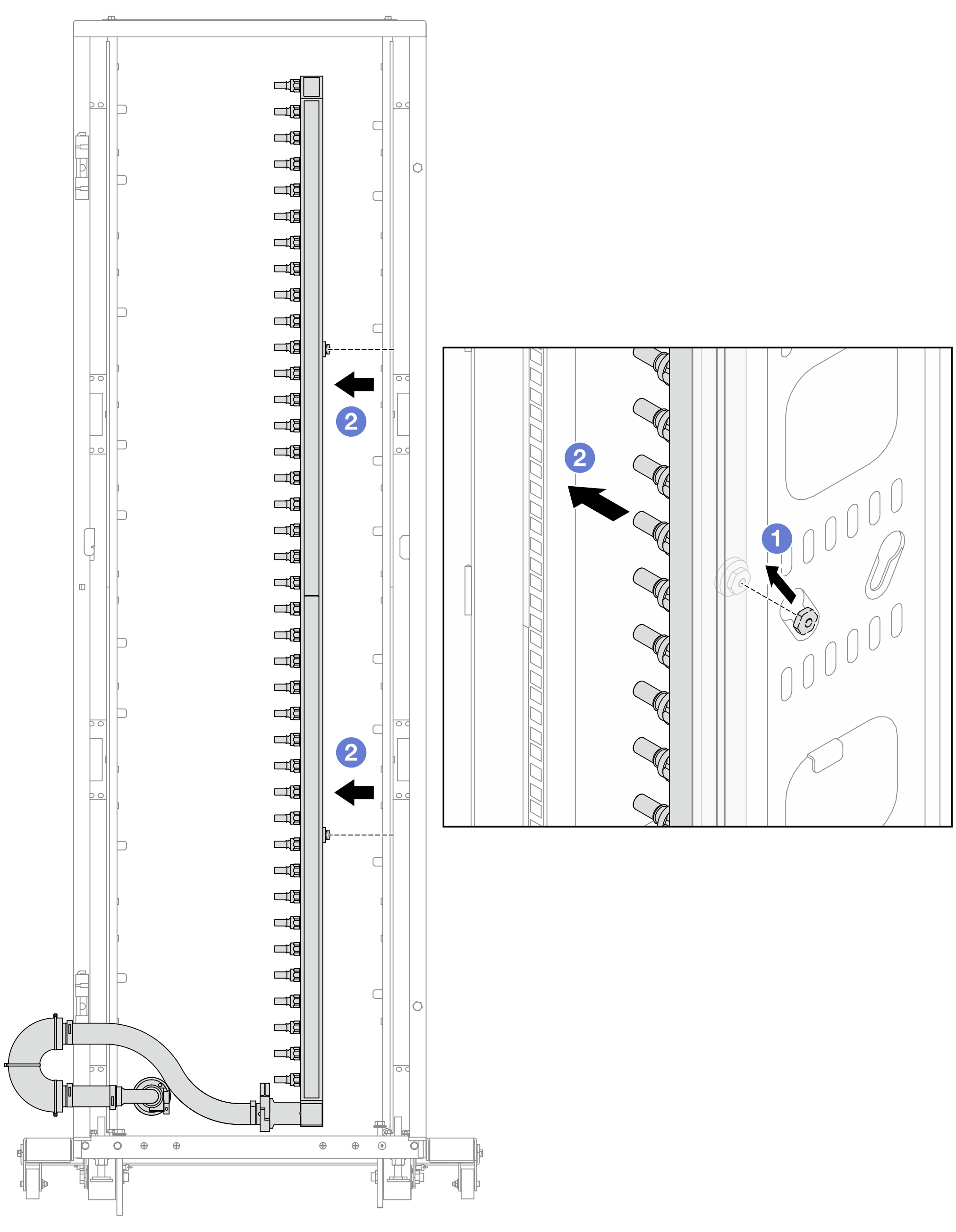

Remove the manifold (in-rack system)

Use this information to remove the manifold in an in-rack direct water cooling system.

About this task

This task must be operated by trained technicians that are certified by Lenovo Service. Do not attempt to remove or install the part without proper training and qualification.

