Install the B200 NVSwitch and retimer cold plate module

Follow instructions in this section to install the B200 NVSwitch and retimer cold plate module. The procedure must be executed by a trained technician.

About this task

Attention

- Read Installation Guidelines and Safety inspection checklist to ensure that you work safely.

- Touch the static-protective package that contains the component to any unpainted metal surface on the server; then, remove it from the package and place it on a static-protective surface.

- Two people and one lifting device on site that can support up to 400 lb (181 kg) are required to perform this procedure. If you do not already have a lifting device available, Lenovo offers the Genie Lift GL-8 material lift that can be purchased at Data Center Solution Configurator. Make sure to include the Foot-release brake and the Load Platform when ordering the Genie Lift GL-8 material lift.

- A torque screwdriver is available for request if you do not have one at hand.

Note

Make sure you have the required tools listed below available to properly replace the component:

- Torx T15 head screwdriver

- Torx T15 200mm extension bit

- Phillips #1 head screwdriver

- Phillips #2 head screwdriver

- Alcohol cleaning pad

- 2 x B200 PCM

- 2 x B200 SXM6 PAD-1

- 2 x B200 SXM6 PAD-2

- B200 GPU F&R shipping bkt kit

- B200 GPU Service kit

- B200 Retimer NVSwitch service kit

- B200 Retimer NVSwitch shipping kit

- B200 NVSwitch PCM

- B200 NVSwitch PAD-1

- B200 NVSwitch PAD-2

Important

Putty pad/phase change material (PCM) replacement guidelines

- Before replacing the putty pad/PCM, gently clean the hardware surface with an alcohol cleaning pad.

- Hold the putty pad/PCM carefully to avoid deformation. Make sure no screw hole or opening is blocked by the putty pad/PCM.

- Do not use expired putty pad/PCM. Check the expiry date on putty pad/PCM package. If the putty pads/PCM are expired, acquire new ones to properly replace them.

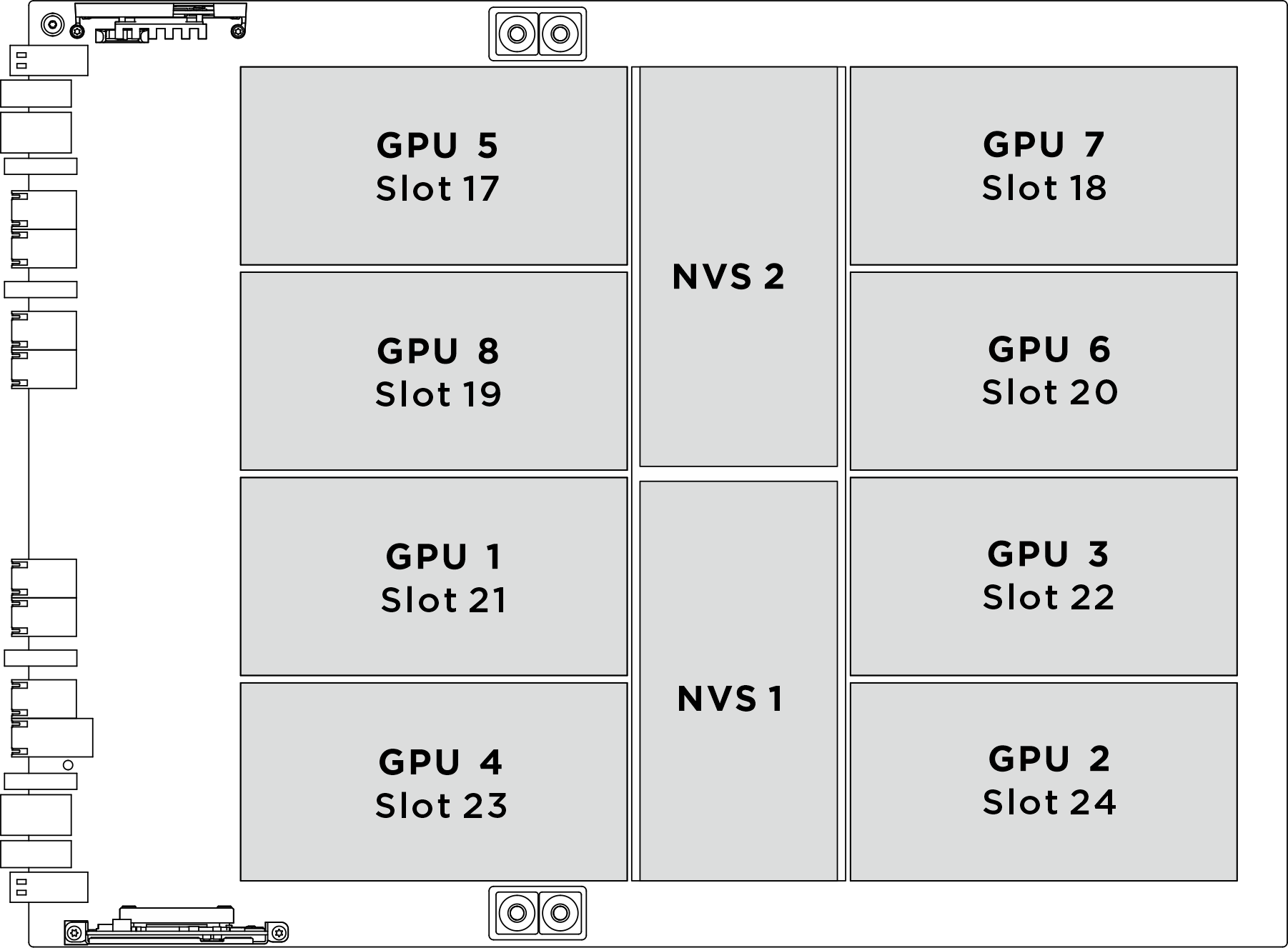

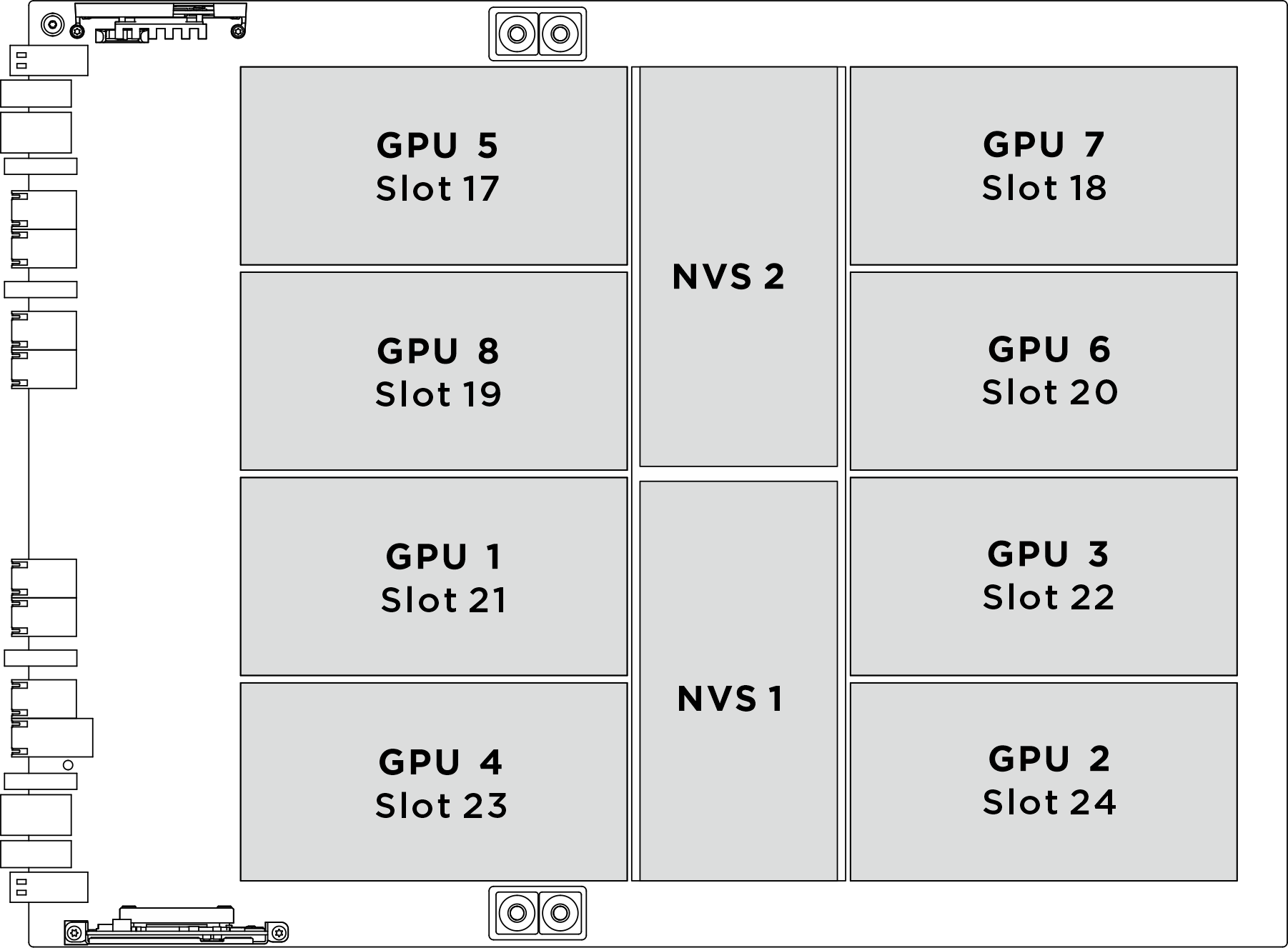

The following illustration shows the B200 GPU numbering and corresponding slot numbering in XCC.

