Install the Lenovo Neptune Processor Direct Water Cooling Module

Follow the instructions in this section to install the Direct Water Cooling Module (DWCM).

This task must be operated by trained technicians that are certified by Lenovo Service. Do not attempt to remove or install the part without proper training and qualification.

About this task

Read Installation Guidelines and Safety inspection checklist to ensure that you work safely.

Power off the server and peripheral devices and disconnect the power cords and all external cables. See Power off the server.

Prevent exposure to static electricity, which might lead to system halt and loss of data, by keeping static-sensitive components in their static-protective packages until installation, and handling these devices with an electrostatic-discharge wrist strap or other grounding systems.

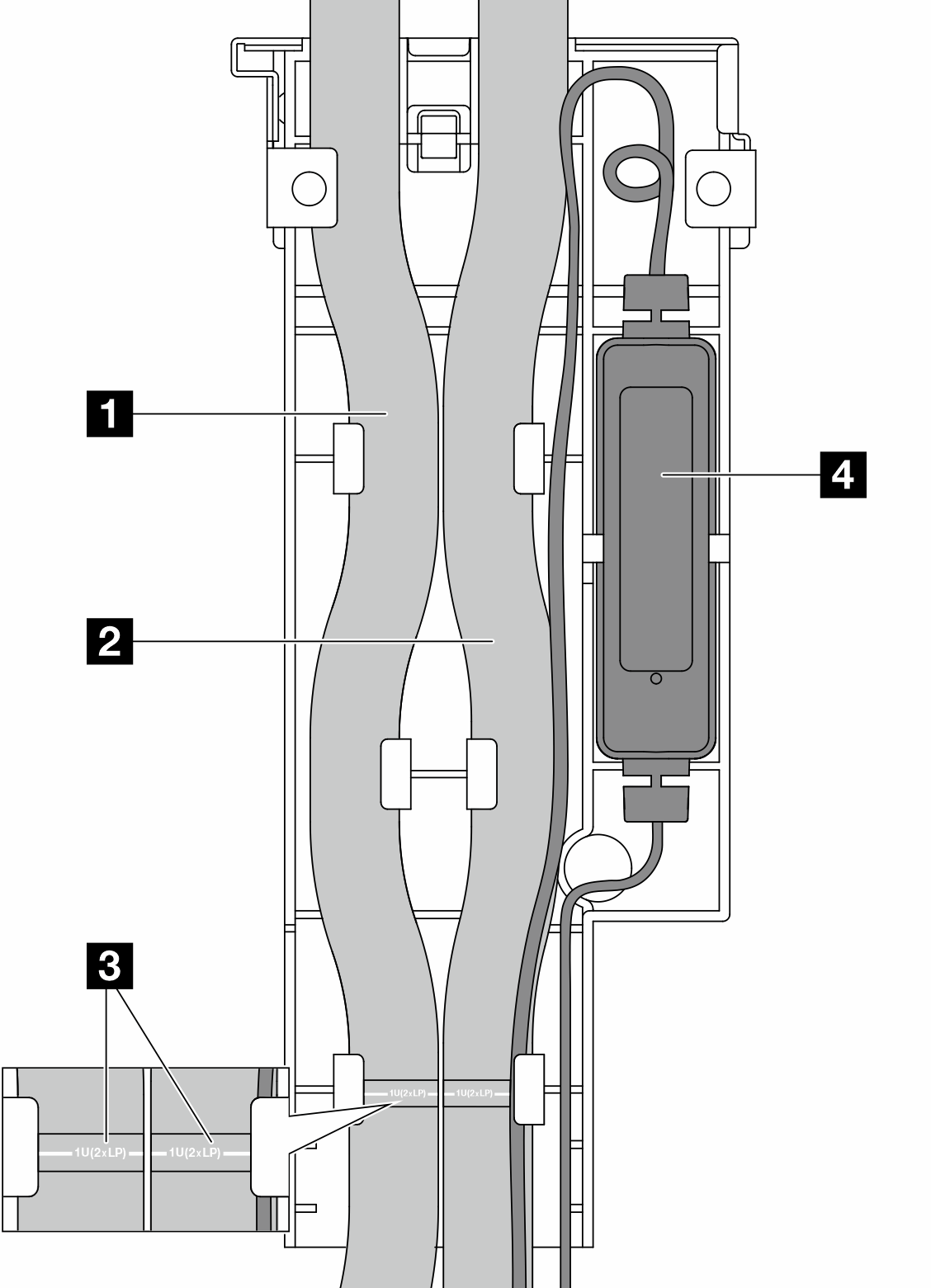