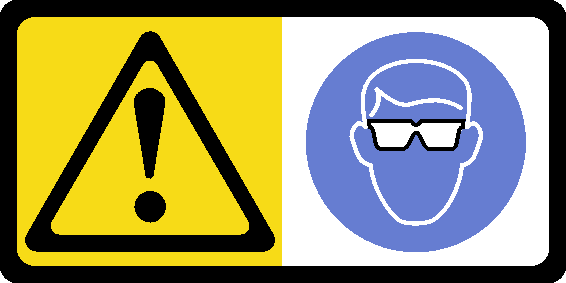

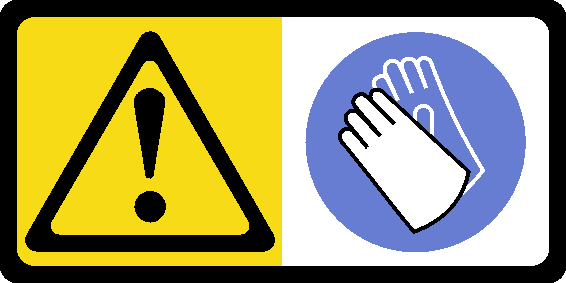

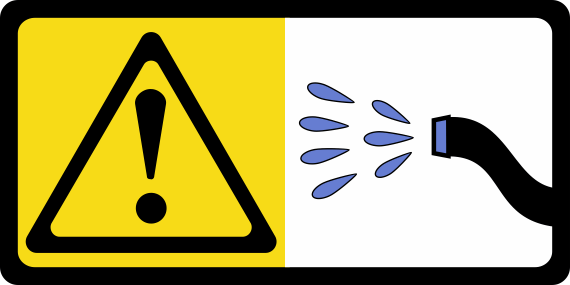

The coolant might cause irritation to the skin and eyes. Avoid direct contact with the coolant.

Read Installation Guidelines and Safety inspection checklist to ensure that you work safely.

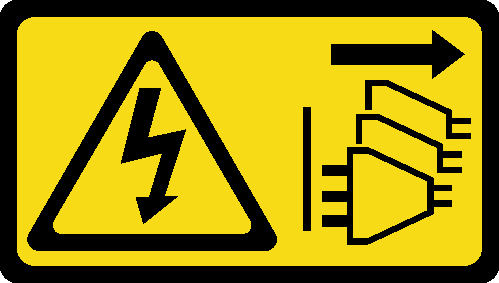

Power off the server and peripheral devices and disconnect the power cords and all external cables. See Power off the server.

Prevent exposure to static electricity, which might lead to system halt and loss of data, by keeping static-sensitive components in their static-protective packages until installation, and handling these devices with an electrostatic-discharge wrist strap or other grounding systems.

Ensure proper handling procedures are followed when working with any chemically treated coolant used in the rack cooling system. Ensure that material safety data sheets (MSDS) and safety information are provided by the coolant chemical treatment supplier and that proper personal protective equipment (PPE) is available as recommended by the coolant chemical treatment supplier. Protective gloves and eyewear may be recommended as a precaution.

This task requires two or more people.

Procedure

If you are instructed to return the component or optional device, follow all packaging instructions, and use any packaging materials for shipping that are supplied to you.

