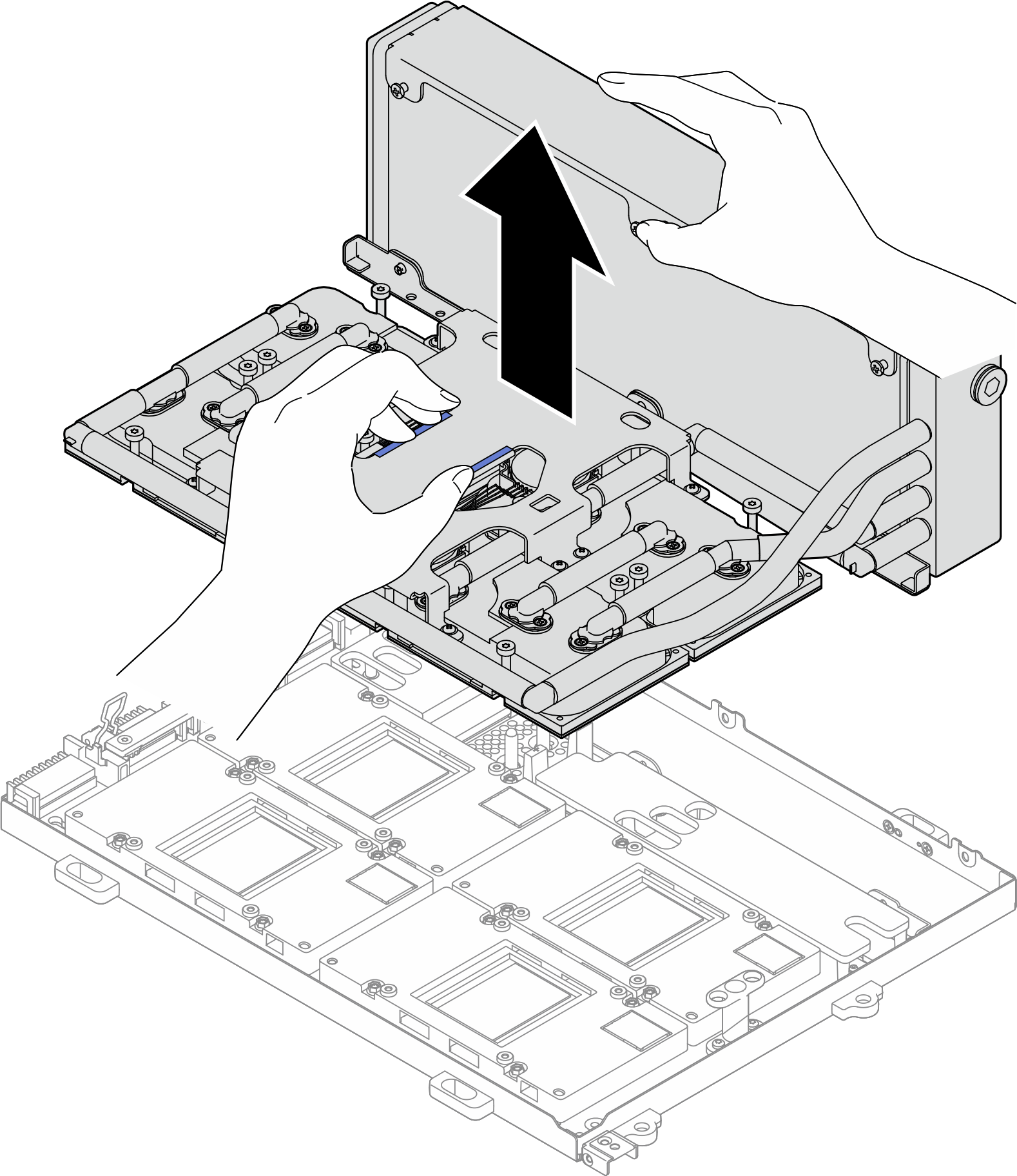

Remove the Lenovo Neptune liquid-to-air (L2A) hybrid cooling module

Follow instructions in this section to remove the Lenovo Neptune liquid-to-air (L2A) hybrid cooling module. The procedure must be executed by a trained technician.

About this task

Attention

- Read Installation Guidelines and Safety inspection checklist to ensure that you work safely.

- Power off the server and peripheral devices and disconnect the power cords and all external cables. See Power off the server.

- If the server is installed in a rack, slide the server out on its rack slide rails to gain access to the top cover, or remove the server from the rack. See Remove the server from rack.

- Update the GPU firmware whenever an SXM Over-Temperature Critical message appears in the system event log and the GPU vBIOS is downlevel. See SXM THERM OT (Thermal Over Temperature) reported in Nvidia GPU HGX SXM5 configuration (trained technicians only).