| Torque screwdriver type list | Screw Type |

|---|---|

| Torx T30 head screwdriver | Torx T30 screw |

Procedure

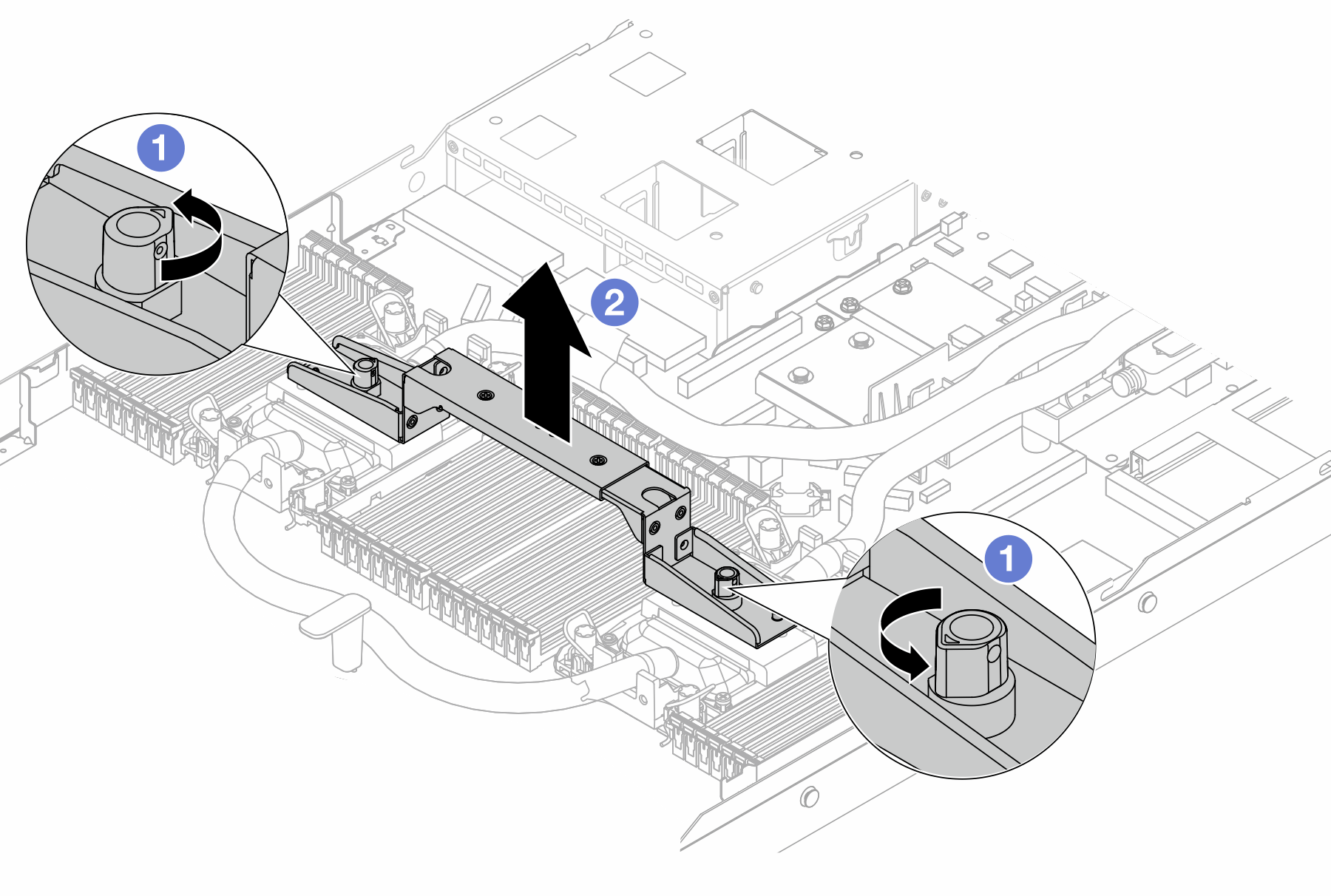

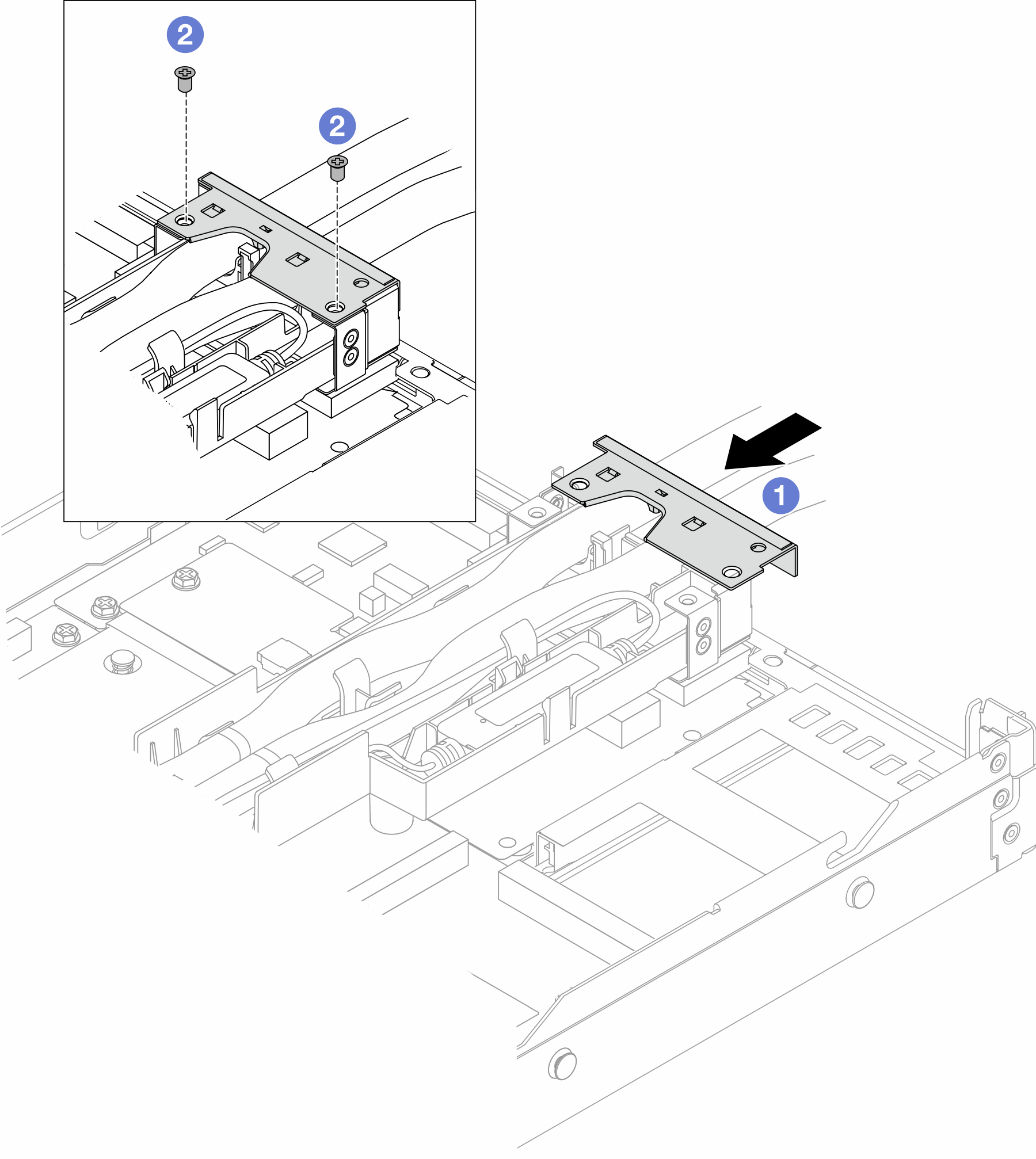

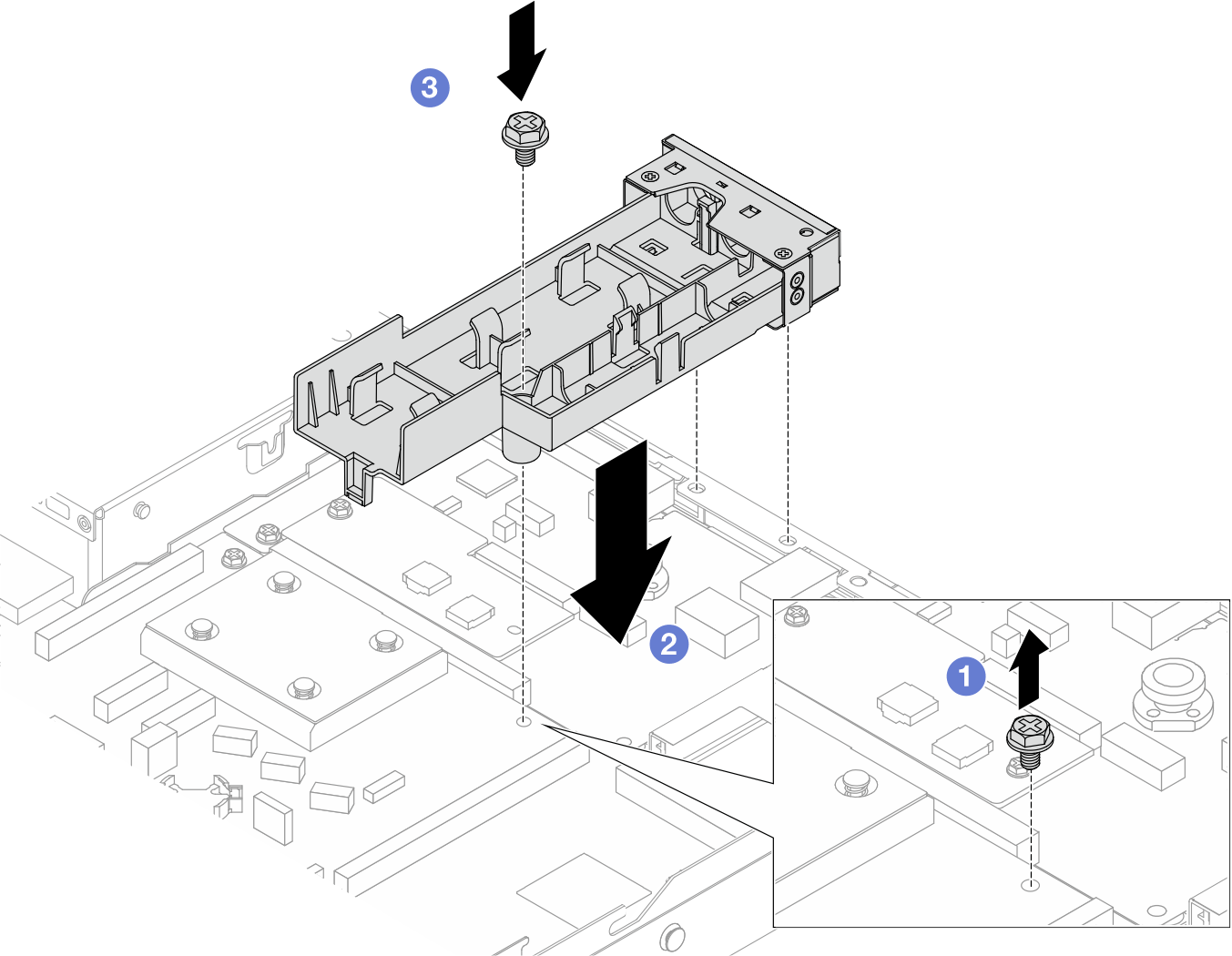

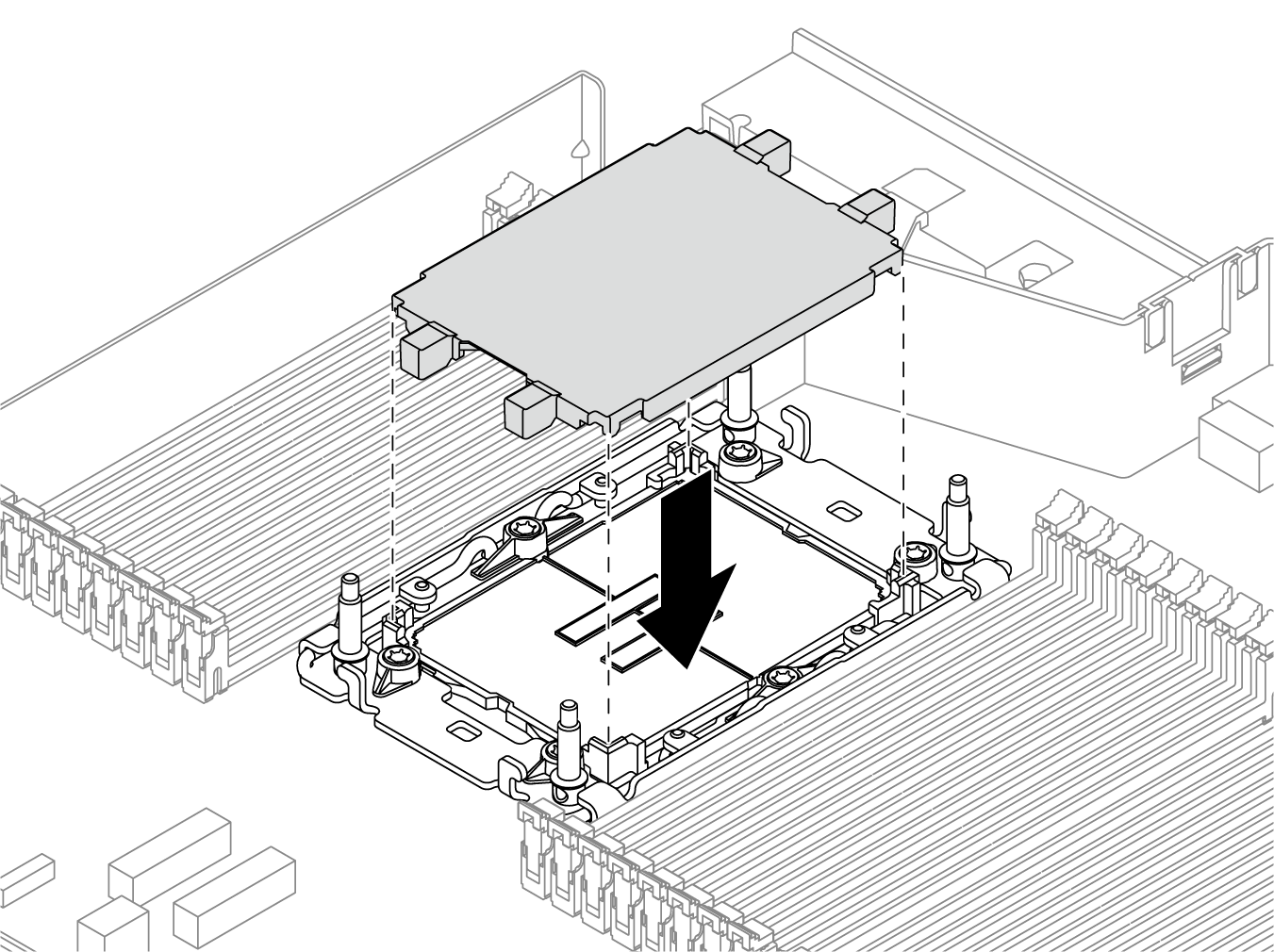

Loosen the screw on the processor board.