Demo video

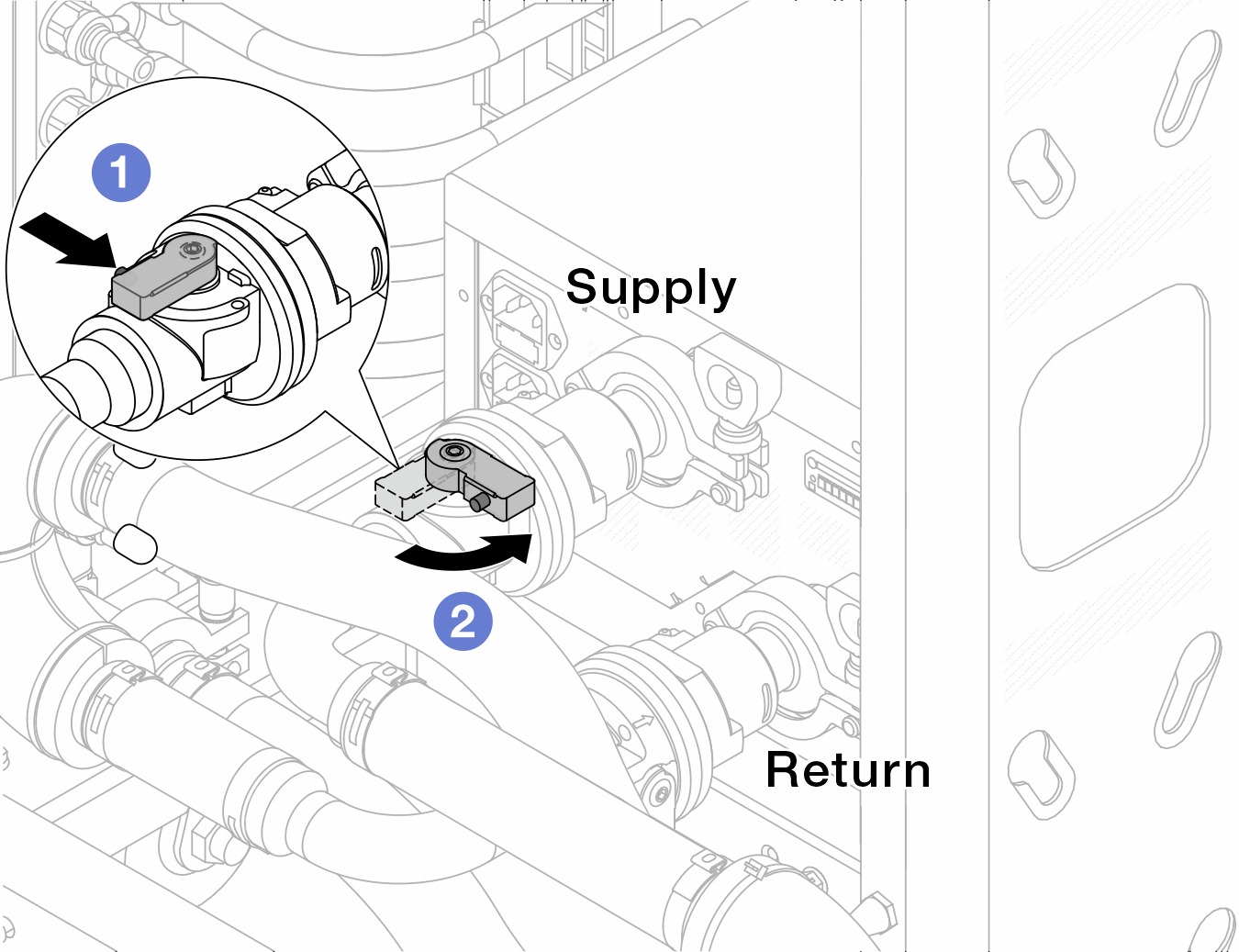

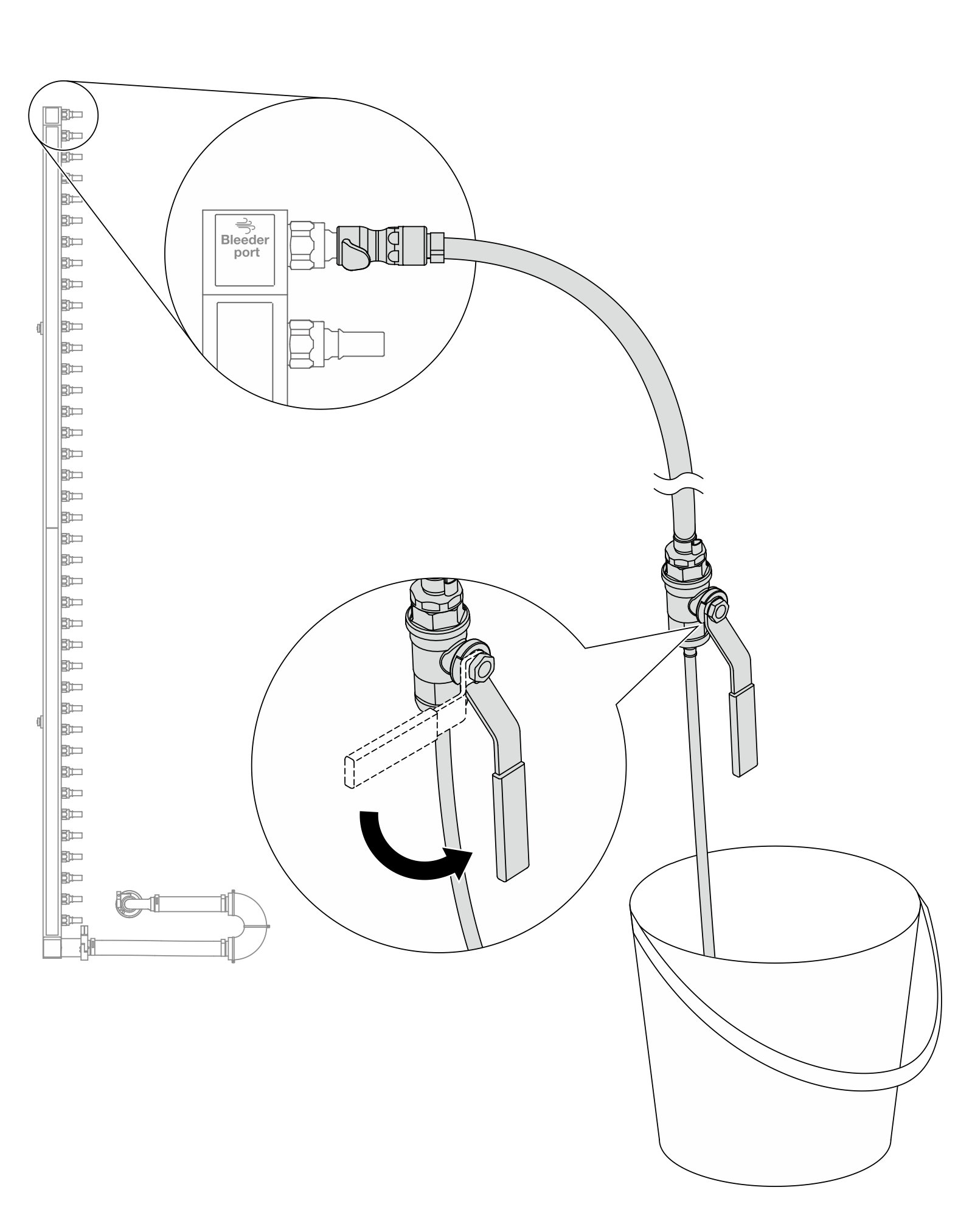

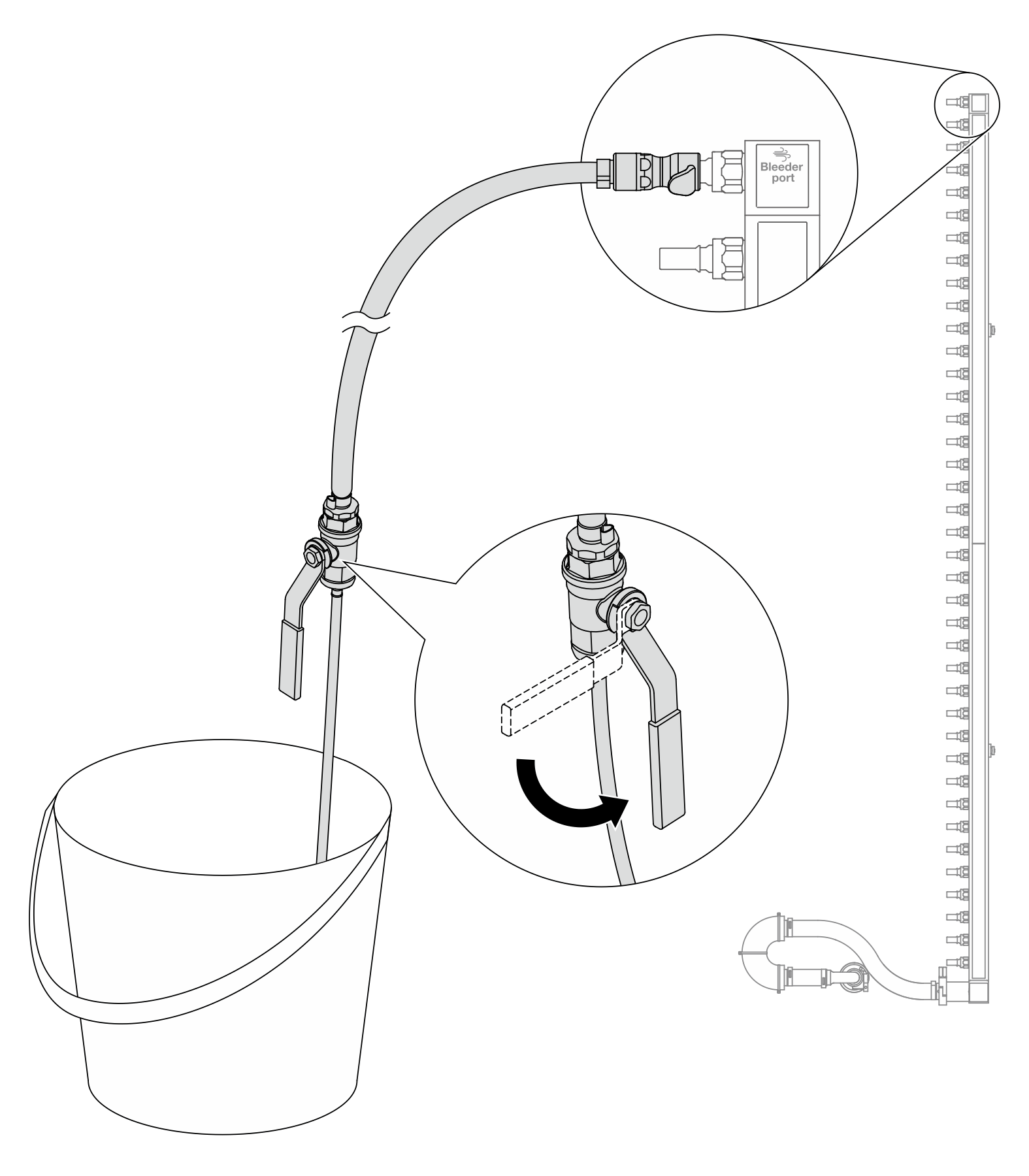

