Install the processor board

Use this information to install the processor board.

About this task

Screwdriver for M3 PH1, PH 1, PH 2, T10, and T30 screws

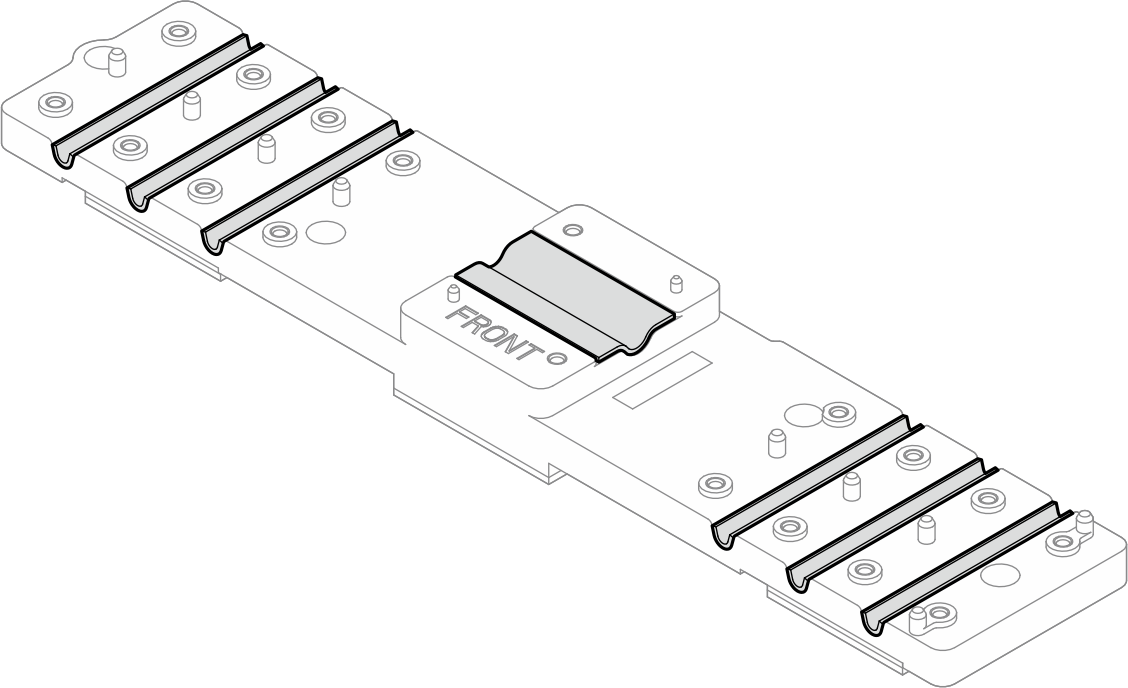

Waterloop Service Kit (SC750 V4) (The water loop carrier in the Service Kit is reusable, it is recommended to keep it at the facility where the server operates for future replacement needs.)

Up VR Gap Pad Kit (SC750 V4)

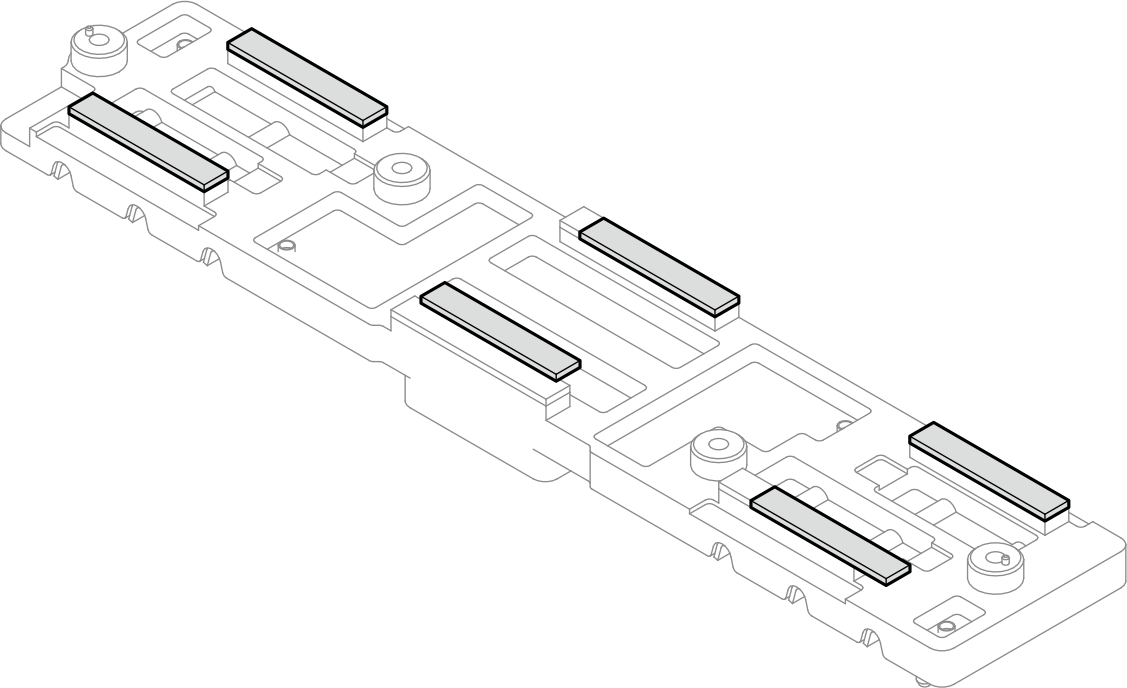

Down VR Gap Pad Kit (SC750 V4)

MID E3.S TOP Gap Pad (SC750 V4) , if E3.S middle drive is installed.

MID E3.S BOT Gap Pad (SC750 V4) , if E3.S middle drive is installed.

Storage Gap Pad Kit (SC750 V4) , if E3.S front drive is installed.

Storage Gap Pad Kit (SC750 V4) , if E3.S 1T dual front drives or E3.S 2T single front drive are installed.

CX7 NDR200 Gap Pad (SC750 V4) , if ConnectX-7 NDR 200 adapter is installed.

CX7 Gap Pad (SC750 V4) , if ConnectX-7 NDR 400 adapter is installed.

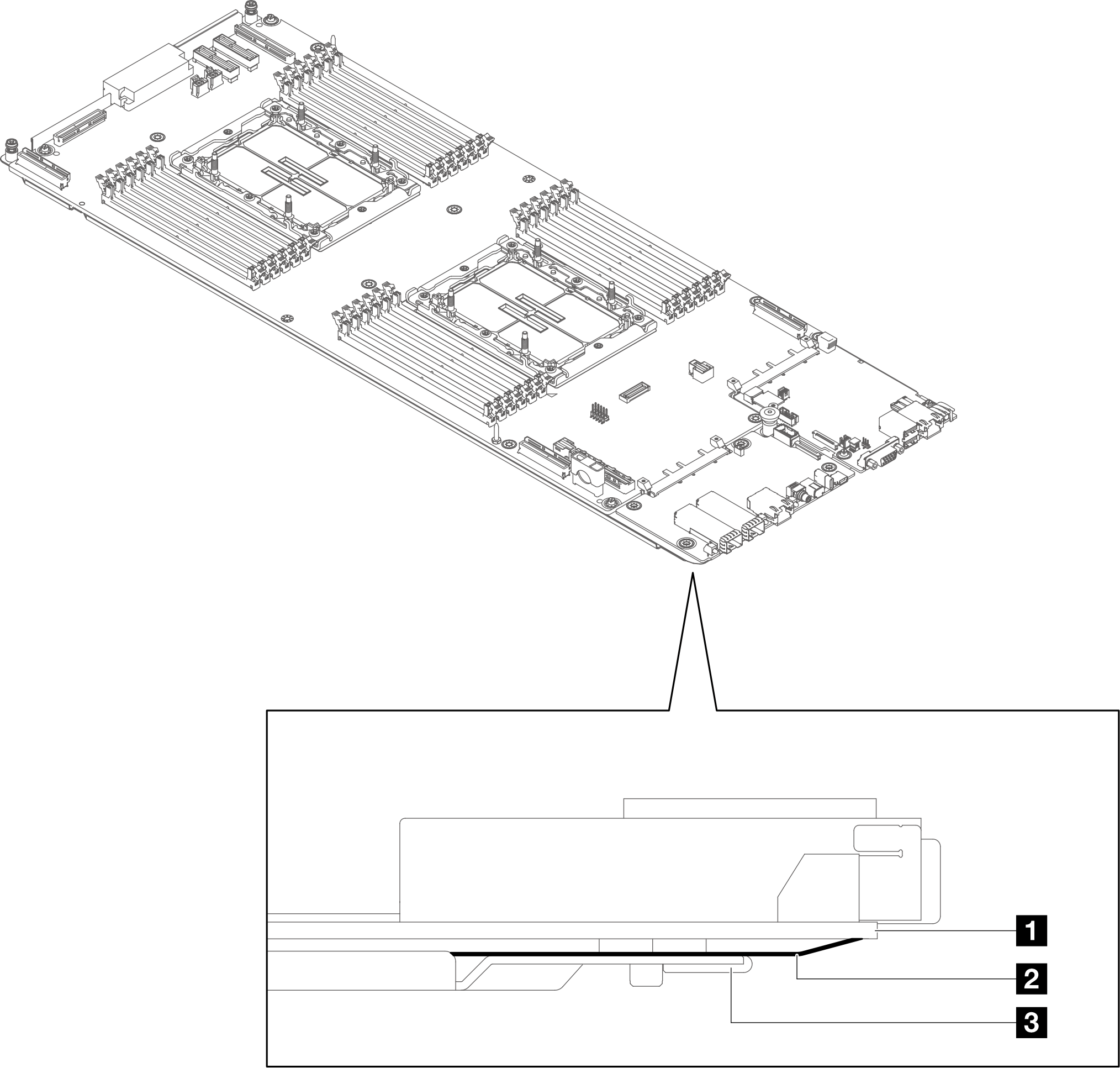

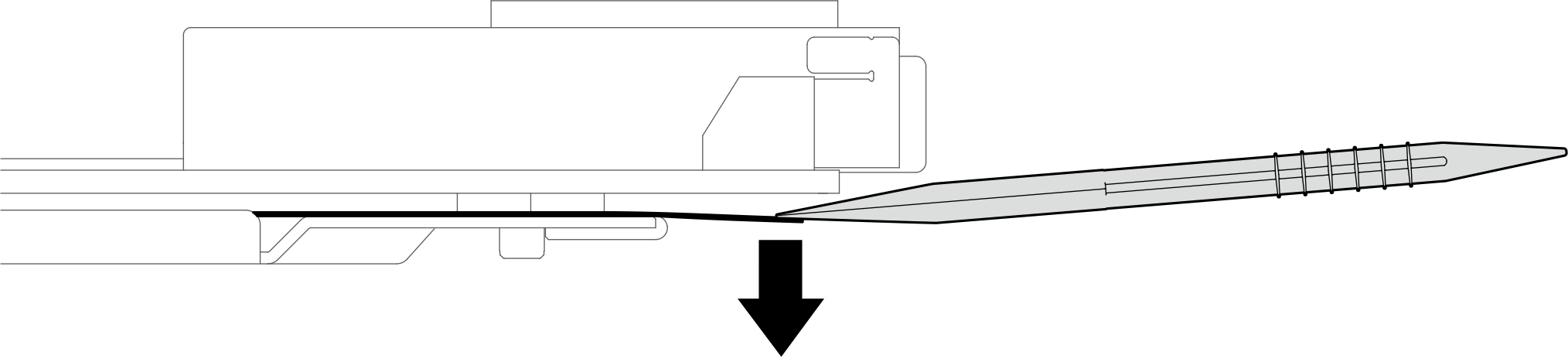

For gap pad location and instruction, see Gap pad identification and location.