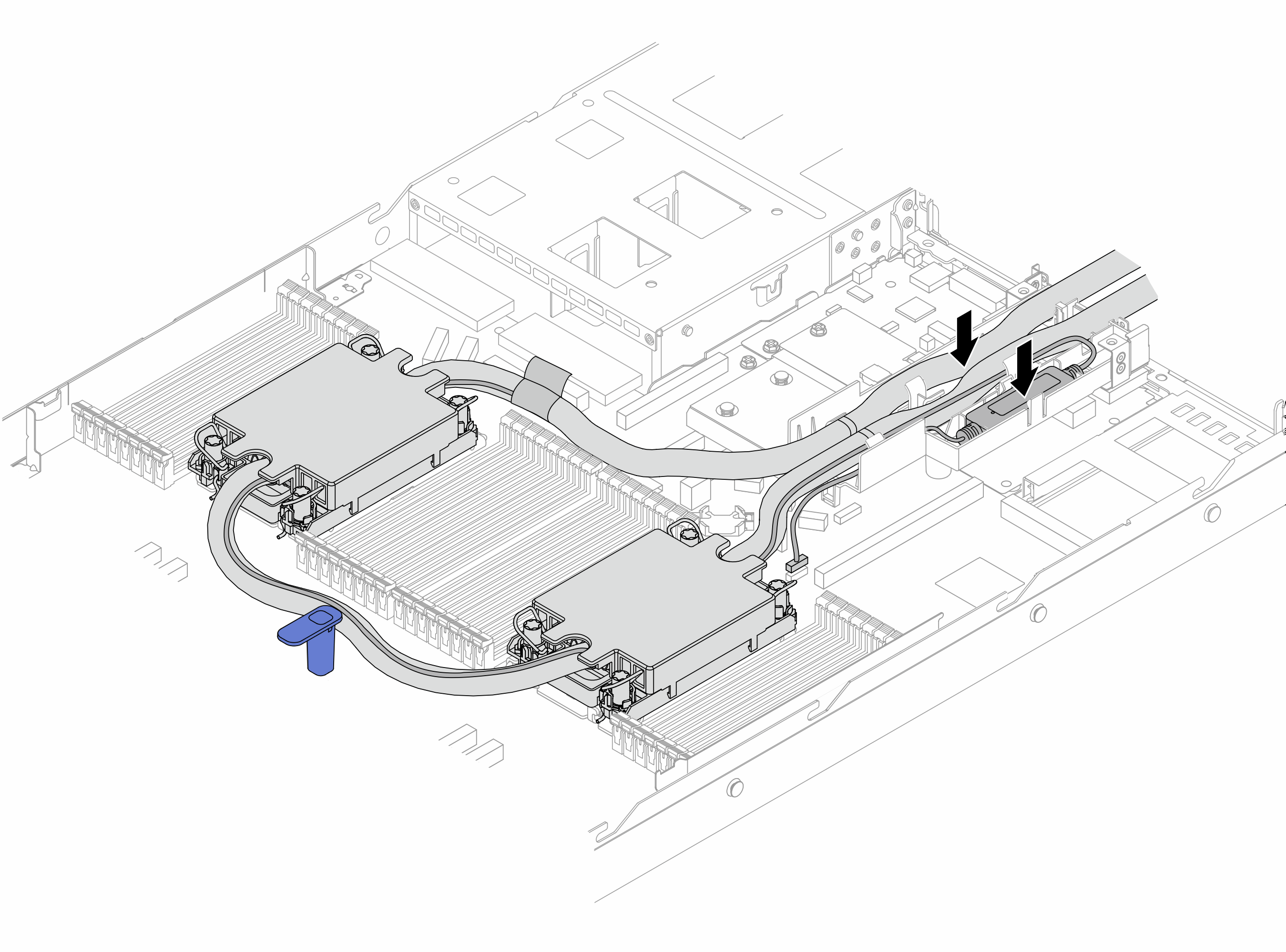

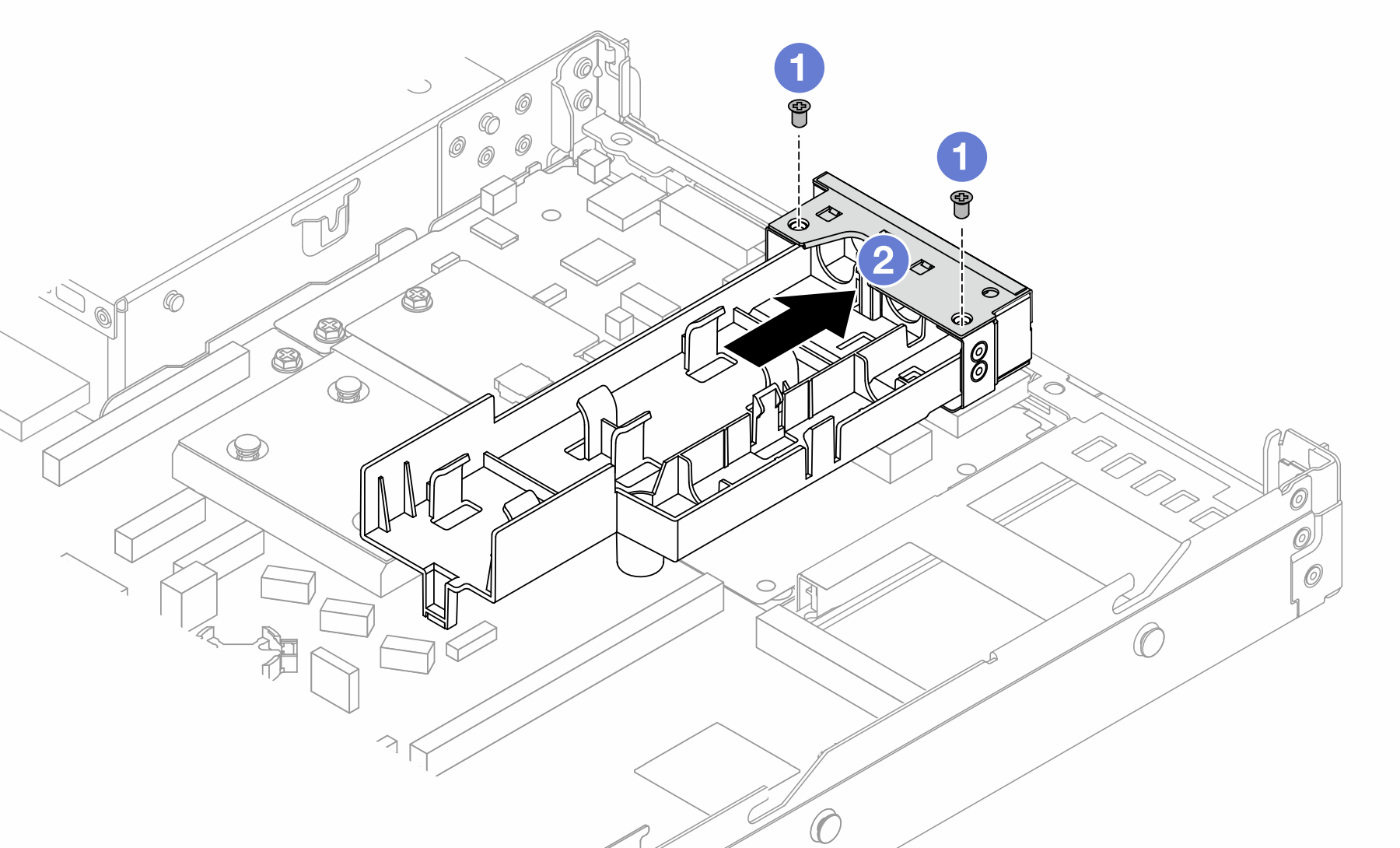

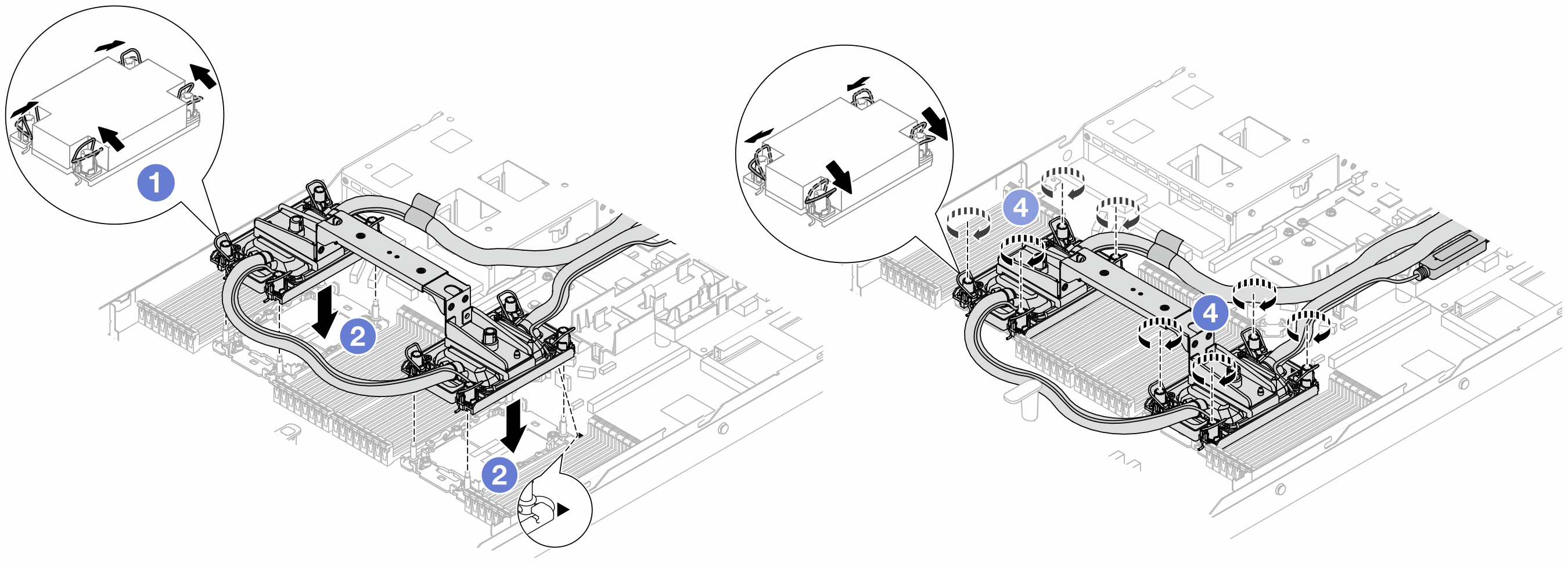

Loosen the screw on the processor board. Align the screw holes on the hose holder and processor board. And align the guiding pins of the holder to the rear wall.

Align the screw holes on the hose holder and processor board. And align the guiding pins of the holder to the rear wall. Tighten the screw to secure the holder to the processor board.

Tighten the screw to secure the holder to the processor board.