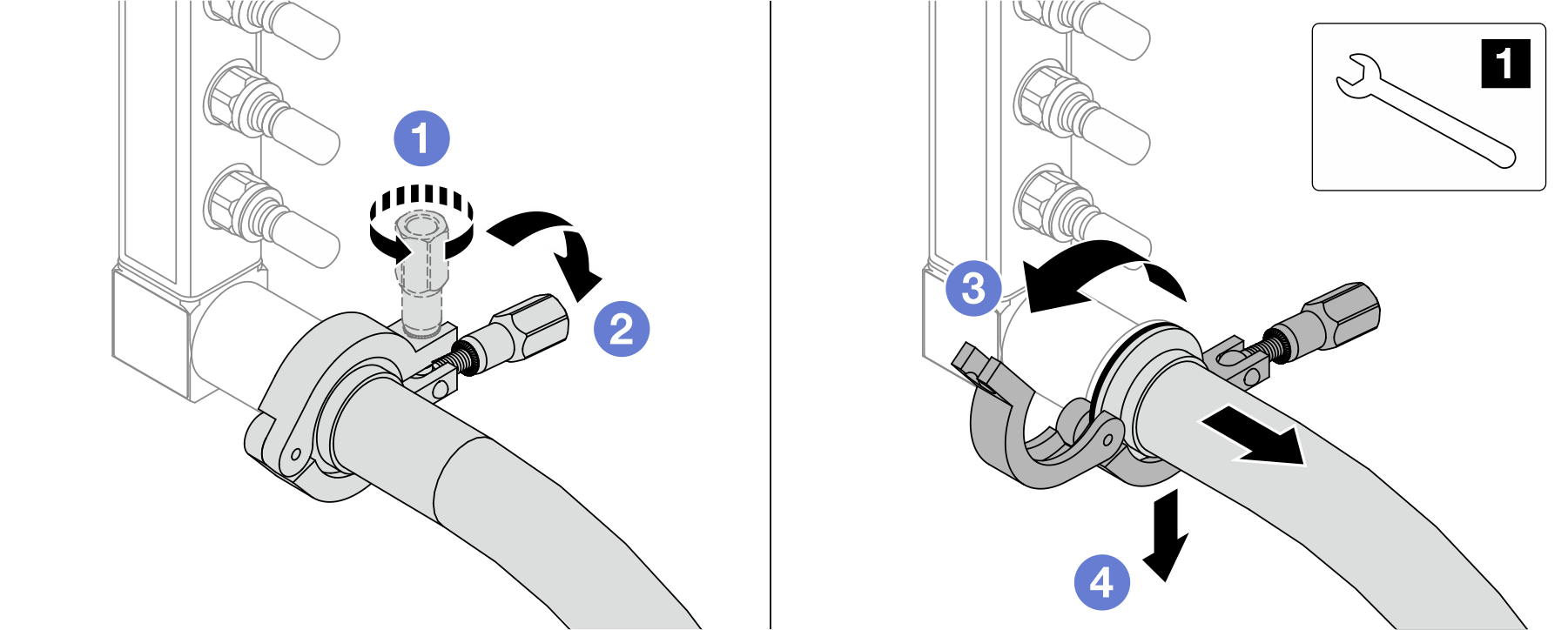

Press the button on the ball valve switch.

Press the button on the ball valve switch. Rotate the switch to close the valves as illustrated above.

Rotate the switch to close the valves as illustrated above.