Figure 1. B200 GPU numbering

| Physical GPU socket | Slot numbering in XCC | Module ID in nvidia-smi |

|---|---|---|

SXM 1 | Slot 21 | 1 |

SXM 2 | Slot 24 | 2 |

SXM 3 | Slot 22 | 3 |

SXM 4 | Slot 23 | 4 |

SXM 5 | Slot 17 | 5 |

SXM 6 | Slot 20 | 6 |

SXM 7 | Slot 18 | 7 |

SXM 8 | Slot 19 | 8 |

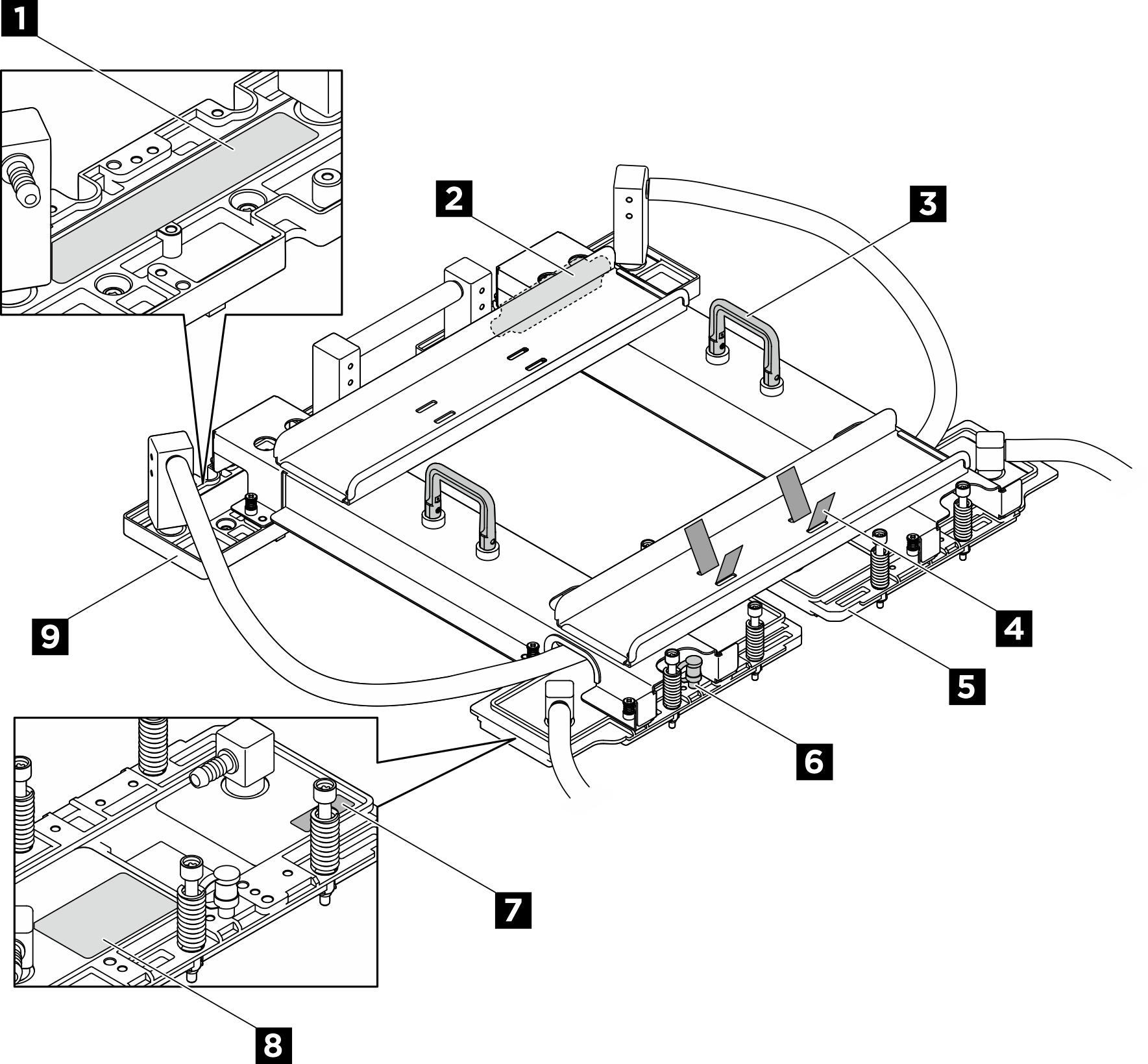

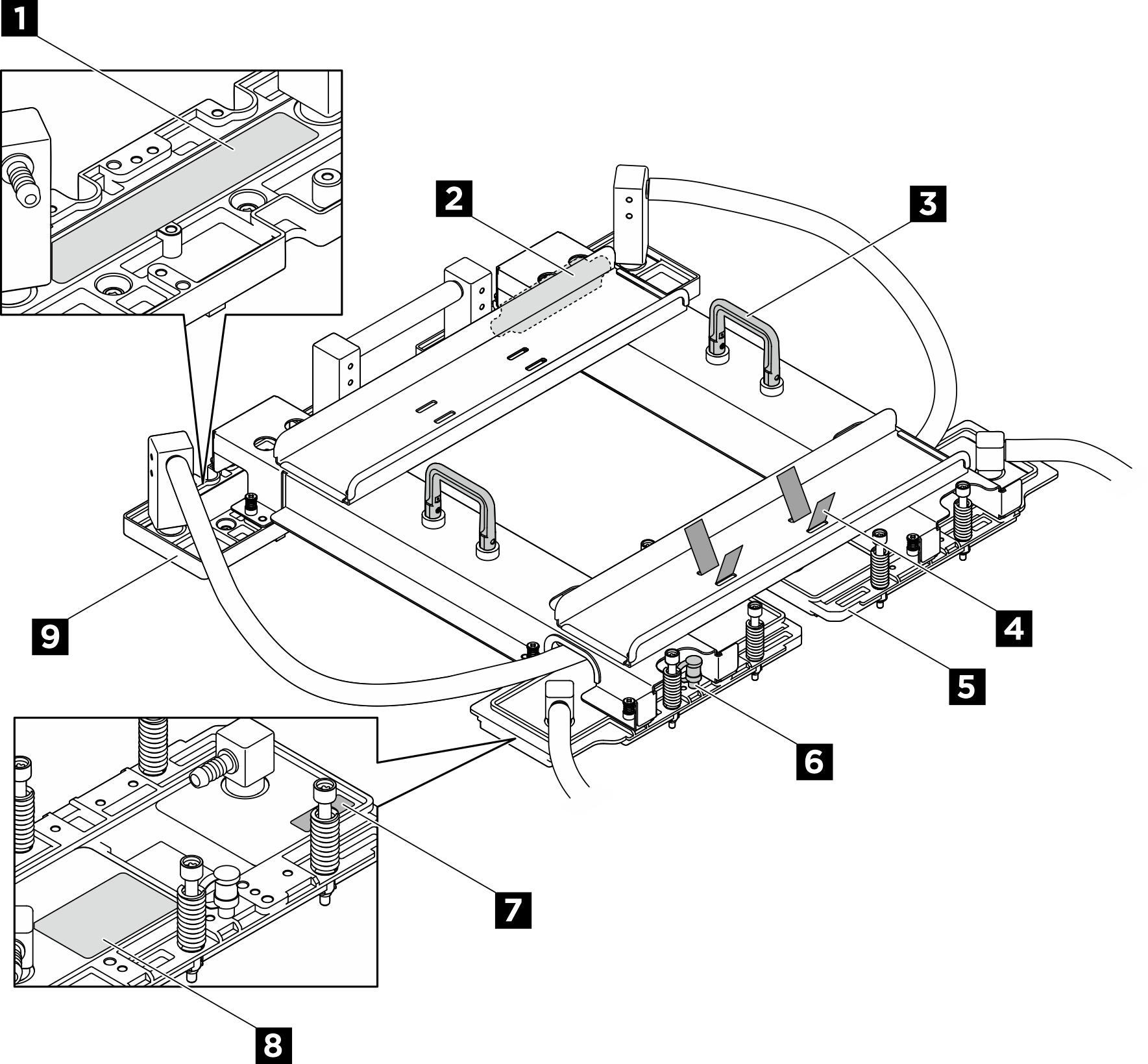

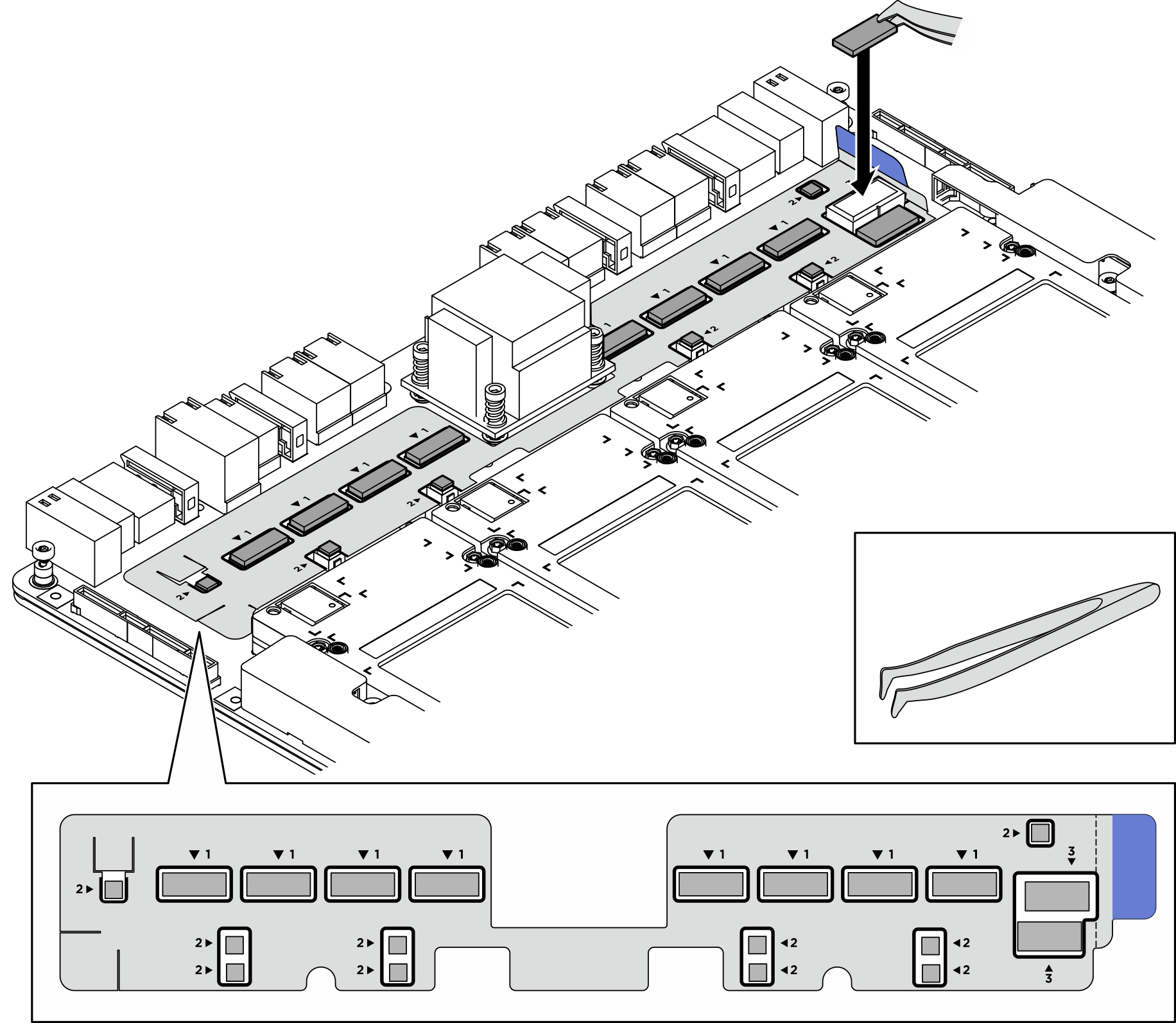

The following illustration shows the components for NVSwitch and retimer cold plate module.

Figure 2. NVSwitch and retimer cold plate module components identification

| 1 Retimer cold plate torque label | 2 Leakage sensor module |

| 3 Handle | 4 Hose tie |