Before replacing the gap pad, gently clean the surface with an alcohol cleaning pad.

Hold the gap pad carefully to avoid deformation. Make sure no screw hole or opening is blocked by the gap pad material.

Read Installation Guidelines and Safety inspection checklist to ensure that you work safely.

Turn off the corresponding DWC tray that you are going to perform the task on.

Disconnect all external cables from the enclosure.

Use extra force to disconnect QSFP cables if they are connected to the solution.

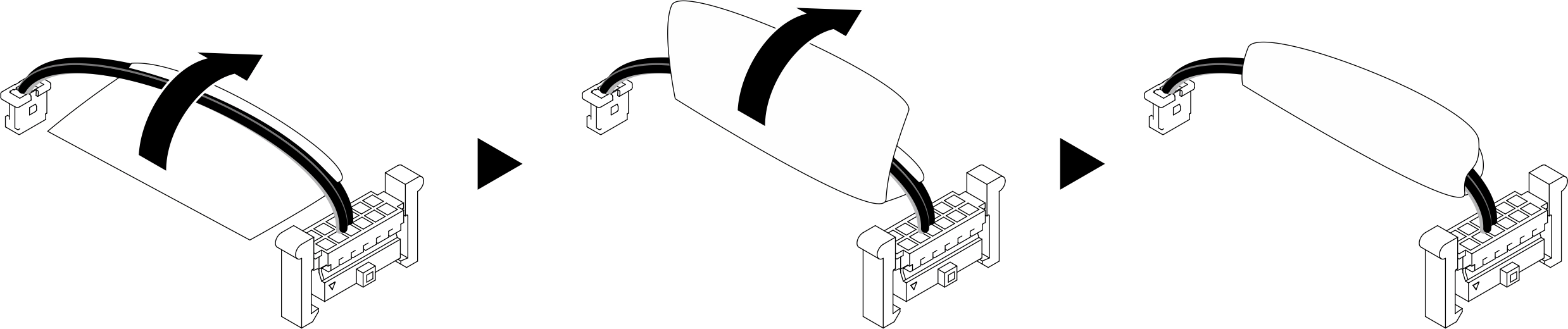

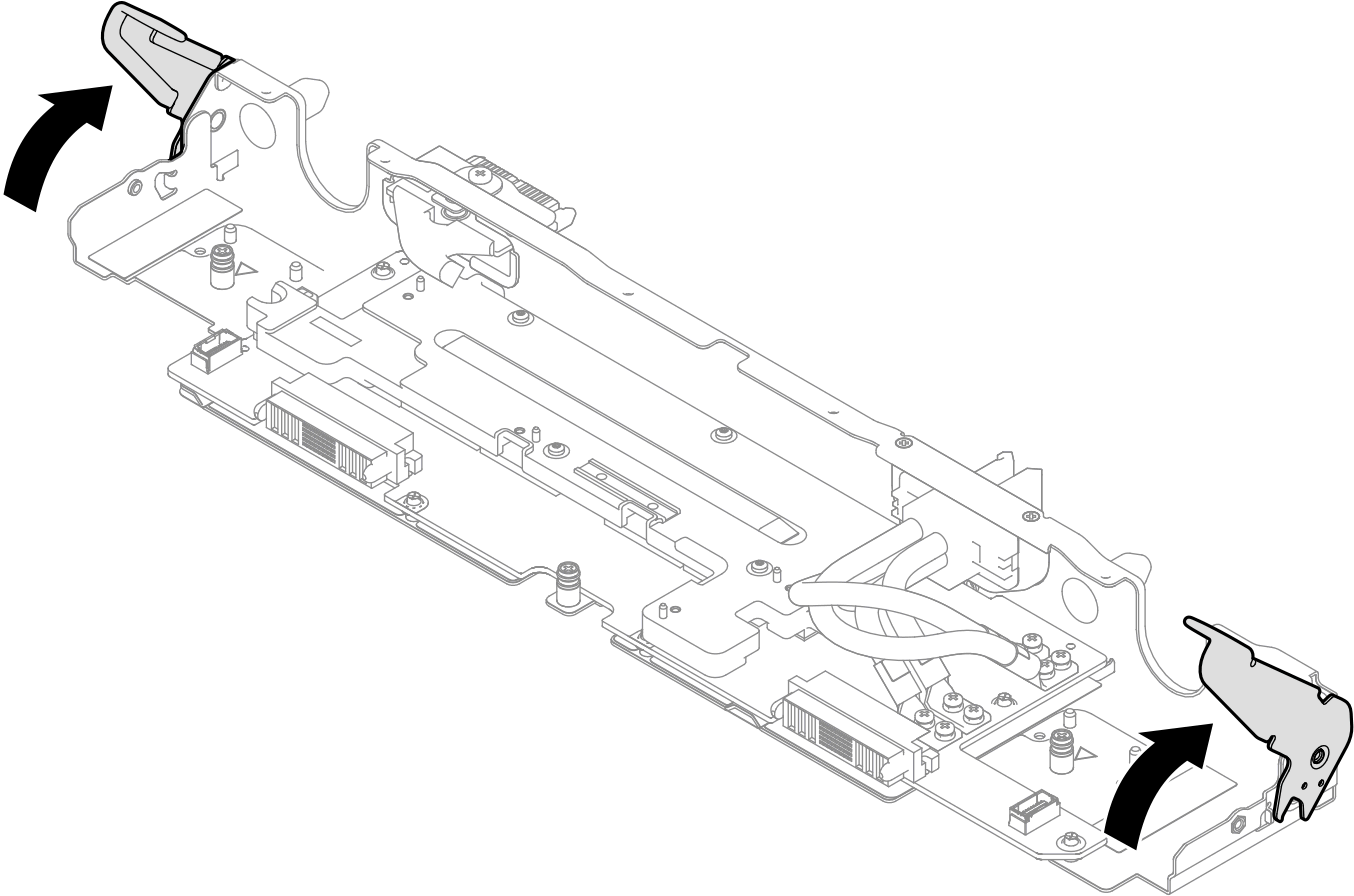

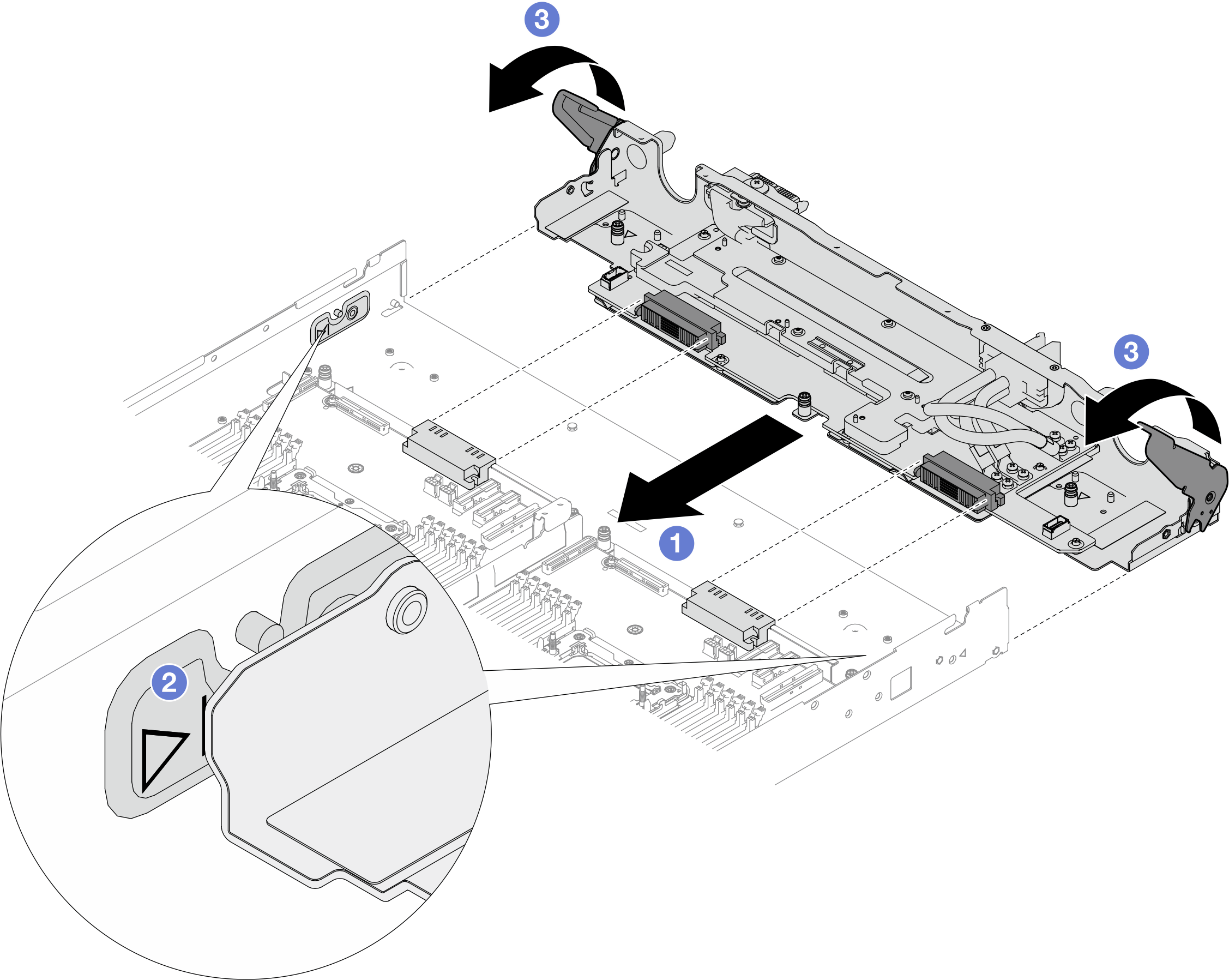

To avoid damaging the water loop, always use the water loop carrier when removing, installing or folding the water loop.

Go to Drivers and Software download website for ThinkSystem SC750 V4 to see the latest firmware and driver updates for your server.

Go to Update the firmware for more information on firmware updating tools.

- A video of this procedure is available at YouTube.