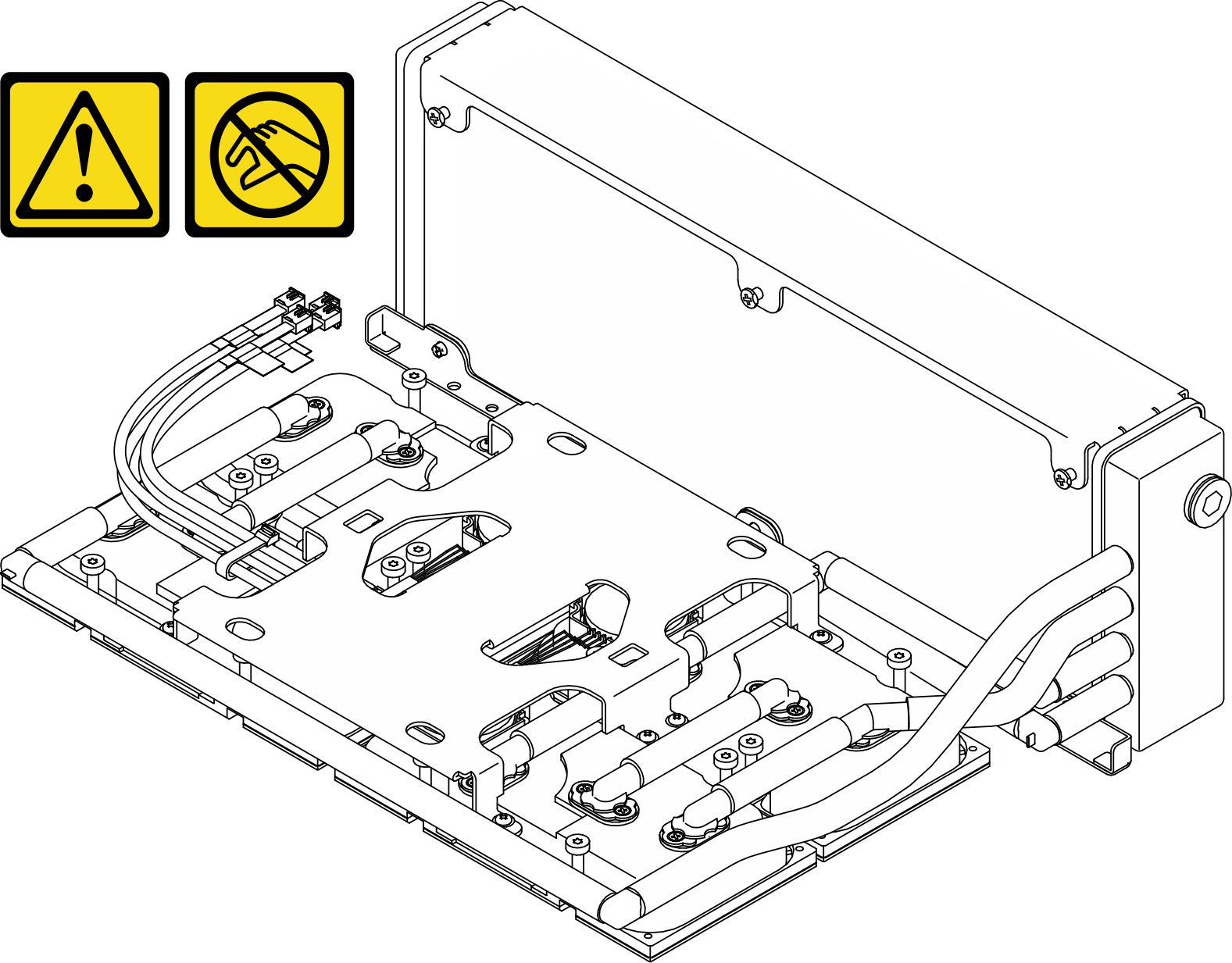

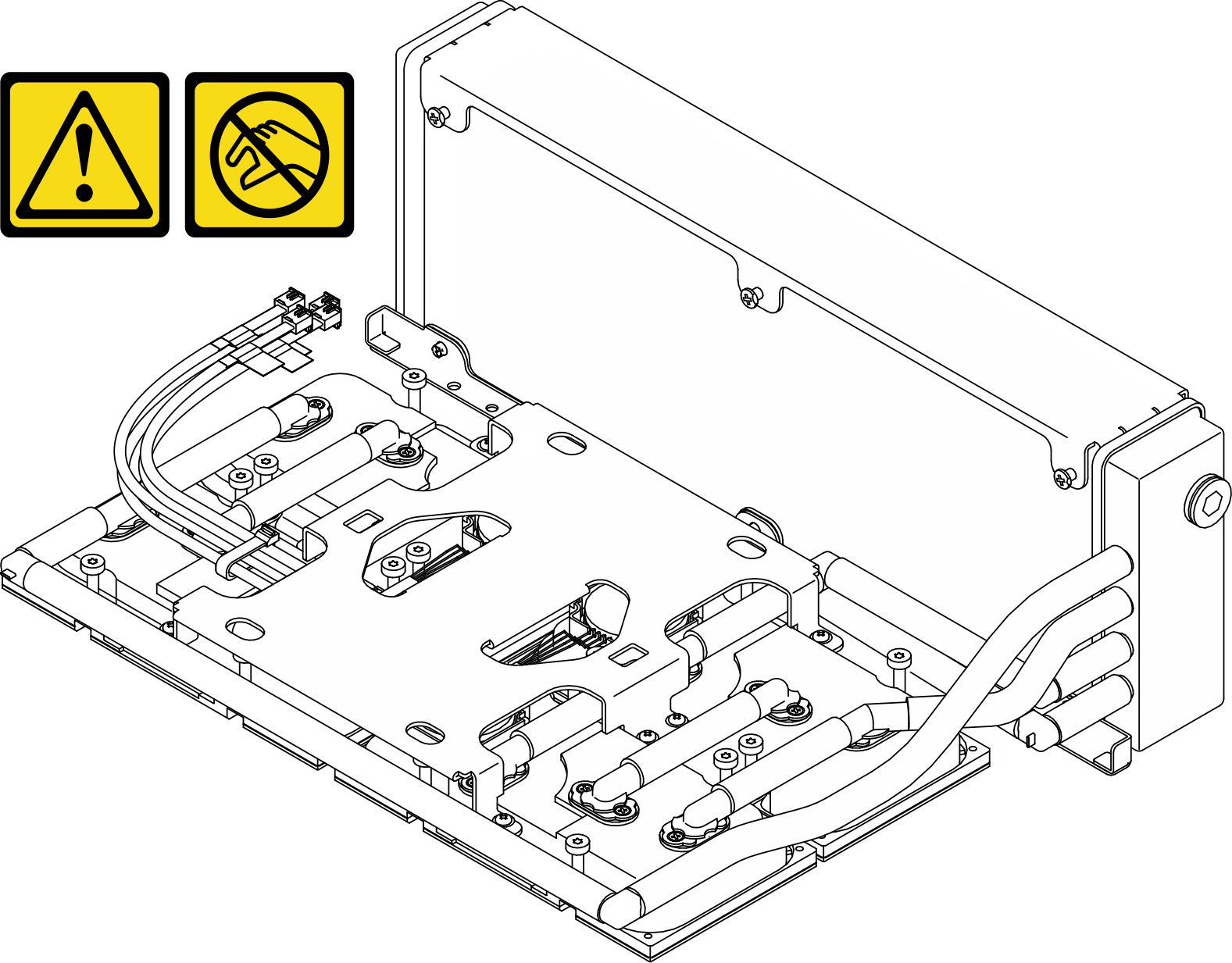

CAUTION

Do not touch the radiator fins. Touching the radiator fins might damage the L2A.

Note

Make sure you have the required tools listed below available to properly replace the component:

- Phillips #1 bit

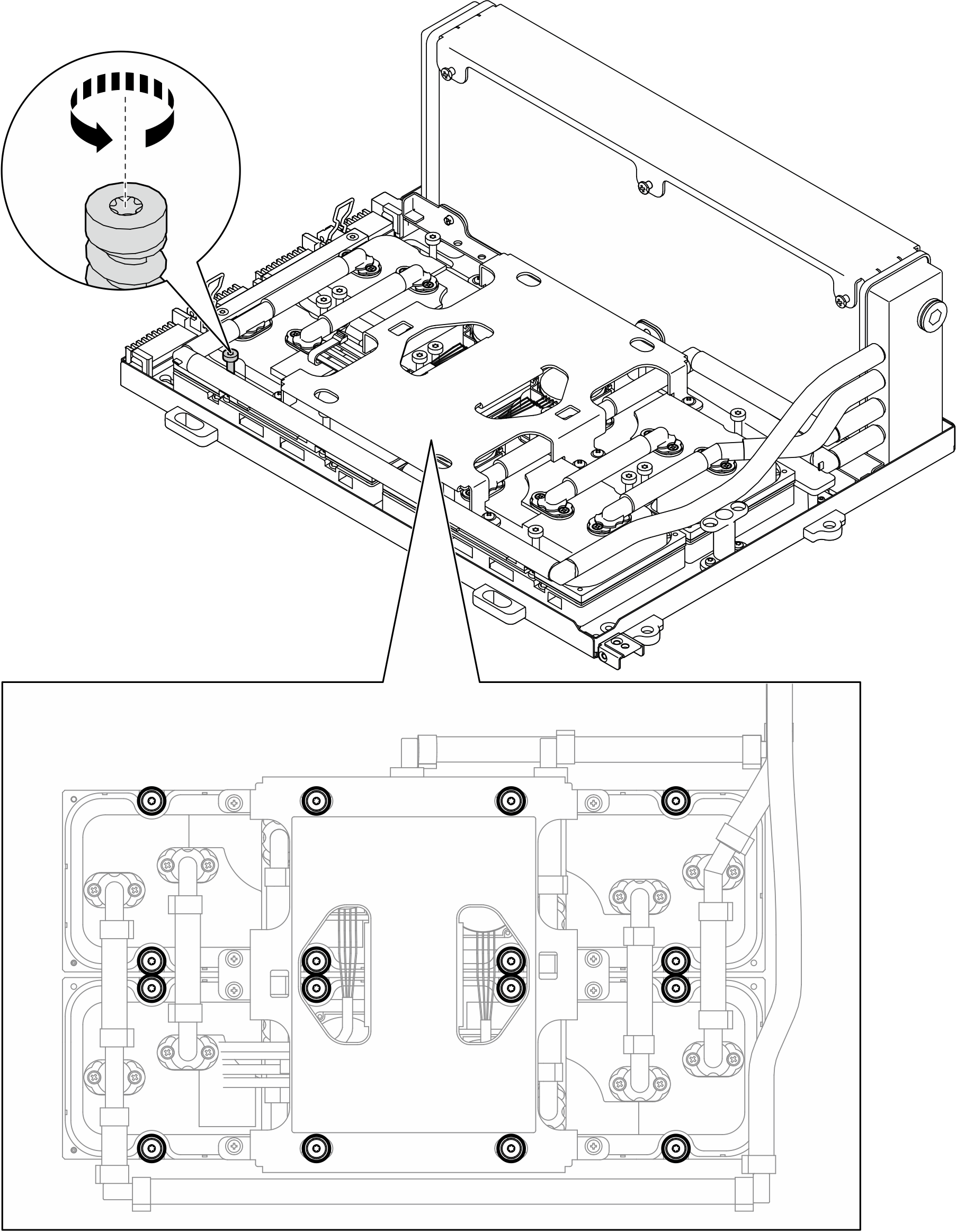

- Torx T15 bit

- Manual torque screwdriver

- DIMM tool

- Alcohol cleaning pad

- SXM5 PCM Kit

- SR675 V3 water loop putty pad kit

- SR675 V3 water loop service kit

Important

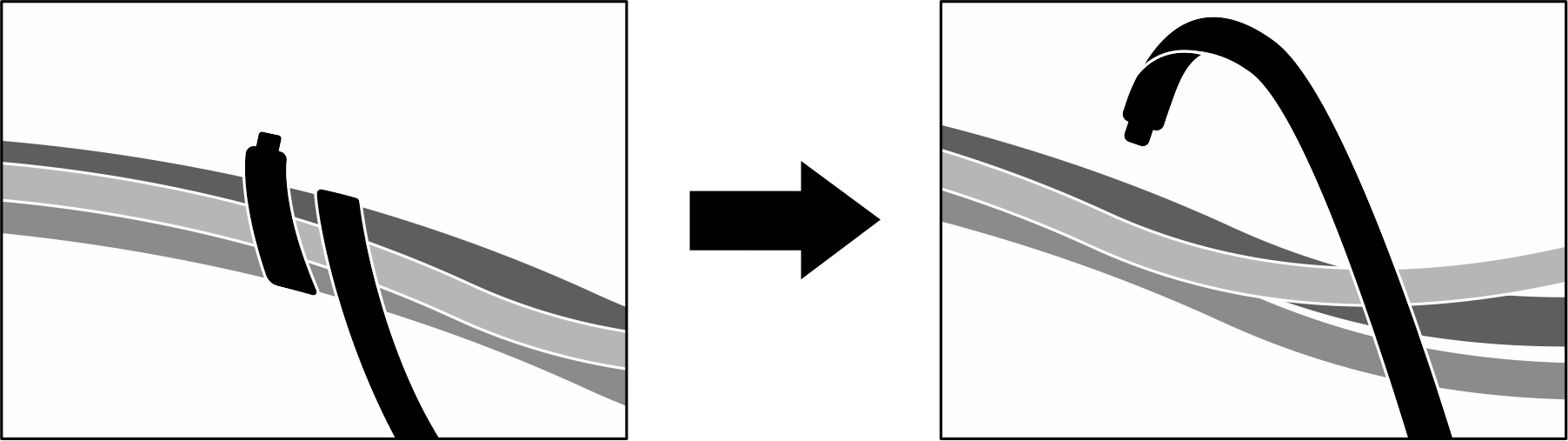

Putty pad/phase change material (PCM) replacement guidelines

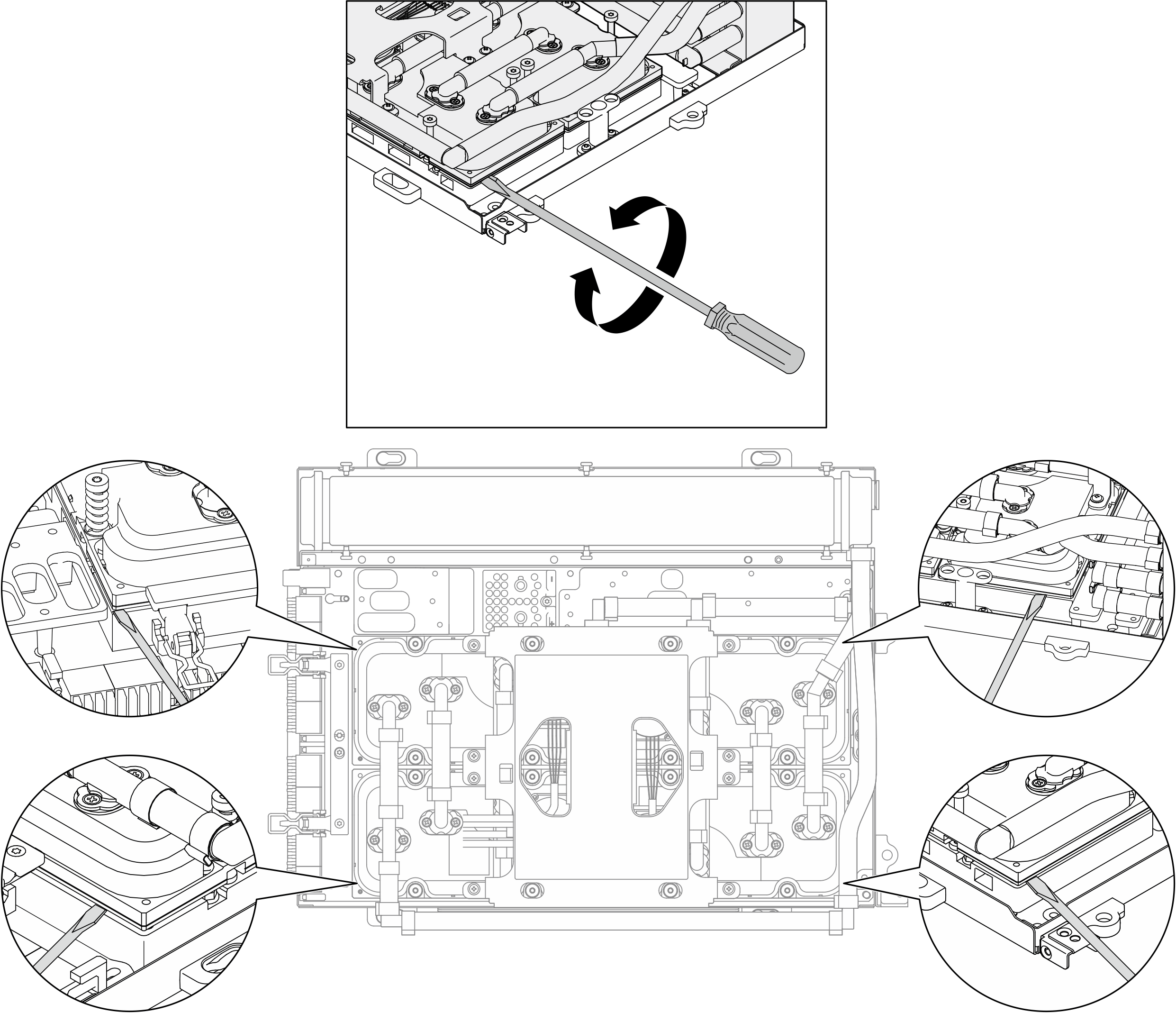

- Before replacing the putty pad/PCM, gently clean the hardware surface with an alcohol cleaning pad.

- Hold the putty pad/PCM carefully to avoid deformation. Make sure no screw hole or opening is blocked by the putty pad/PCM.

- Do not use expired putty pad/PCM. Check the expiry date on putty pad/PCM package. If the putty pads/PCM are expired, acquire new ones to properly replace them.