| 5 NVSwitch cold plate | 6 TIM breaker screw |

| 7 NVSwitch slot number label | 8 NVSwitch cold plate torque label |

| 9 Retimer cold plate |

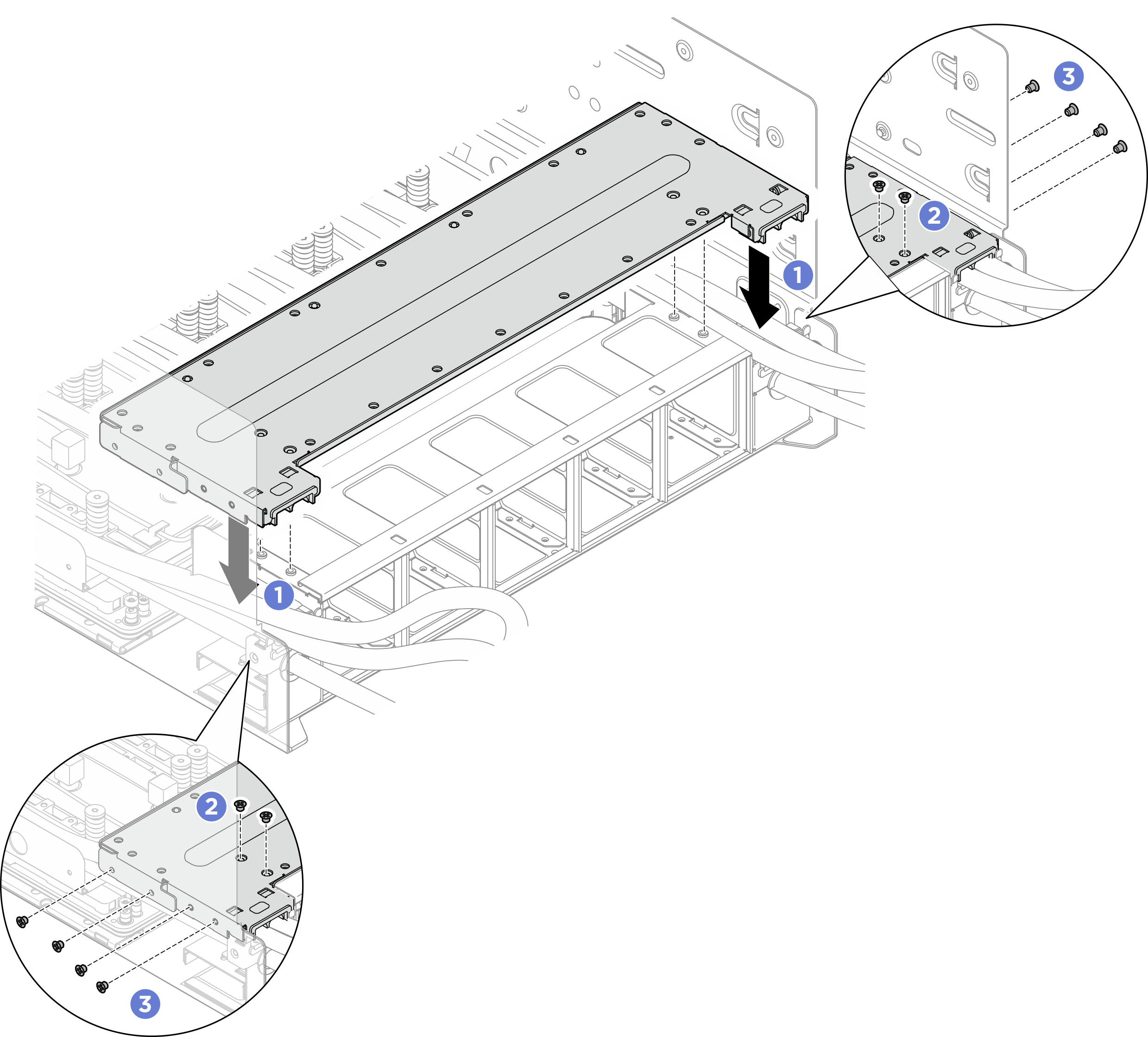

Procedure

After you finish

- Reconnect all the cables that were disconnected. See Internal cable routing.

- Reinstall the power complex. See Install the power complex.

- Reinstall the CPU complex. See Install the CPU complex.

- Reinstall the fan cage. See Install the fan cage (trained technician only).

- Reinstall the rear top cover. See Install the rear top cover.

- Reinstall the front top cover. See Install the front top cover.

- Complete the parts replacement. See Complete the parts replacement.