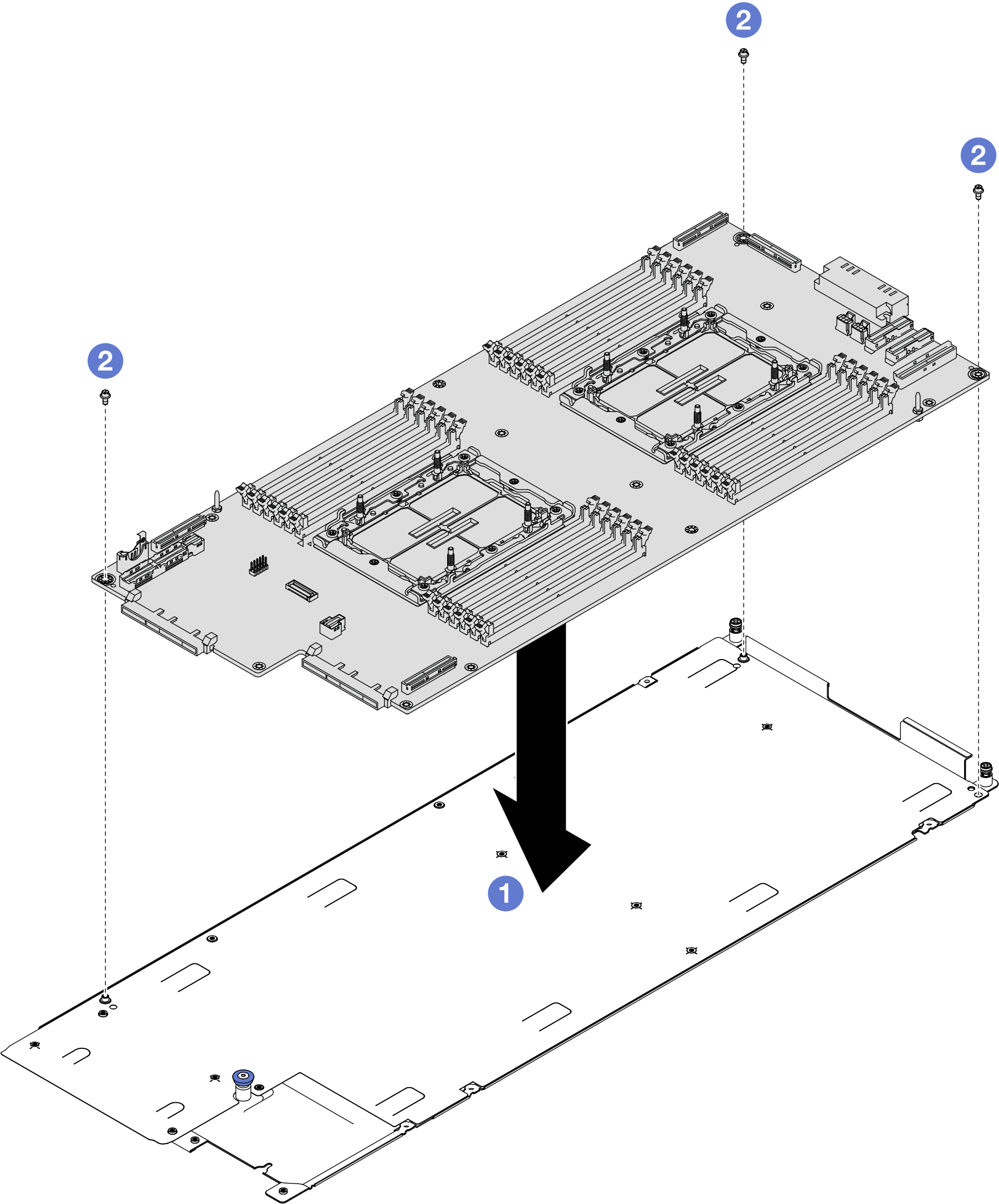

Procedure

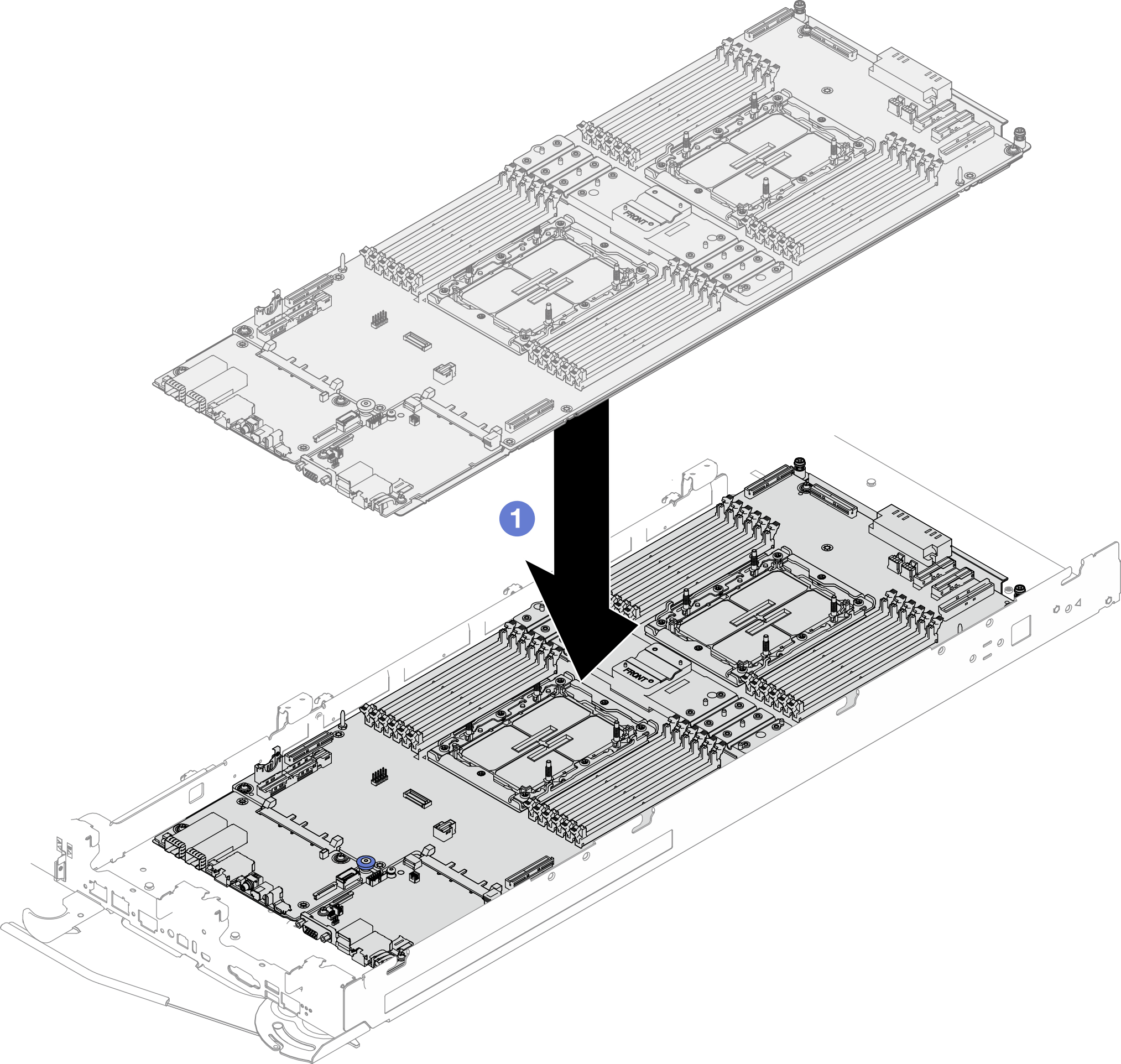

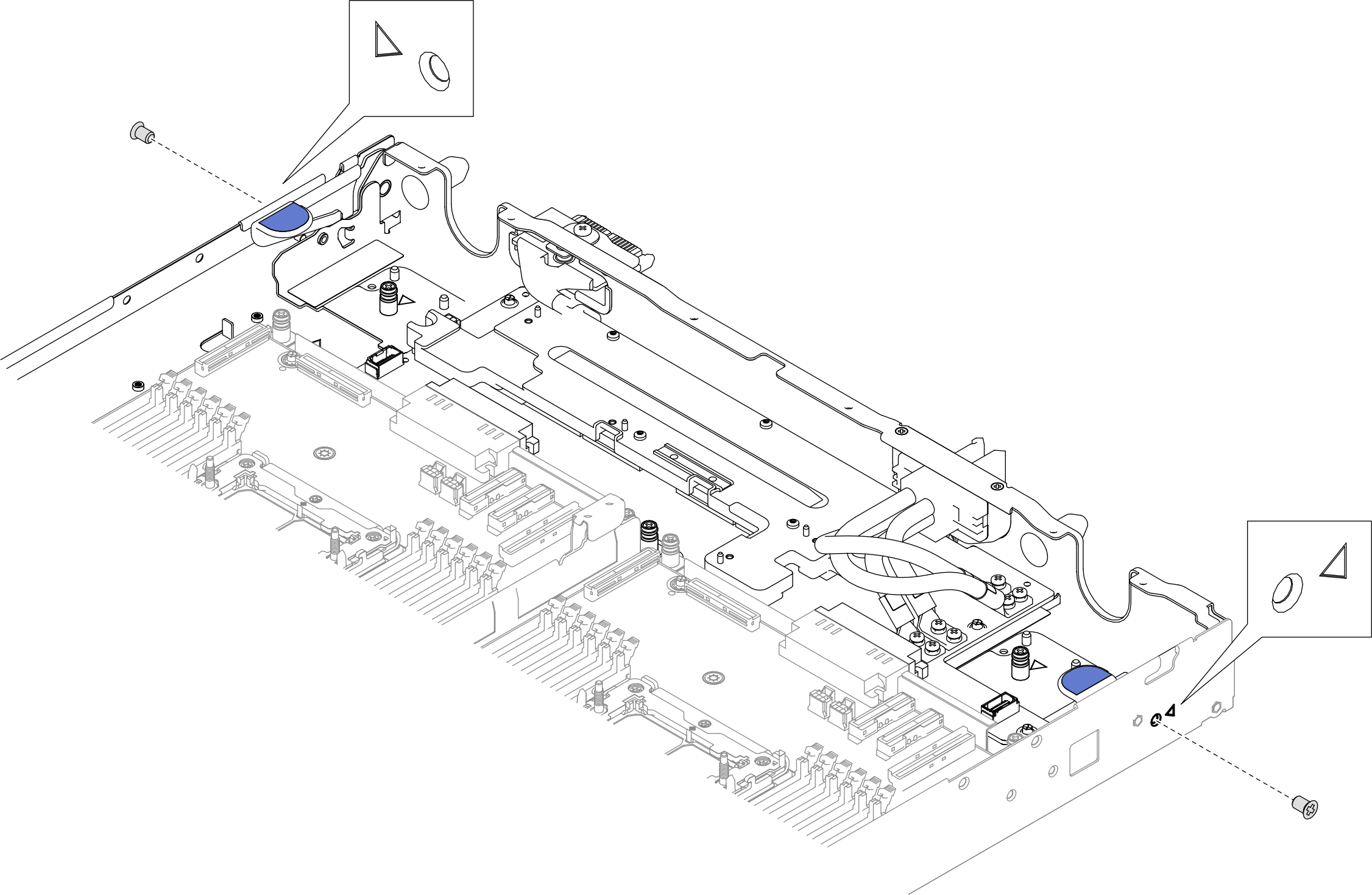