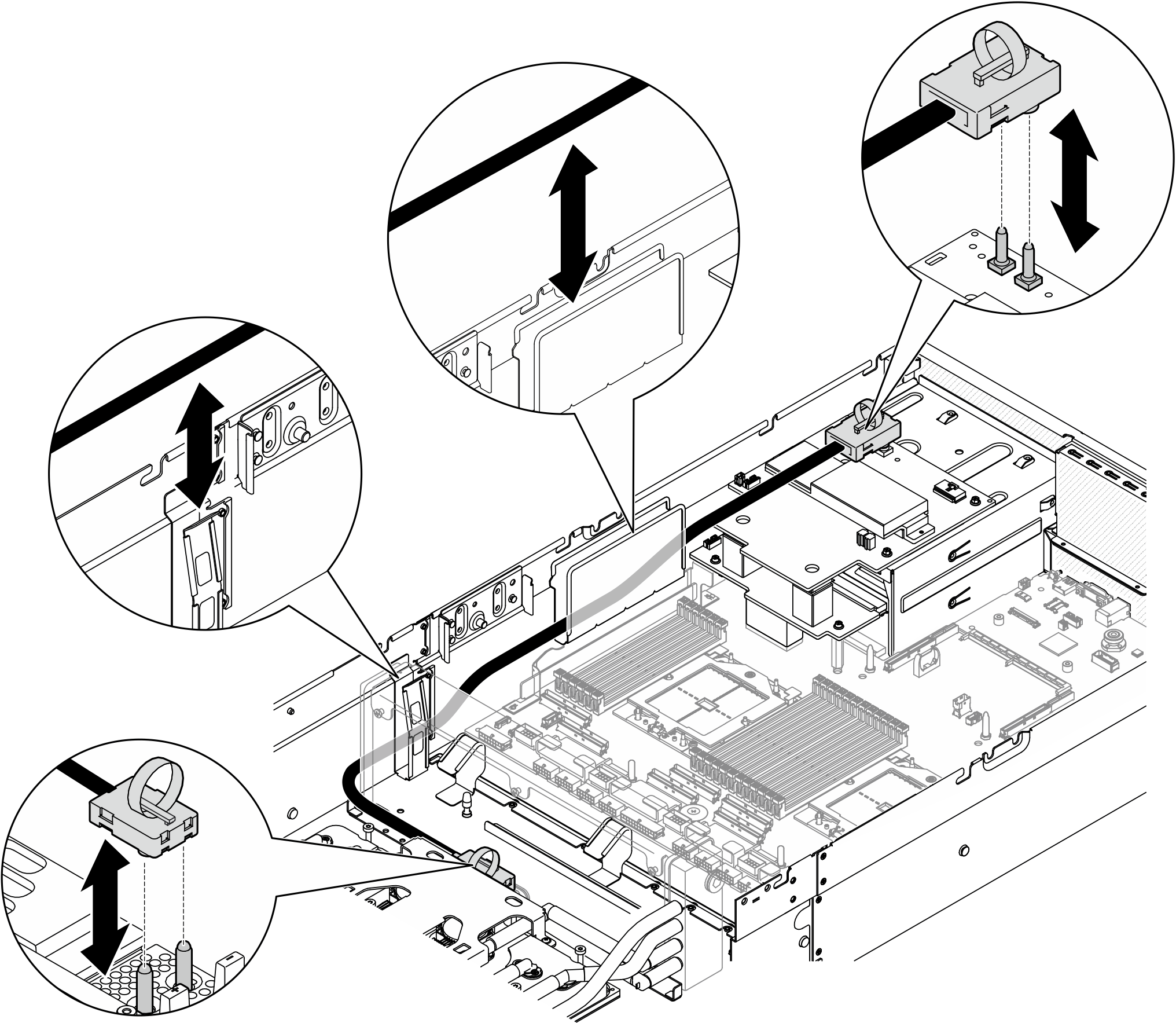

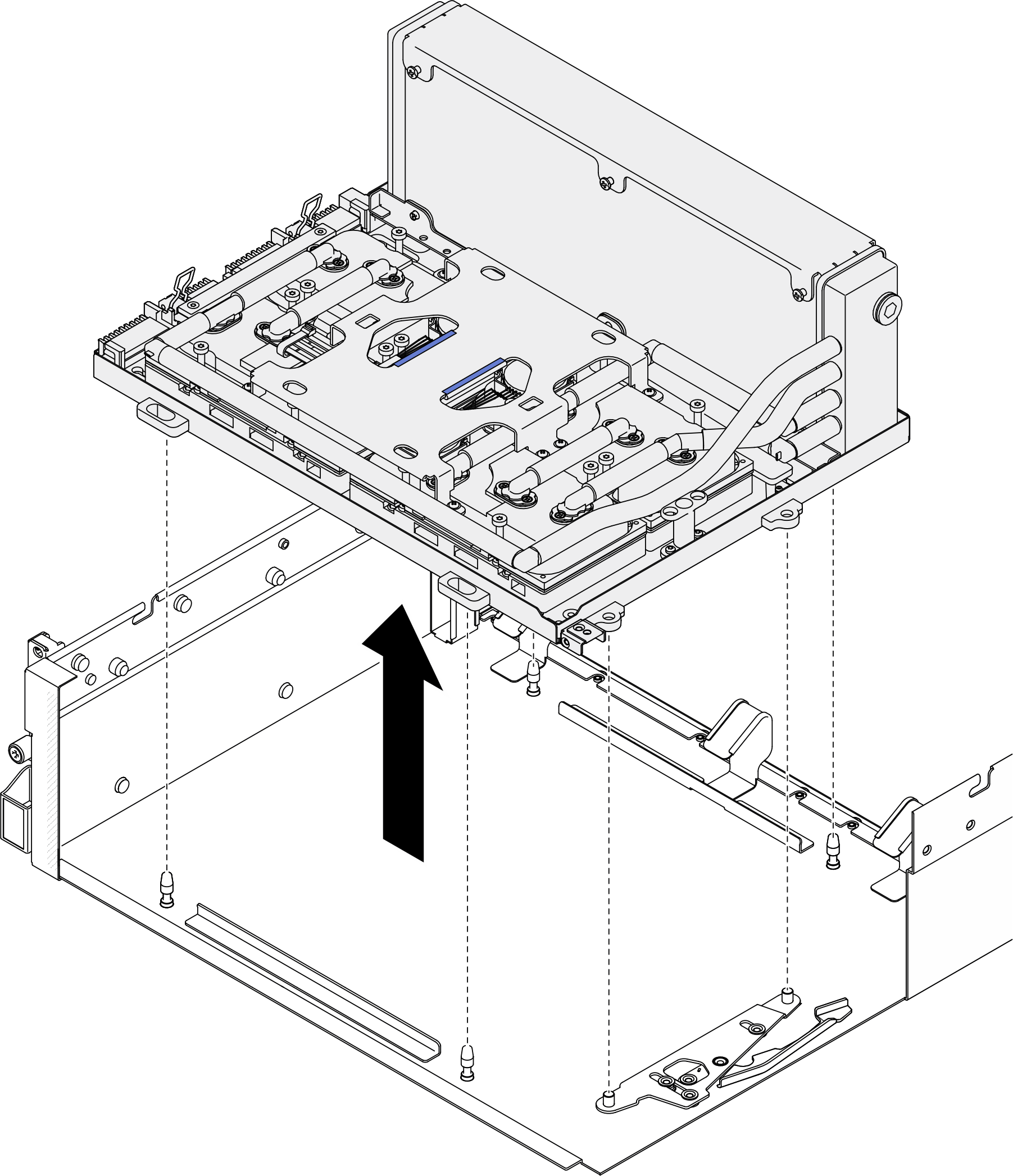

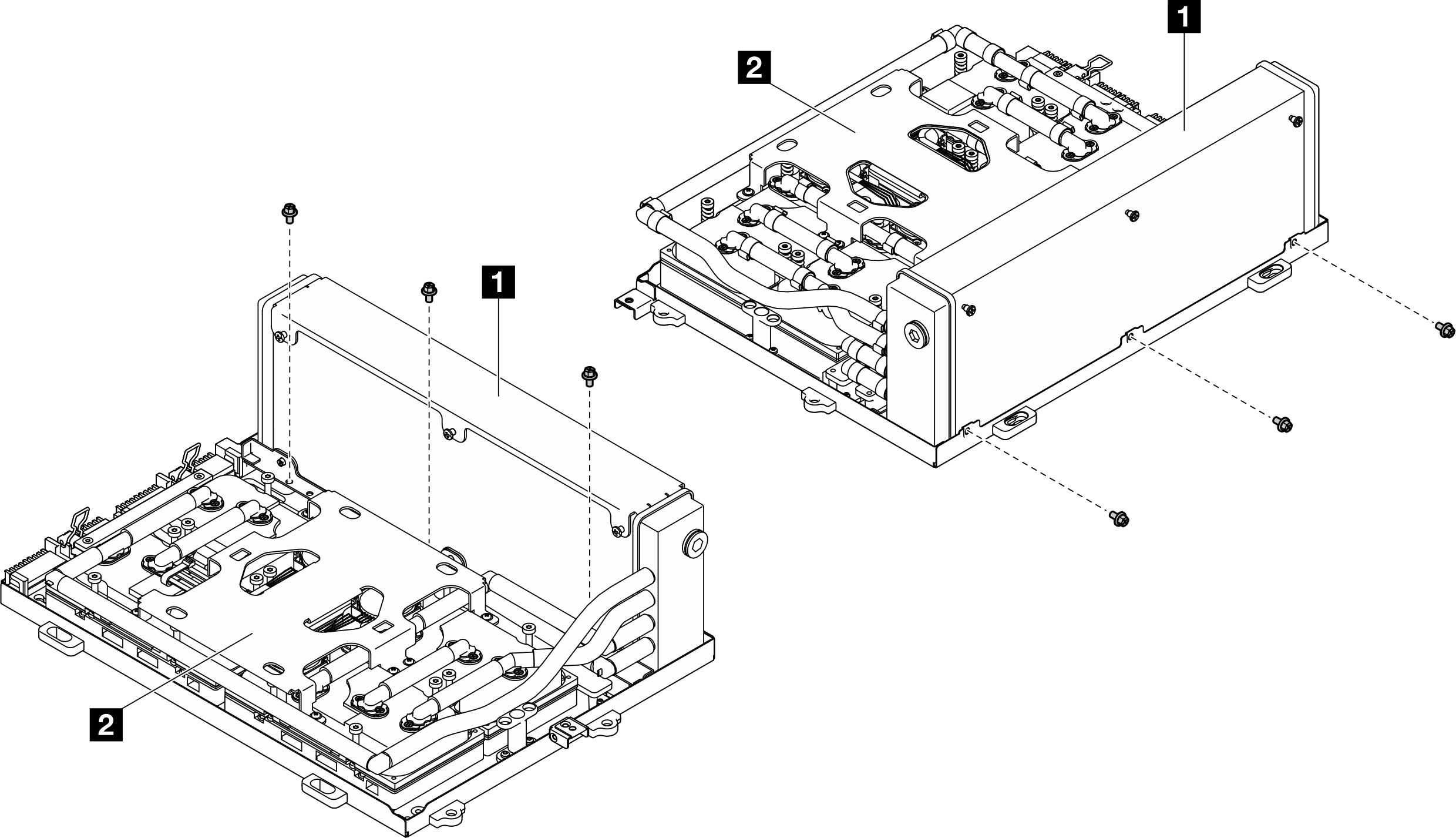

Procedure

After you finish

- To replace the SXM5 GPU board, see SXM5 GPU board assembly replacement (trained technician only).

- If you are instructed to return the component or optional device, follow all packaging instructions, and use any packaging materials for shipping that are supplied to you.