Give documentation feedback

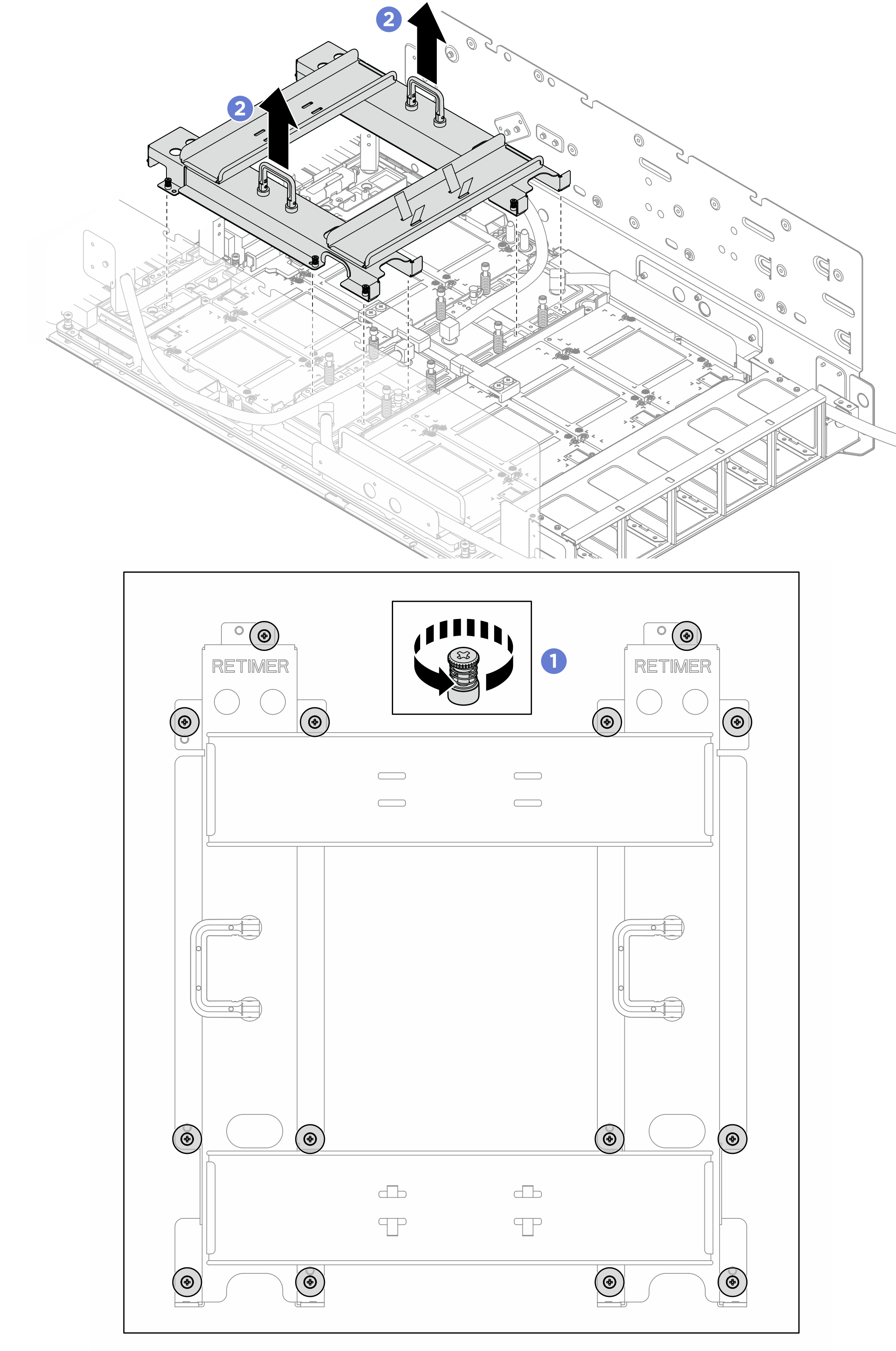

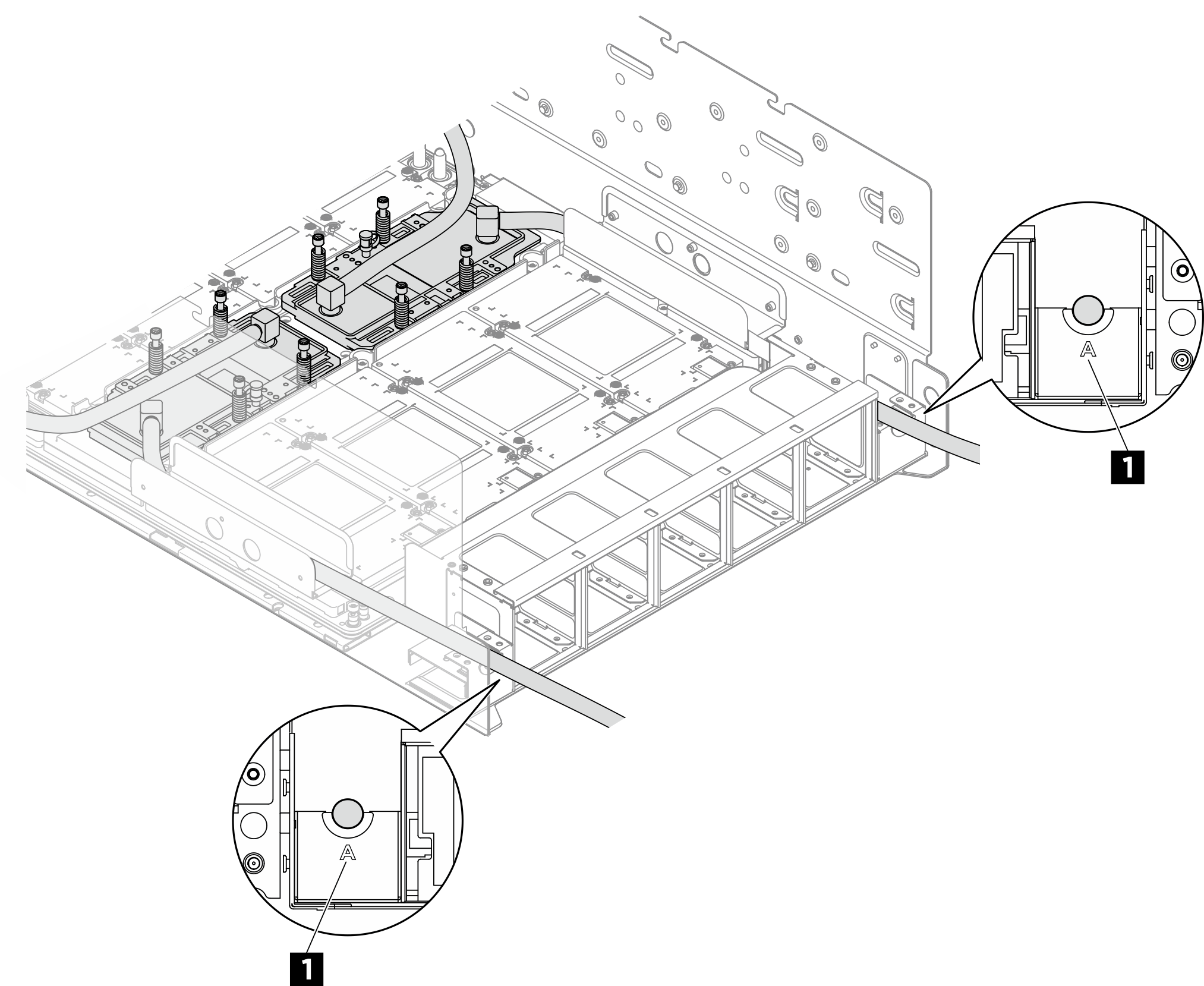

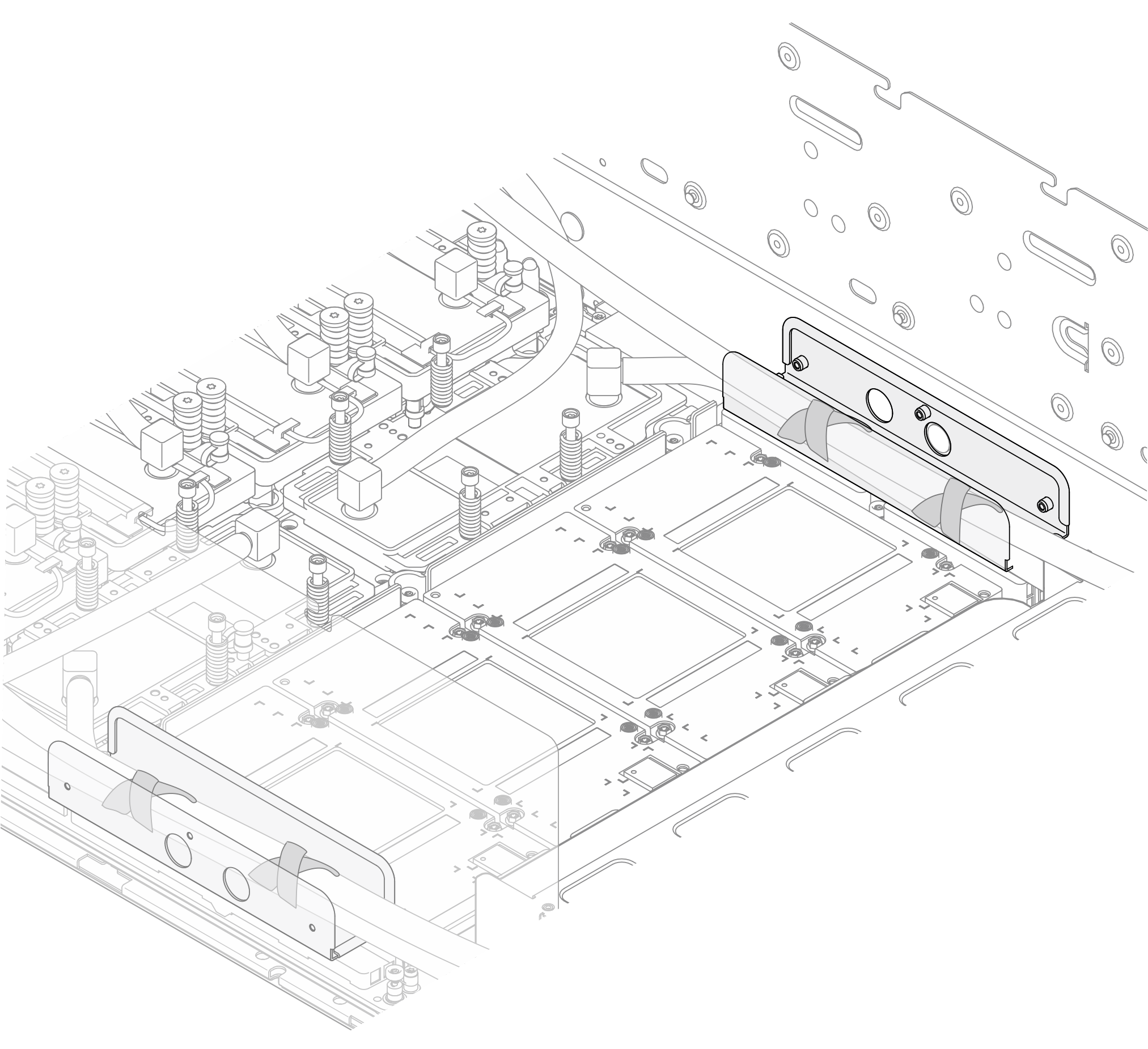

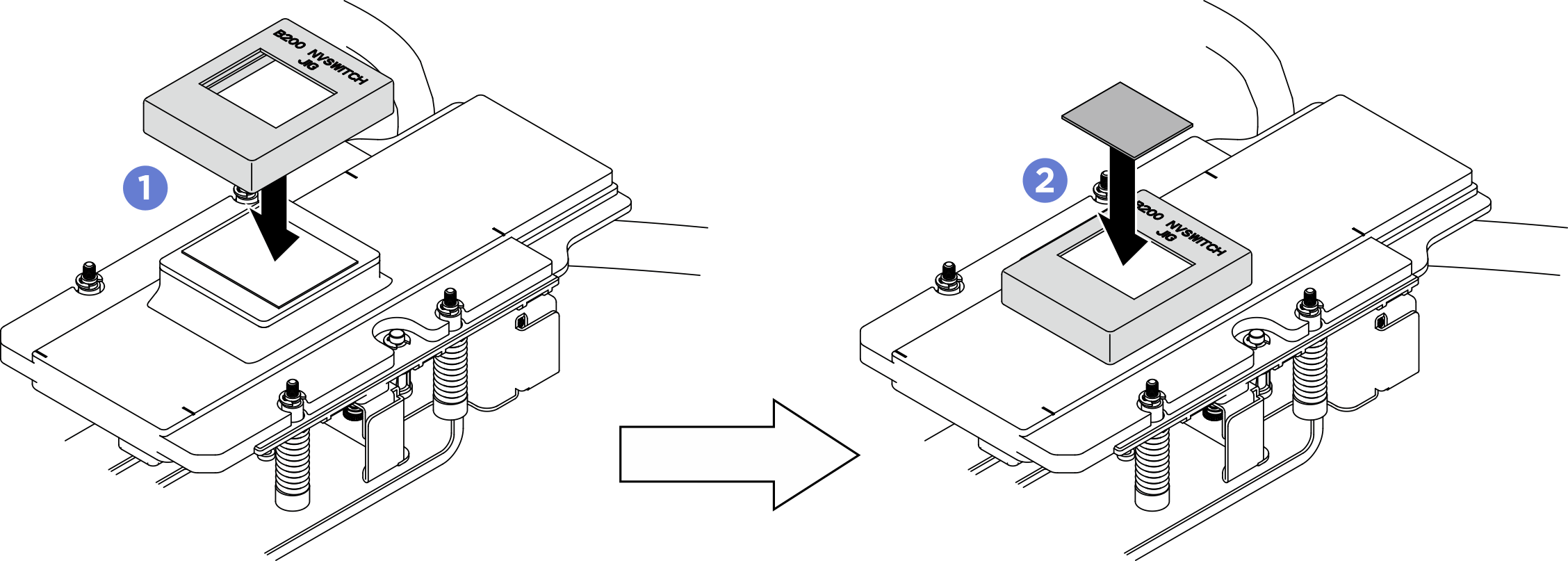

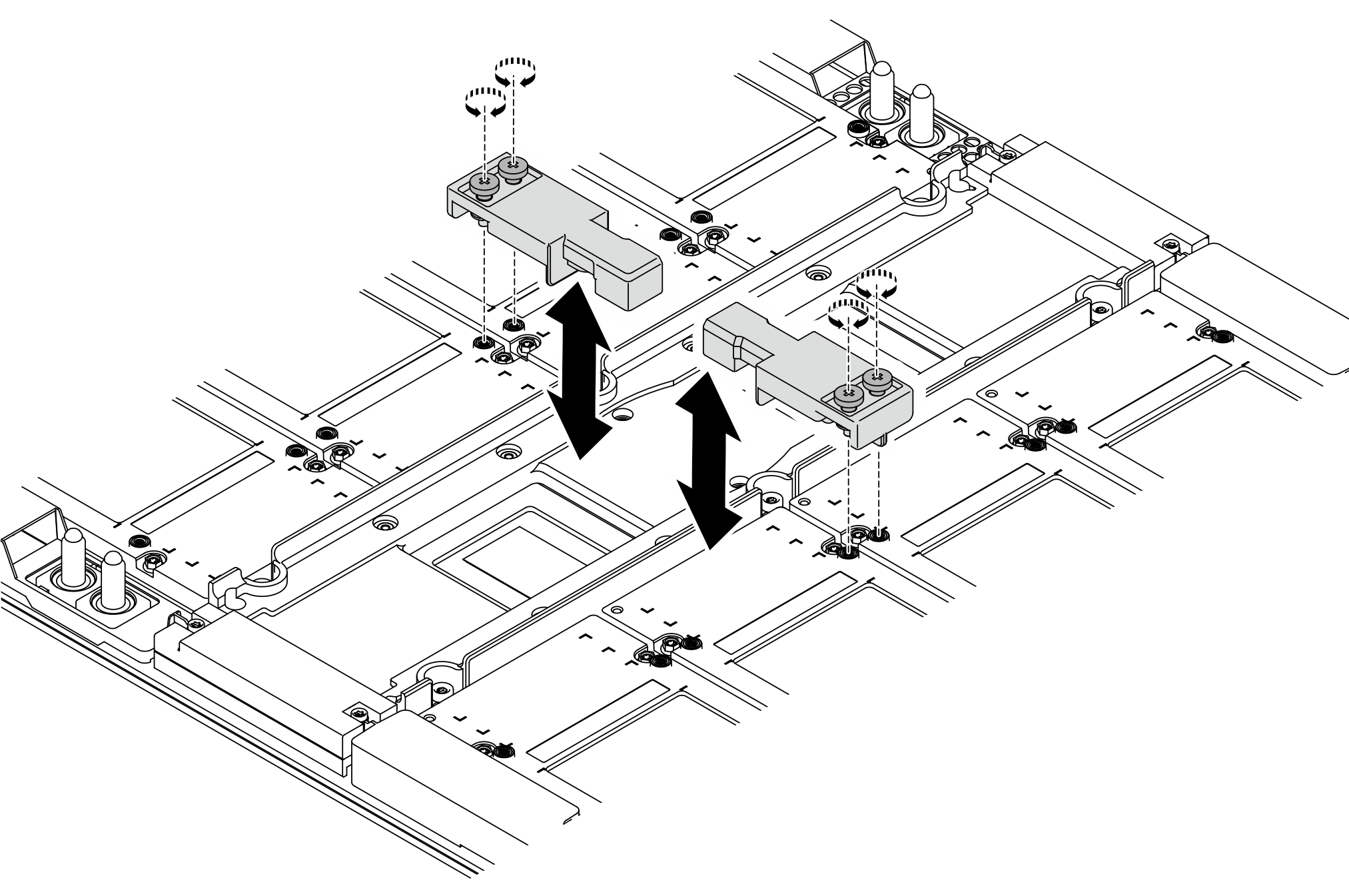