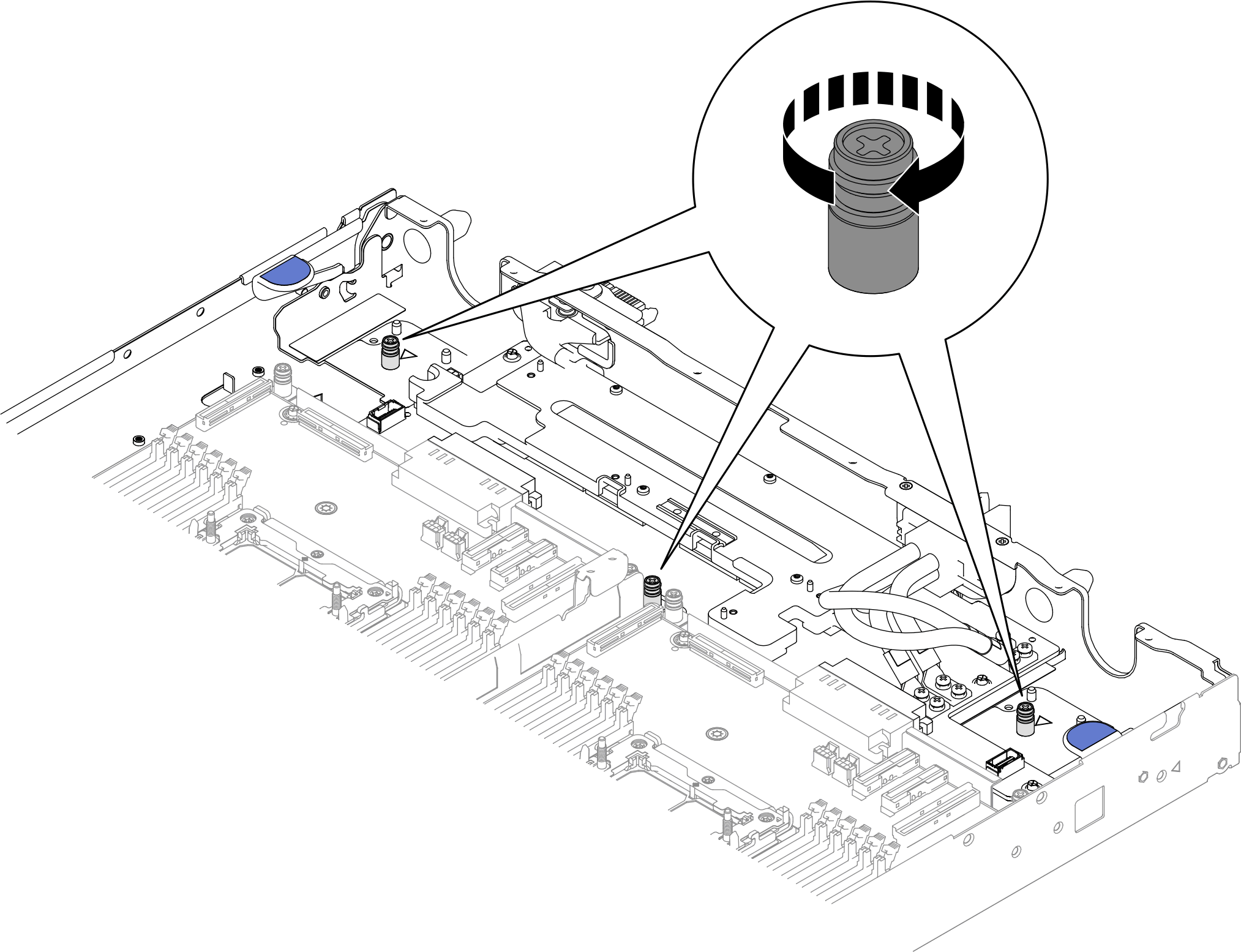

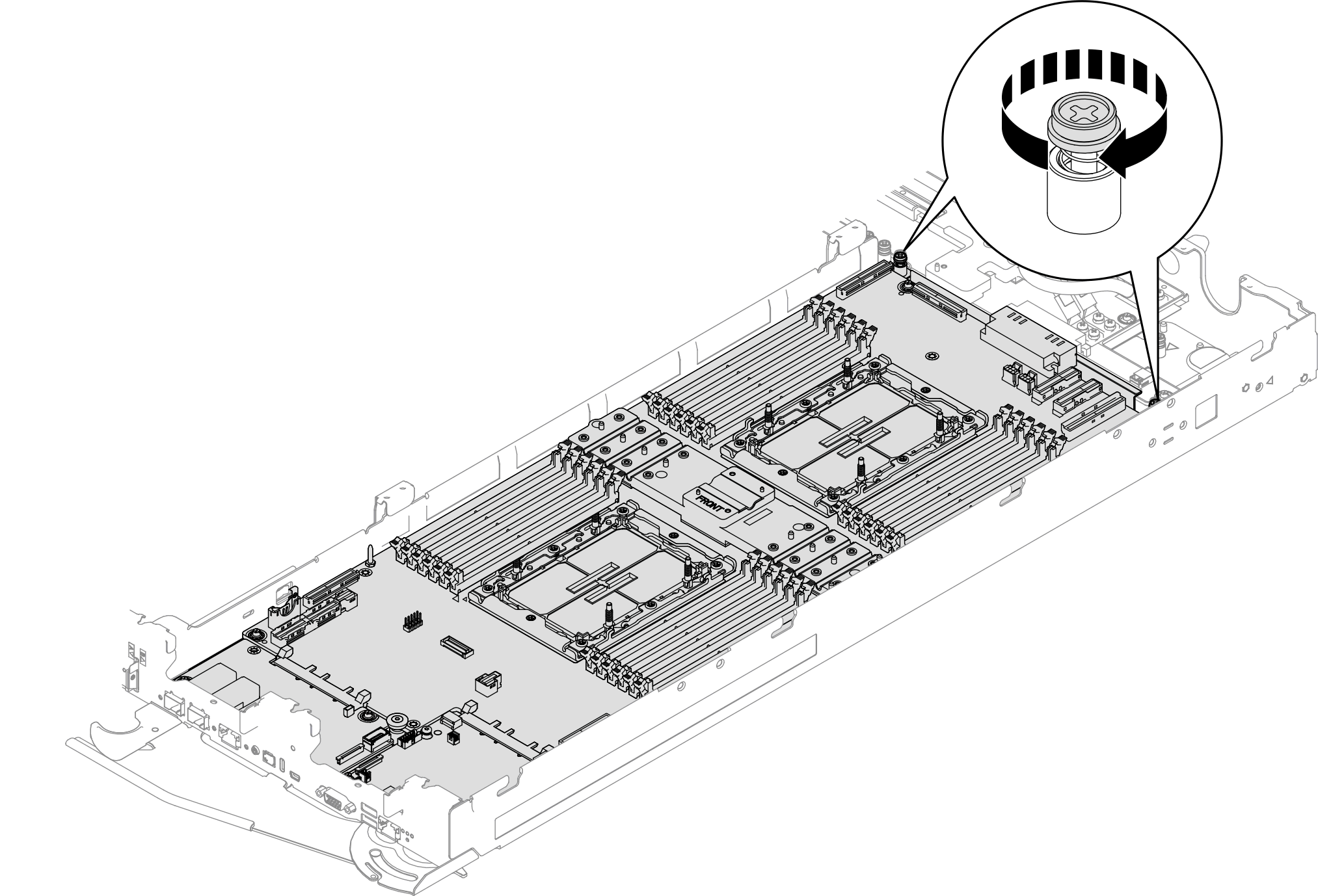

Install the water loop. See Install the water loop.