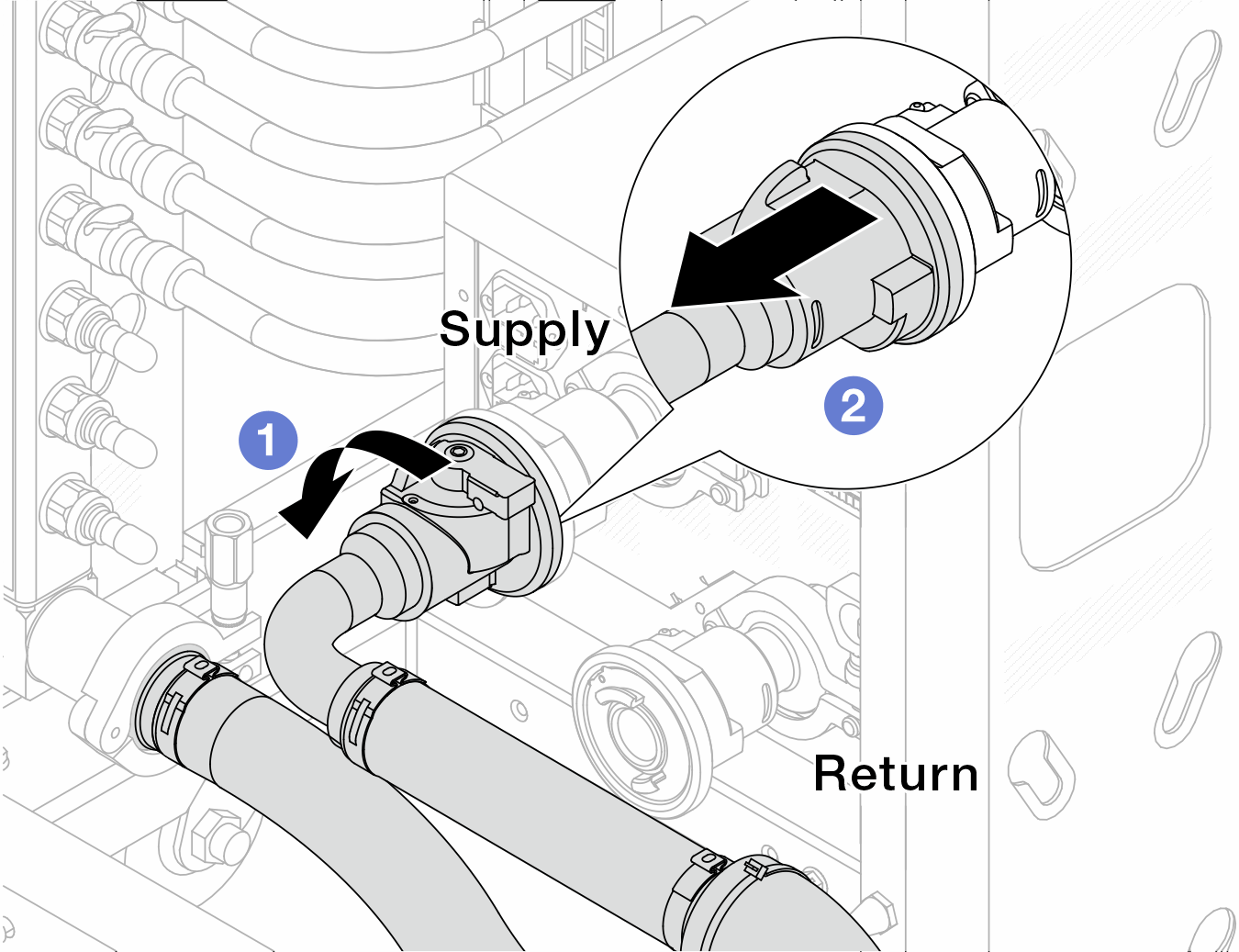

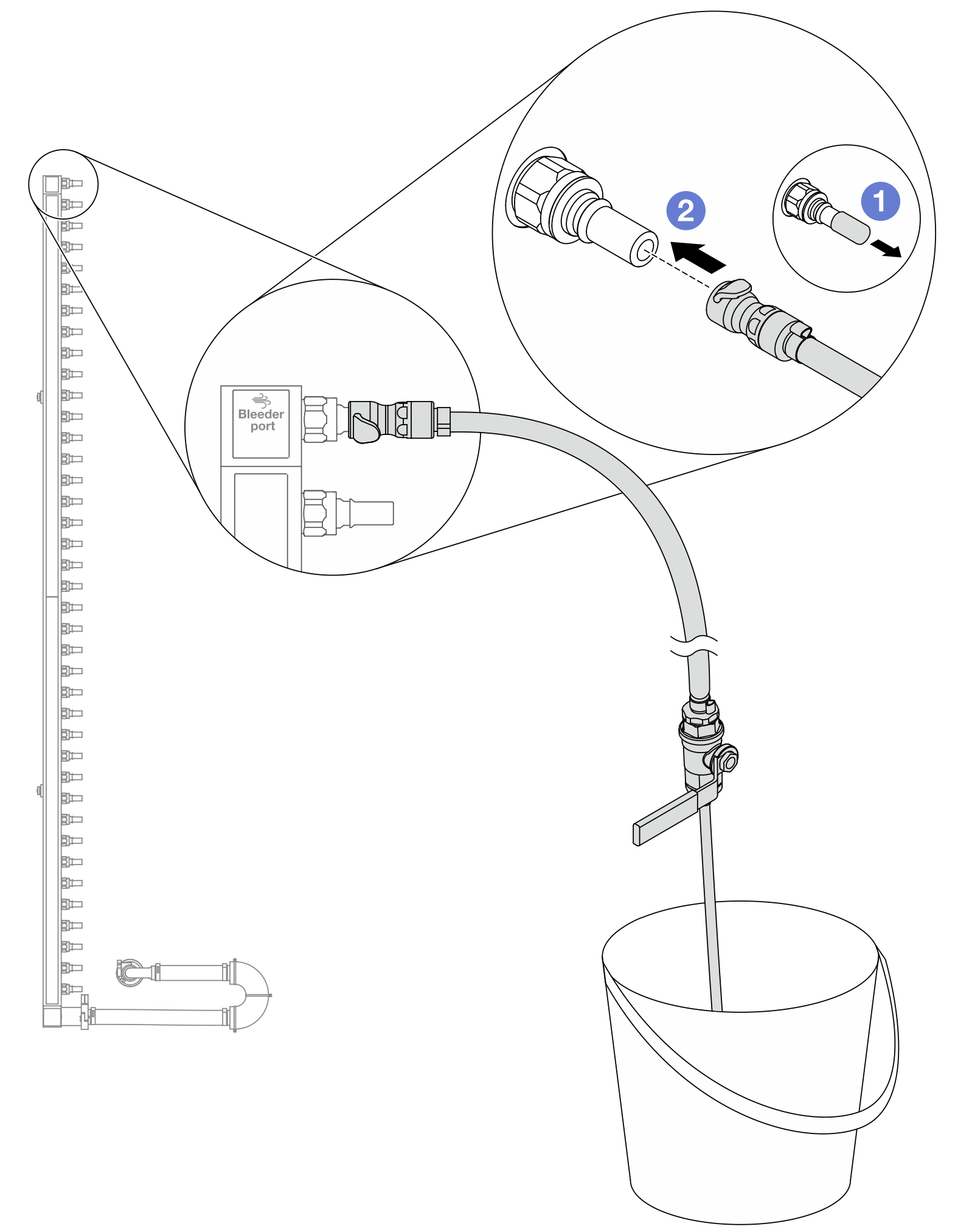