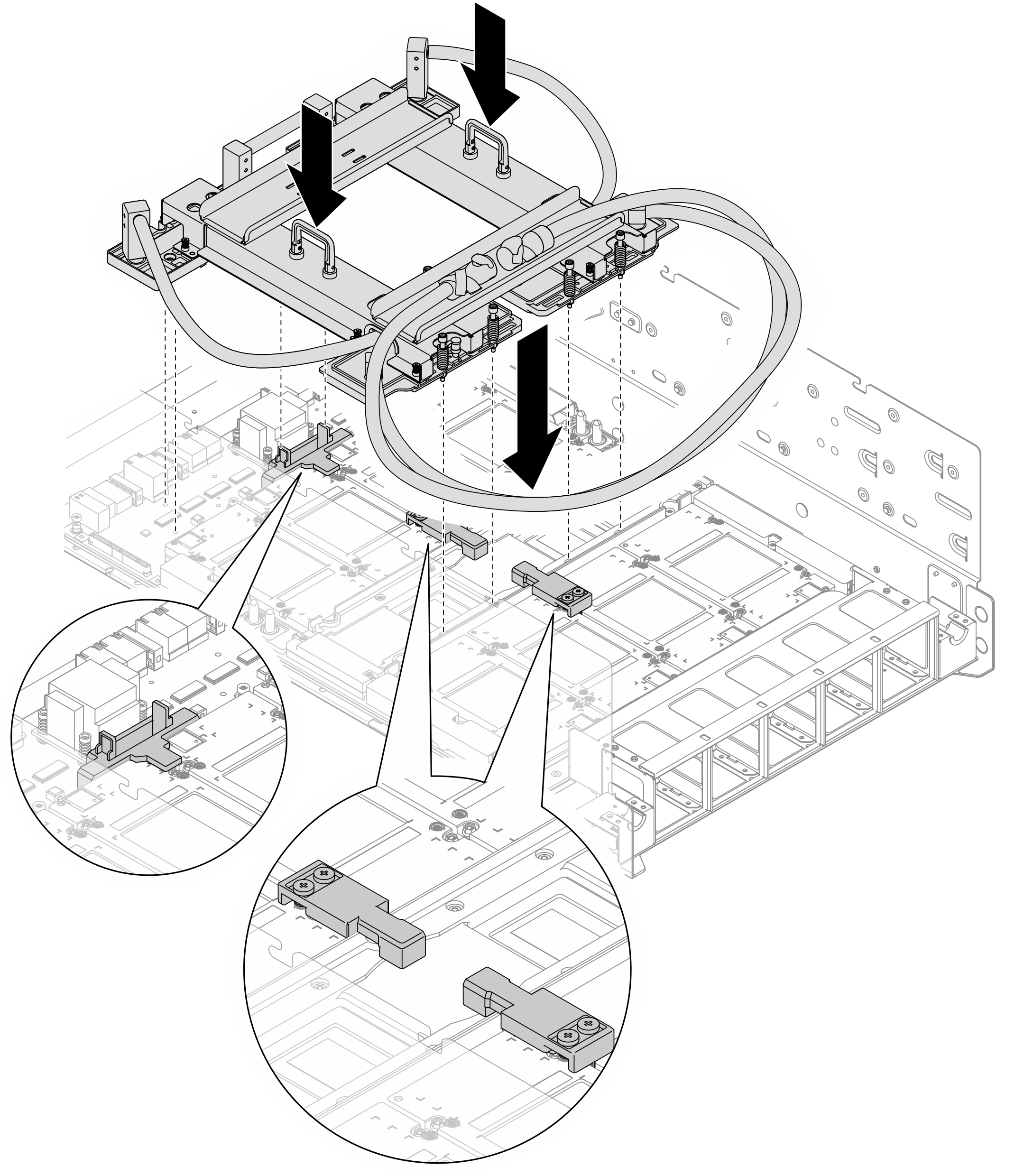

Ensure the shipping bracket is attached to the NVSwitch and retimer cold plate module. Flip over the module and place it on a surface with the cold plate facing upward.

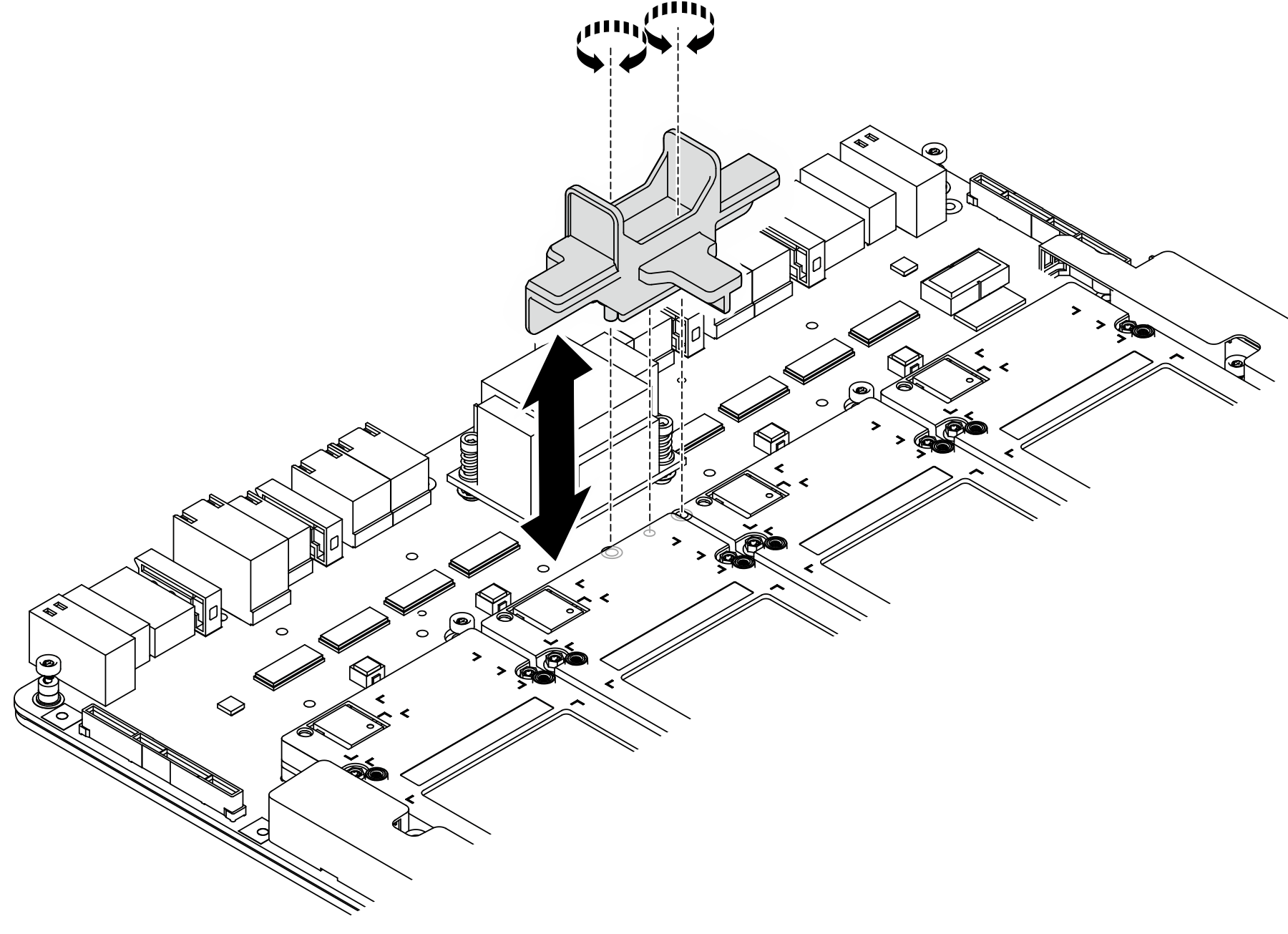

Ensure the shipping bracket is attached to the NVSwitch and retimer cold plate module. Flip over the module and place it on a surface with the cold plate facing upward. Install the jig onto the NVSwitch cold plate.