Demo video

Give documentation feedback

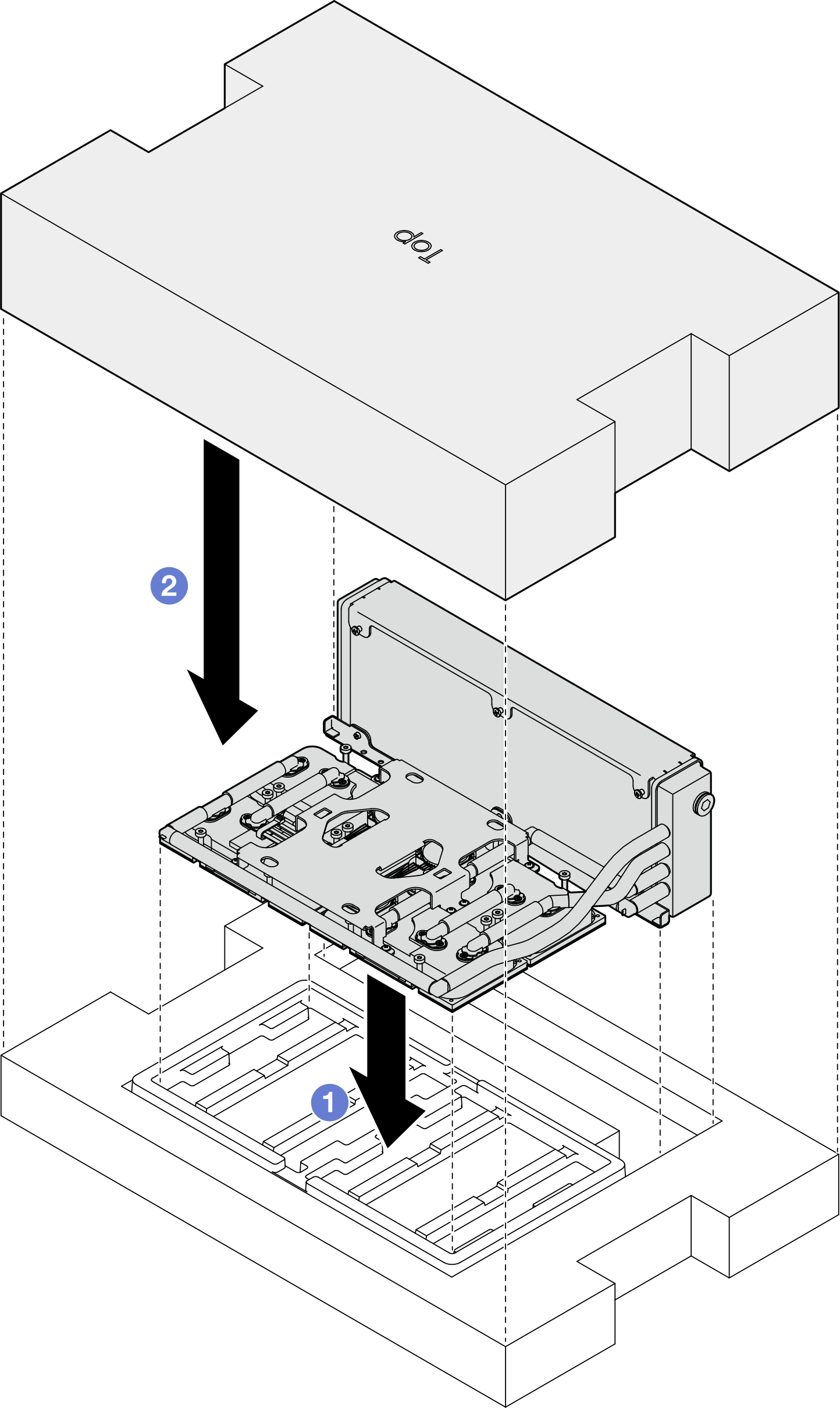

Hold the radiator by its upper edge and hold the

Hold the radiator by its upper edge and hold the  Place the top cover of the

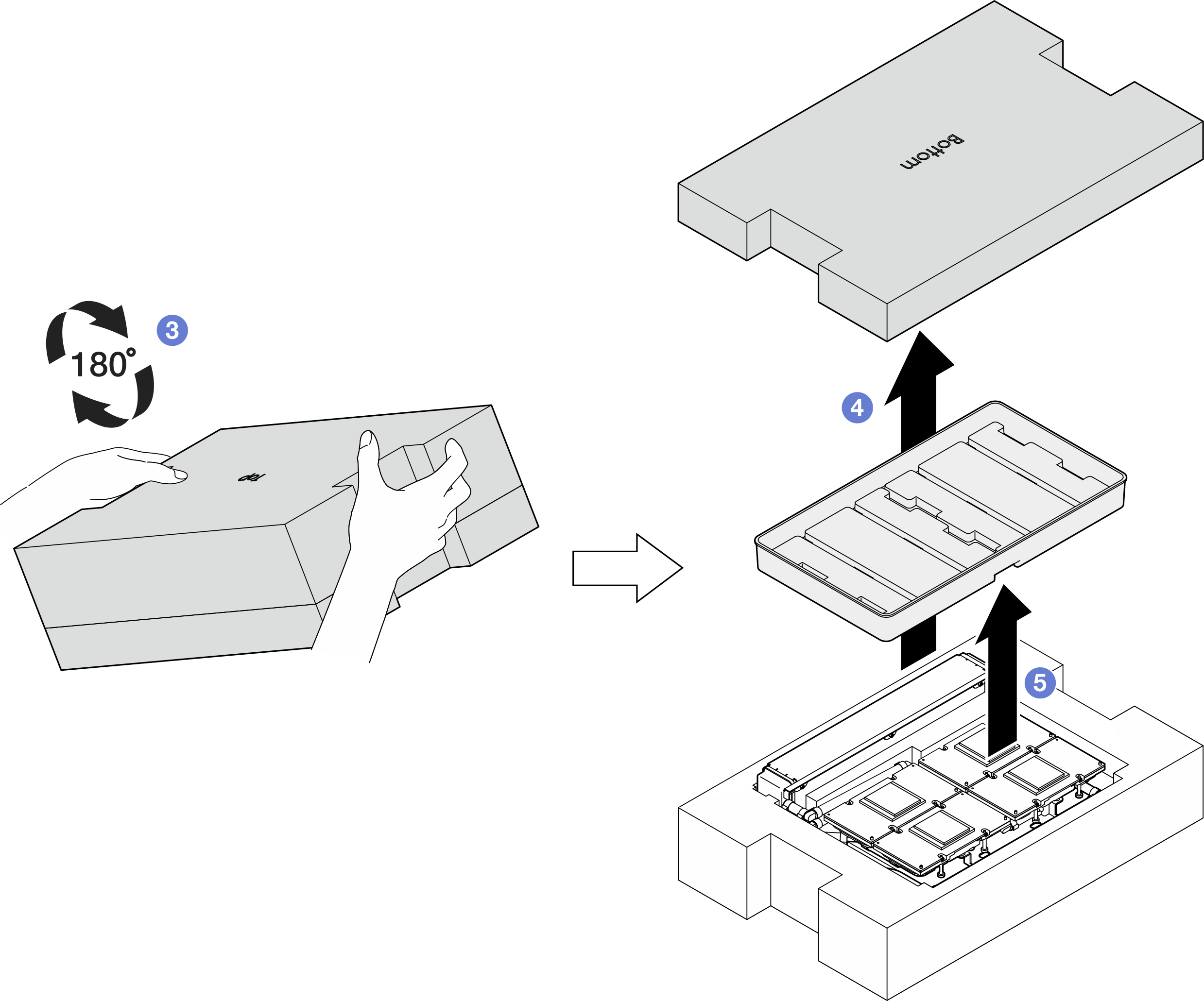

Place the top cover of the  Hold the

Hold the  Remove the bottom cover of the shipping box.

Remove the bottom cover of the shipping box. Remove the plastic tray and the bottom of the

Remove the plastic tray and the bottom of the