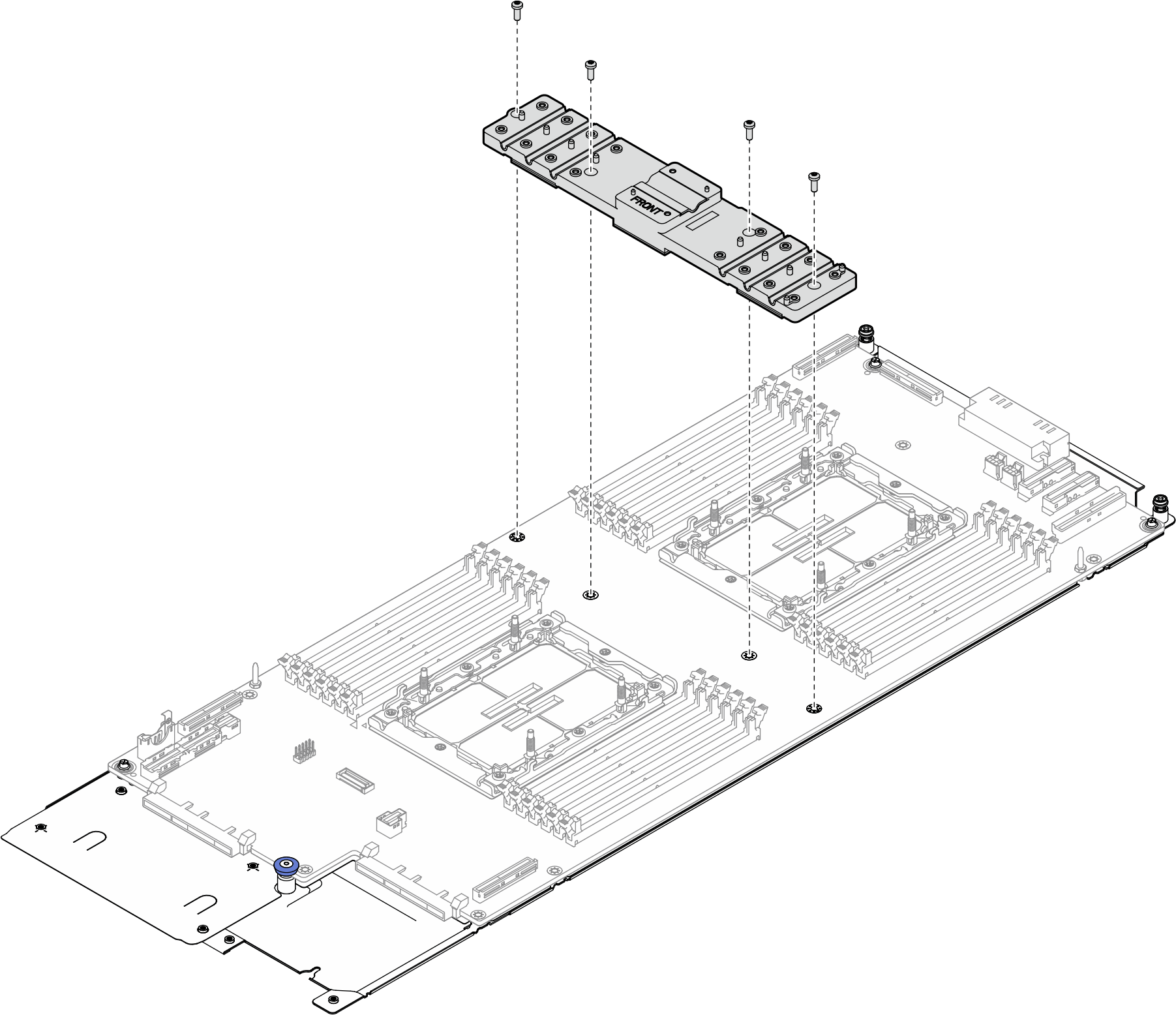

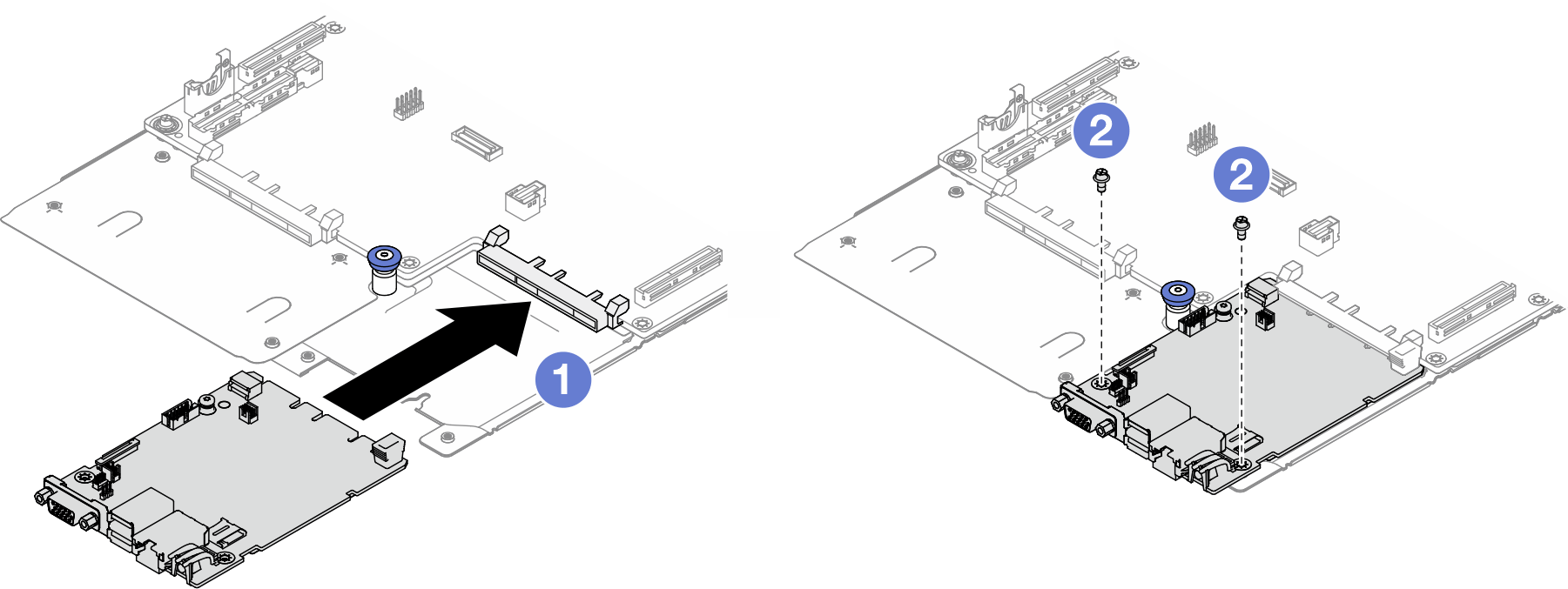

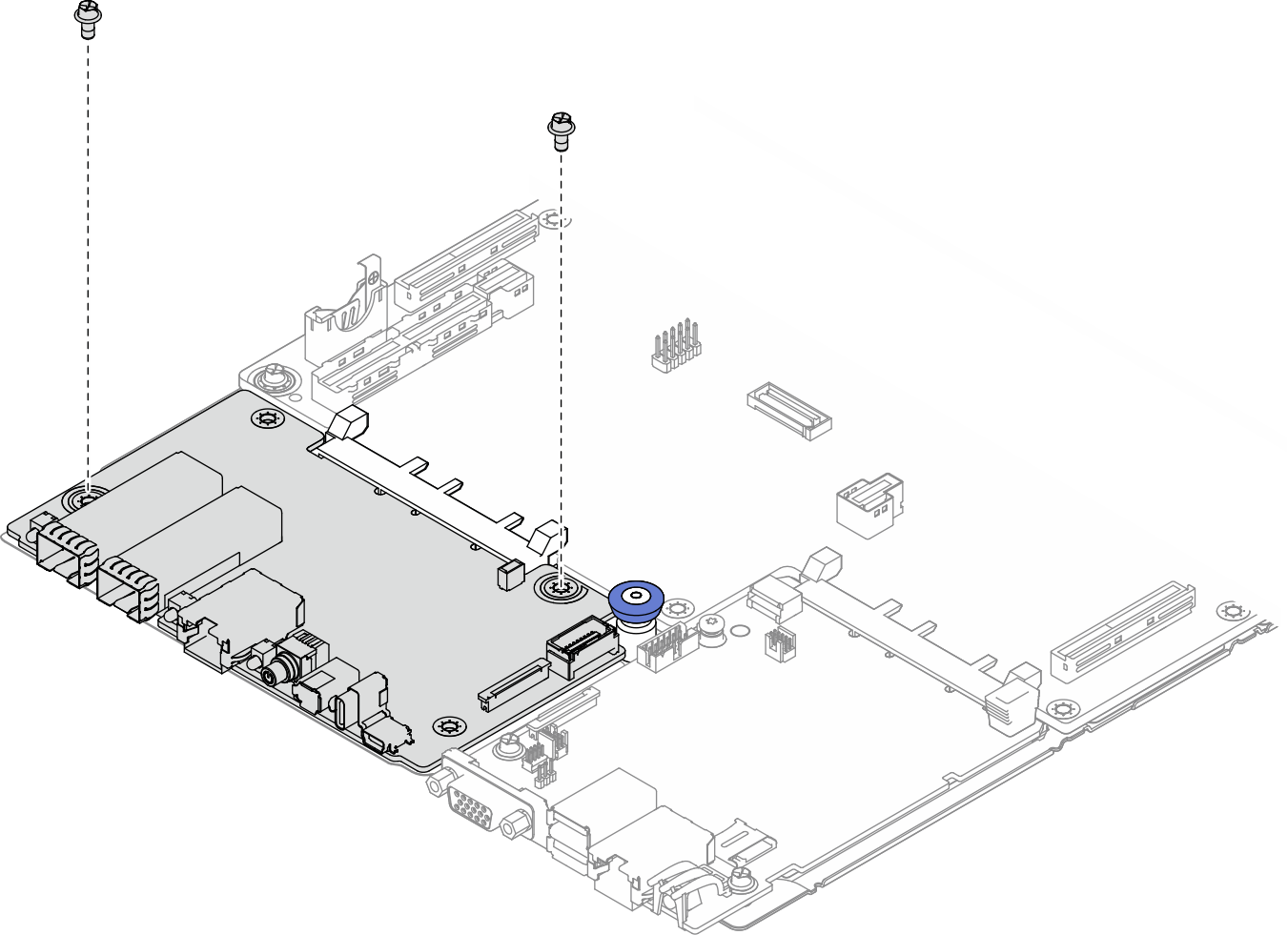

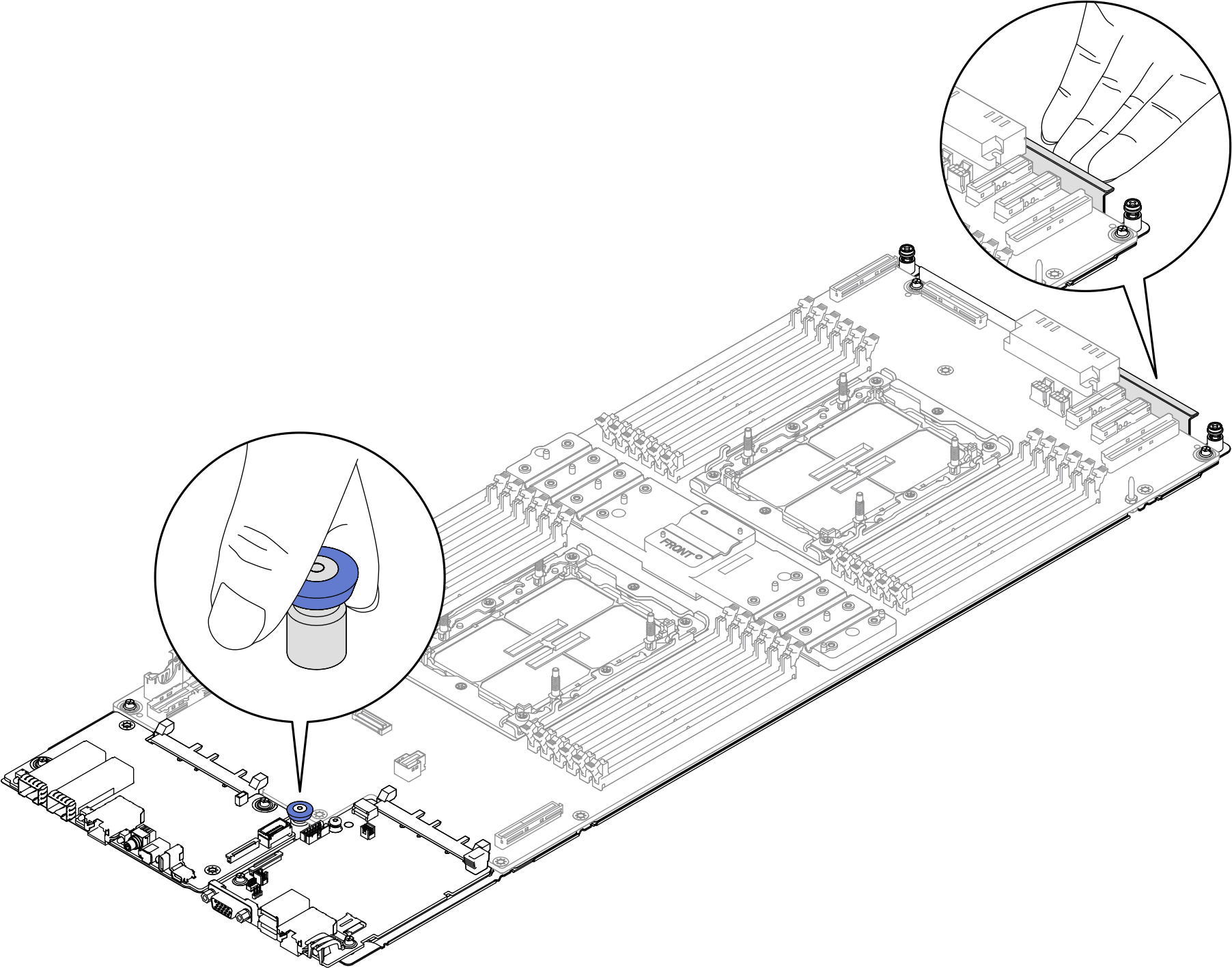

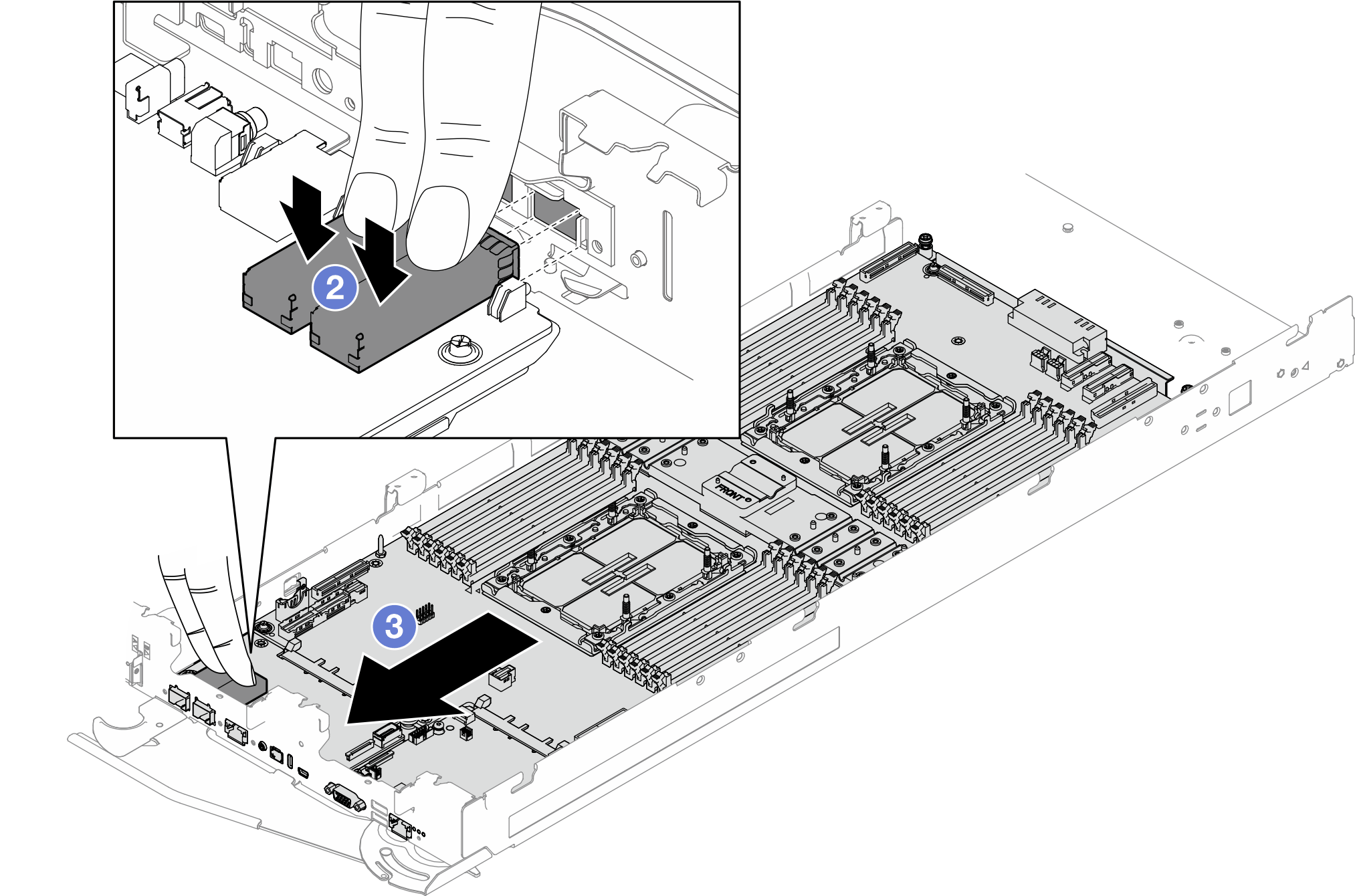