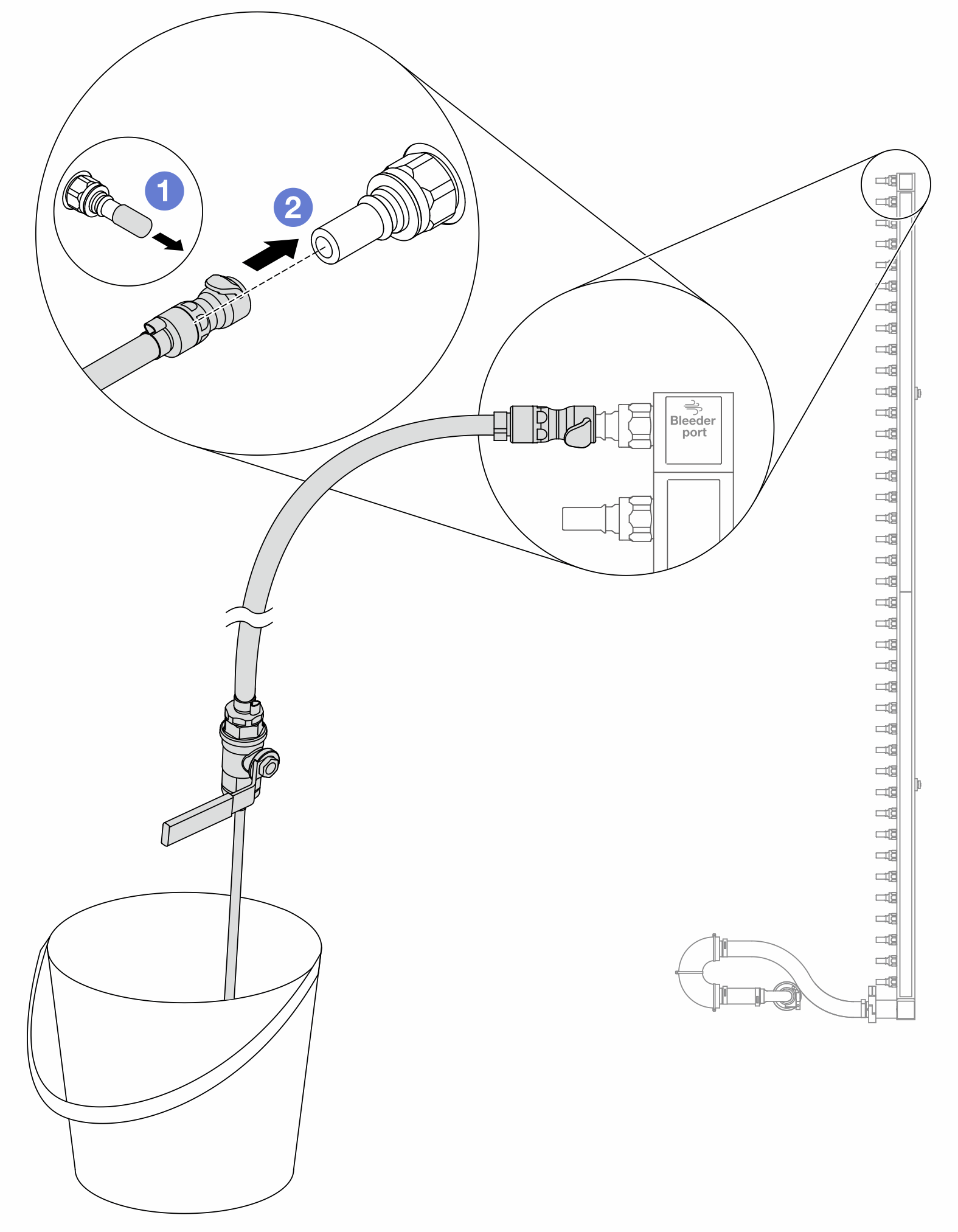

Re-install the rubber quick connect plug covers to the ports on the manifold.