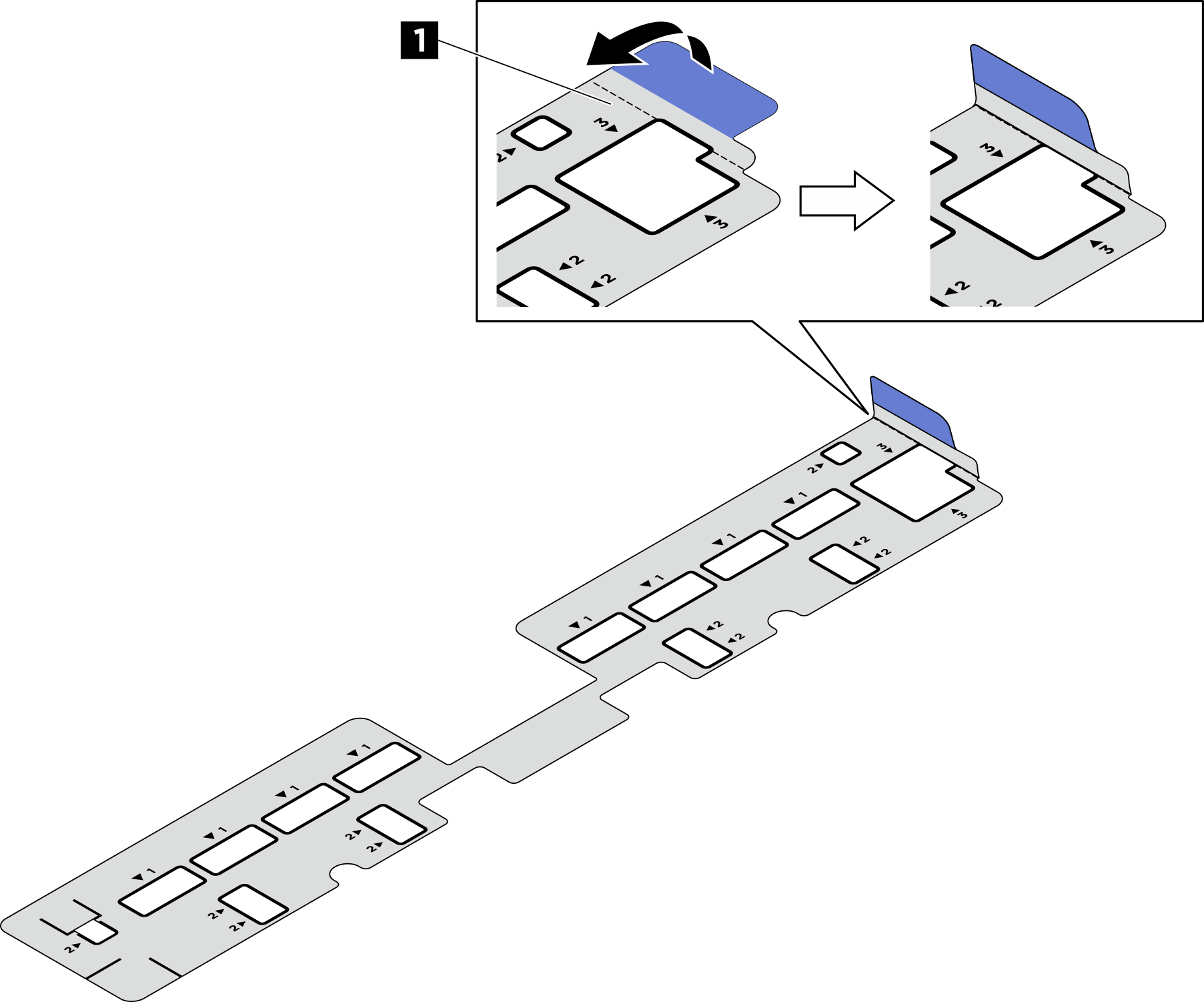

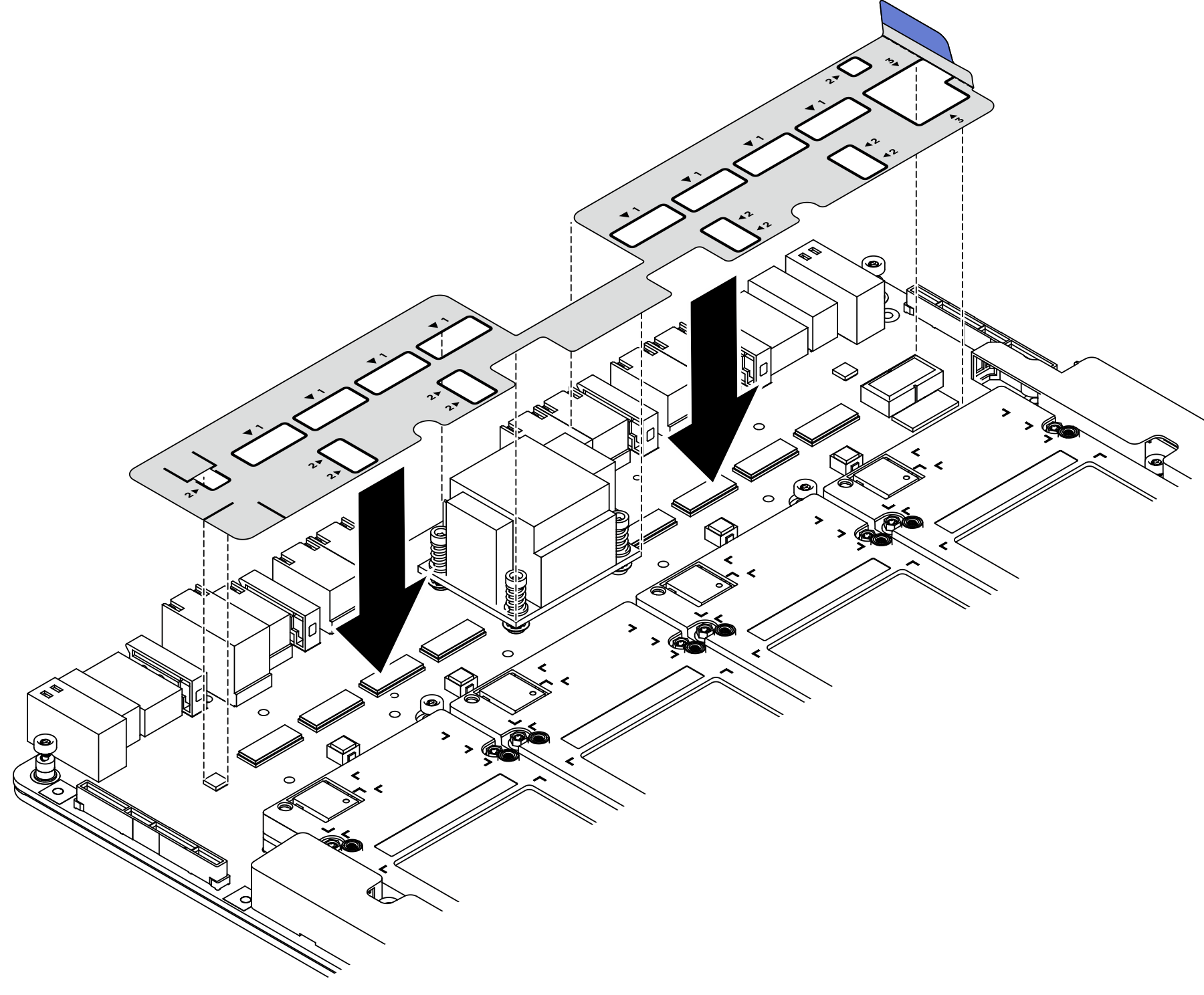

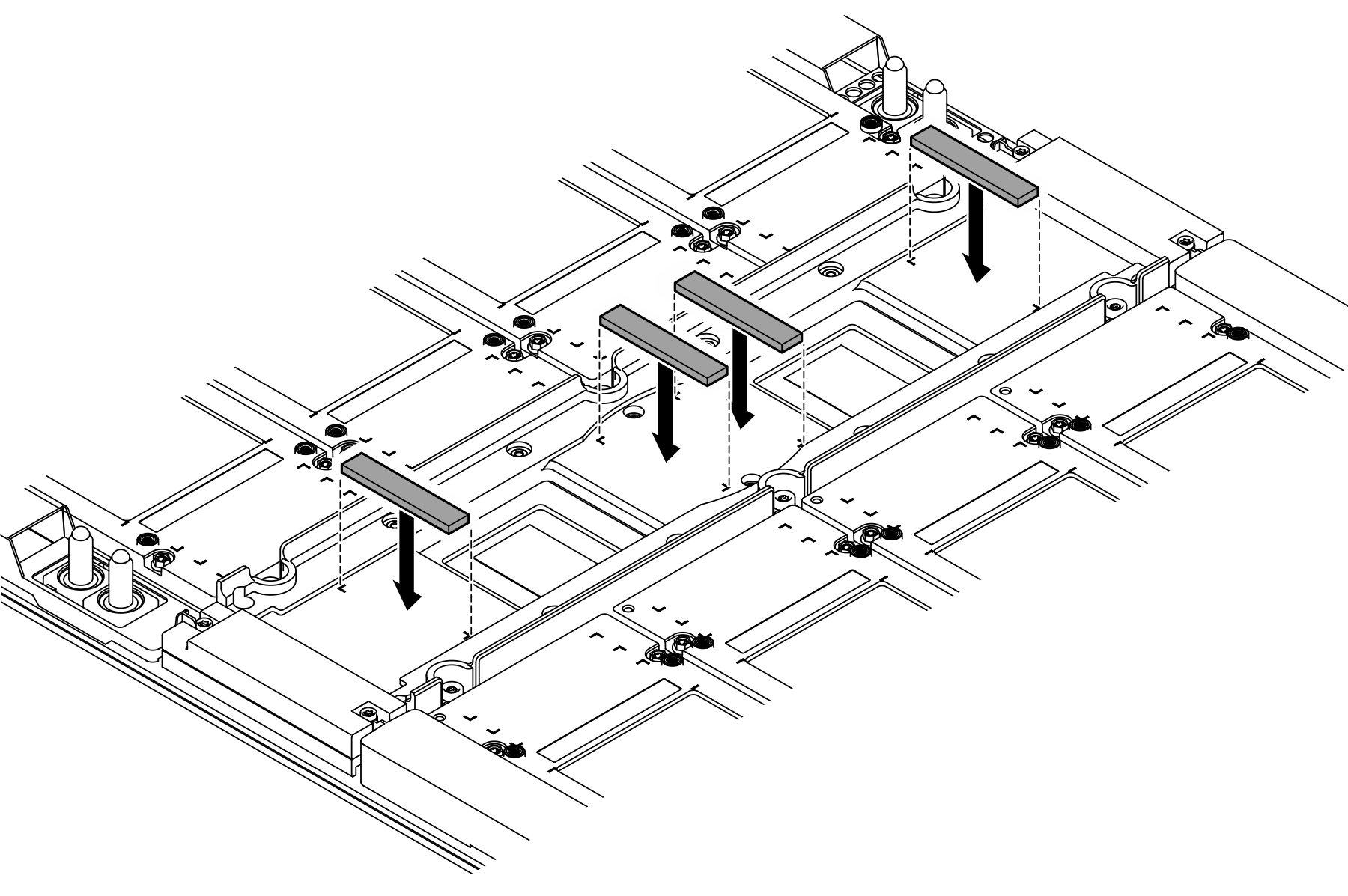

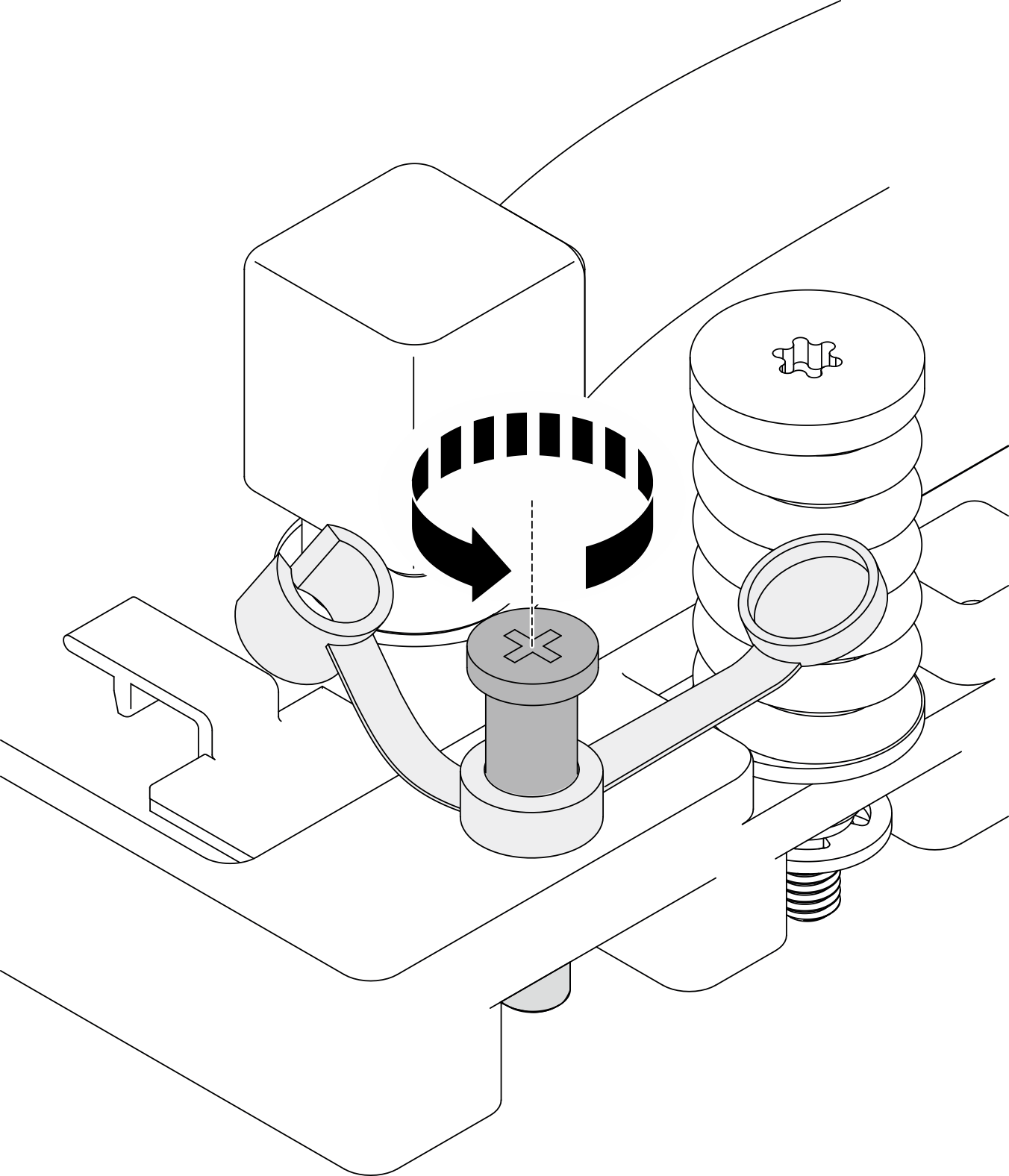

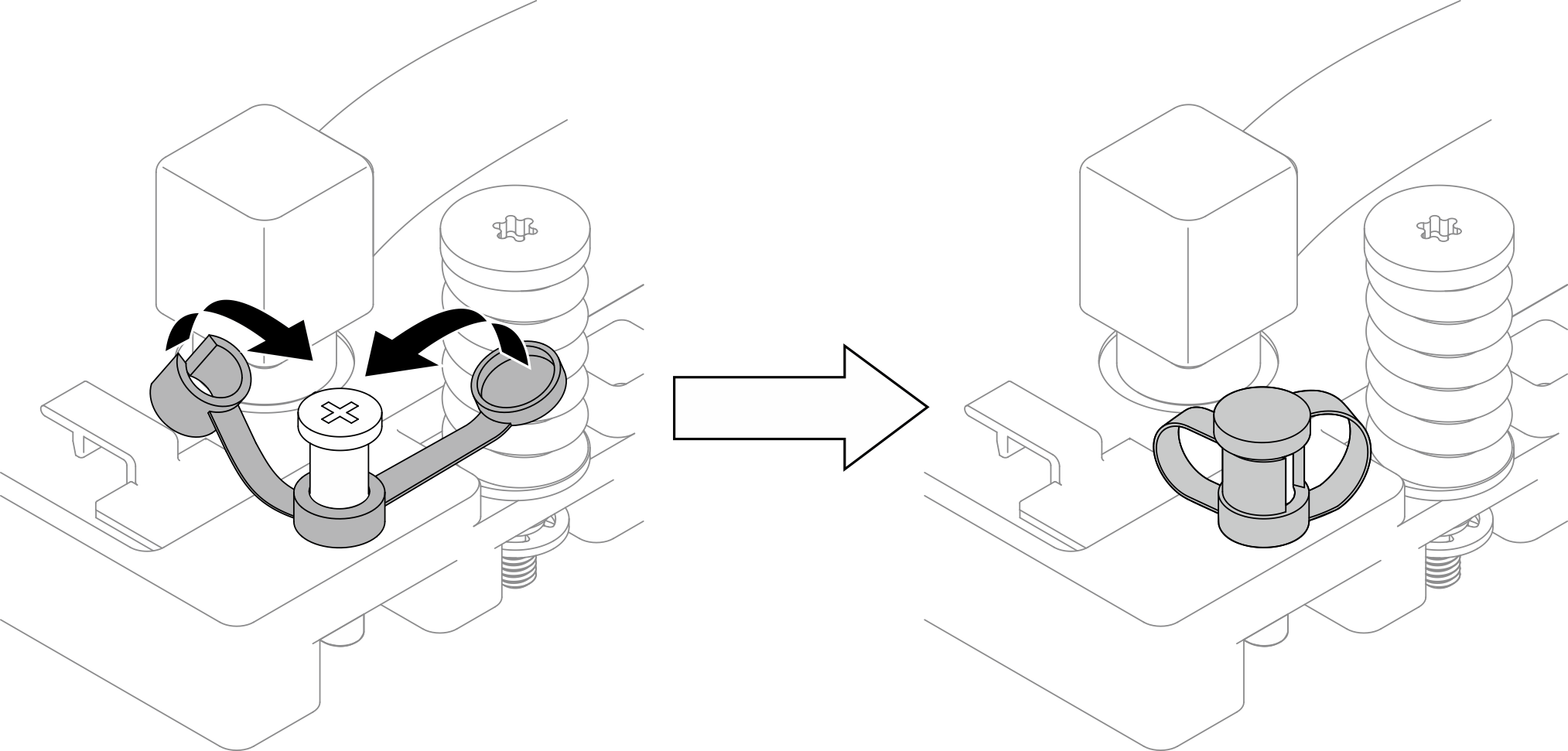

Install the jig onto the NVSwitch cold plate. Remove the liner from one side of the pad. Align the PCM with the jig and place it onto the cold plate. Then, apply finger pressure across the entire surface area of the PCM to remove any trapped air, and allow 1-2 minutes dwell time until it is firmly attached. Carefully remove the remaining top liner.

Remove the liner from one side of the pad. Align the PCM with the jig and place it onto the cold plate. Then, apply finger pressure across the entire surface area of the PCM to remove any trapped air, and allow 1-2 minutes dwell time until it is firmly attached. Carefully remove the remaining top liner.

→

→  →

→  →

→  →

→