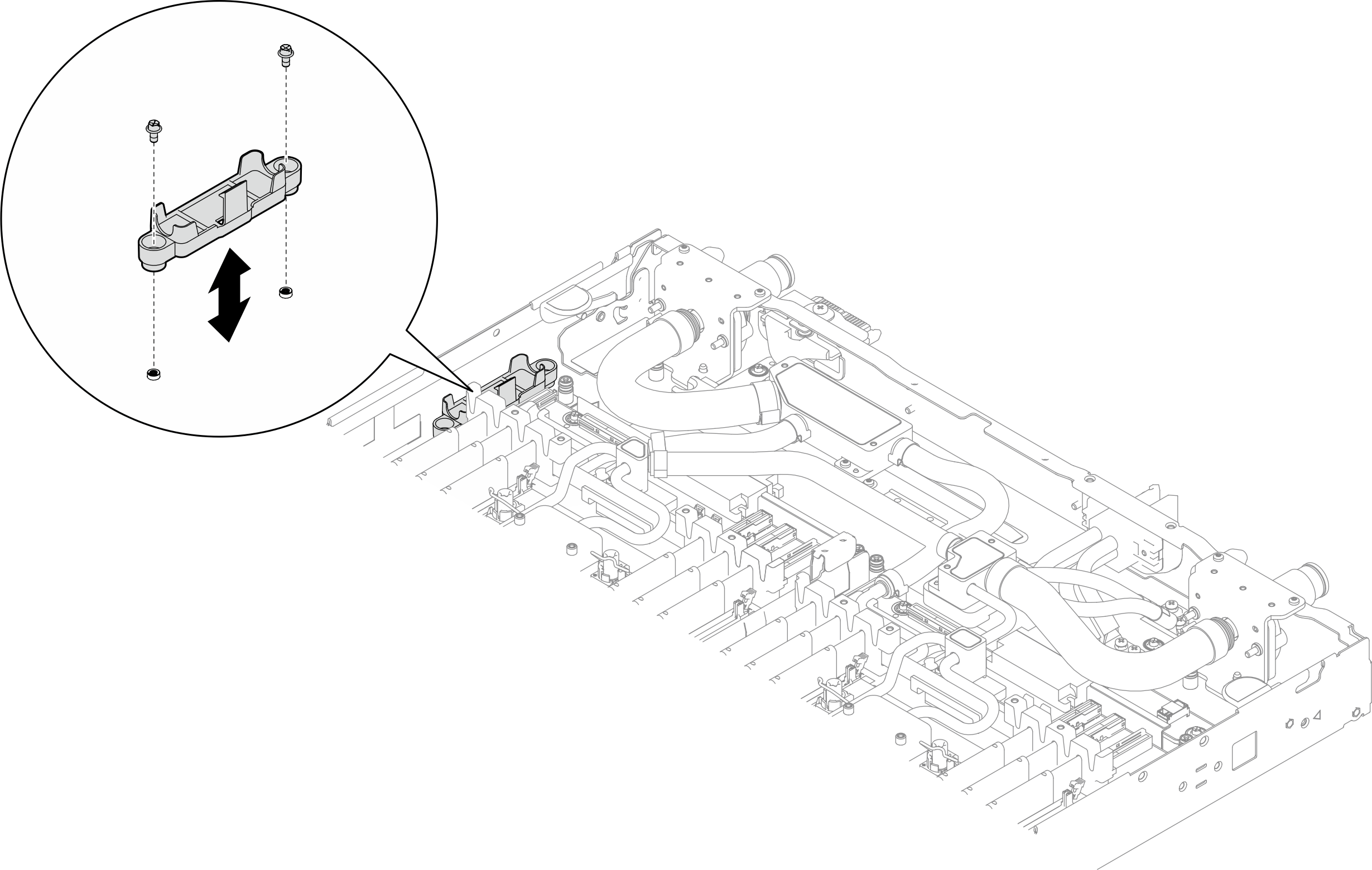

(Optional) When installing processor board to Node A, install the leakage sensor holder. Place the leakage sensor holder to the tray, and install two screws to secure it to the tray.