Re-install the rubber quick connect plug covers to the ports on the manifold.

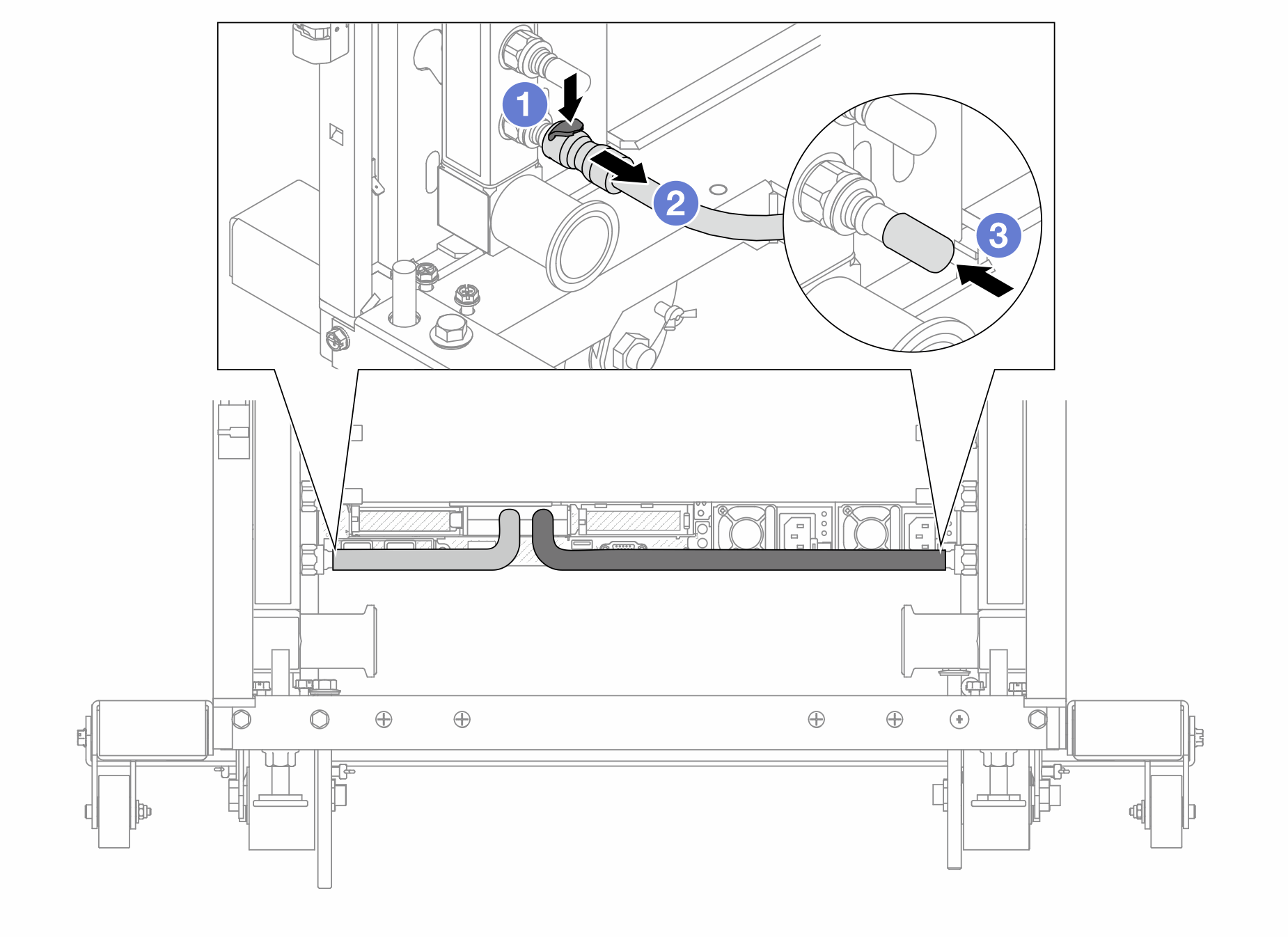

Remove the ferrule and connection set from the manifold.

Remove the ferrule and connection set from the manifold.