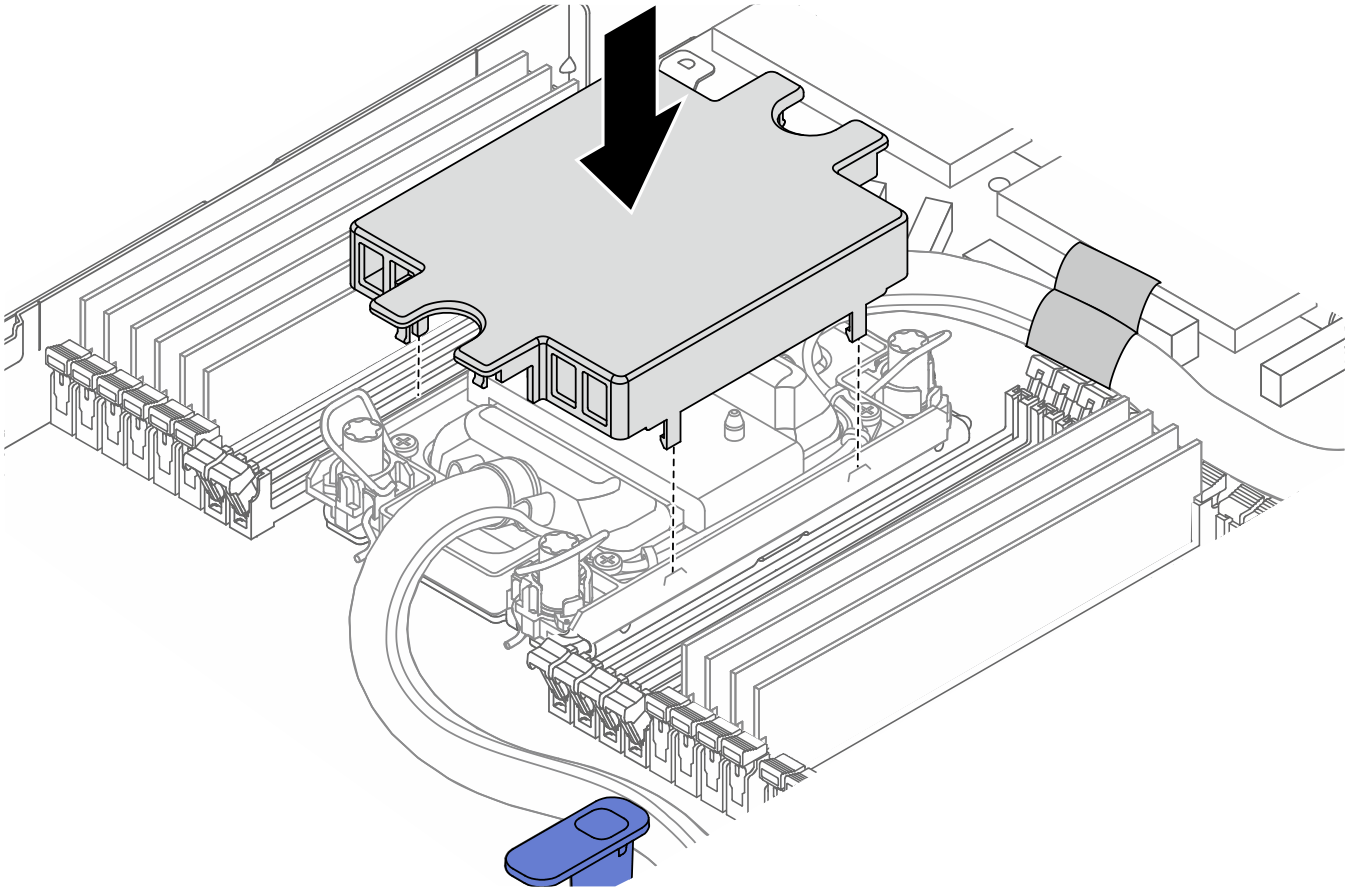

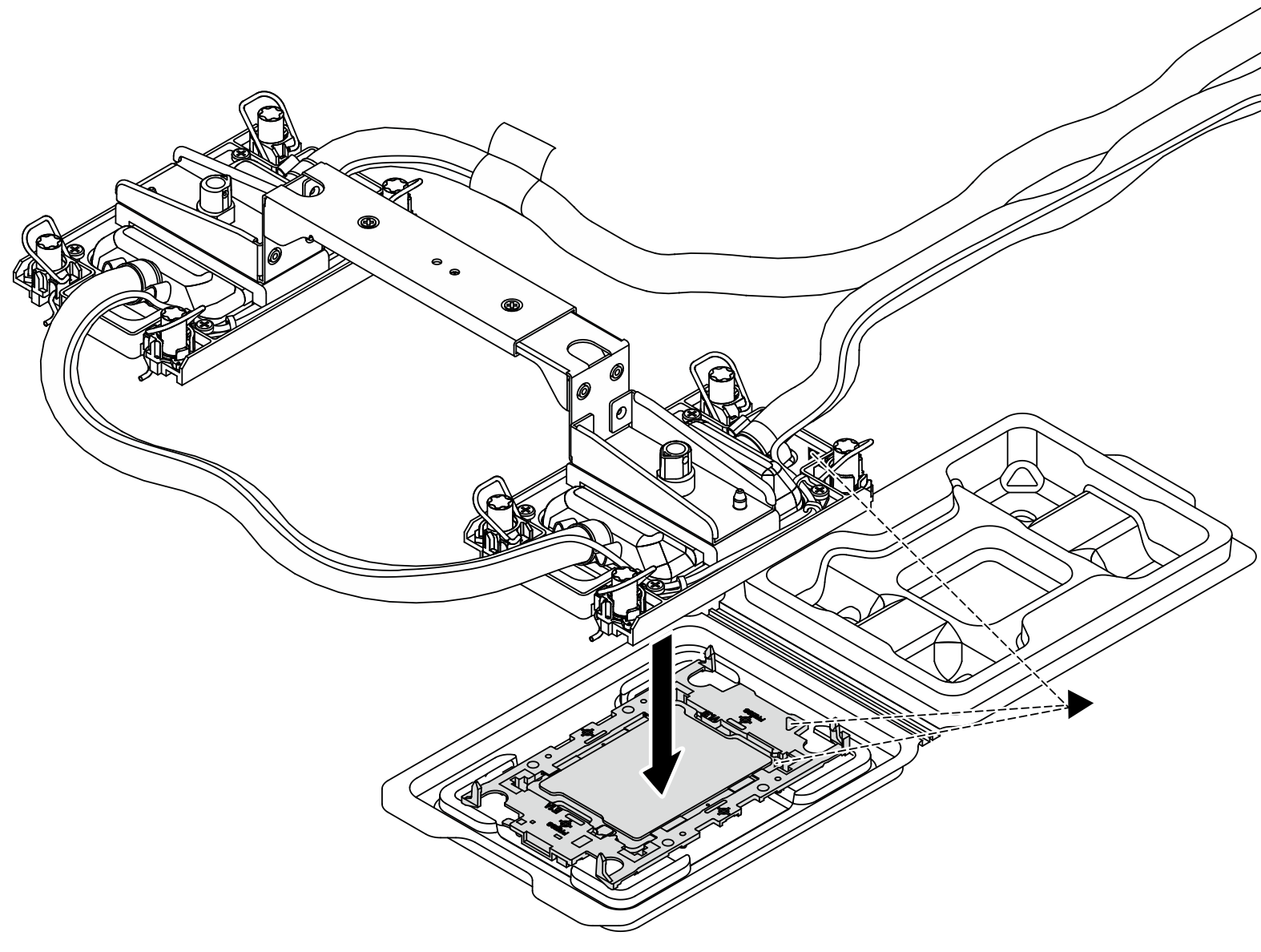

Fully tighten the Torx T30 nuts in the installation sequence shown on the

Fully tighten the Torx T30 nuts in the installation sequence shown on the