Figure 26. Installing leakage sensor holder

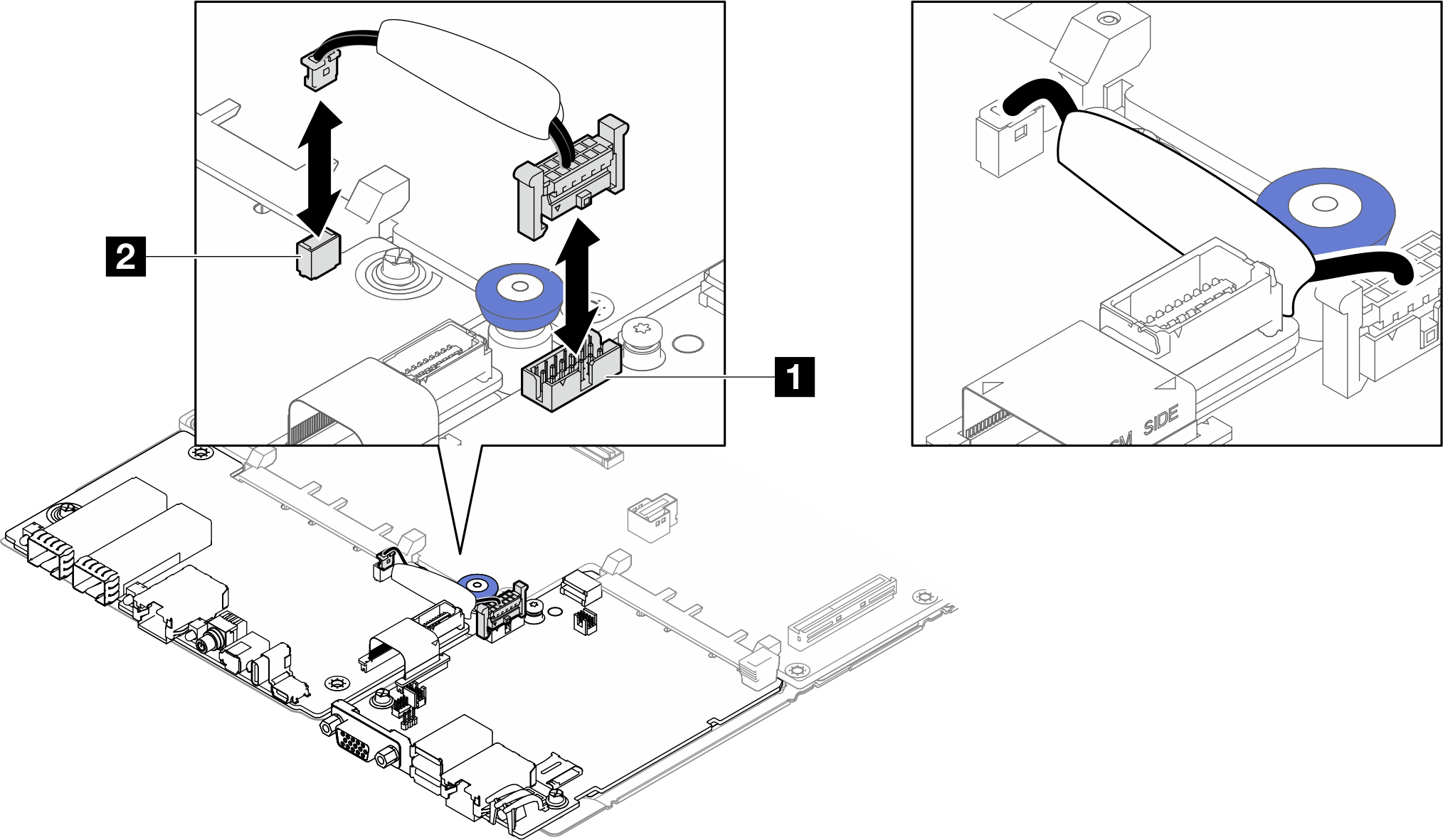

Install the leakage sensor. See Install the leakage sensor.

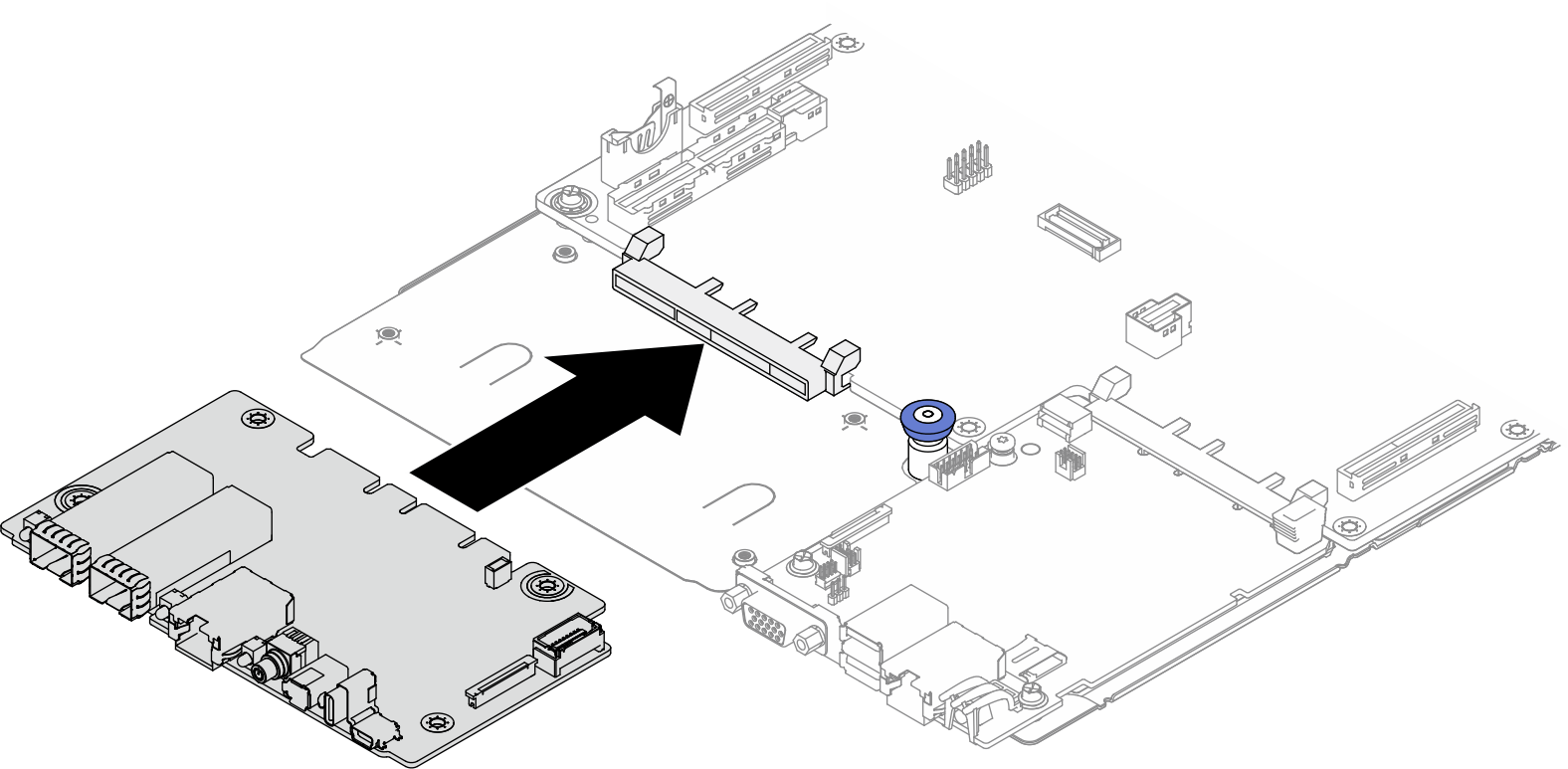

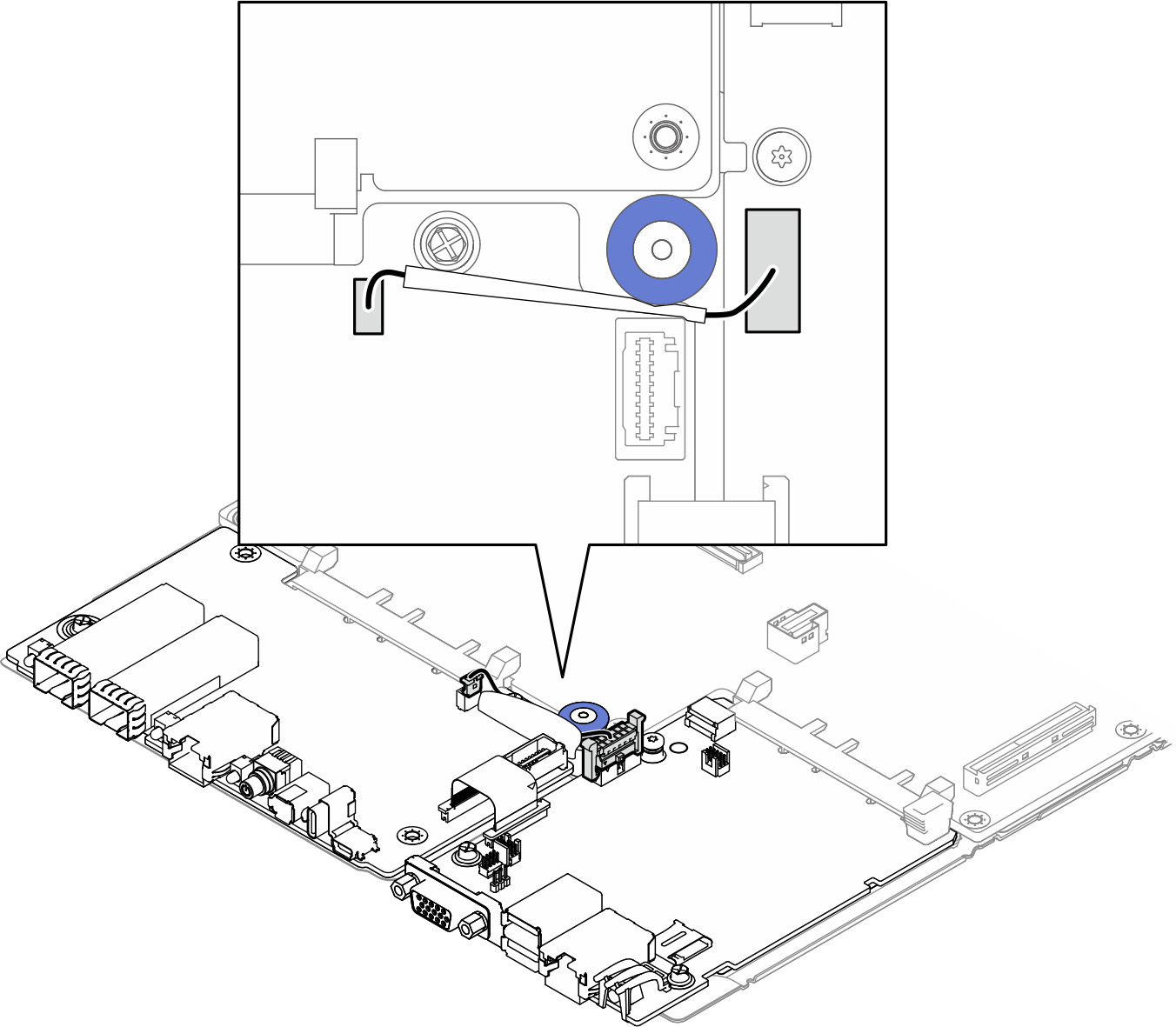

Install the sideband cable kit. See Install the system management sideband cable kit.

Install the middle E3.S drive cage. See Install an E3.S 1T middle drive cage assembly.

- Install the PCIe adapter riser cage. See Install a ConnectX-7 NDR 200 adapter riser assembly or Install a ConnectX-7 NDR 400 adapter riser assembly.

Install the front E3.S drive cage. See Install an E3.S front drive cage assembly.

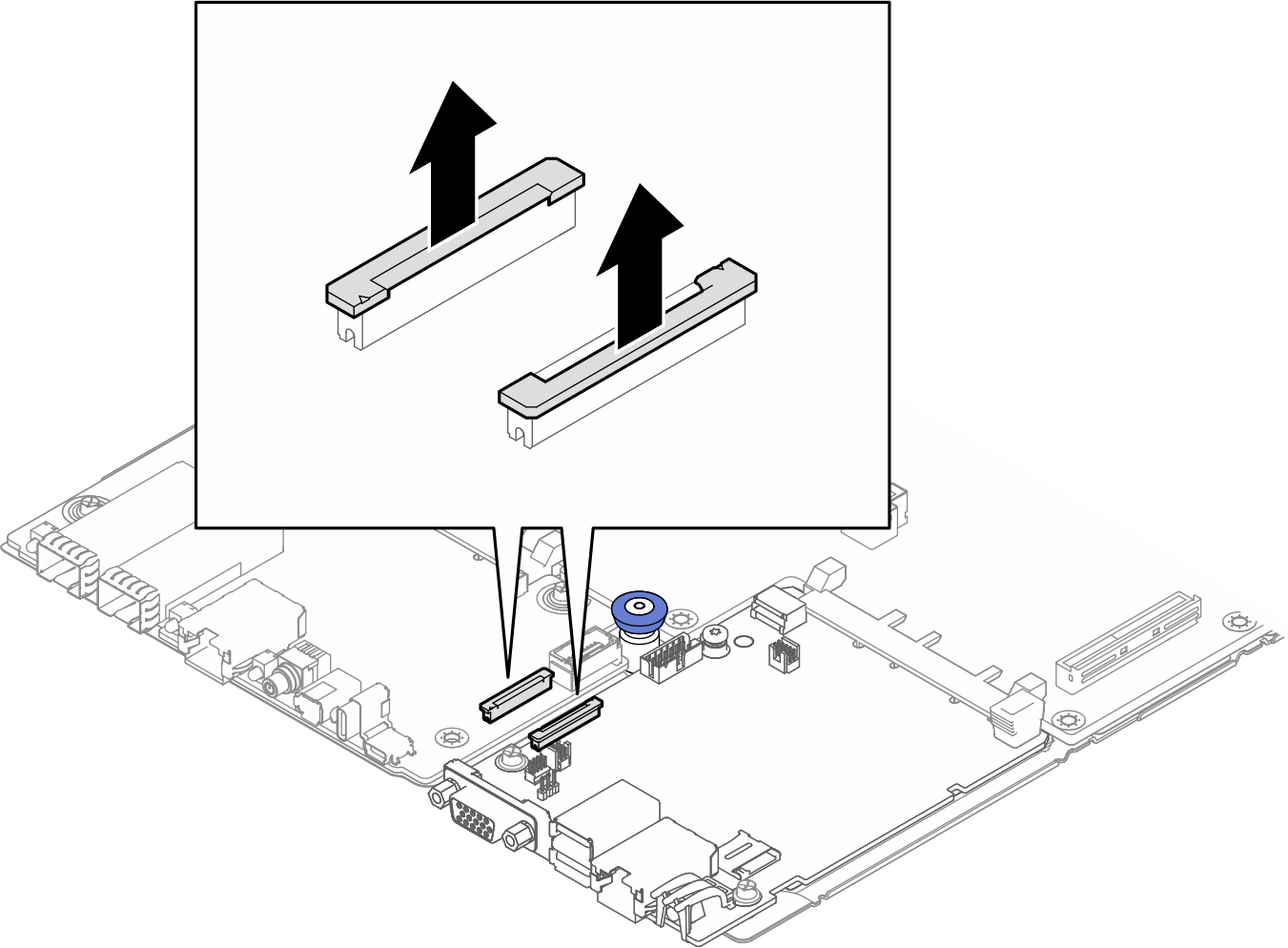

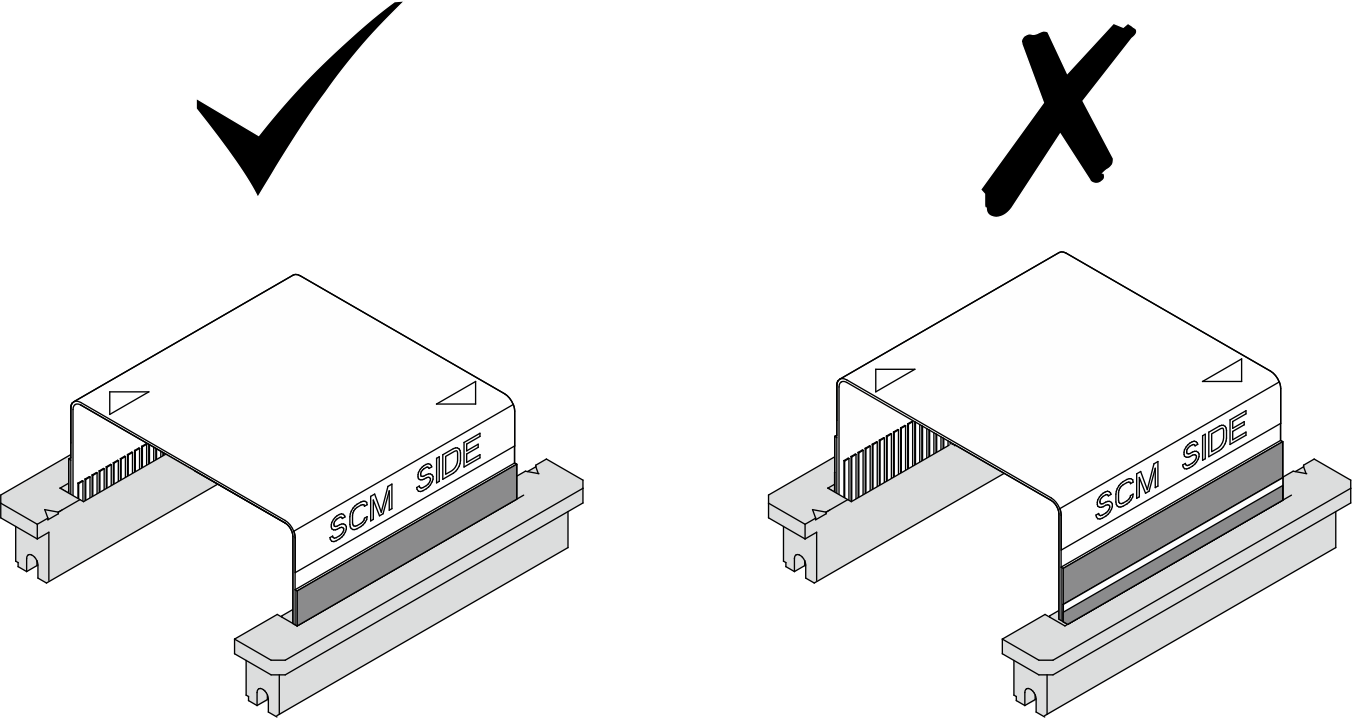

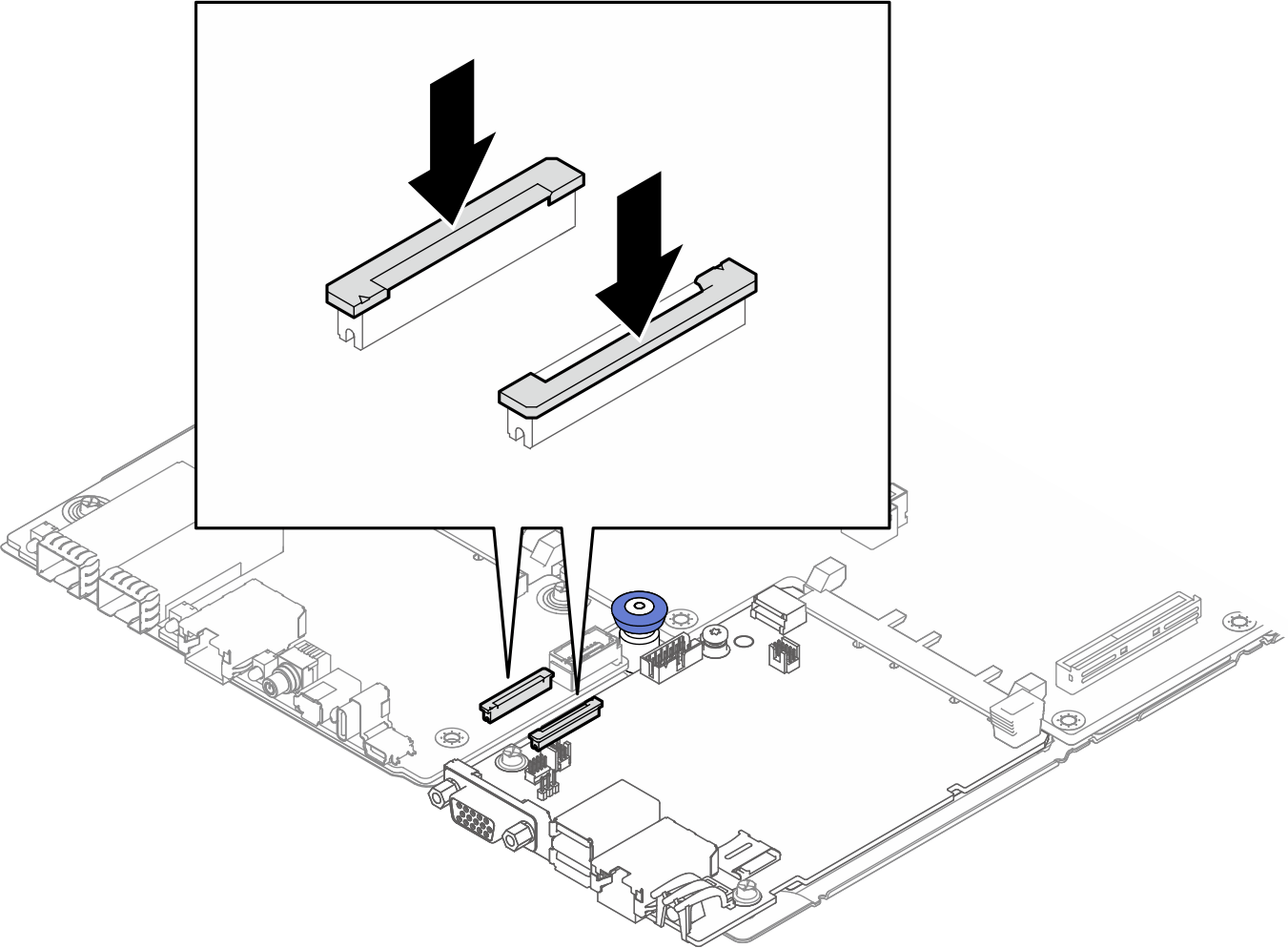

If the system will be installed with memory modules that requires dual-side cooling, install DIMM cooling bars. See Install a DIMM cooling bar.

Install the cross braces. See Install the cross braces.

Install the memory module, perform one of the following.

Install the memory modules that require single-side cooling. See Install a memory module (single-side cooling)., or

Install the memory modules that require dual-side cooling. See Install a memory module (dual-side cooling).

Install the DIMM comb. See Install a DIMM comb.

Install the tray cover. See Install the tray cover.

Install the tray into the enclosure. See Install a tray in the enclosure.

- Connect all required external cables to the solution.NoteUse extra force to connect QSFP cables to the solution.

- Check the power LED on each node to make sure it changes from fast blink to slow blink to indicate all nodes are ready to be powered on.Note

Shared I/O configuration requires specific nodes power-on sequence. When powering on the system, power on Node B first; then, power on Node A. For more information, see PCIe adapter cable routing.

Update the vital product data (VPD). See Update the Vital Product Data (VPD).

Machine type number and serial number can be found on the ID label, see Identify the solution and access the Lenovo XClarity Controller.